Everything posted by 2500ctd

-

Rail Pressure Troubleshooting

Couldn't use the crows foot. No room so I used the calibrated elbow. New filter setup is mounted as well. Gonna run the bf7633 since I have it. And my bf1212's showed up today. So hopefully I can get a ride to get some diesel. Don't think I want to strap 5 gal diesel can to my back on the bike. Pocs of filter setup:

-

Rail Pressure Troubleshooting

New rail is in. Anyone know the torque specs for the fuel lines? Says refer to torque specs. Can't find them in the manual. Running out now to get a crows foot for the torque wrench. Didn't have a 19 mm but I had a 3/4 tube wrench. Also what size is the connector tube nut? 21mm ish? Rail is surprisingly heavy. Well it is a high pressure vessel.

-

Ordered filters. Think I forgot the water/separater

Thats what I thought For some reason I was thinking the 7633 was a pressure side water separator. My filters are going after the lift pump.

-

Ordered filters. Think I forgot the water/separater

Gathering parts for my filter setup. I ordered Baldwin 7633 and a Donaldson p551313. I think those are both filters. I thought the 7633 was also a water/separator. If not I guess I got extra fuel filters.

-

Fuel additives

Doing some searching I found this: http://www.fuelexpert.co.za/2strokeoilindiesel.php http://www.fuelexpert.co.za/2-stroke-oil-in-diesel-technical-study.php

-

What's This Going On???

Mine does the same. At first I heard the chime and never noticed the lights flash. At first I thought it was the parking brake pedal not returning fully. However it does only happen if I'm driving and the grid heaters are active. It chimes everytime the grid heaters cycle off. I believe my batteries are towards the end of their life. its "normal" for now. However after I change my batteries, I'm hoping it goes away. Also, one of my grid heaters is not working. I know since the relay is burned. Happened before I ever had the smarty on my truck. First did it when it started getting cold.

-

Rail Pressure Troubleshooting

What pressure does the relief lift at? I thought I saw it here but cant find it now. My relief valve with the as shown 26112 psi isn't leaking oops found it well top post on this page. I missed the post about calling T&C diesel

-

Rail Pressure Troubleshooting

Ordered the rail. Debating on switching the whole thing out or just pirating what I need off of it. Part number is 4929618 Genos lists the rail as well for 299.00.

-

Rail Pressure Troubleshooting

Can someone double check me. I found the pressure relief valve for $265, the pressure sensor for $217 and a fuel rail for $299 which includes the relief valve and the pressure sensor. It would be cheaper to buy the rail and take the sensors off the new rail. I am reading that right, right? http://hoeslidiesel.com/store/page13.html I was going to stop the local Cummins and have them order a pressure sensor, Might be getting a whole rail now instead.

-

Truck died on highway, and will not start, no other electrical problems?

How did you go about testing the sensor? Did you back probe the harness? I don't like breaking the insulation. A way for contaminates to start corroding the wires. I've used a sewing needle to put as small a hole as possible in the insulation.

-

Rail Pressure Troubleshooting

Local Cummins $230. Reading the thread a few down. 'Truck died on highway…'. Might also maybe pick up a cov.

-

Rail Pressure Troubleshooting

Not yet. Had to rebuild the forks on bike. Easier then the truck now. I pulled the tank and drained it. So hopefully no fuel issue. Which of course after I drain the tank. Easiest way to go about testing the sensor? I'll have to back probe the harness. Least intrusive is a sewing needle. Worked for me before.

