Everything posted by Exalted85

-

Woo-woo-woo under load

Seemingly not speed based..I can be cruising at 80 with 20pct load and no problem. Doesn't seem to be rpm based either. I took it up a pretty big grade today..dropped od, I think I was going about 26 load, 13psi, 2100 rpm..no noise. I'm really starting to suspect od. It seems to come in randomly too, though..but only when I'm in the throttle. The rear drive shaft is spinning full time, right? If it was that, it should do it not just under load?

-

Woo-woo-woo under load

Honestly not sure..it sounds like it's coming from the front to me, which makes me think engine. Short of looking at it while running, anything I should do? This reminds me..my alternator housing came loose a little bit, and I had a clicking up front..solved by tightening it down..could this have damaged something? I'll try to do valves this weekend..I think it's raining tho, of course :/ provided I can get the cap off. when you say transmission..I was trying to reproduce it, and I almost think it's only happening in OD. I remember reading something about imbalanced drive shaft causing od housing to break, could this be happening? Would I just take it to a trans shop to dx? Did the wt mod, ac noise at all time low. I do get a random speed sensor code. Just replaced rear..replaced trans maybe 5k ago. Back plug feels a little loose to me, and it did have metal shavings..I'm assuming because I had the rear diff rebuilt recently..but the code still comes back. Generally not much..20pct load, maybe 5psi..I can't detect any boost leaks, but I'll try to take another look. I did note it was getting worse with higher load, which is also more boost..I think 45pct load / 15psi was going up hill. I have to drive a grade this morning..I'll try to video or take note

-

Woo-woo-woo under load

I think she's at around 215k Stock as far as I know..only smoke I get is a puff when it starts up. Stock hy35. I've actually been wanting to do a valve lash..but truth be told, I'm not entirely sure how to get the front cap off. I guess truck vents out back and has a "12v" cap up front. Not sure if it screws in or I pry it off..didn't want to break it, and it didn't seem to budge budge. Pop test involves removing them I'm sure? Big money? Heh.

-

Woo-woo-woo under load

Hi guys, I'm experiencing a woo-woo-woo noise. It seems it's coming only while the engine is under load, or it gets louder, with the more load. So..if I'm driving on the highway, and I go up a hill, it gets louder when the engine works harder. If I let off, it goes away instantly. It sounds like something is off balance to me, I'm just not sure what could be making the noise, only while the engine is under load. I pulled the front drive shaft. The wheel balancing weights are still on tires. Tires, brakes, rotors, hubs new in the last 15k or less..and this is a new development. Any ideas to look at? Here's a video..you can hear it pretty clear at 15 sec in.

-

Alternator late to kick in, harder starts

So I'm dealing with a new issue. The truck is having some hesitation starting..and for some reason the alternator isn't kicking in for about a minute. Sometimes the voltage will drop off even after the alt has kicked in. I did the w-t mod..but I haven't put a new line from the pdc to the passenger side battery..I know this isn't supposed to be necessary, but could it affect anything like what I'm describing? This issue didn't pop up after the mod..It's been about a month. The only other thing that I can think of..is my gf used my truck to jump her car a couple times in the morning..I've never jumped anything before, and I wasn't present when she did it. Could the added load of jumping her car, whilst cycling the grid heaters on a cold truck, have caused any type of issue? Any ideas what could be going on here? Here's a video

-

Well, bad news post w-t mod.

So I'm getting really weird voltage drop, truck is hesitating to start a little bit..I'm seeing my voltage drop completely to under 12v, like the alternator just isn't working. Could this be because I don't have a wire from pdc to passenger? I can't confirm right now..but I think my driver side battery isn't charging. It's raining and I'm not at the house to check it's voltage..but I did see the voltage drop big several times..like to under 12v, almost like the grid heater was running of battery alone. That's not grid heater dropping it that hard, is it? Truck has always started strong..I'm thinking I've got an issue.

-

Well, bad news post w-t mod.

-

Well, bad news post w-t mod.

So I found some weird stuff. Little black appears it goes straight into the apps loom..so it looks like they tried to rewire the apps ground wire to externally ground on the fender. If I had a terminal that size, I'd try to reterm it to see if that helped. However, I found some other weird tap sites. One on a purple wire leading to passenger side bundle..and one behind the engine kinda. Could these be contributors? Check out this video..I'm not exactly sure how to describe location. Any idea what these could have been for? Alt case checks in at dead zero ohms..Looks good. I actually at one point did bare a appt spot on the housing and ground to battery..it didn't help :/ I've sense gotten rid of it..but my alt ac noise appears to be good. Check out the video above..I think I'm finding the problems.

