Everything posted by Shayne

-

2015 Megacab dually - Looking for Ignition output

I'm wiring up a separate Balmar MC-614 regulator for the second (270A) alternator I have installed. The system is completely independent of the truck and feeds via 2 x 1/0 cables through the bed to a connector to my RV. Looking for an ignition source to wire pin #3 on the regulator to, so that it becomes live when the truck is turned on - not sure of the fuse box setup. 1. Is there anything easily accessible in the cab or do I need to run a new wire from the fuse box? Thoughts appreciated

-

6.7L Cummins Alternator Mount Type

Ha ha, LOL - I completely understand! We almost bit off more than we can chew on this project, but now have a path to completion. Some of the seemingly simple tasks - like running cable can be excruciatingly long when done properly - just dripping the belly mat on the RV and putting it back is an enormous task. We ended up with a very satisfactory solution to the alternator from DC Power Engineering - model DS-270-XP which puts out 27A at peak but most importantly puts out 200A at idle. Despite buying the extra long serpentine belt, we also discovered an extra bracket is required between the alternator and the top of the engine. Have attached a pic of the install showing the second alternator. The big cables zip ties to the RV ladder will run to the bolt on trailer behind and plug into the golf cart which gives an extra 6 batteries to enlarge the house battery count to 10.

-

1/0 alternator cable path under truck

Thanks for this insight WT, much appreciated. Here is where we are up to: We purchased pure copper conductor - two runs of 1/0 for the run from the alternator to the rear bed, and also installed a thick triple copper connector cable for the length of the RV to drop resistance wherever we can. Using The only place left with dual 1/0 CCA cables is a short run at the front of the RV which was installed when it was opened up last year and I’ll keep an eye on that. We have purchased a Balmar marine regulator for the truck, and a Balmar smart gauge which will be installed in the RV, and also a data logger and some current transducers to monitor the current in the parallel battery strings. There are also several cat5 cables which will carry the data reporting current charge or discharge. the rig is also at the shop presently while they cut into the rear cap and install a hatch into the rear cap And we will mount waterproof RJ45 data sockets for the data cables to plug into. the whole thing should be complete in about 3 weeks.

-

1/0 alternator cable path under truck

Thanks Jag1, appreciate the comments. That’s essentially what I am planning. I'm using the AWG 1/0 DS18 CCA (copper clad aluminum) wire which is very flexible and has thick insulation. Plan to use two runs in parallel encased in plastic. The only uncertainty is the exact path...

-

1/0 alternator cable path under truck

Does anybody have experience where two 1/0 high amperage cables should be run safely under a 2015 ram3500 dually megacab? I want to provide two output sockets in the rear bed next to the 7 pin trailer wire and it will require up to 25’ of cable from the alternator. This is a follow on from my two earlier posts. I found a 270A alternator which is the same frame as the OEM Mopar. It has original Denso parts built by a specialty outfit in FL. The idle output is 200 Amps and peak is 270A. The external viltage regultor is from the marine industry and the two places have worked together before. There is also current limiting on the regulator gauge which can be dash mounted.

-

6.7L Cummins Alternator Mount Type

Trying now to establish if the RAM Cummins engine uses a J180 mount for the alternator. Sidebar: Check out this pic with 6 Alternators - it's insane! http://www.cumminsforum.com/forum/94-98-powertrain/1977393-d89s-big-rig-alternator-install.html

-

6.7L Cummins Alternator Mount Type

Does anybody know the type of mount for the second alternator on the cummins engine? Is it "Pad Mount" (like the big trucks) or "Swivel Mount" (adjustable bracket) The reason I'm asking is I've found a 200A Alternator with inbuilt regulator here https://www.diamond-gard.com/a200 It gives high output of 130A at only 800 RPM, and I'm trying to assess if it will fit. I'm avoiding the RAM OEM as it doesn't have a regulator and fitting it after market would require a lot of extra wiring. The other details of the project can be found here: I called Mitsubishi and sent pics of the mount and it is hinge mount. Looks like I'll need to find a hinge mount alternator, which is brushless, with high output at low RPM and has an inbuilt regulator. A bit like a golden unicorn but maybe it is out there...some pics are below of the existing alternator and of the second alternator mount point.