-

Rail Pressure Troubleshooting

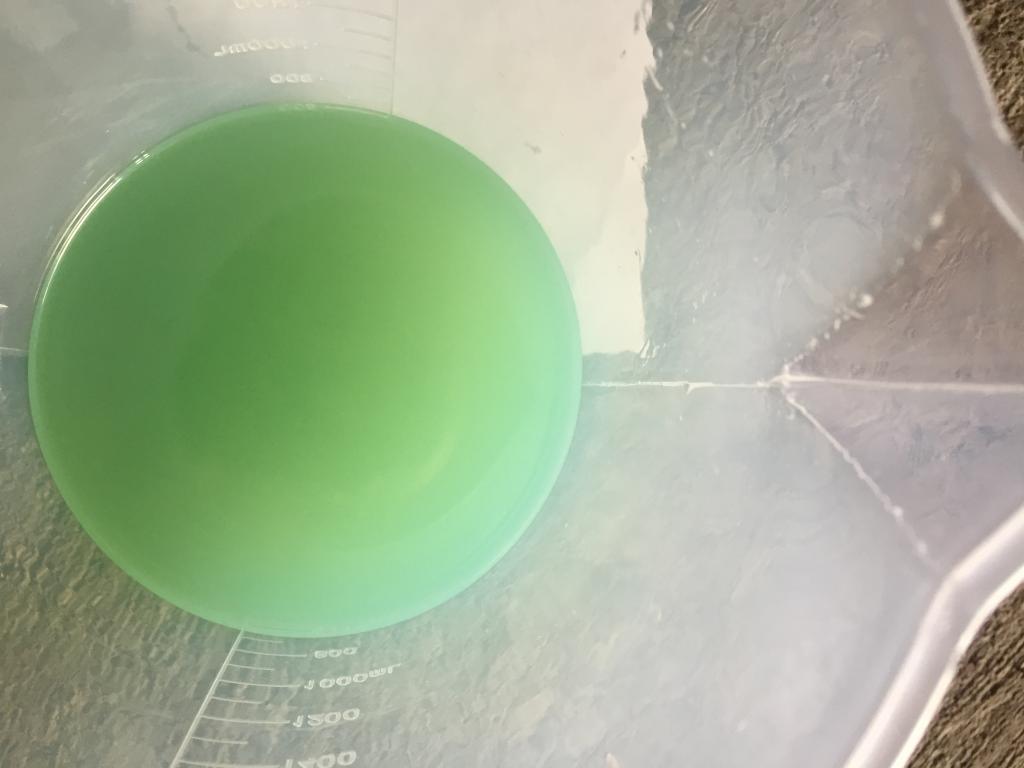

Riddle me this: when I did the test the fuel looked like emulsified water. Now, that same sample is clear. It's 56° now. I wonder if this diesel is a winter blend? tends to make me think it was not a fuel issue.

-

Rail Pressure Troubleshooting

Next thing after the fuel is the pressure sensor testing. I will check that thread. I saw water pooled around the tank vents. Hence the vent relocation. When I pulled the filler tube hose off I saw a little dirt that got between the hose and tube. Also looks like a little dirt on the bottom of the fuel module screen. I have a plan to fix that. I have a flatbed so I have around 7-8 inches of clearance above the tank. Enough for water and dirt to splash up there. I do play in the woods as well.

-

Rail Pressure Troubleshooting

the two little barbs on each end of the tank maybe a 1/4 hose would fit on. I have a flat bed and had to redo the filler neck. refilling kept tripping the nozzle. I don't think the filler tube vent is a source for contaminates but can be cleaned up a bit.

-

Rail Pressure Troubleshooting

Pulled tank. Nothing obvious, minus Cloudy fuel. Is there a way to raise the tank vents? I'm almost thinking water might have gotten in that way. I thought dodge had a fuel tank vent tsb or severe duty vent kit? Also trying to use the lift pump to drain the tank. It'll run about 5 seconds and then quit pumping like its sucking air. Worked fine in the truck. Wonder if the free flow of the pump is faster then fuel can flow into the module. During pumping it has a solid stream until it sucks air. Top of tank is dirty. Wow.

-

Rail Pressure Troubleshooting

Started dropping the tank yesterday. Only owned the truck since February '14

-

Rail Pressure Troubleshooting

I have around 15 miles on the fuel filter. When the issues started I swapped the FCA which was within a year of my last one. Under warranty. When I picked that one up I got a new fuel filter. Swapped FCA's. Ran fine. Swapped the filter and then it ran like crap. Got another FCA ran fine till the next morning. I have no codes, Havent checked recently just after the new FCA went out. No codes. Ill program the truck back to stock and scan for codes. Smarty is showing rail pressure desired at 6000 at idle, and the actual is 26112. Good thing I guess is during the HPRV test there was no leakage. Bone dry. At least that isn't leaking. No one to swap FCAs with. After swapping out the 2nd one, I drove the truck down to return it. Next morning, max rail pressure. It is slow to build rail pressure cranking but after it starts it maxes.

-

Rail Pressure Troubleshooting

just over the weekend. During the winter cold starts, when it isn't plugged in almost doesn't crank fast enough. Plugged in for about 3 hrs before I leave and starts easier. Batteries are old. I don't think they'll last another winter. I will keep that in mind about the smarty. Ill return it to stock and then keep it unplugged till I needed. That would be the 3rd FCA. Not saying it cant be, just I don't buy it. Also with the cloudy fuel I could have other issues. The pressure appears to be working. Truck sounds/behavior mimic the RP on the smarty. I will see if I can test the sensor. should be a 5V sensor. Nothing to difficult......famous last words.

-

Rail Pressure Troubleshooting

Only running the stock canister now with a fleetguard. I have 2 filter heads for extra filters. Gotta make a bracket and mount it. how can you tell there is 2 stroke in there? Looks like rust. Really hope it isn't. Reminds me of emulsified water in the fuel.

