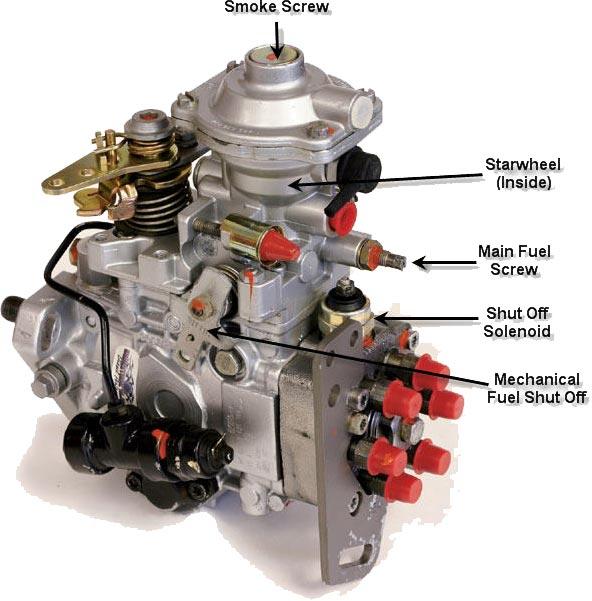

Here is a brief write up on how to turn up the power on your 1st Generation Cummins truck with a Bosch VE Injection pump.

Low Boost Fueling Adjustment (Smoke Screw)

Beneath the cap is a Torx T-25 screw and a lock nut that holds it. The locknut is 13 mm and has a 'break-away torque' of around 100 in-lbs. Tightening this screw will increase low boost fueling. Loosening this screw will reduce low boost fueling. You should adjust this screw to the point there is a light haze with heavy throttle but 0 boost pressure.

Full Load Fueling Adjustment (Fuel Pin)

The fueling pin is located under the cover with the smoke screw. Carefully remove the banjo bolt from the rear of the cover. Take notice to how little torque it took to loosen this banjo bolt. This banjo bolt is very thin and can be easily broken. Remove the cover and the diaphragm is underneath. Mark the position of the diaphragm before you remove it. Take notice that this pin, when removed, has a taper to it that is offset from the center of the pin. The deeper the offset placed forward will increase fueling. Shallower will decrease fueling. There are ground pins that are ground even deeper that will enhance fueling even more. The governor pin comes from the front of the pump and points towards the rear on the pin.

There is aftermarket fuel pin available from vendors on the internet like www.dennytperformance.com .

AFC Starwheel Adjustment

The star wheel adjustment will change how fast the fuel pin will move in relationship to boost pressure. More you screw the starwheel down (tighten) the quicker the fuel pin will react to boost pressure. More you screw the starwheel up (loosen) the more boost pressure it will take to move the fueling pin.

Full Power Adjustment (Main Fuel Screw)

Take a 13mm wrench from the bottom area you should be able to reach up and loosen the jam nut. Now the more you screw in the main fuel screw the more fuel will be delivered. This adjustment will alter idle setting so more your screw in the higher the idle will become.

WARNING! Turning up the main fuel screw too far might cause a run-away condition so make sure you have a board or a heavy rubber cap or such to cover the turbo with to shut down the engine in a runaway condition.