Everything posted by rogerash0

-

VP44 PSG5 limitations read/write

Im going to re-read this a couple times to get a better grasp on it all. So my torque converter is a lot to blame for the early up shifts? Mine will be in 4th gear still at 25 mph probably, it takes quite a bit to get it to finally down shift, and when it does it goes straight to 2nd gear. It stack shifts thru third gear on the upshift right into fourth probably 95% of the time. Theres been a couple times it pulls 3rd gear out and boy is it nice. Now wide open throttle it wont stack the shift -- I dont think -- but daily driving yes. Im just wondering I suppose why my TC is too tight when I ordered a Comp I from Firepunk. I was thinking springs in the valve body and/or pressure screws needed adjusted to fix my early up shifts.. I read Dave Goerend's website with the FAQ about the torque converter, efficiency, stall speeds and such, but I still overall dont really have my head wrapped around what exactly a looser converter will do and how it'll fix my shifting problem(s).

-

VP44 PSG5 limitations read/write

I didnt think it would leave 1st gear in "1" when shifted manually. I can give it a go. As for how the TV lever is set on your truck Im confused. I dont even think mine is set right, I wasnt getting full swing of the lever with the pedal floored. Im going to stop by Firepunk on my way to Virginia here in a month and hopefully they can both help and educate me.

-

VP44 PSG5 limitations read/write

Also, I took off the 35's and put on some "stock" 3rd gen 17's, and gained an absolute ton of lowend back. The motor rpms spin up so much faster its incredible. Gets right to 1600rpms when the powerband starts to come in right away off idle.

-

VP44 PSG5 limitations read/write

Sorry I didnt see your replies guys. I thought I got emails / notifications. I wasnt checking the board regularly. So a fairly loose converter is a higher than stock stall speed? The metallic sound is worrisome. Does anyone know where to get the plate covers for the TC port window & the barring hole? Im missing both. Somehow two bolt holes on the TC port window are stripped... Does the higher than stock stall speed make the tranny hang gears out longer? I'll put it back on my radar to have him restall it... just gotta find a way to work, this is my daily and my wife is away for a few more months in tech school. The TC cable adjustment seems to have a marginal effect at best :\ Also, is it normal for my max boost to be 43psi @ 32degs *F when yesterday it was 38psi @ 62 or 65degs*F? I was either in error and not at top gear with TC locked when I saw 38 psi, and thought I was, or I truly gained 5psi with the temperature loss. I ran the truck out several times and was convinced I was at a boost loss /w 38psi being max with these 62/68 + S475 compounds. I thought 43 psi was low to begin with. (but I have the bar and plate intercooler, stg2 head porting + intake plenum, 4" banks boost tube and elbow, 1.32 & .80 exhaust housings on, 5" downpipe, 5" exhaust, so I was trying to keep boost numbers lower for the sake of the motor). Also I double checked my valve lash, reset everything having only had done it once before.. and the belt was previously slipping when I turned the alternator nut. So I bought a new belt, cleaned all the pullys, put it on, it now turns the motor over when I turn the alt nut, and the truck is running much stronger with less smoke. Definitely more low end power. Starts better too. I was still only seeing 38psi max at WOT with the valves/belt done, which was previously 42psi, and so I checked for boost leaks very thoroughly and couldnt find any even with friends looking and a few lights..... however we cant see or spray the bottom of the billet intake plenum with soapy water, and I believe it to be prone to leaking there due to maybe 1/4" of surface area for it to seal in many parts -- but now today with the temp down to 30-35*F its getting 43psi max @ WOT all of a sudden, and all that changed was the air temp. Seems like thats a bit big of a gain from just the air temp. Has me a little puzzled. Also I tested /w no air filter on today, on the hwy running it out to around 100mph, and I gained 1 psi of boost at WOT in top gear /w TC locked. I assume thats pretty optimal to only lose 1 psi /w the filter on (?). Also if any one could help me find the Edge low-end fueling chart with the %'s, boost levels, and so on I would appreciate it. I looked and looked, and cant find it. Moparman has posted it before.

-

P0121 after 10 hrs driving high rate of speed

I better not have to buy another APPS. I admit I had no idea the timbo was all mechanical. I thought it was similar to OEM but made by "timbo" for less $$$. Thanks the advice, I'll double check the Wells instructions and see how the voltages are looking. Is there any truth to the APPS sensor voltage being higher or lower at max/min ranges affecting torque converter lockup? How hard it locks up and the time at which (rate of speed) it locks up at.

-

P0121 after 10 hrs driving high rate of speed

My ac noise was .01v last I checked. I'm going to set the apps idle to .48v because I learned about the idle validation switch thanks to moparman. I know the writing rubbed off my switch, but I'm assuming it's IVS is .519v like others I've seen pictured. I went with duralast because it's the Wells unit which had some video documentation posted on YouTube by wells that I liked. It's a magnetic holieffefct (sp) sensor that won't wear out.