-

Second Alternator in 3500 dually megacab towing big RV

Thanks John, great feedback. really appreciate the comments about Alternator duty cycle and extra battery. committed to proceeding with second alternator because of: 1. Additional capacity during peak load times, and 2. If the genset fails in inclement weather we can have a 2.5KW backup via the second alternator. Visited a Dodge dealer yesterday and learned how the high idle works and also that periodic driving of the truck is required to clear build up in the emission system if it sits idling for an extended period. Also found through online research a high output diamond-gard unit at diamond-gard.com with regulator built in, and gives high output at low revs. Still need to figure out best path for two 1/0 wires under the truck to the bed from the engine...

-

Second Alternator in 3500 dually megacab towing big RV

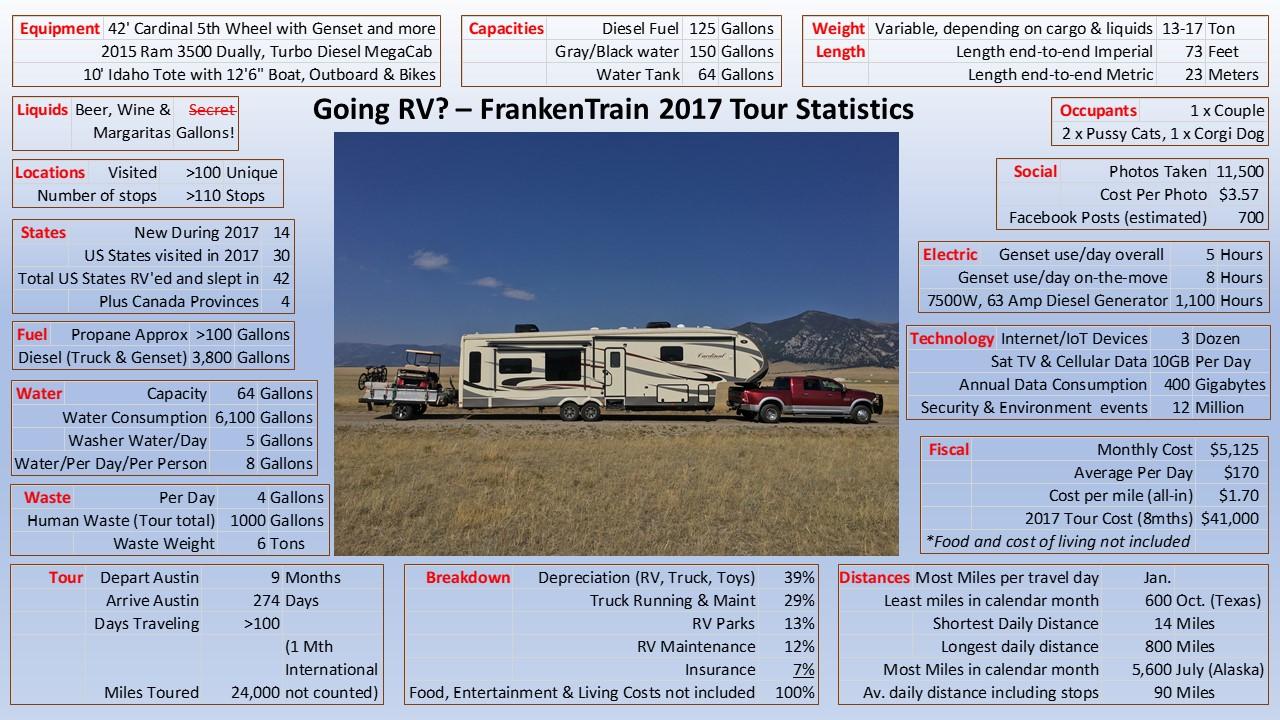

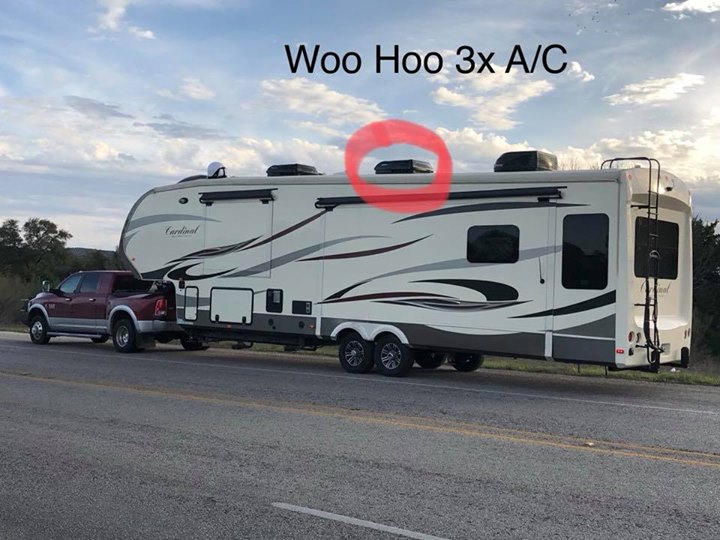

I’m wanting to install a second alternator in my 6.7 liter, 3500 dually megacab and looking for tips on alternator type, whether to install it standalone, and the cable path for two high ampacity 1/0 cables. I tow a big 42’ 5th wheel with an extra, dual hitch 10’ trailer behind the RV, with self turning trailer wheels (Idaho tote). On the tote is an electric golf cart, 12’6” zodiac type inflatable boat with outboard, and bicycles. We are experienced RVers with 70,000 miles and 42 states under our belts. I plan to use the six additional matched golf cart batteries tied to the four identical batteries in front to make a total of ten house batteries which are 5 parallel banks of 6+6v=12v. Over 2,000 ampere hours of total capacity. The purpose of the second alternator is for several reasons in the order of importance below: 1. To charge the ten batteries after overnight boondocking, maybe without generator use, and charge them from the second alternator as we drive down the road to the next destination. 2. To supplement power during peak use time of the generator while boondocking. More about this further below. The Cummins Onan generator is a specially installed 7,500W commercial quiet diesel, with a 32 gallon tank, and is topped up from the 56 gallon tank at the front of the bed which has a GPI pump and long hose. 3. To provide enough power to charge batteries while the inverter runs a single A/C or heat pump while driving down the road. No more hot tin can RV and waiting for it to cool down! We successfully ran the generator and A/C’s one-two hours before destination, during travel last year and it made a huge difference as we setup. The initial high current start of the A/C will be handled by the generator, and the 11-14 Amps @120v will be maintained by the 2,000 watt inverter by a