-

Well, bad news post w-t mod.

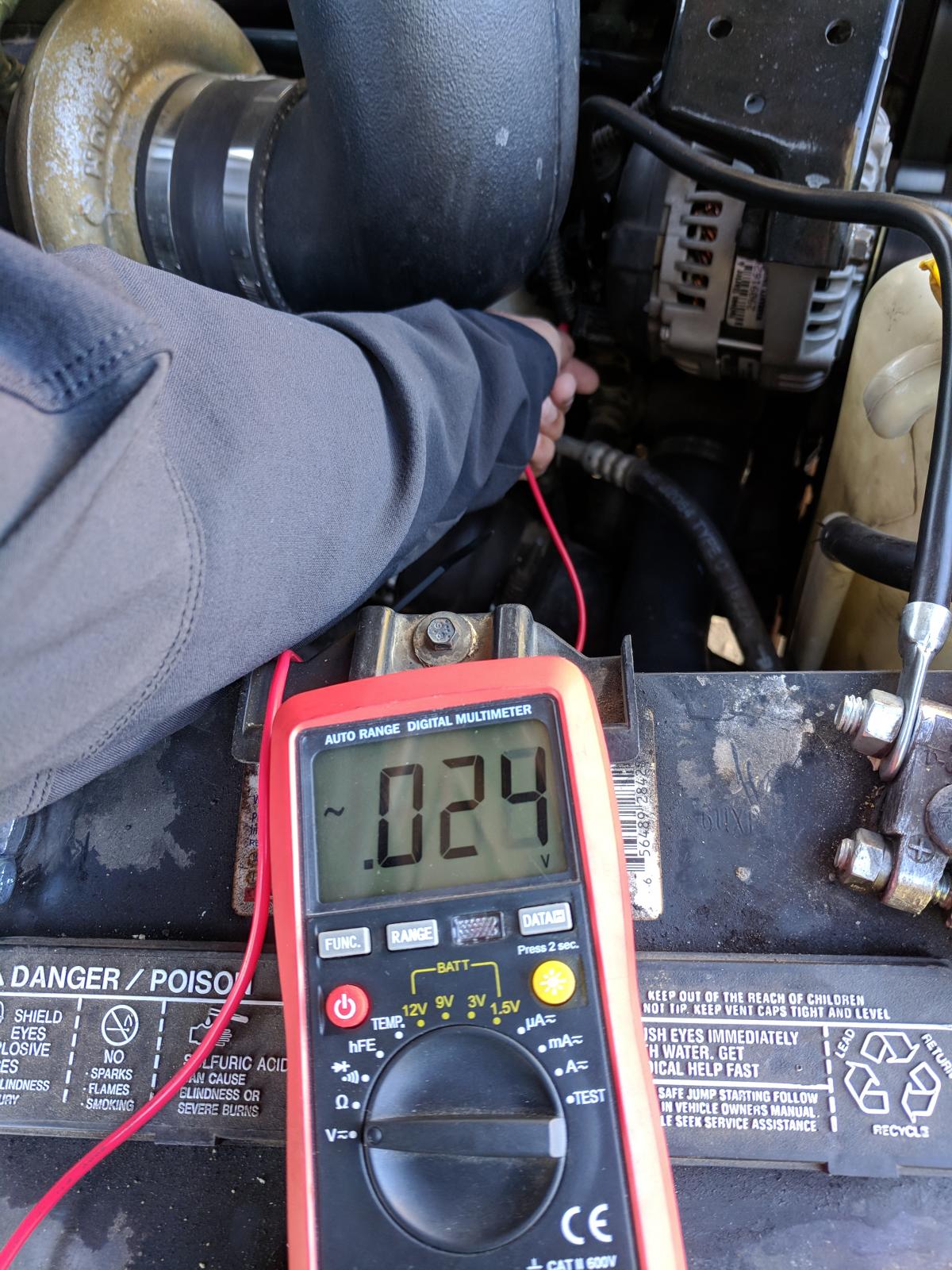

You were right about the noise..tested right now, averaged about 0.016..I did see it hit 0.02. It's a nation's alternator, probably 25k on it. Going to look into that ground and try to see if I can check voltage on apps and look for anything else that might look funny..but it's definitely looking like a timbo might be my next step. However, I have been getting a p0500 vehicle speed sensor code..just read that might be an issue too? I replaced the trans one recently, it was mucked up..had the rear diff replaced too at a shop during other work. I wanted to try to pull that to see if it had any collections on it..but was having a hard time getting it out a few weeks back.

