Everything posted by Zach B

-

APPS sensor adjustment and reset difficulties.

Took a look at Genos Garage. I found the rebuild kit, but it only includes brushes and bearings. I’m looking for the rectifier/diode to replace. I can’t seem to find one for my specific alternator. I went to densos website and got the part number for the alternator my year/model truck, but when I Google search it I can’t find any of the rectifiers that fit that model.

-

APPS sensor adjustment and reset difficulties.

I got it figured out, I measured .002-.003 volts with the truck off and .004 with it running. Even though I got the AC noise down to .025-.033v, I think I’m still going to rebuild the alternator. I’ve been looking and can’t seem to find a kit that comes with the new diode specifically for the denso on my truck. Does anyone have a link or a place to get the kit from? Now that I’ve done the WT ground mod and the PCM protection mod, After I rebuild the alternator and my AC noise is still at the levels it is now, I should be good to send my ecm out and get it repaired, right? No more risk of it getting damaged again?

-

APPS sensor adjustment and reset difficulties.

Yep, that’s what I did to test AC noise and got the reading of .025-.033v. Got the same reading from both batteries. What I’m talking about is mopar man said to test if you need the parallel cables, you are supposed to set the multimeter to DCmv and put the black probe on a battery terminal and the red probe on the block. The reading that your supposed to get is around .003mv. I was confused on this part because when I placed my multimeter probe on the battery and then the block it read OL.

-

APPS sensor adjustment and reset difficulties.

Cool, that’s what I was looking for. I didn’t get the chance to read through it yet and I already completed the mod, but so far everything works fine. I tested my AC noise and it’s down to .025-.033v at idle. I wasn’t sure how to test to see if I needed the parallel cables though. In mopar mans simplified article, he said to put the black probe on the battery and red probe on clean metal on the block. I just found a clean bolt head going into the block. I set the multimeter (Fluke 110plus) to the DCmv scale and it wouldn’t take a reading, it read OL on the display. Also, what does he mean by take jumper cables and run from negative post to negative post? Am I testing DCmv between the two negative terminals? Just not sure what I’m supposed to be doing or what I am doing wrong

-

APPS sensor adjustment and reset difficulties.

Okay I understand now. I was a little lost In molar mans version of the mod but now I see what needs done with the power wire. Thank you for the reply

-

APPS sensor adjustment and reset difficulties.

