Erratic Tachometer or No Tachometer

For all of you with 3rd generation trucks where the tachometer is bouncing or just showing true values, you need to continue to read on here. The reason for poor tachometer performance is caused by the lead-free solder used on the cluster printed circuit board.

Tools Required

#2 Phillips screwdriver

T15 Torx screwdriver

Fine Tipped Soldering Iron

Total Time for Repair

1 to 2 hours

Removal of the Instrument Cluster

The knee bolster needs to be removed first. There are 2 Phillips screws at the bottom.

Then it unsnaps from the top.

Now remove the center trim around the stereo there are no screws it's simply unsnaps from the dash frame. Be aware there are power point plugs that you will not need to remove.

Now you should see the cluster trim screws should be 4 Phillips screws holding the trim in place. Now be careful the headlight switch is plugged into the back.

Now the cluster is held in by 4 Phillips screws.

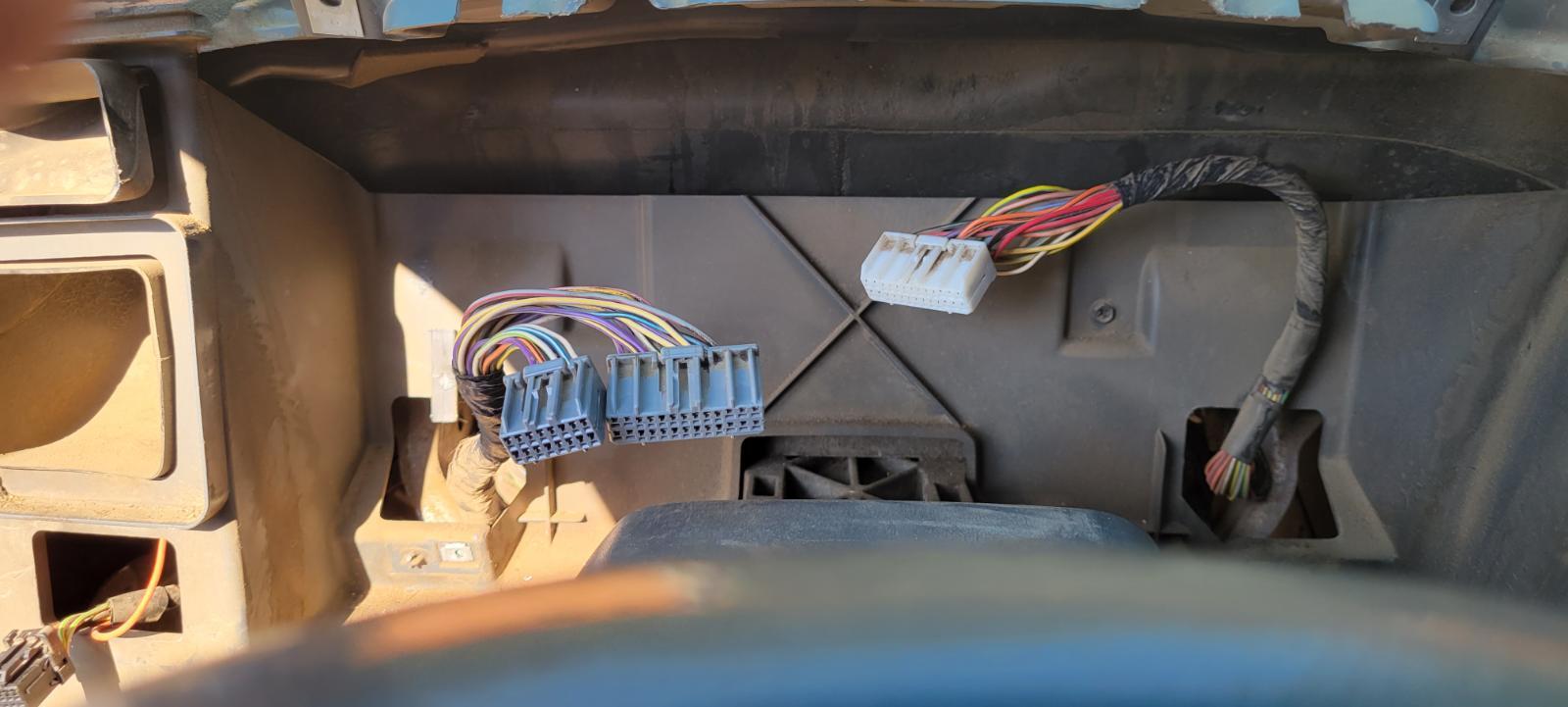

Tilt the steering wheel all the way down to gain a bit more room. Staring on the passenger side of the instrument cluster tilt it out to gain room to unplug the connectors on the back of the instrument cluster.

