Everything posted by yohon

-

Water methanol for mpg.

Yeah I'll for sure do that next time lol. Hopefully I wont waste the life time coolant I added as well. I'll try and do a write up on the brake lines I should have taken more pictures when doing it. And yeah these trucks are shockingly efficient. I have yet to turn my electric fans on here in texas

-

Water methanol for mpg.

Yeah the overheating was not good. Had to help a friend in need and rushed the truck a bit. I believe it was a large amount of trapped air in the head I had hadnot burped out during the cam break in. Didn't let oil temp exceed 200 degrees but I know i didn't do anything any good. And yes I replaced all the brake lines with stainless was only 185$ for the lines and about 2 hrs of work.. I highly recommend inspecting the clamp under the brake booster where it mounts to the frame. Thats where mine rotted out at the clamp holds water that splashes up from the road. The thermostat was a murry brand new 200 degree but for whatever reason was missing the little air jigglers ( small bypass holes with metal tabs in them) i think that caused it to air bind in that section.

-

Water methanol for mpg.

Day 1 overheat with mechanical fan ( no shroud) install electrical fan set up and wire Day 2 blow brake line going 80 mph during engine break in Day 3 transmission cooler line is severed internally ( routed different then previous and the sharp end of the tube cut the line) work loved the giant red puddle Day 4 finally find source of overheating to be bad thermostat ( thought electric fans were in effective) Today's mission find source of hard start ( fuel leak somewhere) pressurized tank to about 10 psi and got fuel from above tank no where else pulled valve cover and verified no injector leaks. Next thought is connector tube o ring but not sure how to test besides smoke on start up.

-

Water methanol for mpg.

Im itching to try it myself but want to give the new engine the best chance at breaking in well. So I have been holding off. I also convenientlyhave a new problem every day to fix with it. Once I get a few thousand miles on it I'll give it a shot

-

Water methanol for mpg.