-

P0121 after 10 hrs driving high rate of speed

So today I get a dead pedal / stumble off idle, erratically. First time it happened once on my 12min drive to work. Coming home it dead pedaled maybe three times. Could be dangerous when pulling out into traffic. Yesterday I did a 10 hour round trip at a high rate of speed, hit 130mph per GPS on my phone, did much of the trip at 85-100mph often pulling upto 110-120. Lets just say it was some real long, real open old highway and I had a long way to go. *I was trying to get back before it got really dark, any tips on additonal lights I could mount on my bumper that are cheap and effective I am open to. So the kicker is its a P0121 code, which after reading on here Moparman says is the APPS. Well I just put in a new Wells (duralast) Apps sensor maybe 18 months ago and I havnt had a problem up until now. I calibrated the voltage with my Fluke and so on. It was a fairly cool day out, high of 77 and low of 42 in Glendive, MT. In Great Falls it was a high of 67 and a low of 44. Im running 50hp injectors with an Airdog 200, my VP44 is 16psi at idle, and 10PSI at WOT. I had a lot of sustained 10PSI WOT. It was my impression this would not hurt the VP44, but now after reading I think it may have. However my code P0121 being the APPS does not coincide with this theory of the VP44 being hurt. I do have a new VP44 that I could put on, it's already been on and off the truck, so I'm not dying to install it again, but I could. I've done everything under the sun to raise my lift pump pressure at WOT besides clamping the return line like JL told me to do (I think it was JL). I still need to try that, which I think will work. Any tips/tricks/banter greatly appreciated! I have to move in a month and buy a trailer so I already have a ton of other stuff to do, I wasnt hoping to be turning more wrenches on the truck now. Plus, I have to drive 2400 miles in the process of moving. So your help goes a long way. Thanks

-

VP44 PSG5 limitations read/write

Cool thx man

-

VP44 PSG5 limitations read/write

Would it be a good idea to store my new II vp44 that I'm not using with it full of diesel?

-

VP44 PSG5 limitations read/write

First thing I did was take that white clip out and adjust the cable. Went max distance both ways. Seemed to make no difference at all. Firepunk told me it would make the truck shift higher or lower. All it did was make the downshift to second gear nasty, so I set it back to where it was somewhere around the middle. I had used a paint marker. Putting load on sooner to help build boost sooner makes sense. Since my compounds are pretty small, esp the s300, I would think the slightly lower than stock would still be optimal. You're saying it's a matter of opinion, so I would think it's ok. Pulling the tq converter out and going without a truck for awhile may not be worth the effort right now while the wife is gone and I don't have a second vehicle. At the same time I think the metallic sound and bog says there's something wrong with it.

-

VP44 PSG5 limitations read/write

Thanks a ton guys. To take the slack out do I pull the apps cover and adjust it in there somehow? Last I thought the cable terminated like any other dirt bike throttle cable and just had slack. I don't remember a set screw to hold the cable to adjust it and take out the slack. Also I just got off the phone with a Phil at DPC and he says my converter needs restalled. Firepunk told me it was slightly lower than stock stall speed, I relayed that to Phil and told him my old engine setup, how it seems to bog and make the metallic sound on lockup, after the D&J engine went in, and he says the metallic sound might be a loose bolt but the converter with my 62mm SXE and S475 needs restalled back to stock. Does this sound right? I asked why they would have shipped it with lower than stock stall speed and his explanation didn't exactly resonate with me. He said the engine would come on sooner with lower stall speed, but no hard numbers, and I dont see why my current setup would need something different?