-

Well, bad news post w-t mod.

I figured the red one was previous owners doing. I'm going to try to get bell housing off tonight and get rid of it. The alt on it was leaking ac when I got it, he was probably trying to fix the same issue I am. Hopefully the wt will fix it, and that addition won't be necessary anymore.

-

Well, bad news post w-t mod.

Surry, electrically challenged. Is that a stock ground then?

-

Well, bad news post w-t mod.

Weird..it didn't post. Here we go. I'll probably buy a timbo. I was thinking the same thing, mopar..I was expecting lower..which makes me think it might be an issue elsewhere somehow, but I'll check it again after I get home. Oddly enough, cruise control worked fine on the way to work..which might suggest that it's the actual apps intermittently doing it's job right. Here's pictures of the little wire. I'm assuming I should be able to get rid of it when I replace the apps? Actually, maybe I'll try to remove the wire first and see what that does for me.

-

Well, bad news post w-t mod.

I'll look into timbo..heard mixed reviews way back when. I saw my ac go as hug as 0.034 while warming up at 1100 rpm..averaged around 0.025..which is actually almost identical to what I remember it being before the wt mod. Do I need this little wire? I wanted to pull the apps cover off but will have to look into how..didn't have time with voter research. Could this little wire be causing grounding issues? That the wt should have fixed?

-

Well, bad news post w-t mod.

So, as I feared, the truck is still struggling to maintain highway speeds with erratic engine load. Watch the video on 1080p..you can probably hear the truck revving and dropping, but even if not, you can watch the engine load on my obdii cell phone in the top left gauge (shout out to moparman for sending me his obdii gauge file a year ago) and you can see the needle all over the place trying to maintain speed. 0-52, 25-50, etc etc..it's revving hard, dropping, revving, dropping. She as it used to. One curious thing I noticed while doing all that electrical stuff..is there seems to be a random wire, probably #18, going from a body mount in the front, grounding on the body in the same spot as a probably #8 ground coming off the driver side negative battery terminal. First pic shows location, second, you can see it heading into the apps loom. (I didn't know how hot that black plastic tube got, so I put some spare loom around the battery negative and the #18 wire) Is this little body mounted ground to tps factory? It doesn't feel seem like it. Could this be part of the problem?

-

Grounds and electrical stuff.

Well..it definitely took me more than two hours..but I got it done right, I think / hope. Instantly I noticed when I started it..it idled at exactly the same rpm, rather than bouncing around. I was excited. Drove highway to get gas, no cruise control hiccups. When I started it back up after fueling up, the rpm was bouncing again..It ran home fine with cc again..so I'm hoping the rpm at idle bounce isn't an indicator that the apps is losing control again..so I'm still a little skeptical on that point. Usually when I reset, it takes a couple days to degrade. All in all, super stoked, learned a lot, and really appreciate the help along the way. Definitely not a two hour job for a rookie, haha.

-

Grounds and electrical stuff.

Okay guys..I'm about wrapping this up..but I have one more problem. The black and tan wire..I didn't re use it. I previously had an auto shop "delete" the gray quick connect..but what shall I do with it? I'm abt About spent..I was gonna clip it and cap it..but I'm not sure if that will create problems or not

-

Grounds and electrical stuff.

What tape did you guys use for looms across the front of the motor? I only seem to find electrical tape 176f tape at auto parts stores..does the front of the engine exceed that? I found "loom harness tape" on Amazon..but I'm trying to find something local to finish this today.

-

Grounds and electrical stuff.