There are 3 plugs in total. Once unplugged you can remove the cluster and take it to a suitable work table.

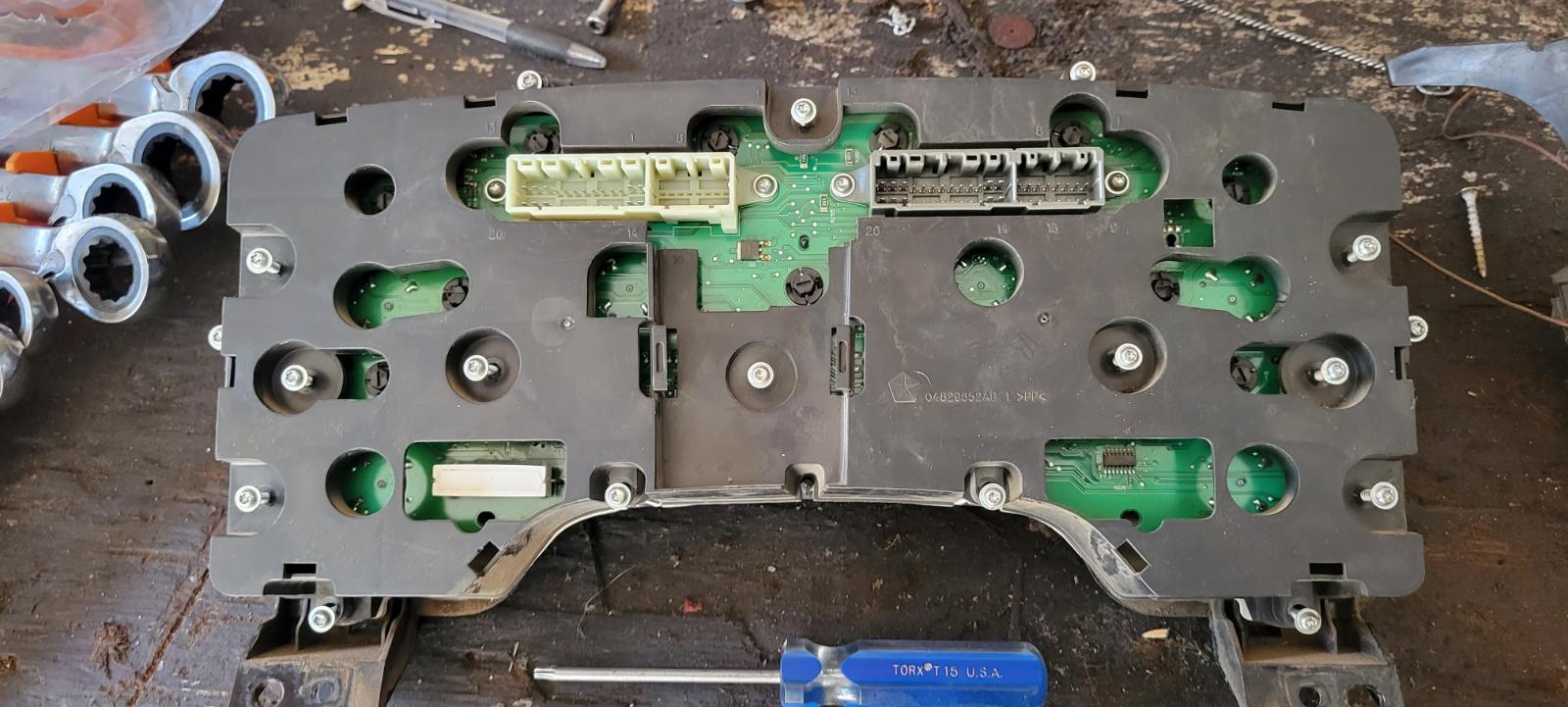

Now at this point, there are 18 screws. These are all T15 Torx screws. Remove all Torx screws holding the black plastic cover in place. Be careful the outside screws hold the cluster front lens in place so be careful not to damage the gauge needles or front side. Also do not remove any screws on the plugs not required.