-

VP44 PSG5 limitations read/write

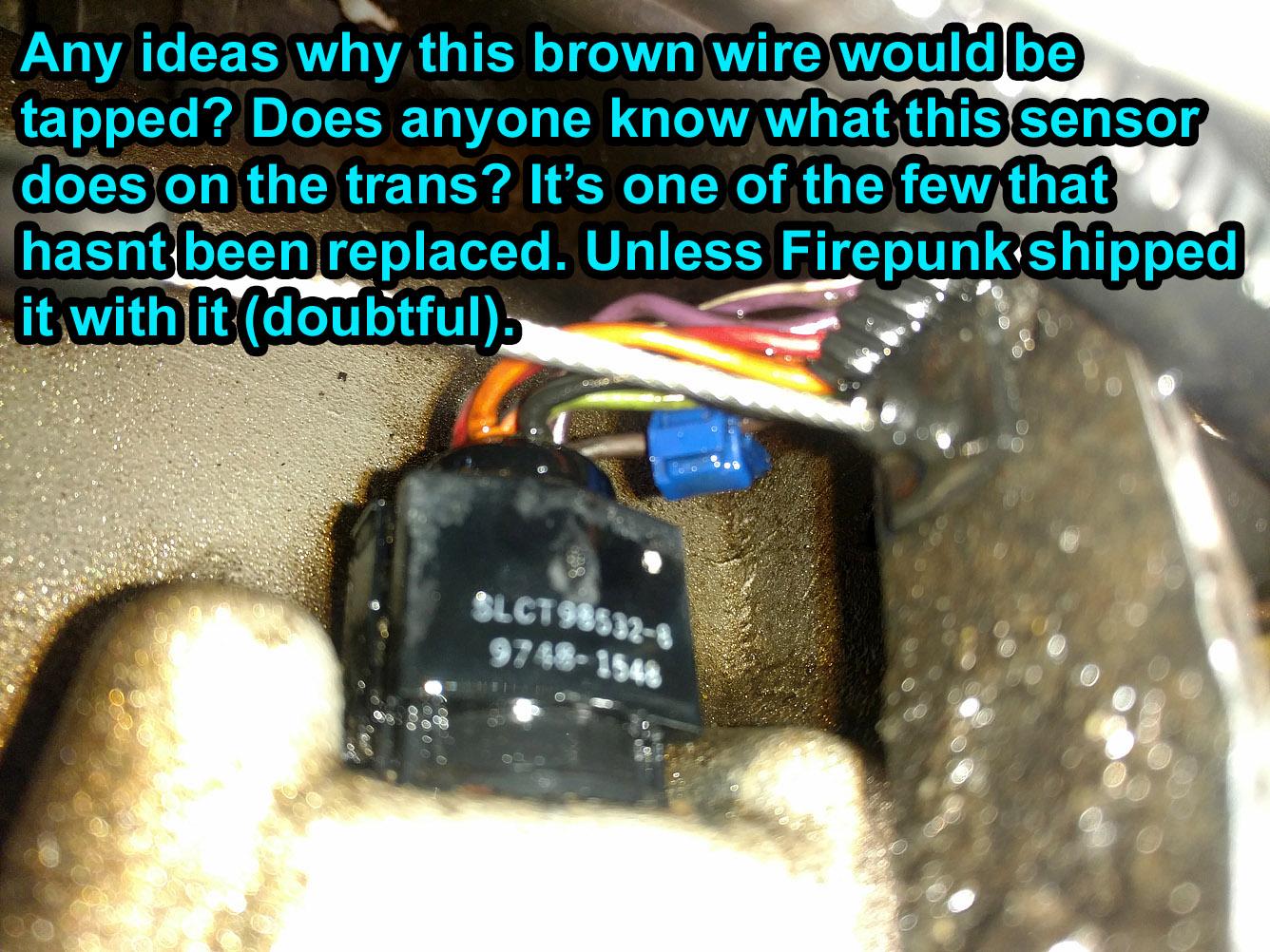

Do you know where the voltage regulator for the tranny and resister mod would exist? I tried an external voltage regulator when I was having alternator issues but pulled it back out. With those brown wires tapped, is a switch that hooks them up all I need to have the lockup command capability? Im interested in it because, for example, today my engine was up to normal operating temp, and I went to pass without realizing I was at 48-49mph, and as soon as I stepped into it I hit 50 mph, TC locked, and the truck bogged like hell. Putting out a big cloud of black, with the 50hp injectors Edge on lvl 7 lowend on 3 timing on 2. That type of thing drives me nuts. It also bogs in third with OD off when it engages at 30mph. Surely it shouldnt bog as it does.. All this wiring non-sense started as I cleaned the cluster **** of wires above the trans, trying to make sure my TV cable is set right. It was bent around pretty bad in a ziptied wire bundle, but the truck still drives the same with the mess undone. Im convinced the TV isnt set right. I took pics of the cable & TV lever down by the trans with the pedal floored and at resting positon. I dont know if that would be helpful to show you guys? Basically I still had half an inch of throw in the TV lever/cable with the pedal to the floor. I do have a floor mat in the truck, but thats it. So my next step was to pull the APPS cover and try to adjust the cable. Am I on the right track there? I feel so clueless sometimes :\ Ultimately my truck stack shifts 3rd and fourth. When It goes into third it seldom rests in third for more than a brief moment without going into fourth. From my notes, roughly a year ago: 12mph - 2nd gear shift 21mph - 3rd gear shift 26 mph - 4th gear shift I can coast down to 20mph and the truck remains in 4th gear. After fixing a ton of stuff on the truck, sensors blah blah, today it did: 12mph - 2nd gear shift 24mph - 3rd gear shift 26 mph - 4th gear shift I think if I could get it to rev out in the gears more, my smoke problem would be considerably less. All the time Im crusing in 4th gear at low RPMs and I gotta put my foot 1/2 way into it to make it downshift, and it goes right to 2nd gear. Thanks guys

