Feed Circuit Test - Voltage Drop Test

The starter feed circuit test (voltage drop method) will determine if there is excessive resistance in high-amperage feed circuit. For complete starter wiring circuit diagrams, refer 8, Wiring Diagrams. When performing these tests, it is important to remember that voltage drop is giving an indication of resistance between two points at which voltmeter Example: When testing resistance of battery positive cable, touch voltmeter leads to battery positive cable clamp and cable connector at starter solenoid. If you probe battery positive terminal post and cable connector at starter solenoid, you are reading combined voltage drop in battery positive cable clamp-to terminal post connection and battery positive cable. The following operation will require a voltmeter accurate to 1/10 (0.10) volt. Before performing tests, be certain that following procedures are accomplished:

- Battery is fully-charged and load-tested.

- Fully engage parking brake.

- If equipped with manual transmission, place gearshift selector lever in Neutral position and block clutch pedal in fully depressed position. If equipped with automatic transmission, place gearshift selector lever in Park position.

- Verify that all lamps and accessories are turned off.

- To prevent a gasoline engine from starting, remove Automatic ShutDown (ASD) relay. To prevent a diesel engine from starting, remove Fuel Pump Relay. These relays are located in Power Distribution Center (PDC).

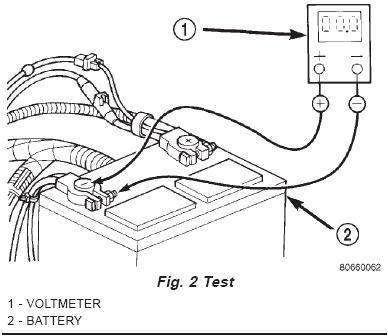

1. Connect positive lead of voltmeter to battery negative terminal post. Connect negative lead of voltmeter to battery negative cable clamp (Fig. 2). Rotate and hold ignition switch in Start position. Observe voltmeter. If voltage is detected, correct poor contact between cable clamp and terminal post. Note: If equipped with a dual battery system (diesel), procedure must be performed twice, once for each battery.

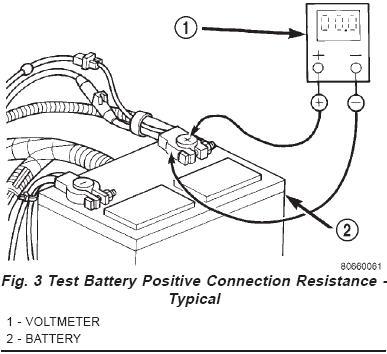

2. Connect positive lead of voltmeter to battery positive terminal post. Connect negative lead of voltmeter to battery positive cable clamp (Fig. 3). Rotate and hold ignition switch in Start position. Observe voltmeter. If voltage is detected, correct poor contact between cable clamp and terminal post. Note: If equipped with a dual battery system (diesel), this procedure must be performed twice, once for each battery.

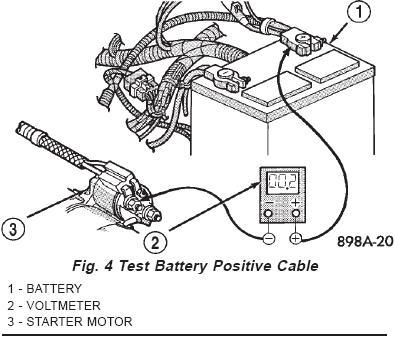

3. Connect voltmeter to measure between battery positive terminal post and starter solenoid battery terminal stud (Fig. 4). Rotate and hold ignition switch in Start position. Observe voltmeter. If reading is above 0.2 volt, clean and tighten battery cable connection at solenoid. Repeat test. If reading is still above 0.2 volt, replace faulty battery positive cable.

Note: If equipped with a dual battery system (diesel), this procedure must be performed on driver side battery only

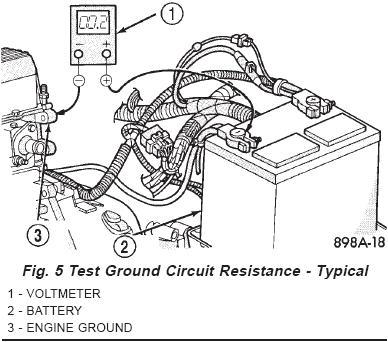

4. Connect voltmeter to measure between battery negative terminal post and a good clean ground on engine block (Fig. 5). Rotate and hold ignition switch in Start position. Observe voltmeter. If reading is above 0.2 volt, clean and tighten battery negative cable attachment on engine block. Repeat test. If reading is still above 0.2 volt, replace faulty battery negative cable. Note: If equipped with dual battery system (diesel), this procedure must be performed twice, once for each battery.

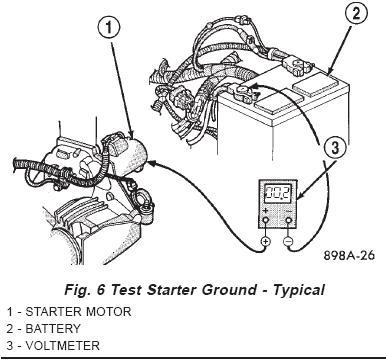

5. Connect positive lead of voltmeter to starter housing. Connect negative lead of voltmeter to battery negative terminal post (Fig. 6). Rotate and hold ignition switch in Start position. Observe voltmeter. If reading is above 0.2 volt, correct poor starter to engine block ground contact.

Note: If equipped with a dual battery system (diesel), this procedure must be performed on driver side battery only.

6. If equipped with dual battery system (diesel), connect positive lead of voltmeter to driver side battery positive cable clamp. Connect negative lead of voltmeter to passenger side battery positive terminal post. Rotate and hold ignition switch in Start position. Observe voltmeter. If reading is above 0.2 volt, clean and tighten passenger side battery positive cable eyelet connection at driver side battery positive cable clamp bolt. Repeat test. If reading is still above 0.2 volt, replace faulty passenger side battery positive cable.

-

3

3