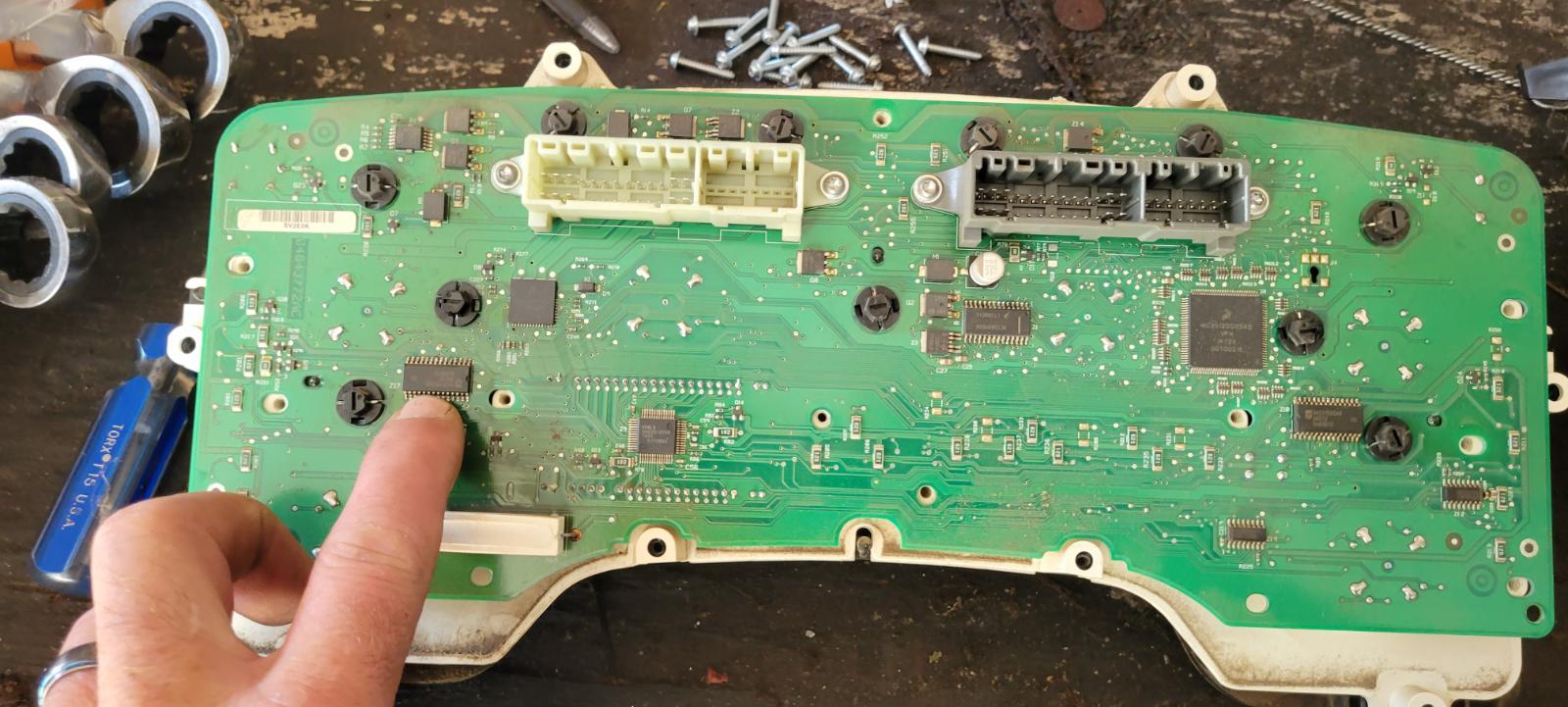

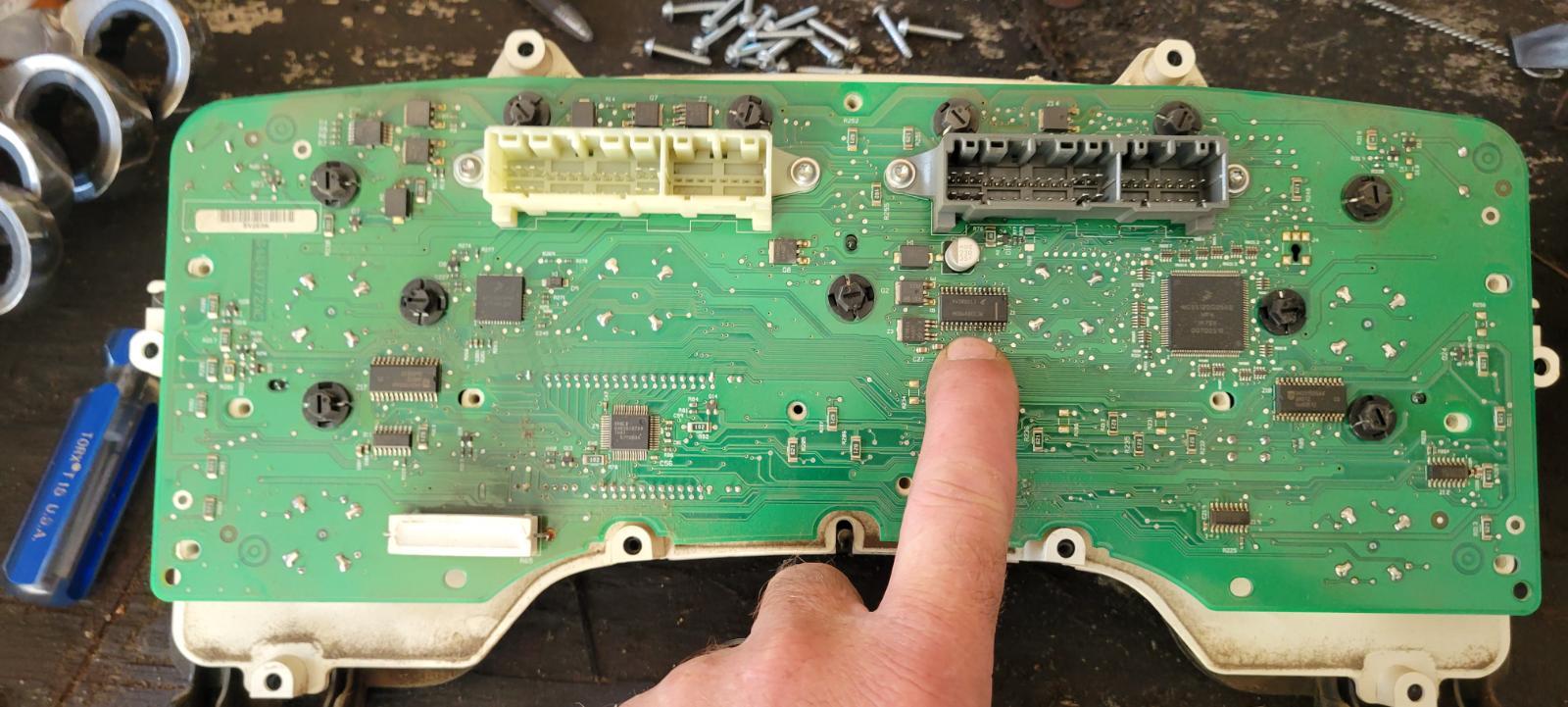

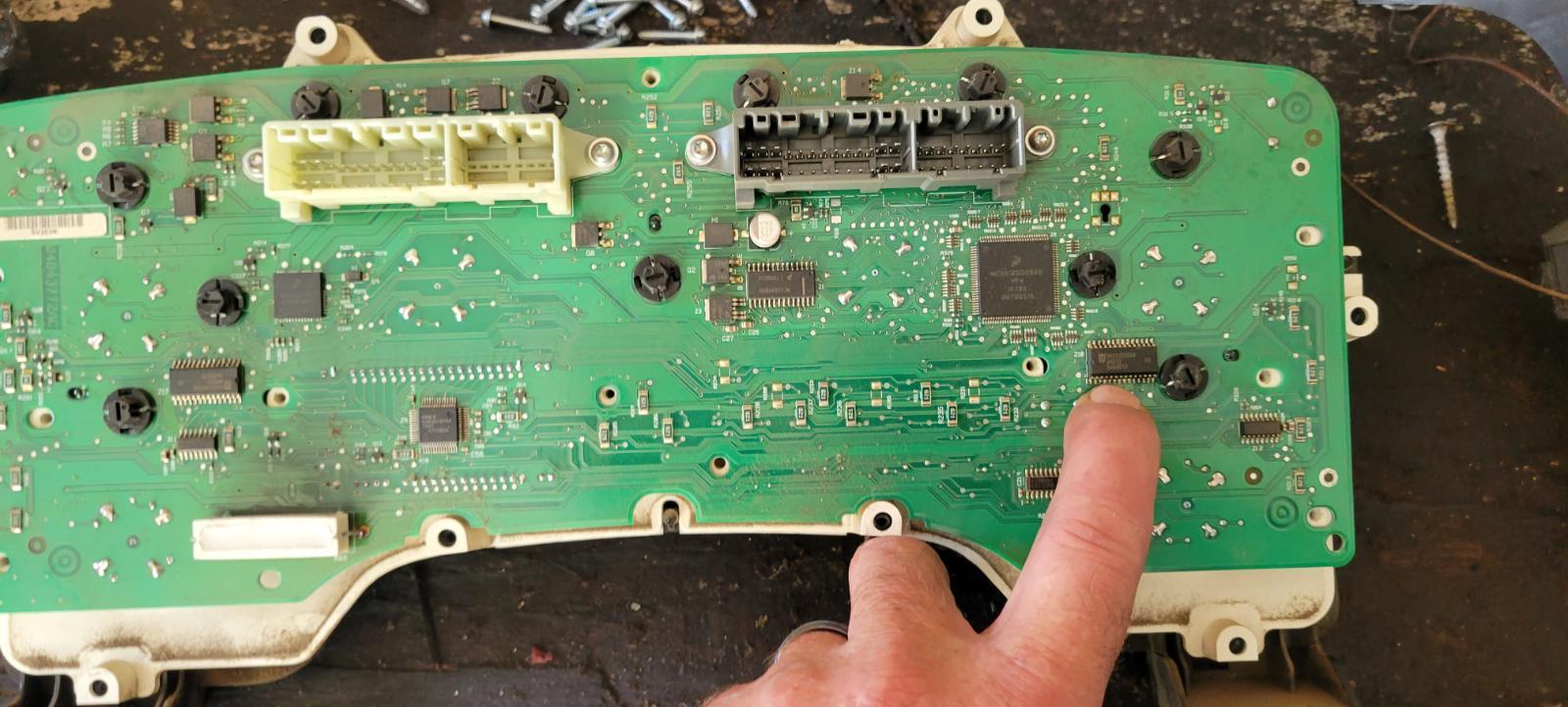

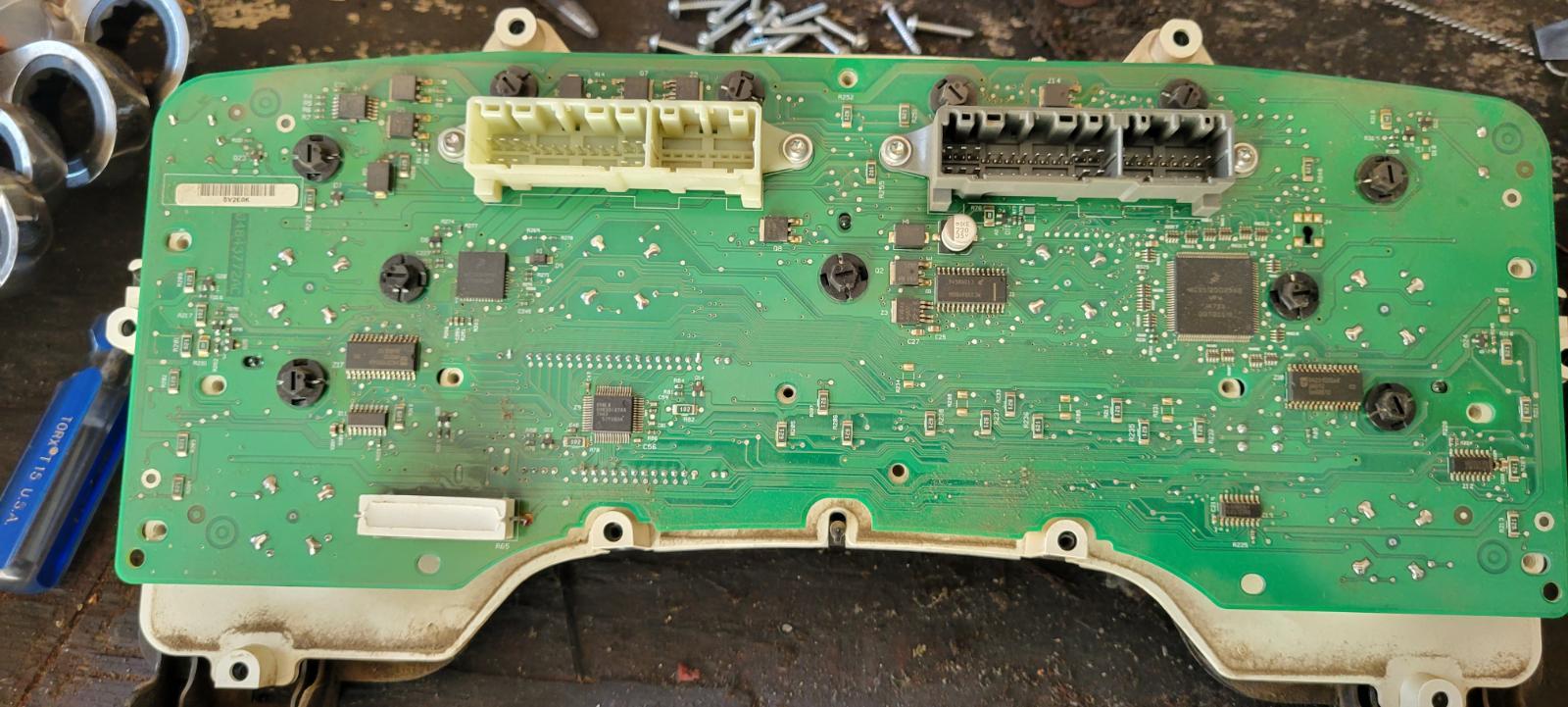

Now there are 3 chips, in particular, to pay attention to. There are 28 legs in total on these 3 chips that control the data for the tachometer gauge.

Here are the three chips I reflowed the solder...

Here is where you are going to use a fine-tipped soldering iron and carefully heat each leg of these chips and flow the solder again. DO NOT add any solder at all it is not required. When you complete one chip take your cellphone and start your camera and set the zoom for 3x. Now you'll be able to get up close and look at all the legs and verify that no solder has a bridge between any of the legs.

Then move on to the next chip and repeat. When all 3 chips are done double check your work this is very important if there are any bridges between any of the legs of any chip you might cause irreparable damage. The photo above shows the 3x zoom of one of the chips and allows you to see that no legs are bridge soldered. Again double check your work and be sure there are no bridges between the legs.

Testing

You can slip the cluster back in and plug in the instrument cluster after you have replaced the rear plastic cover and at least the outer rim of Torx screws. Then plug it in and start the truck and verify the tachometer is working properly. If so the project is done. If not double check you actually flowed all the legs again till you get the problem resolved. If you can't get the tachometer working or you happened to cause damage during this repair you can contact "Module Masters" in Moscow ID and have them test and repair your instrument cluster for your truck.

Reassembly

Just now reverse everything you did to remove the cluster.

There are no reviews to display.