-

VP44 PSG5 limitations read/write

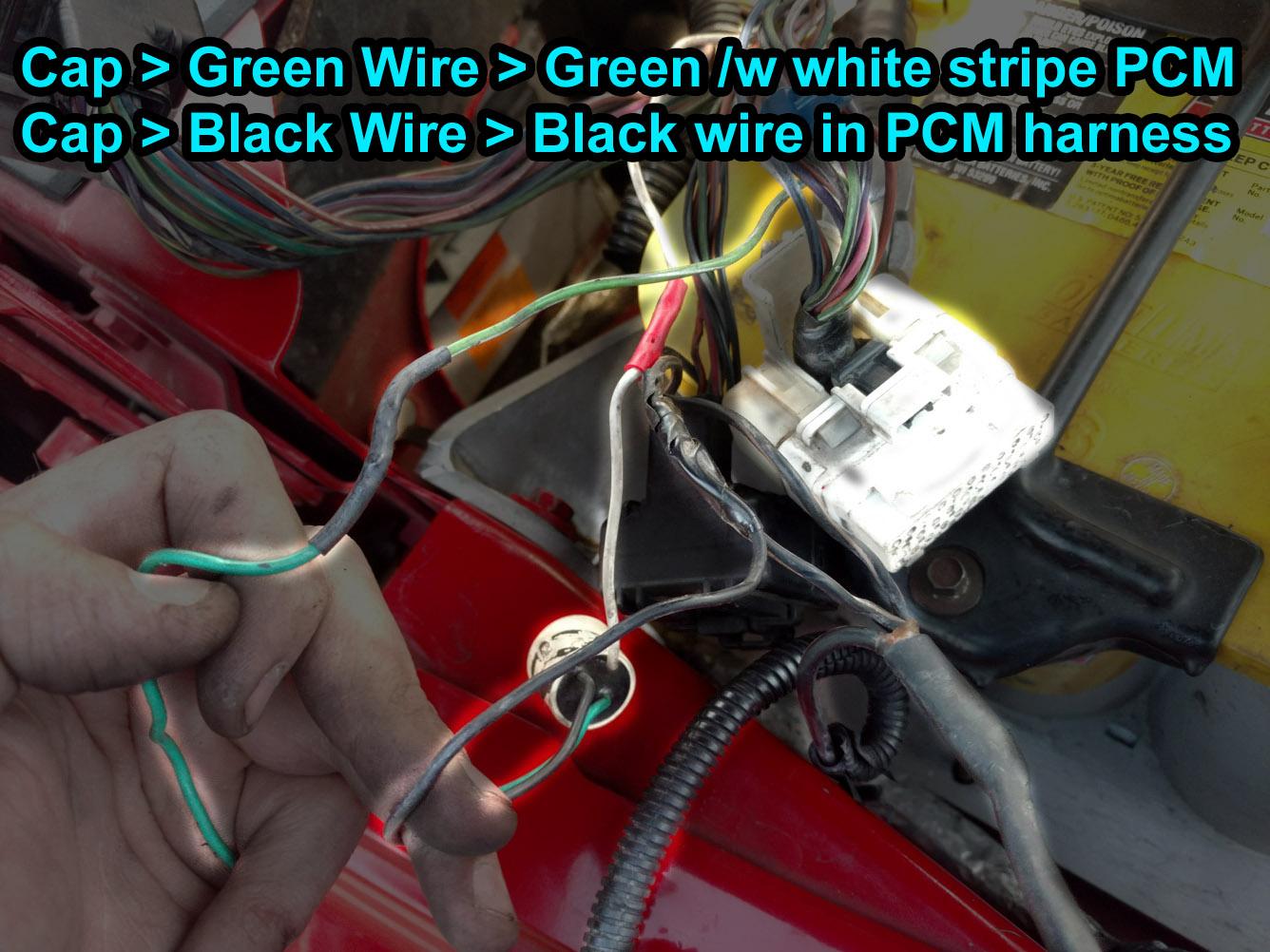

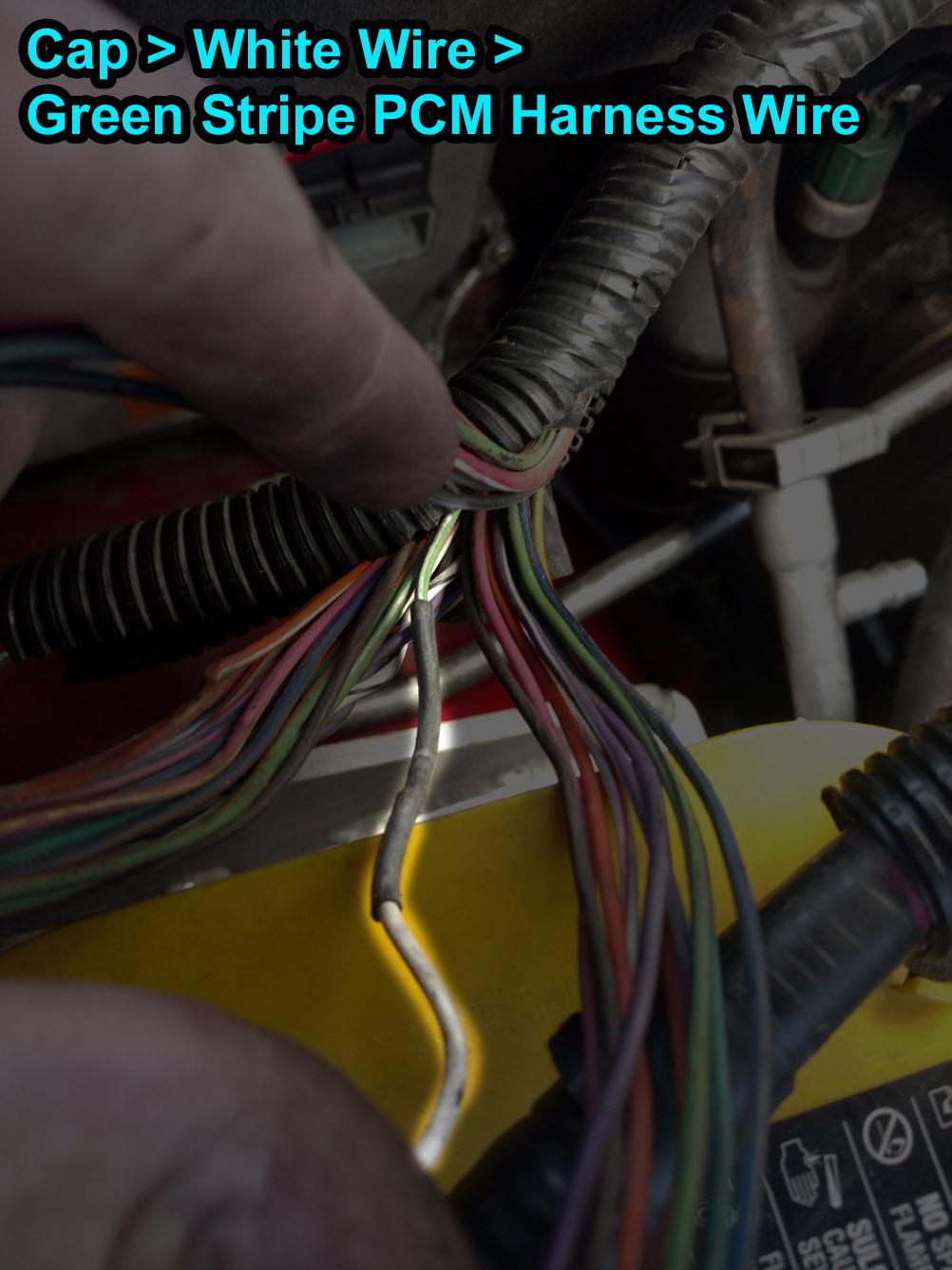

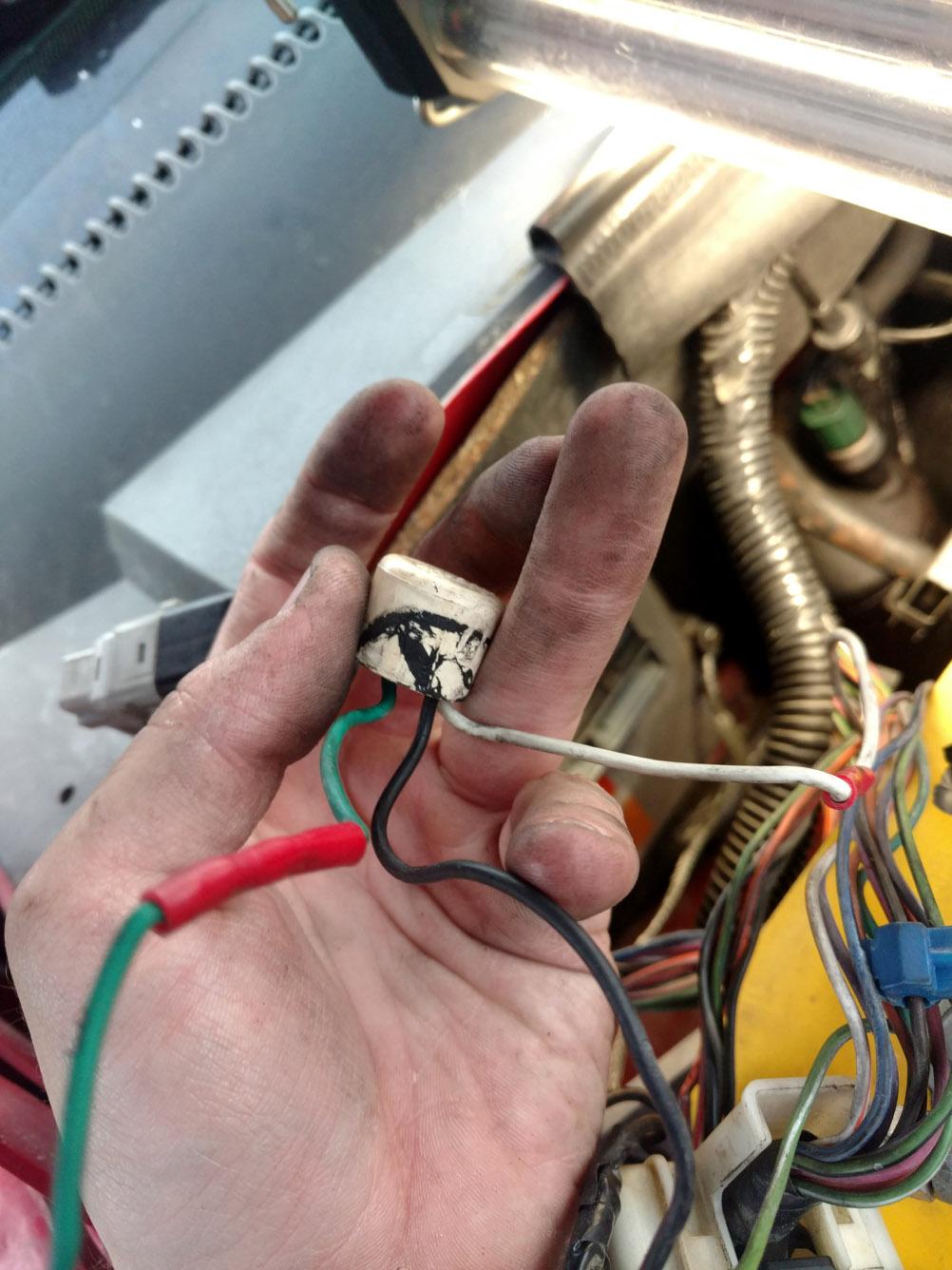

I have some big questions I hope you guys can help me on. First I'll show where & how I found this "cap" in the PCM harness. It seems like its a homebrew 1/2" CPVC cap that someone has neatly filled in. It's got black going to black, solid green from the cap going to green with white stripe in the PCM harness, and a white lead out of the cap going to a green with white stripe in the PCM harness. See images: Cap1, Cap2, Cap3, Cap4, Cap5, Cap Green and Black, Cap White Wire. I also have a Tranny Mystery image, a Tranny Tap image, and finally a PCM Tap image. Any insight is appreciated. Thanks

-

VP44 PSG5 limitations read/write

Yep that's them.

-

VP44 PSG5 limitations read/write

I read Quadzilla's site and I saw nothing about sensor input / support. Will I be able to utilize my pressure sensors in the exhaust manifold and inbetween turbos?