I'm at a loss at this point..the 60w iron sat on it for minutes..so did the 30. They're both rounded..neither brought it up to temp. I saw the flux melt..but no solder. I tried filling down a spot on the terminal to copper and tapping in there..no go either. I did tighten both the one I just bought and the old one. If it was conducting properly..just how long should it take to heat the wire? Minutes? Hours? Did I just not let it sit long enough? I can't imagine it needing longer than a few minutes..but I could be wrong, hell, I'm more than likely wrong. I tried applying as much surface area as I could as well. Is it possible the terminal itself is incapable of transferring heat? I tied setting it in direct wire and terminal too..nothing. I'm doing something wrong..I've never heated a terminal up before..so I'm certain it's me

-

Grounds and electrical stuff.

It'll melt solder..really confused here. Could it just be dissipating heat too fast? So odd. I'll have to look into a pencil torch tomorrow..I have one more day :/ It's definitely just not conducting heat for some reason. I held it on there for a while, then touched it..nothing. I hate electricity. Need fire. Just for shits..I held it under a candle..it definitely got hot..but did chill pretty quickly.

-

Grounds and electrical stuff.

Well, I went to get some flux, ended up buying a 60w iron kit for 15$ more tart came with it..let it sit on a test terminal for like 5 minutes..still wasn't hot enough to melt solder. The thing claims to get 1300 degrees..the metal on it turned blue..I could feel the wire was definitely heated through the rubber case..but wouldn't melt solder. I'm pretty skeptical about space and hazard of firing a torch in the engine bay..but I just don't know why I can't get this to work heh.

-

Grounds and electrical stuff.

Thanks guys. I am using a soldering iron, not sure of wattage..but I was definitely doing it wrong, by just touching iron to solder and dipping and spreading. I now know what you meant about crimping, I think. You crimp opposite of the split on the inlet. I didn't understand what you meant, because mine weren't flat. I'll go buy some flux, didn't know what this was..but do now and that definitely seems necessary. I'm assuming if I apply iron to crimp box, that once the terminal and wires are properly heated, when I touch solder to the wires, it'll travel towards the heat, into the inlet crimp, where heat is being supplied? I hope my iron gets hot enough..I think it's like 30 watts? It's a cheap one if I recall

-

Grounds and electrical stuff.

I don't have flat terminals, they're circular on the inside. Would you still crimp with these? Like I did? On soldering..I had to twist the wires together to feed them into the circle hole of the terminal..am I understanding you right, I'm trying to drip solder into the hole I fed the wire to? It's a pretty tight fit, I'm not certain any would pass into the circular spot even if I didn't crimp it. But should I not crimp and try? I just cut and stripped the wire / brought a term out of the box..I think everything was clean. I'm totally new to any of this..I'm just tired of my truck driving unstable so I'm trying to fix it..but fix it right. Electrical stuff makes me a little edgy..if you can explain to me with detail how you'd do it with what I have, that would be great This was the end I cut off to do a trial run on, because I've only used solder once in my life..I just wanted to make sure I could get the four wires into the terminals I have, and attempt to crimp and solder them. The real wires are still waiting..I did the trial to practice..because I'm as far away from an expert as can be. With the solder, what exactly should I try to do? I twisted the 4 wires together to feed them into the circle of the terminal..should I not do that? I'm not sure I can get them in without doing that. I did kinda just hold the solder above the twisted wire ends exposed past the end of the inlet..am I trying to somehow get solder into the hole with the wires, like get to it soak into the terminal inlet? Not just cover the wire ends? I'm not quite sure there's enough room for that, tbh, if that's what I'm supposed to be doing. Can you tell me what you'd do with the solder and the terminals I have? Crimp, don't crimp? How to get solder in there, not just over the exposed wire tips and on top of the inlet?

-

Grounds and electrical stuff.

So I decided to take the wires i clipped and do a trial run..cuz I'm electrically challenged..so I stripped the wires back, took my ring terminal that looked pretty tight on entry..so I spun the wires together, then twisted them into the terminal hole, spinning it the same direction as the wires were spun, so if anything it tightened them..I went a little bit past the end of the of the circle I spun them into..then I crimped it (that square spot on the wire case thing) then I tried to apply solder over the exposed wire tips..is this what I'm supposed to do? Pics of before and after solder applied. Would you use this connection and expect it to hold up? If not, any tips or methods for the "real deal" ? Edit: I ohm tested the ring I added it..it sat at 0.1ohm for a bit before going to zero..tested on the ring and the solder job I did. This suggests it's okay? Oh yeah..these were the only 5/16 ring terminals at auto zone..think these will work alright? I peeled the weather proofing off this one..but I'm thinking I might leave it on on the final attempt and just cut the tip of it off so I can use the weather proofing. Oh yeah, what kind of tape did you guys use to re tape the looms?

