Introduction

I've increased,

with fuel. pump 20-25 20-25 ounces of makes it to harm known.

two-cycle to my lubricity. might add oil to fuel.

More Information on ULSD...

First, increase important to

diesel from less than 500 ppm fewer than eliminates sulfur fuel.

Sulfur is a...

pressure additive. Applications under pressure conditions lubricants, compounds chlorine, or the pressure with only the metal compound coating the protection exactly protection sites temperature are high

temperature increase beyond effective range the protection. When force. of wear experience the coefficient of is greatly increased and the temperature rises damaging level.

Testing Fuels Lubricity

There are several methods of determining lubricity in fuels. The most common are: Ball on Cylinder Lubricity Evaluator (BOCLE), Scuffing Load on Ball Lubricity Evaluator (SLBOCLE), and High Frequency Reciprocating Rig (HFRR). The HFRR has emerged as the world standard and has been adopted by the ASTM and all of the engine manufacturers as the de-facto standard for measuring lubricity of fuels. HFRR ratings are counter-intuitive with the lower number showing better lubricity than a higher number.

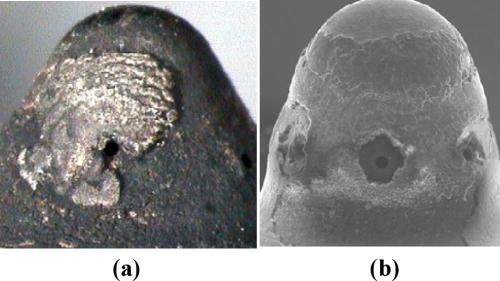

On an HFRR test the number given is a measurement of the scar diameter (microns) produced during the test. The larger the scar diameter, the lower the lubricity, the smaller the scar the better the lubricity

Here is a few ASTM HFRR Standards...

| Product | Sulfur Percentage | Sulfur ppm | HFRR Rating |

| High Sulfur Diesel #2 | 0.5 - 2% | 5,000 - 20,000 ppm | 300-390 HFRR |

| Low Sulfur Diesel #2 | 0.05% | 500 ppm | 350-500 HFRR |

| Ultra Low Sulfur Diesel #2 | 0.0015% | 15 ppm | 520 HFRR |

| Ultra Low Sulfur Diesel #1 | 0.0015% | 15 ppm | 520 HFRR |

In the matter of Lubricity the ASTM after many years of discussion, has set its standard at HFRR 520 for diesel fuel as a minimum.

Amount of lubricant in diesel fuel at 1 Gallon and 35 Gallons of ULSD diesel fuel.

| Product | Sulfur Percentage | Quantity Of Lubricant (35 Gallons) | Quantity of Lubricant (1 Gallon) |

| High Sulfur Diesel #2 | 0.5 - 2% | 22.4 - 89.6 Ounces | 0.64 - 2.56 Ounces |

| Low Sulfur Diesel #2 | 0.05% | 2.24 Ounces | 0.064 Ounces |

| Ultra Low Sulfur Diesel #2 | 0.0015% | 0.0672 Ounces | 0.00192 Ounces |

| Ultra Low Sulfur Diesel #1 | 0.0015% | 0.0672 Ounces | 0.00192 Ounces |

When you look at it from this stand point the amount of lubricants have been reduced to next to nothing.

Updated: Jan 03 2007

products additive are using mineral spirits, However, remember conditioners Cummins Forum, I've

find lubricants With injection pump whole more lubricants in and improve the comes enhanced

Mix ratio for 2 cycle Oil

The easiest oil. Thiswill

oz of oil to gallon of fuel...

Update! How is Diesel Fuel Transported and Handled - April 18, 2007

I found some interesting document about the way that diesel fuel is shipped and I'm going to share these document with you...

http://www.arb.ca.gov/regact/dieslub/notice.pdf <- Some information on how diesel fuel is now shipped.

http://www.arb.ca.gov/regact/dieslub/hor.pdf <- More on how diesel fuel is handled.

http://www.ncagr.com/standard/diesellubricityenforcementpolicyletter11504.pdf <- How North Carolina is handling diesel fuel.

station.

RAW DIESEL FACTS - BEFORE A ADDITIVE PACKAGE

Ultra Low Sulfur #2 Diesel by law cannot contain more than .0015% (15 ppm) of sulfur. This fuel will generally have an HFRR rating of 600-800.

Ultra Low Sulfur #1 Diesel by law cannot contain more than .0015% (15 ppm) of sulfur. This fuel will generally have an HFRR rating of 700-900.

Remember: 1000 Microns = 0.039369999999999995 Inch

As you can see above raw untreated USLD diesel is well outside the range of the 520 HFRR limit. It requires a additive package. But once again the is no regulation that insure that package was added to the truck in proper quantity for that load.

Now saying this... I know there isn't a single diesel additive product on the market today that can promise to improve the diesel fuel lubricity below 520 HFRR level! Especially if its untreated diesel fuel with a HFRR value of 700-900!!! Just something to think about when you buying a fuel additive. But I know that 2 cycle oil is reducing that number for sure!