-

VP44 PSG5 limitations read/write

What's good then JL? Also I spoke with a nice lady at F1 Diesel and they recommend the Mach 4's for me. Those are 150hp. They are on the shelf Rdy to ship anytime. $1000+$200 core. 7 hole sac , she spoke with Don and he said there are no marine nozzles for VP trucks. Shipping is $20. It's $500 for me to buy Mach 2's and have them enlarged to Mach 4's she said. She was leaning towards 2's for a minute because of the towing I do. I said I can probably go slow over the passes in third gear locked around 50mph and not have egt's too high, even with the Mach 4s. I have her my build specs and so fourth. I have someone buying my camper very soon so it's possible I could fund these and sell the DDPs on FB. Im gonna pop the DDPs back in and see how they run. I'd like to do a back to back test with them against the Mach 4's.

-

VP44 PSG5 limitations read/write

That's why I switched to the non-adjustable original AD100 base. I forgot the spring and ball were in the return port.. that's how I adjust my operating inlet pressure. I have two new springs from AD that I havnt tried yet. I cut down one of the original springs down that was giving me 25psi. I meant to try the other ones, because Im sure the ball isn't liking the pokey, non-rounded end of the spring too much. I was pretty unimpressed when AD told me to use my original non-adjustable base; I was hoping to sell the unit to return some coin. I ended up keeping it on there b/c the ports on the fittings are bigger, and because the adjustable ADII base sounded like it was sucking air in at times thru the regulator/adjustor assembly. I didn't trust it. Sometimes I would adjust it and I would hear a big woosh like it was sucking a ton of air in, and it would jump from say 23-24psi straight to 40psi when the vacuum sound would come on. It didn't seem like it worked well. They also told me the original non-adjustable base design was better suited for VP trucks. Overall super unimpressed with the Airdog..