transfer switch that changes over to power in about 80mS (about 1/12 of a second). This is definitely a science experiment and won’t be without snags, but we will see how well it works. I’ll most likely have to turn the thermostat down very low and see whether the cycling of the A/C will pop the inverter breaker. USE I am installing the third A/C presently which will give a total of 42,500 BTU’s of cooling with all three running (total load of 39 Amps at 120v). I calculate it will allow up to 40f of temperature difference in the summer and we can be comfortable in a 100f+ desert environment and continue working inside. I’m installing a second 2,000 Watt inverter in the RV which is the same type powering a large residential electric fridge freezer. The second inverter has two transfer switches to switch load between the inverter and a Cummins 7,500W diesel generator when it runs. The generator in turn is also connected to a bigger transfer switch to change between shore supply and generator. It looks like the idle speed of the truck can be controlled by programming, and I am specifically interested in: 1. A 220 Amp (stand alone?) alternator and regulator package and 2. The recommended cable path for two 1/0 wires to carry the high current to the rear bed attached to two connectors near the 7 pin trailer plug. The rest of the wiring is complete between the RV battery box and the front overhang of the 5th wheel to drop into the bed through an access panel where the trailer plug also now routes. Through that point, I have two separate 1/0 cables for positive, which will be in parallel using separate but identical truck connectors with the thick single pin that is a similar form factor to a 7 pin trailer plug. For the return path to earth, there are two more 1/0 cables using Anderson Power two pin 4/0 sb35 connectors (found in forklift batteries) which will connect between the truck chassis and the RV hitch for good grounding. The voltage loss I calculated seems acceptable to still charge the ten batteries up, and allow them to run the inverters. In high load circumstances (like 100f heat in summer), the extra 2,000 watts from the alternator can charge batteries on the two inverters and I can route the inverter use through the batteries by leaving the circuit breakers from the generator open to use the batteries charged by the truck. This will allow me about 10KW of electric power, 7.5 from the genset, and 2.5 from the truck. Has anyone done this before? I’m ready to commence buying an alternator and want to confirm I may be better keeping the alternator/regulator package separate vs the RAM dual setup. Any thoughts or insights appreciated. If you made it this far you have great insight to our very complex setup, but it’s our home for a while!