How to pin time your pump from ground zero with a dial indicator.

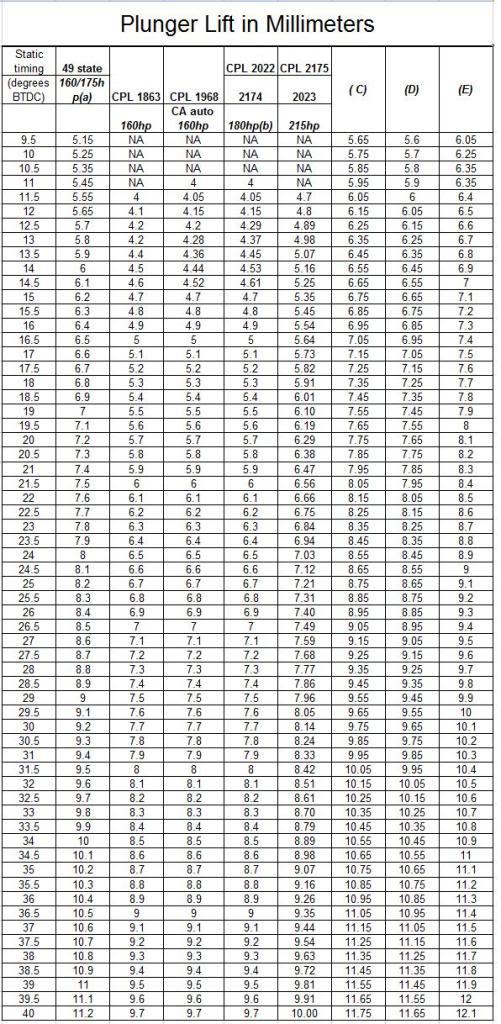

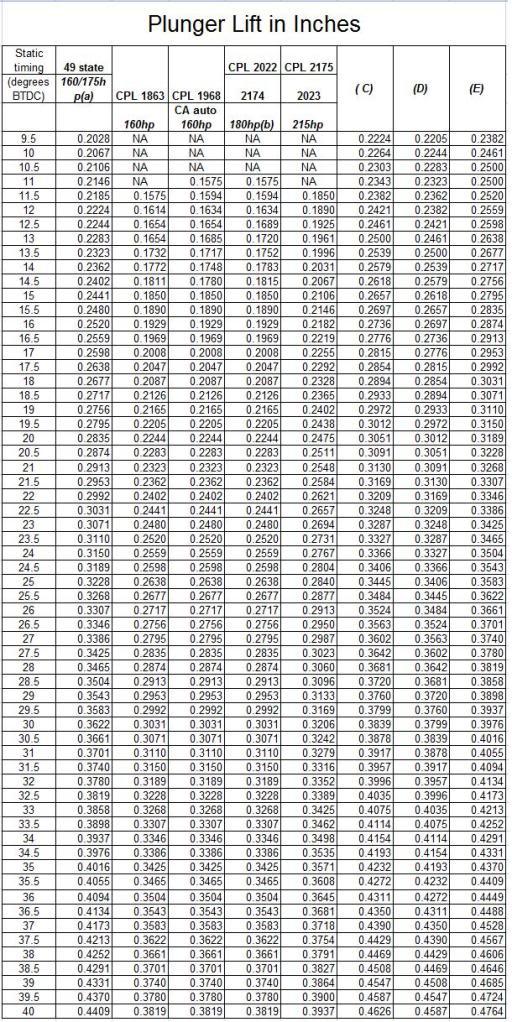

If you're using a dial indicator, you'll need the plunger lift charts, I've supplied them at the bottum of the article! One's metric and the other is inches, otherwise they're identical.

OK, well first things first is you'll need to find #1 TDC. TDC (Top Dead Center) is where #1 piston is at the absolute top of it's stroke. We also need to make sure that's it's the compression stroke, both are very important for a successful timing job. Always double check your TDC and make sure it's the compression stroke, remember, if it's not, you need to spin the engine 360°.

- Place engine at approximate TDC Compression.

- Remove DV and Install Dial Indicator into Plunger.

- Rotate the engine BACKWARDS (CCW when standing in front) until the dial indicator stops dropping.

- Check the Dial indicator to make sure it's still contacting the plunger and hasn't maxed out, if it's still riding on the plunger continue.

- Zero the Dial Indicator

- Rotate the engine FORWARD until your set lift is achieved, lets say it's a 215 pump and we're shooting for 17°, so that's 5.73mm.

- Pop the injection pump gear off, careful to do it evenly as to not rotate the pump.

- Once the gear is off, rotate the engine to exact #1 TDC Compression.

- Clean the shaft thoroughly with brake cleaner or electrical contact cleaner (do not use carb cleaner).

- Torque Injection Pump gear to 20 ft/lb's and let sit to seat the gear on the shaft.

- Tighten down the Injection Pump gear nut to 144ft/lbs as specified in the FSM.

- Recheck your TDC and plunger lift to ensure nothing slipped while tightening the gear.

There are no reviews to display.