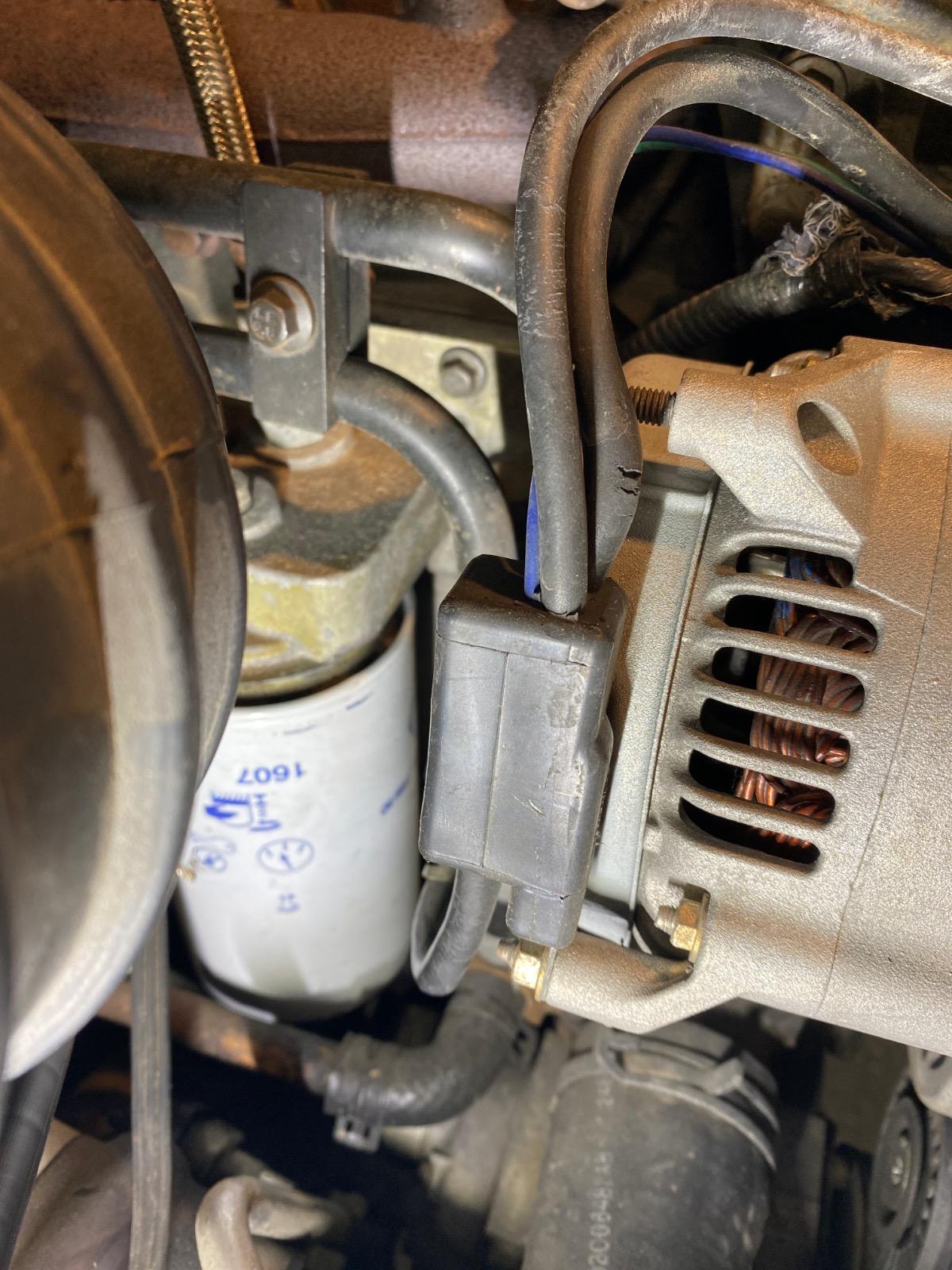

Alright, working on the WT ground wire mod and have a question. I was unable to find the original article so figured I’d ask here. my question is in the first picture, the charge wire coming from the alternator is the large black one. I’m confused on where to cut that as the directions aren’t clear. Do I just cut it here and run it over to the passenger side battery? Or do I have to chase it all the way through the harness and unhook it somewhere? Second question, in my second picture there is the little block that the charge wire goes into and then the wires come out the top. Do I leave that alone and run the charge wire coming out the top to the battery? In the directions it appeared the alternator did not have this little block on it with the wires coming out the top.

-

APPS sensor adjustment and reset difficulties.

Alright so that’s what it means, I tried looking online to find out what the N stood for, I figured the D stood for denso. Thanks for the info! Yep, I’m going to wait until I do the modifications and see what my AC noise level is at before I send the computer out to get rebuilt. That way I don’t fry a new one again. Ill let you know if I have any issues with the mods tomorrow, I do have a little question about the ground wire relocation mod but once I get it apart I may answer it myself. Thanks for all the help so far

-

APPS sensor adjustment and reset difficulties.

Sweet, I’ll go ahead and order the rebuild kit for it then and do the wiring modifications tomorrow to see if it helps any

-

APPS sensor adjustment and reset difficulties.

- APPS sensor adjustment and reset difficulties.