-

VP44 PSG5 limitations read/write

I noticed the other day after a nominal amt of driving in town that the AD200 motor was so hot I could barely keep a finger on it. Makes me think it'll fail. I have the original 100 motor, the new 4G 165 motor, and the 200 motor they sent me as a warranty to try to fix the pressure drop. What would be the smartest way to regulate return, a 1/2" needle valve? Thanks moparman, I'll get some stuff moved over to that terminal then. I do have way too much crap on the batt terminals, I need an expandable block (or whatever they're called again) badly. Just another thing on the to-do list.

-

VP44 PSG5 limitations read/write

Dieselfuture -- Yes, all other hobbies and expenditures have stopped due to the cost and time this truck requires. It's something I said I would do, so I now pay the price. The lift pump is wired up per the instructions, there is a pos and neg lead going to the battery, then the 2 pin connector at the harness is ajoined so when the ECM calls on the lift pump, it energizes a relay in the AD wiring harness and comes on. It has absolutely no restrictions in the inlet & outlet of the pump. No brass fittings ajoining the line, no T for fuel pressure (I have some special AN fittings from a local shop), etc. I have done everything I can to ensure nothing restricts flow. It's all 1/2" line. When I drive the truck I have a readout of my battery voltage on the Edge display, and its not dropping below 13.6-13.7v. I did notice that the voltage dropping to 12.1-12.7v when the alternator was bad causes a massive pressure drop in the pump output. I assume voltage at the pump is good since voltage at my batteries is good. I've also swapped relay's in the wiring harness to no effect. I will certainly try pinching the return on the AD, thanks for the advice. Maybe it needs 3/8" hose? I can hear tons of fuel coming back in the filler neck with the 200gph mounted.

-

VP44 PSG5 limitations read/write

Question that just came to mind: my reman vp44 that is on the truck now and was on it when I bought it, was getting fed 40psi because my Airdog came set wrong and the installer was an idiot. It got that pressure for probably 3-4 hrs of driving, because it was in another town about 2 hrs away and then I drove it to work for a week. Long story short, it seems unphased, unhurt, it runs as good as my new II vp44, and I've turned it back down to 15-17psi. Under WOT it currently still drops to 10psi with 1/4 tank of fuel, sump kit installed, and 50 hp injectors. It's the airdog II 4G 200. It was a 165 and we put (AD tech support sent me) a 200 motor on there to try to fix the pressure dropping. It made no difference. I've ran new fuel lines three times, all new sealing washers, had the vp44 lines off at least 3 times, swapped vp's, new wiring harness, went to the non adjustable base, installed the 4g 200 motor on my non adjustable AD I base so it negates an airleak at the adjustment screw. Also ran two different diameter fittings bc the AD I base has larger diameter fittings holes than the ADII base. Also changed filter and water separator to new units of slightly different design from Napa. Nothing has fixed my pressure drop. Essentially when I put 120hp injectors back in the truck and I go WOT with half a tank of gas I bet the truck will go to 8psi or less, and the VP will die unless I roll out of the throttle pretty gently. Are u guys firmly against running 25-40psi to the vp44 to keep the truck from dying on me in traffic when I let off after a wide open pull? The problem was so relevant I went thru a starter. Bleeding the lines sucks and would take roughly 10 sec of cranking with #1 #3 #4 cracked to bleed the air. Even happened in traffic once, seems like it would happen too easily. I've also tried two sump kits because a bolt snapped in half on my XDP sump kit. I thought it stripped out because it's a steel bolt going into an aluminum clamp per say, but turns out the bolt had actually snapped. That was the dual oring design from xdp. I now run one with a gasket from Sinister with The Right Stuff on there and a pretty true 7-9 ft lbs on the bolts and no leaks.

-

VP44 PSG5 limitations read/write

I'm just at a complex as far as ordering smaller F1 injectors that can tow and DD or ordering the size your suggesting. I plan to tow a 26 ft enclosed trailer full of dirt bikes about 45-65 minutes to the track on the weekends, in VA at sea level. Also estimating I'll tow around 7000 lbs across the country to VA. Why would DDP sell an injector that doesn't spray in a stock bowl? Why would they not be transparent about that?

