This will show the progress in installing the Holset he351ve into my 2nd gen Cummins Second Gen Cummins should be considered 94-02 but there may be some difference depending on year. I will update as I go along. This is not dealing with the controller needed for the he351ve. The thread that covers the controller can be found here

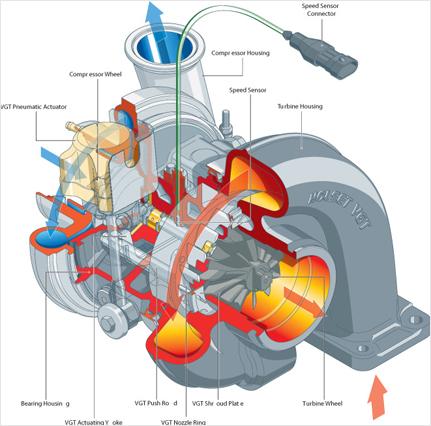

The Holset He351 ve vgt turbo was found on the Cummins 6.7 L trucks on late 3rd and 4th gen dodge trucks. It is a very tough turbo and was selected for use due to the ability to improve low throttle boost and the built in Exhaust brake. It should be good for near enough to 500 hp not to matter.

Parts

- HX40 style Downpipe click to go to vulcan for the part ($125)

- t3 to wgmt flange adapter to mate the he351ve to the t3 exhaust manifold. ($150)

- 2x he351ve turbo exhaust gaskets ($10)

- 1x hx35 exhaust gasket ($5)

- 4 Ft of 5/8' coolant hose for your local parts store ($10)

- 5/8" oil rated hose 2' worth ($5)

- 10 x 5/8" pipe clamps.

- T3 oil drain ( ebay, if I was to do it again I would have gotten one with a bend in it to help with the oil drain.

- 2 x 5/8" T fitting ($5) Local Parts Store

I

- HE351Ve turbo ( $300-$600) depending on where you get it. I would suggest CumminsForum or here of course if one is for sale.

- You will need some way of attaching the hotside intercooler tubes/boots to the turbo since the output from the Turbo faces forward rather than down like the 2nd gen turbos.

went with the charge tube from Stainlessdiesel.com HERE ($85)

- You will need a 2.75" to 3" silicon boot reducer and clamps for this to work.

There are also reports that a 45* reducing elbow will work also. unsure on that but you can try. I got min efrom www.siliconintakes.com

First Specs on the Turbos

LEFT Holset HX35 56/60/12 60ish lb/min vs RIGHT Holset HE351ve 60/68/3-25 69ish lb/min

The Install

Start pulling the old turbo off

Use PB blaster or similar on the flange bolts for a few days prior to removal.

Double nut the two bottom studs and remove them. Take your time use PB Blaster or similar.

Bolt the adapter flange to the manifold. The short bolts go in the bottom and the long bolts with the nuts attach the top holes of the flange. You will need to use the hx35 exhaust gasket between the manifold and the first section of the Adapter plate.

Next if your truck is like mine (auto) there is a hard coolant line just behind the exhaust manifold that will block the rear most bolt on the adapter flange from being used. you can see the bolt hole in question.

Use the 5/8" coolant hose and a 5/8" T fitting to remove the hardline and replace it with the coolant hose. You will need to run this to just in front of the oil filter and also to the output of the coolant line from the HE351ve.

Next you need to remove the old downpipe if you don't already have an HX40 style installed. this is a PITA to say the least. I had to cut mine out. The hx40 style downpipe flange will attach to the back of the he351ve without the elbow.

Next it is time to pull apart the turbo into it's 3 sections. The turbo weights a lot so it is much easier to install it one section at a time. There are 2vband clamps that hold it together, one fo the compressor housing and one for the exhaust housing. Once the turbo is apart attach the other half of the flange adapter to the exhaust housing of the turbo. You will need to install one of the he351ve gaskets between the flange and the turbo. Use the long bolt for the through hole on the exhaust housing. I also had to cut one of the bolts to make it fit better. Without cutting the bolt I couldn't clock the center as nicely as I wanted. Ensure you remote the alignment dowels out of the compressor cover and exhaust housing. This will allow you to clock the turbo as you need.

Once you have the flange tightly bolts to the turbo you can install the exhaust housing. ENSURE you put the last he351ve turbo gasket between the 2 sections of the adapter flange. It is somewhat hard to center it, but not impossible. Tighten down the 4 Allen head bolts supplied with the kit to hold the flanges together. You will need to tighten them very tight.

In order to allow for a more vertical position of the center section I cut off the top of the strut nut. This will allow you to clock the center section of the turbo to within the 30* off vertical for the oil drain spec'd by holset.

Next you need to install the Center section of the turbo.

I would practice this beforehand on a bench to get the feel for it

Take your time doing this as the fins on the vgt section must slide into the exhaust housing in their slots. This can be tricky, I found it best to extend the vgt all the way out and then try and sldie it in gently by rotating slightly. Here you can see the Center Section installed. Notice the clocking of the center section. You will need to loosed the oil supply line and rearrange it to make it bend nicely.

Follow the hard oil drain tube down the the rubber joiner and remove the clamp holding the hard tube on. You will slip your PFE hose into the joiner and tighten it. This hose is not under pressure so you just need to ensure it is a good fit. Run your pfe hose to the oil drain on the turbo, using a hose clamp to hold it on.

You can see in this picture that I just reused the OEM banjo bolts for the coolant connections. I used a hack saw to cut the braided section off so it was just a solid metal banjo bolt. I then just pushed the 5/8" coolant line over and used a hose clamp. I will do an fittings at some point, but for now this will work.

Then install the Compressor cover onto the turbo. Be careful not to damage the compressor fins. Once the housing is on tighten the vband clamps tight enough to hold the housing, but not too tight as to keep you from rotating the housing.

Use the preferred method of connecting the charge pipe, I choose the stainless diesel pipe and a 2.75" to 3" reducer then reused the oem 3" to 3.5" elbow at the inter cooler. Align all boots and tighten down the clamps. Once everything is lined up tighten the vband clamp so that the compressor housing can't move.

Note the position of the passenger side neg battery cable to the engine block. I might have to redo this with a new longer cable, I have been meaning to anyways, but I haven't gotten to it.

Hard to see in the picture but run the other coolant line into the bottom of the turbo and T into the other heater core line. Ensure you leave some space between the exhaust manifold and the coolant hose. You might use zip ties or something similar to hold the hoses together.

Then install the air filter and you should be good to go. Check for any coolant or oil leaks.

there you go the holset he351ve has been installed into your 2nd gen Cummins.

Some Videos

Exhaust brake apply at 55 in 3rd with TC locked. Turbo builds 50ish psi of backpressure quickly.

http://www.youtube.com/watch?v=qyvpx-p6e5U

Here you can see smoke output from standstill at %50 throttle. You can see it clears up nicely

http://www.youtube.com/watch?v=Kx681iLXSvw

Sea Level smoke at %100 throttle

http://www.youtube.com/watch?v=Rc2NSMaPYCc

http://www.youtube.com/watch?v=3m3sPPji2gs

There are no reviews to display.