CRANKSHAFT POSITION SENSOR

DESCRIPTION

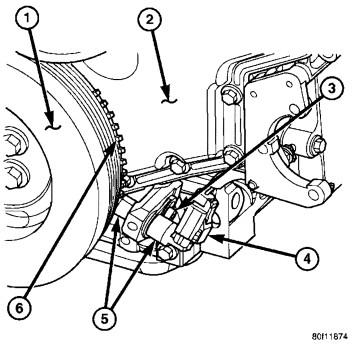

The Crankshaft Position Sensor (CKP) on the diesel engine is attached at the front / left side of the engine next to the engine harmonic balancer (crankshaft damper).

OPERATION

The Crankshaft Position Sensor (CKP) (5) is the primary engine speed indicator for the engine after the engine is running.

The CKP contains a hall effect device. A rotating, notched target wheel (tone wheel) for the CKP is located behind the engine harmonic balancer (2). This has effect device detects notches located on the tone wheel. As the tone wheel rotates, the notches pass the tip of the CKP.

When the leading edge of the tonewheel notch passes the tip of the CKP, the following occurs: The interruption of the magnetic field causes the voltage to switch high resulting in a signal of approximately 5 volts. When the trailing edge of the tonewheel notch passes the tip of the CKP, the following occurs: The change of the magnetic field causes the signal voltage to switch low to 0 volts.

The Camshaft Position Sensor (CMP) also provides a signal to the Engine Control Module (ECM) at all times when the engine is running. The ECM uses this CMP information primarily on engine start-up. Once the engine is running, the ECM uses the CMP as a backup sensor for engine speed.

REMOVAL

1. Raise and support vehicle

2. Disconnect electrical connector (4) at CKP sensor.

3. Remove 1 sensor mounting bolt (3).

4. Remove CKP sensor.

INSTALLATION

1. Position and install CKP sensor (5) to engine.

2. Install 1 sensor mounting bolt and tighten to 9 N·m (80 in. Ibs.) torque.

3. Install electrical connector (4) to CKP sensor.

There are no reviews to display.