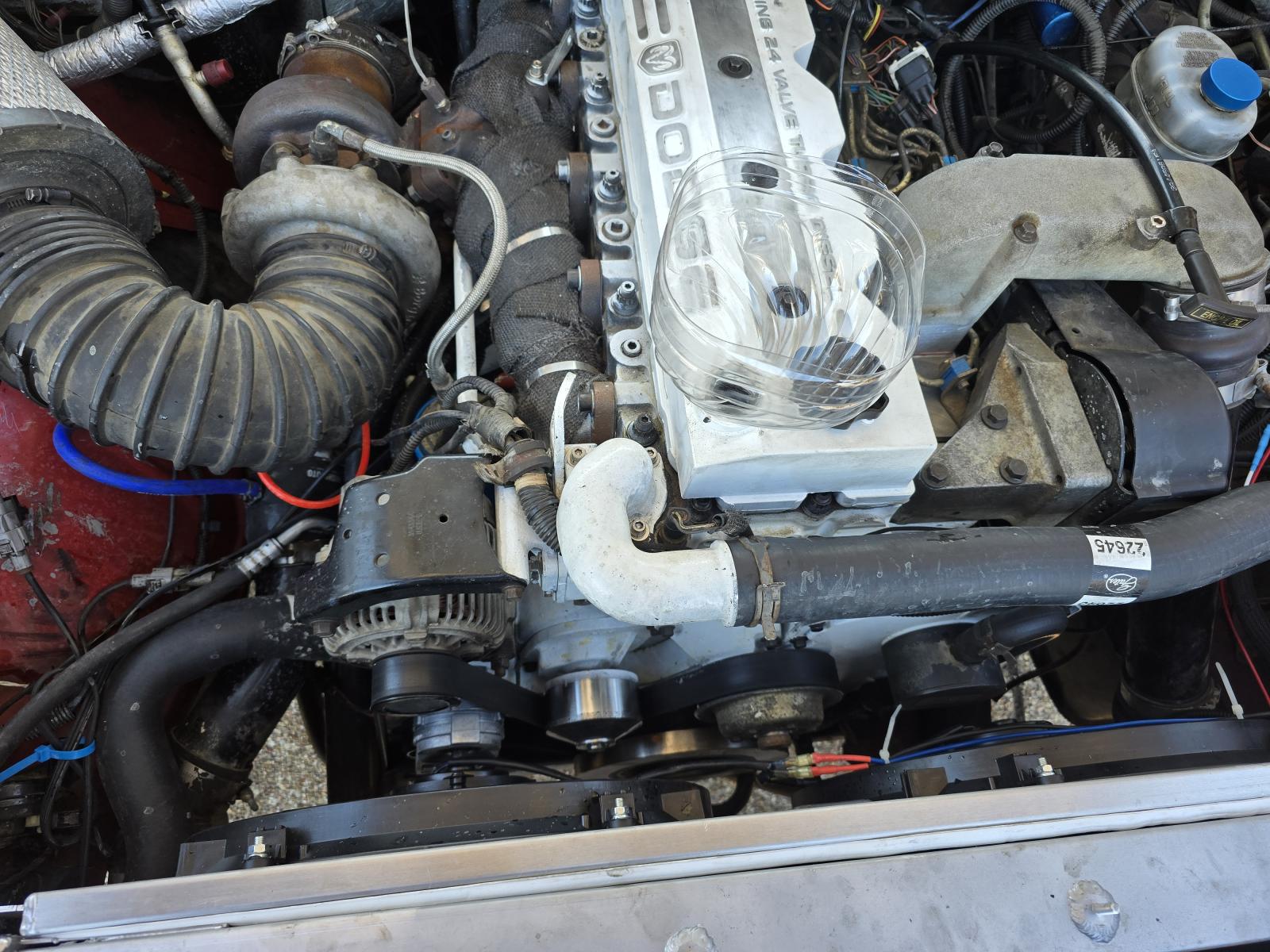

Running and driving now. Still breaking it in and finishing up small things ( finally got new upholstery for the seats ) once I get a few thousand miles on it I'll swap from air to air intercooler to air to water and try out the water methanol. I do have a dummy spool made up to attempt intercoolerless operation but I dont have high hopes for it to be honest. Also fun fact water jugs from heb make great funnels they even have the same threads as the oil cap

-

3 pin vs 4 pin blend door actuator

Will do im going to attempt to relearn the actuator once I get to work on the truck again ( father took it down to Houston) will keep yall posted.

-

3 pin vs 4 pin blend door actuator

I have a off brand version from amazon that should replace the doorman part number ( could be the problem) I'll call doorman up and see about the calibration procedure

-

3 pin vs 4 pin blend door actuator

Correct the 3 pin vs 4 pin "male side" with the pins on the green board. The wiring harness or "female side" has a blank block that will fit up to 6 wires ( only uses 3) and it is 100% the actuator replaced the adapter and even went as far as to swap the 3 pin bad motor with the working motor from the 4 pin however the green board itself is actually bad ( sat full of coolant from bad heater core)

-

3 pin vs 4 pin blend door actuator

I have a bad blend door actuator on my father's truck (2002 3500 stock) ordered a replacement and all I can find is 4 pin units when plugged it it only rotates 1 way and makes a full 360 turn ( when installed it goes hard agains the blend door in the cool position. no matter the temperature setting. The old unit was a 3 pin but every part numbers listed is for a 4 pin. Am I missing something?

-

Understanding stock Quadzilla

Here is the link to one of the big tuning post on this forum dont let it overwhelm you. https://mopar1973man.com/forums/topic/12002-quadzilla-v2-custom-tunes/ i wouldn't get too craxy with Timing until you get a set of headstuds copy your current tune in the format provided on page 1 and we will get you tuned up !

-

Understanding stock Quadzilla

Any modifications done to the truck? I dont think my quadzilla came with any tunes but its fairly easy to turn.

-

Fresh engine break in recommendations.

Yup cummins just called for conventional 15w 40 too nothing special. And I can get alot of conventional 15w 40 for the price of x1 round of break in oil. Cummins i trust to say what their engine needs and dont need mopar/dodge I'll take with a grain of salt

-

Fresh engine break in recommendations.

So I finally have my new engine installed ( bone stock rotating assembly except I did put a tow cam in it) and im looking at engine break in procedures they all recommend towing decent weight no idle time ect all makes sense but I have 2 questions 1 ) should I run higher timing with the quadzilla to try and raise cylinder pressure for better ring seal? 2) highly contrivosal but does anyone recommend a break in oil if so what type? Ill be switching to Synthetic after the first 1000 miles and changing oil after the first 400-500 miles ( block has been sitting for years so lots of dirt and such probably in it)

-

Time for truck's AC summer check up

I wasn't sure if it needed to be circulating at all times so I put a 3 way valve on mine to "bypass" the heater core didn't want to take a chance after I broke the last head stud.

-

Adding inline power steering filter with system flush update

The rebuild kit i got had one for it https://ebay.us/m/U9ICf1 I will say its a easy rebuild but not much use all your really doing is re sealing the system I never could find replacement punp "vanes"

-

Time for truck's AC summer check up

Any update on this? I did the same thing to mine along with a new evaporator and was disappointed with the results. Im about to add cut off valves to the heater core and inslate the ac lines from the orfice to the cab and see if that helps.

-

Adding inline power steering filter with system flush update

Thats a good point. I just rebuilt my power steering pump and was shocked how much was on the magnet especially since the only worn part i found was the aluminum sleeve the whole pump shaft rides on my only thought was it must be from the gear box. Im about to find and read your original article and add a filter to mine along with a cooler.

-

Adding inline power steering filter with system flush update

That's cool to see. Have you checked the magnet in the pump?

-

Water methanol for mpg.

Motor is just about ready to go in. Can anyone get me a measurment from the bottom of the closed hood to the top if the valve cover? Im looking at a 4 in thick water to air intercooler I'll install if the water methanol don't work. But I never got that measurement before I pulled the motor.

-

Help me build the perfect motor

Thats not bad at all thank you for checking my water methanol pump draws about 15 and im looking at adding a small fan for the tran cooler and ac condenser seat heater and cooler any possibly upgrading the factory raido so electrical power is high on my worry list. Thankfully im in texas and have my grid heaters disconnected.