-

VP44 PSG5 limitations read/write

Well, I like what your telling me about the VP and the turbos being capable. I was starting to wonder if I had the recipe all wrong. Am I tracking correctly to say to fix my tuning and run optimal injectors for the smoke and power I'm after it would be the iquad and F1 or the other places you mentioned 6x.013's? I think those are roughly "150hp" injectors. Forgive me for not really knowing the injector size's (inch measurement? ) fueling / power / smoke. That's a real shame to hear the DDPs are crap. I really felt like they were spraying out of the bowl andor with huge droplets / low atomization because of their total $hit performance / smoke show. Luggy, slow to spool, smokey, etc.

-

VP44 PSG5 limitations read/write

In Nov Im coming down thru Rogers, MN and Indianapolis to see two old best friends from when I was a kid. On my way over from MT to VA. I'll have the 30' trailer tho with all my belongings in tho, so probably not best to throw the 6.018s in there. Arent those roughly 200hp injectors? That's what I originally spec'd out for this truck, to meet my power goal, but two were not popping at the right pressure, so the truck was knocking on fuel and dumping white smoke like a holy mother. It took a shot of carb cleaner to start, from the guy who put the motor in. Another guy told me only do a shot of carb cleaner with a shot of WD40 for lube. I thought carb cleaner should never, ever be used. After that problem I had them put 120hp tips on -- perhaps a knee jerk reaction. But with how smokey the 120's have been for me in the past, I couldnt imagine 200's. Now that I have the leaks solved a ton more I need to get them in. Im not sure if towing will be really good with them though. I hate to put them in now to test, take them out to tow to VA, then at sea level and no need to tow heavy again, put them back in again. There's a good chance I'll do that though. Gotta put in the work and the hours to learn how everything gets along and runs. So you're saying the only way to make the power Im expecting is big injectors? I thought they would need a strong pump behind them to be effective. Im guessing you'll fire back with "yeah, a p7100". If I was to daily drive a set of big injectors for the power I was expecting, I assume it would need something more like a 64 & a S480 minimum to give them the air they need to burn. Sometimes I wonder how much worse the spoolup would really be, ie. I wonder if it would be marginal, and then burn clean like it does now when the chargers are properly lit. Im curious how the retainer would drop down low enough to wipe out the valve seal. Also, how do you even set clearance for that, I would clearance would be depicted via valve stem length and/or the spring's height whilst compressed.

-

VP44 PSG5 limitations read/write

I'd love to get together Moparman, Im sure I could pick your brain about a million things. I'm in Great Falls, MT unfortunately. ID is way nicer, I just recently drove through on the way down to Vegas not that long ago. JL, it's got a Hamilton 182/214 cast cam. I cant say that the motor really drops my jaw to the floor, even with all the mods. Sometimes I think my chargers are too small for the flow that the Stg 2 head can move, or what the Stg 2 is optimized for if you will. They sold me on it saying spool up will be improved further more, but I have a hard time believing spool up is any better. Now if I was running some big *** chargers I could believe it, but with these tow chargers, I think the stock manifold may run just as good or better, save a ton of coin, and likely not be nearly as prone to leaks. Today I finally got my wastegate set to crack just-a-tad-more-than-slightly at 20 psi, by 30 psi its half open, and 40 PSI its full open. It definitely felt better. I had to put two nuts on the actuator arm to set it properly, it only came with one on there, which really threw me off for a long time. Its no longer audibly slamming open /w 40-45 psi compressed air, and its definitely closed with 0psi going to it. The mid-range did feel good, torque feels up. I didnt get to test drive it enough to see if my big charger was still putting out 1/2 the PSI of total boost, but I know previously it was. When I say 1/2 the total boost, it was within 1-2psi. I still wanna take a pic of a white circular thing that I think is a capacitor that someone wired in, up by the PCM.

-

VP44 PSG5 limitations read/write

I think I have a filter added to the harness by the PCM. I'll get you a pic. It doesnt look stock to me, but its wrapped up in the harness. The alt has two very small posts that can put it in a full field effect, and the big post with the battery cable coming off of it. The big post with the batt cable coming off of it is where I measured 0.015vac. It's a "brand new" duralast alternator, been on the truck maybe 2 months. After going thru 1 reman Napa alt, and 1 brand new Napa Bosch alt, they quit helping me out. I got a third alternator from them, and its in the garage, and its a reman, but Im running the duralast right now. Im basically keeping the Napa reman as a spare in the garage, I had that many problems. JL - Im beyond confident the valve seals are the source of the white smoke.. I see what you mean now by why isnt it blue. The ports all being wet in the exhaust mani shows it coming from the valve guides. Why my new oem seals took a crap like the first set is beyond me. The guys at Rocky Mountain Cummins say if those metal rings from the valve seals drop down to the pan, and the oil pickup sucks em up, it'll seize the oil pump right away. So here's to hoping the debris stays in the top of the head. I couldnt find any of the rings even with a magnet. The oil is so darn dark and deep throughout the head.