-

Rail Pressure Troubleshooting

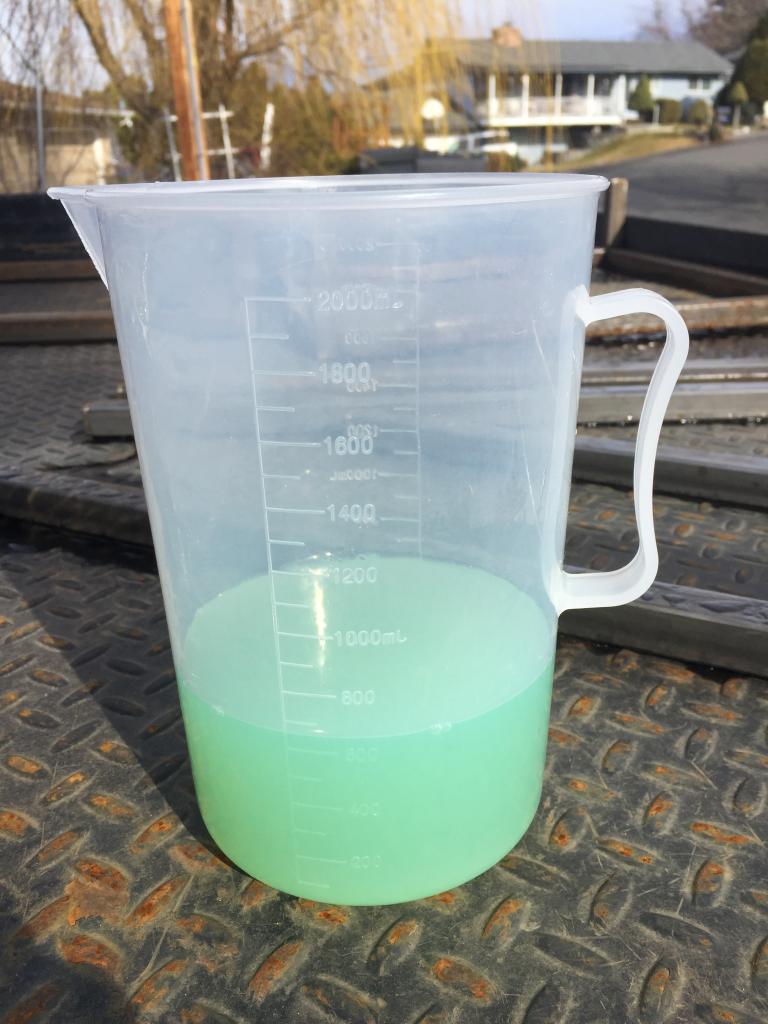

did this test. 600ml. Had truck plugged in. So not at operating temp. ~127° the other thing, rail pressure is maxed at 26112psi during the test. So is the excess fuel due to that or is it still valid results? Another thing was the fuel:

-

Rail Pressure Troubleshooting

Just finished testing the hprv. Passed, no fuel from it. Setup to do the injector return test. According to the video, truck needs to be at operating temp. Not going to do that with max rail pressure, so I have it plugged in now. I did pull the fca and do the shake test lol I know that test is pointless I actually pulled it to see if there was anything I can see that might have gotten in there and maybe jammed the fca yea I'm reaching. Of course no change. Must has no trouble hitting 26kpsi. Seems slow to build pressure though. With it at idle and max rail pressure, the initial lift pump pressure was @ 7psi. A quick throttle tap. Dropped to 5 but no lower. Figure at max rail pressure and 5 psi. Intank pump is at least good enough to rule out for this issue which I didn't think it was the lift pump but the psi test is easy enough. Banjo bolts look like a little rust on them or is it just me? What about mounting aux filters higher then the tank? They will be higher then the tank but lower then the engine mounted filter. During filter changes, I will probably crack a line to let the fuel drain down to minimize spillage. Plus they are up and hidden. Ill post pics when installed. I don't believe it to be an issue as the pump still has to lift the fuel up to the stock filter level, and being the intank pump, its all pushing fuel. Much gooder for the pump as opposed to drawing fuel up that high. Yes gooder is a valid word in my vocabulary. ?

-

Rail Pressure Troubleshooting

Not sure on how to test that. I have a smarty touch. Rail pressure seem to mimic the truck. At max pressure truck sounds like crap. Same as unplugging the fca. When it would almost die, rail pressure went down to under 4K with the worse it bouncing around 1700-2000 psi. It did take a bit longer to build rail pressure. Longer then normal. I gotta have something returning to much fuel. I am suspecting all this is due to a tank or 2 of bad fuel. I recently switch stations. (Cheapest in town, Arco)shortly after, around a week filling up the water in fuel light came on. Never happened to me before. Not in the 01 nor the 05 till then. Pulled over, drained it and good to go. Well about a month later the dead pedal starts. Initially it started as a hiccup during shifting. At first I thought it was me. So slight. Well now…

-

Rail Pressure Troubleshooting

Wish I could change the title. To somethings else. Not batteries. Lol Got all the fittings in. Installed the tapped banjo. Lift pump has 5 psi at idle. Noticed that now rail pressure goes straight to max like the fca is unplugged. Desired pressure is ~6K as reported by the smarty. Haven't done return flow tests yet. Last of my fittings came in today. With maxed psi I would lean towards the fca. However 2 already I doubt its the fca…again. Never say never though. I have a 2 filter bases I'm going to install after/if it gets fixed. Will the timbo work on 3rd gens? Futher plans are a new lift pump. I have Walbro on my 01 with the draw straw. ?

-

Rail Pressure Troubleshooting

I have the cummins test plugs coming and a tapped banjo for the cp3 as well. I'll just plug the banjo bolt till I get my gauge mounted. Don't have one to mount in the truck yet.