Update! Winter Time Performance of 2 Cycle Oil - April 30, 2007

For starters my lowest temperature around here was recorded at -20.2*F (-29*C) on January 16, 2007 in New Meadows, Idaho. This was recorded by my on-board thermometer which hold histories of HI and LO temps for both inside and out. During this entire season I never use a single anti-gel product on the market. Just diesel fuel and 2 cycle oil.

Now remember above in the specs sheet for ULSD the gel point is 0*F.

Now think about it. A snowmobile runs on a mixture of about 40:1 to 50:1 gasoline and 2 cycle oil. This very same snowmobile must run in extreme temperatures down as low as -40*F (40*C) and maybe lower. But what I want to point out here is...

- There is no problem with 2 cycle oil gelling up in a snowmobile in extreme temperatures as low as -40*F (-40*C)

- With mixtures as low as 40:1 a high performance snowmobile runs great. There is no reason why a 128:1 mixture in you diesel truck would lose performance to that mixture.

- Knowing that 2 cycle oil is lubricating your entire system compared to using a harsh solvent (that thins the lubricants) to breakdown the wax of diesel to keep the fuel flowing.

- Remember that very same snowmobile has no other lubrication system on board only the 2 cycle oil in the fuel to lube the entire engine. So it a prefect lubricant for your fuel system on your diesel truck.

As you can see I've go no loss of power or economy with the use of 2 cycle oil. All I got is high points! Think about it most people see a decrease in fuel mileage during the winter time. I'm not seeing much of a decrease this winter between the Edge Comp and the 2 Cycle Oil used in my fuel.

As for IP and LP pumps. I'm currently got 43K miles on my Bosch VP44 injection pump with no problems so far. Then I got 10K miles on my current carter Campaign pump. Which still got 11-12 @ WOT yet!

Update! Using 2 Cycle Oil in ULSD Designed Trucks (2007+ Diesel Vehicles) - April 30, 2007

I would highly suggest that no one uses 2 cycle oil in a vehicle that is already designed for ULSD. These engines have some very expensive equipment on board like diesel particulate filters etc. These device are not cheap to replace. Also remember this might or will VOID your warranty on your truck. These engine have been redesigned to be run on fuel that are very low in lubricants (Sulfur content).

UPDATE! May 19, 2007- 2 Cycle Oil And The DynoJet...

Well there has been a lot of talk about 2 cycle oil hurting to HP/TQ numbers. Well I'm here to set the records straight for once and for all...

First off let me lay down some baseline information. You all have seen my web page on my BOMBs and MODs I've done. Ok... We all know that the 2002 Cummins SO is rated for 235 HP 460TQ at the flywheel.

Run #1 - Stock mode with Edge Comp Turned off.

228 HP - 462 TQ

Well this proves there is very little drag between the flywheel to the rear end. Also this proves there was very little improvement in HP/TQ number concerning 2 cycle oil. I'm using conventional Dino lubes in everything except the transmission which requires the Castrol SynTorque. But still even this number is high for HP/TQ at the rear wheels... 2 Cycle oil maybe???

Run #2 - Edge Comp turned on 5x5

379 HP - 831 TQ

Run #3 - Edge Comp turned on 5x5

381 HP - 826 TQ

Ok we all know the Edge Comp give about 120 HP on 5x5 setting but now do the math. 381 - 228 = 153 - 120 = 33 HP difference! Where did this power come from? I got no other fueling enhancements and only a BHAF and straight piped exhaust 3"... Stock injectors, stock turbo, stock Bosch VP44 injection pump and lift pumps.

As for my fuel / 2 cycle oil ratio he is what I had. I filled up with 26.306 gallons of diesel fuel and poured in 32 ounces of 2 cycle oil (SuperTech Outboard). So that means...

26.306 (Gallons) x 128 = 3,367.168 Ounces of fuel.

3,367.168 / 32 Ounces Of Oil = 105.224:1 Ratio of diesel Fuel to Oil.

I admit this is a bit heavy mixture of 2 cycle oil to fuel. But I've been getting a bit lazy about measuring my oil so if I'm nearly empty I would add the full quart regardless.

It's got to be the 2 cycle oil helping the burn of the fuel.. So never the less I'm a extremely happy camper and will continue to use 2 cycle oil in my fuel.

Is 2 Cycle Oil Safe For My Cummins?

EGR the injection pump plenty of well.

Will 2 Cycle Oil Plug Up My Fuel System?

simple withsolely oil additives cleaners. The rest them looked the same.

Then here is what WEO/WMO or ATF looks like after a short period. (From another Cummins owner) Can you just imagine what the combustion chamber looks like?

What's Wrong With Using ATF In The Fuel?

fluid to DOT inspector.

What's Wrong With Using Waste Engine Oil In The Fuel?

the scale

There are no reviews to display.