Swapping between 98.5-00 & 01-02 Dodge Cummins ISB 24v VP44 Engines

Many people need to change their engine out due to “53” blocks, catastrophic failures or just plain wear & tear. Most do not know about the differences between the two “Sub generations” as I will call them. I will try to explain it all in this article. I will also give known ways to accomplish the swap & why. I will also give an alternative way that I presume will work, but cannot guarantee.Firstly, for some basics. If at all possible, get a replacement engine of the same sub generation if at all possible to make your life easier. Second, if you must use an engine from a different sub generation, GET A FULL DONOR VEHICLE.For the proven method of swapping sub generations, you WILL need the ECM, PCM, full engine harness & PCM at a minimum. Now, there have been a few cases where either the donor truck or recipient truck has the factory security system. In these cases, you may need the gauge cluster and/or the CTM (Central Timer Module).

Here is an exerpt from http://dodgeram.org/tech/dsl/ECM/ that explains most of it & I will denote my changes to it with “**” at the beginning & end.98.5-00:

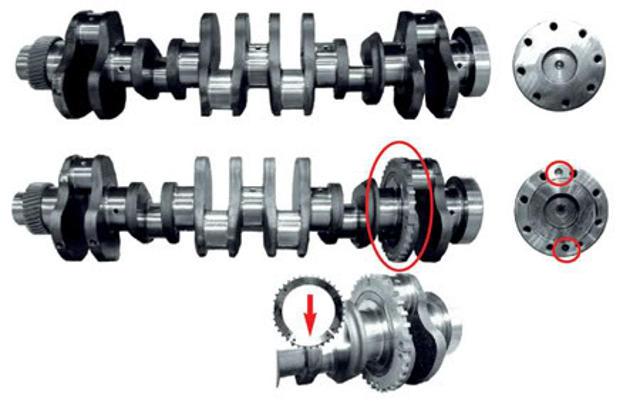

“ Engine RPM and timing are derived from the Crankshaft Position Sensor (CKP) on 1998-2000 models. A 35 tooth tone ring with a gap where the 36th tooth should be is bolted to the crankshaft. A hall effect sensor registers each tooth as it passes and sends the signal to the ECM. The tooth gap corresponds to 60 degrees BTDC of cylinder #1. A Camshaft Position Sensor (CMP) senses a hole ** Slot ** in the back of the camshaft drive gear to check for TDC of cylinder #1. This signal is used for diagnostic purposes and is not used to control the fuel system. ** It is also used to drive the tachometer to my understanding** Here is a picture of the back of the 98.5-02 gear”. **Notice the depth of the slot!**

Picture captured from www.ebay.com

Now, here is the crank & crank gear from: http://www.dieselbombers.com/dodge-diesel-tech-articles/15100-ram-tough-rebuild-cummins-engine-specs-brief-history.html“

The upper most crankshaft is the first design used from 1983-1997.5 and from 1999.5-2002 for Dodge applications. The crank in the middle is the second design with the crankshaft position sensor trigger ring that was used from 1997.5-2002 for non-Dodge applications. The lower inlay shows the that the trigger ring is two pieces and can easily be replaced without crank removal. The second-generation crankshaft is forged steel and induction hardened as well. It also has 8 flywheel bolts and includes two dowel pin holes for flywheel location. This crankshaft was used from 1997.5-1999.5 for Dodge and 1997.5 through 2002 for non-Dodge application. In Figure 4 you’ll notice the slightly different relief as well as other differences. This crankshaft uses a bolt-on crankshaft position trigger ring, which is manufactured in two pieces. It could actually be replaced in-chassis if it needed to be done that way”.If you read the article, you will see that it is a 2 piece gear that is replaceable with the crank in place. I do not think the 01-02 Dodge crank is machined for it, as per the article.Another possible option for this gear replacement is a product from Destroked that is a tone wheel, sensor, bracket & hardware to go on the front of the crankshaft.

Here is the link: http://www.destroked.com/prod_tach_kits.php

It is the “36 minus 1 tach kit”. Although, this seems like it will replace the crank wheel, I am not positive that the signal is exact. Please contact Destroked for more info on that.The only other differnece that I can think of between the sub generations is the MAP sensor, as the 98.5-00 reads a different value than the 01-02.01-02:

Now, again from the article :http://dodgeram.org/tech/dsl/ECM/ :

“The crankshaft position sensor was deleted for 2001 and 2002 models; engine speed, crankshaft position, and injection timing information will be derived from the camshaft position sensor signal. Notches are cut into the rear face of the camshaft gear. A hall effect sensor registers each notch as it passes, and sends the signal to the ECM. A missing notch corresponds to TDC of cylinder #1”.

Here is the cam gear:

This image captures from a Fourwheeler.com article: http://www.fourwheeler.com/vehicle-reviews/131-0407-dodge-ram-cummins-upgrade/

As far as I can count, there are 60 or 61 teeth minus 2 (Difficult to count from the image). Now, NOTICE that the 2 missing teeth are beside each other. To compare that with the crank gear from the 98.5-00 crank gear (Counting a 2:1 rotation of the crank/cam rotation), the older crank signal would have 72 teeth, minus 2, but the 2 “Minus” teeth would be on opposite sides of the cam gear. Now, go back up to the text of the 98.5-00 cam gear & remember that I mentioned the depth of the notch? That is depth from the outer edge of the gear. Notice the difference of about 1/4” difference (From my uncalibrated eyeballs)? Also, the depth inward to the face of the notches is deeper on the 01-02 gear. To me, this means that along with the cam gear, you will also need the full gear housing & 01-02 CPS (Cam Position Sensor) to make the 01-02 electronics work on a 98.5-00 engine. Just block off the Crank sensor hole, or leave the sensor in, but not connected.

MAP sensors:

The 98.5-00 MAP sensor reads a different value than the 01-02 MAP sensor. Also, the 01-02 MAP sensors read the same values, but have different plugs. If swapping between 01 & 02, you can use your original MAP sensor, or get an adapter from many diesel suppliers that adapts the plug.Other than these issues, there should be no differences that will throw a CEL (Check Engine Light), or make any driveability differences.

Author: Ed Grafton

Screenname: Yankneck696

Recommended Comments