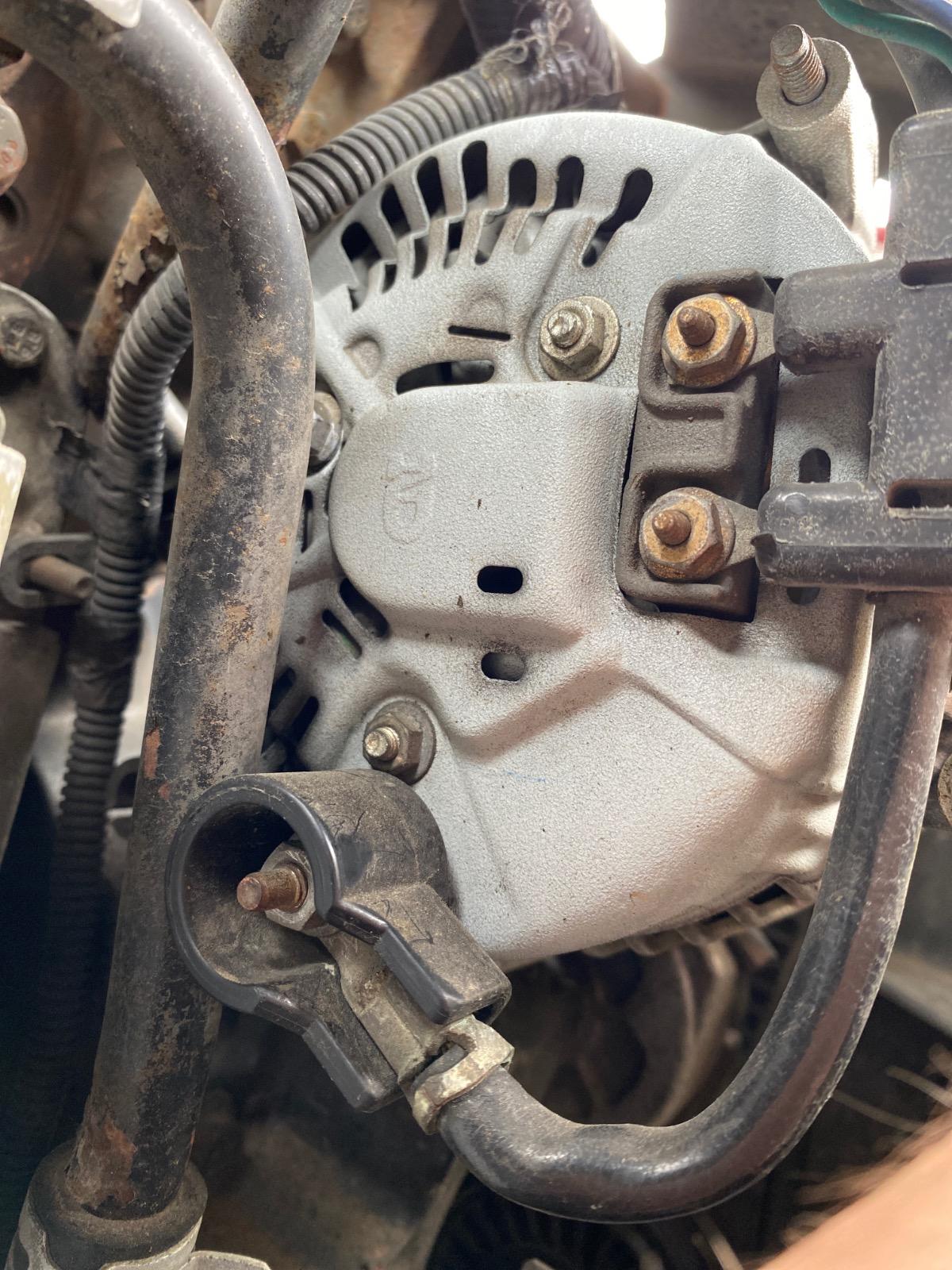

Alright, I’ll take a picture and post it tomorrow, I’m at work today and don’t have any tools to take the alternator off for a good picture of the back (I work 24hr shifts). Unless someone thinks they could identify it with a picture of it still on the truck Okay, I did read somewhere to go with the ND over the Bosch. I’d like to rebuild mine because of the cost but I may still get a new one, have yet to decide- APPS sensor adjustment and reset difficulties.

Alright, I'll do the mods you suggested and repair the alternator before sending the ECM off for repair. The reason I asked if there's a way to identify the alternator is because when I purchased the truck two years ago it had two brand new batteries and a remanufactured alternator that had just been put on. The alternator does not have a sticker on it to identify the brand and I have no idea where it was purchased from. I'd hate to buy a rebuild kit for a denso alternator and end up having something else...- APPS sensor adjustment and reset difficulties.

Thank you for the reply and advice, I believe I just found my issue. I have a friend who has a 98 24v, exact same truck as mine, same manufacture date and everything. His is P-Pumped, so he loaned me his ecm to plug into mine. I plugged it in and immedietly noticed it idled lower, had more power, and the APPS read 0-100% like it should. By the end of the day it was doing everything my old one was. Delayed wait to start, low power and APPS reading between 8.6-71%. I went and bought a fluke 110 multimeter, and did the AC voltage test for what seems like the 100th time. At idle I got between .044-.061v. Then, had a friend hold it at to 1500rpm which is norma cruising rpm, and got a reading of .13v. So correct me if I’m wrong, but I believe the reason I never caught this sooner was because I was testing it at idle when it was not putting out much current, but cruising down the road it was giving my system a constant .13v and that is what hurt my ECM. Now, do you recommend getting a whole new alternator, or can I buy the rebuild kit myself and do it? Also, I have no idea what alternator I have. There’s no sticker anywhere on it to determine the brand. Is there a brand of alternator you would recommend over others, or is a new NAPA or Advanced Auto unit okay? Sorry, final question. My friend said I could have the computer off his if I need it, and I’d give him my rebuilt one I got two years ago. Would you recommend sending the rebuilt one I got two years ago to Auto Computer Specialist to get rebuilt, or should I send them the OEM dodge one off my buddy’s truck to be rebuilt? I’m sorry, I’m not real good with computers and don’t understand them, but I’m just not sure which would be easier for them to rebuild to work with my specific truck or if it doesn’t matter- APPS sensor adjustment and reset difficulties.