-

Help me build the perfect motor

Awesome is the power steering pump rebuild pretty self explanatory?

-

Help me build the perfect motor

I'll have to look into it for sure. Any idea the electrical load of the remote vacuum pump?

-

Help me build the perfect motor

Finally got the vacuum pump and power steering pump out and need some advice. Should I replace these units? They are both OEM and have almost 300k with no obvious leaks on them vacuum pump i can rebuild and found seals for it. The power steering pump makes me nervous oil in it looks like crude oil. I hate to get a reman and it be worse then I one I have. I did find a link talking about rebuilding it. But the link didn't work I also found a article on this site about hot roding the pump ( drilling out the orfice slightly) and I'll for sure do that. Any chance anyone has a working link on how to rebuild these? Or know of a reliable aftermarket pump.

-

Water methanol for mpg.

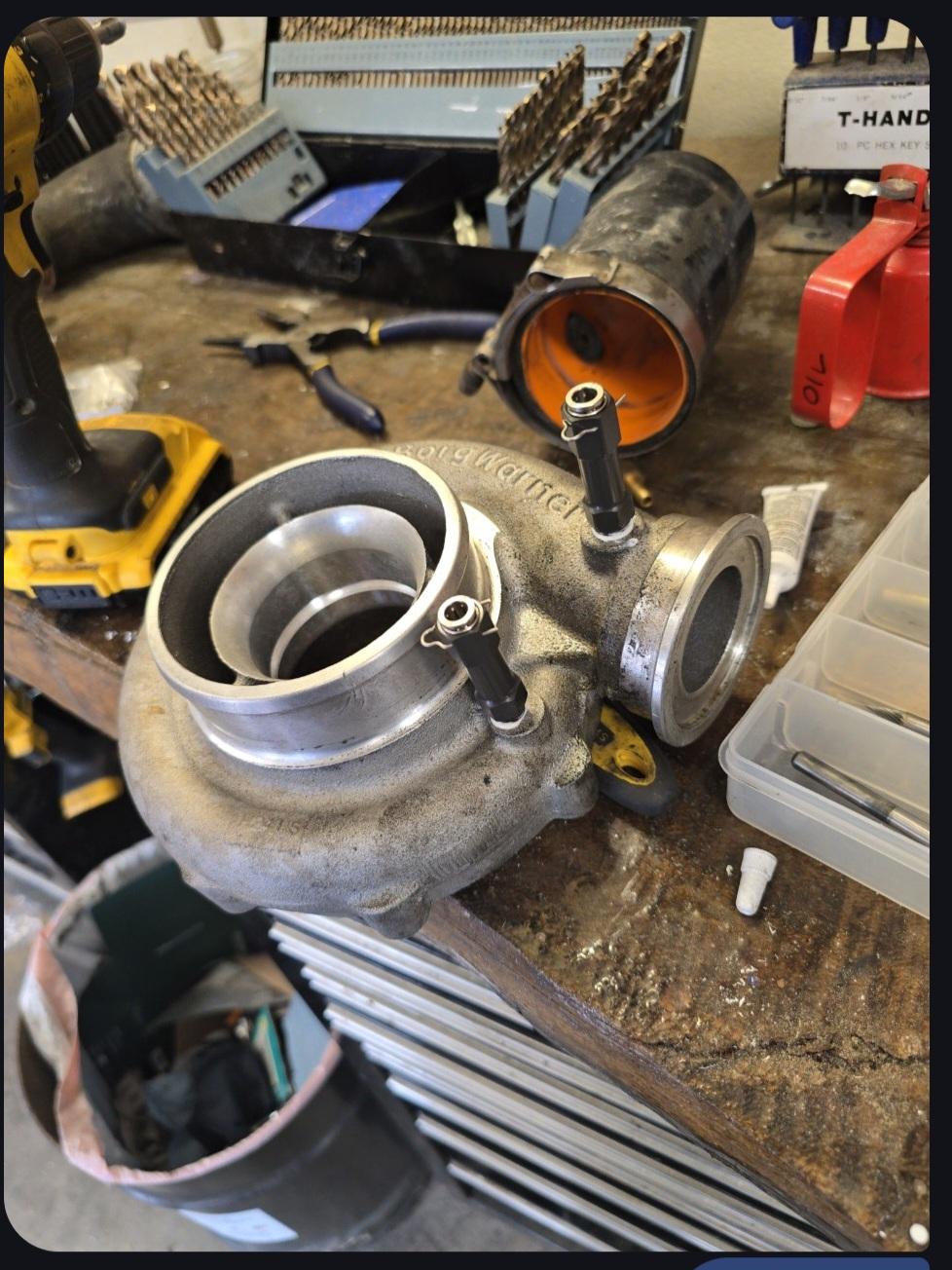

Build is progressing slowly then id like but trying to do it right the first time. Slow transferring all the parts to the new long block but got the turbo drilled tapped for water methanol and gasket matched the manifold and the turbo.

-

Water methanol for mpg.

Will absolutely be careful with it. This is indeed my daily driver and If im being honest with myself at all I will be converting back to a intercooler when this doesn't work. But I have to try and fail or else I'll always wonder.