I’ll go ahead and see if they’ll replace it first because that’s obviously the cheaper option. If I still have issues I’ll turn to you guys. My grounds should be clean, cleaned all the ones I could get to two years ago when I had the same issues before replacement and my voltage is 13.8 while the truck is running. Thanks for the help!- APPS sensor adjustment and reset difficulties.

I gotcha, it makes a little bit more sense now. I’m not good with computers at all, so when it comes to anything of that nature it’s like a different language to me. May be hard for me to explain what’s going on to them if I don’t know what I’m talking about haha Okay, not what I wanted to hear, especially with being a fairly new ecm. Is there a chance that I just got a bad one, or would you think there’s an issue on my truck causing it to go bad again? I did get my ECM from auto computer exchange. Honestly have no idea if they’re a reputable company or not. Would it be worth using my warranty with them and getting a new one? Or is there a chance you guys are better with these computers than they are? Sorry for all the questions, just want to get rid of this issue and not have it repeat for a 3rd time…- APPS sensor adjustment and reset difficulties.

Sorry, I don’t know exactly what EEPROM and Flash Memory is? Also, don’t know if it matters but I got my ECM from auto computer exchange. Should I see if I can replace it because I did pay for the lifetime warranty?- APPS sensor adjustment and reset difficulties.

Yes, my wait to start light is delayed. About a year ago I replaced the ECM with a new one I got offline because the old one went bad. Caused my lift pump to quit working and took out my VP. Had my lift pump on a toggle switch for awhile until I ordered the ECM, replaced it and everything seemed to work great. I still had the delayed wait to start light even after replacing the ECM but not like before. Before, it was delayed about 10 seconds every time I turned the key. Now it comes on right away about 80% of the time and when it is delayed its about 1-2 seconds. Do you think my new ECM could be bad again? I did everything I could before installing it to try to ensure its longevity by replacing the alternator and rerouting the passenger ground wire getting the AC noise within tolerable limits.- APPS sensor adjustment and reset difficulties.

Hello all, just joined the page so please forgive me if I don't do this right. I have a 98 2500 24v auto, and ever since I've owned the truck I've been having this issue but just never attempted to do anything about it until now. I've just rebuilt my transmission to hold 550hp, am looking to add a tuner but I know I should fix this before I try to add more power. I have read the forum here about adjusting the apps and numerous other forums and cannot find anything to specifically relate to my issue. To start, my issue is that when I plug in my OBD scanner, my APPS sensor was reading 8.6% at idle and 71.3% at wide open throttle. So, after doing some reading, I attempted a reset. I unhooked the batteries, let the truck sit for about an hour with the key on, and then turned key off, hooked batteries up and continued with the reset process. I have done this multiple times and it seems to correct the readings on my scanner to 0% at idle and 100% at WOT for about one day, then it resets back to the 8.6% and 71.3%. I am pretty positive my OBD2 scanner is reading correctly, I plugged it into my friends truck whose is identical other than his being the 2000, and his read 0% at idle and 99% at WOT. His is also bone stock but appears to have much more power than mine. Next, I tried adjusting the apps sensor using the method Mopar Man posted here in the forum. I am pretty positive my APPS sensor is stock. My idle voltage was .49v, and the back of my apps stated the voltage should be below .569v so I adjusted the apps to .54v at idle (note, I did not loosen the apps screws and rotate it, I used adjustment screws like what was recommended). I then adjusted the WOT voltage. It was reading 3.63v, and while I couldn't find an exact voltage anywhere, I found a YouTube video Mopar Man linked to the adjustment forum that said it should read around 3.8v, so I adjusted it to 3.8v. Also, I checked to be sure that the apps did not have any voltage spikes or drops throughout the travel, which it did not. It was a nice smooth climb from idle to WOT. Now, after the adjustment was completed, I checked my APPS reading on my scanner and it's now showing that my idle percentage is 10.2% and my WOT is 74.3%. I've tried resetting it a few times and continues to default back to the 10.2% and 74.3%. I'm stumped. I've done all the research I can to try to figure this out without creating another post because I know there's thousands of them out there, but I cannot find anything that relates to my issue. Do I need to just replace my apps sensor or is something else wrong? Any ideas or suggestions would be greatly appreciated.- Garage Vehicle: Purple Cummins

Vehicle Nickname: Purple Cummins Date Added To The Garage: 2022-08-05 Garage Link: Purple Cummins - APPS sensor adjustment and reset difficulties.