-

Grounds and electrical stuff.

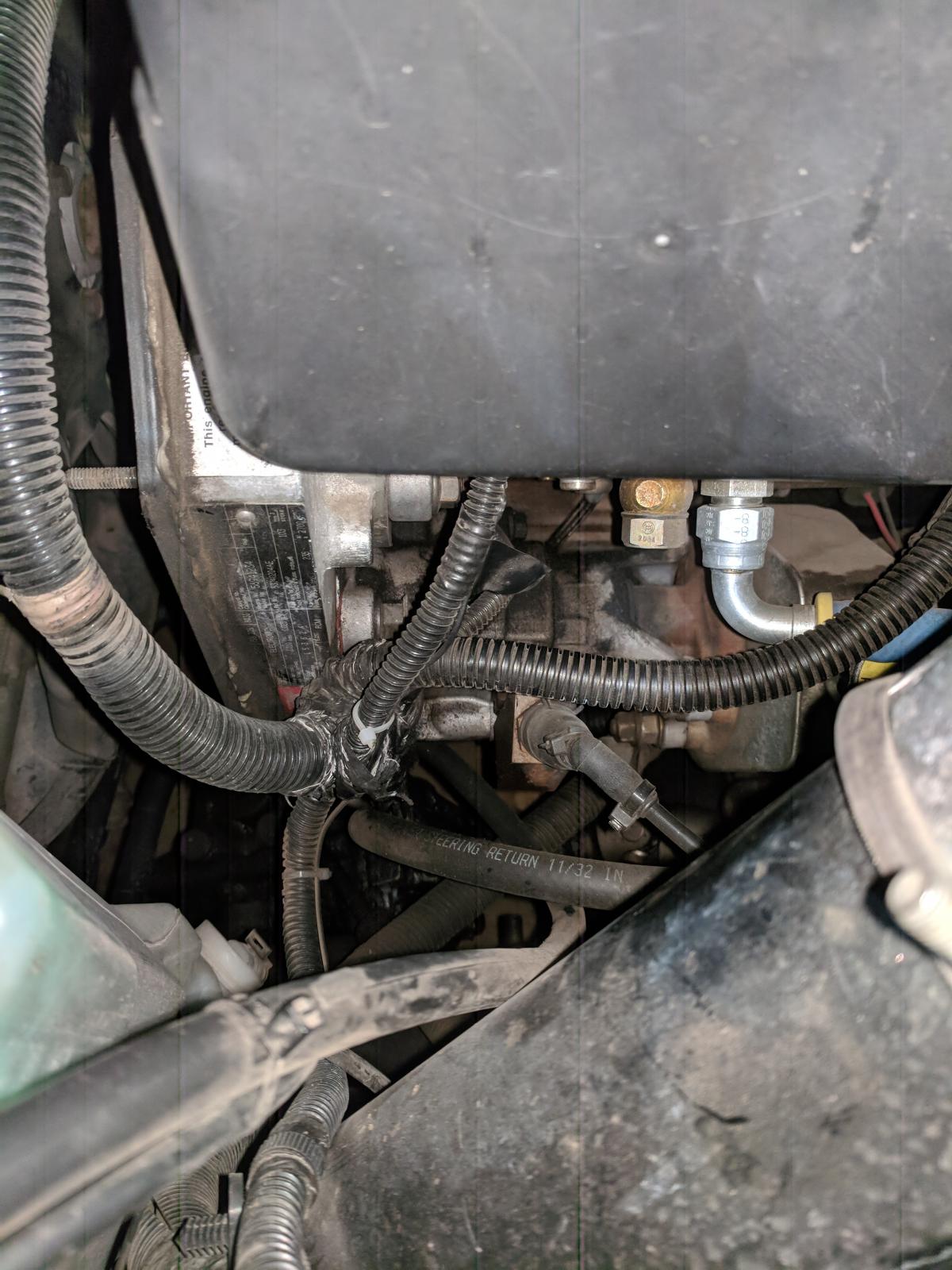

Alright, back at it today..so I'm disconnecting the 4 little blacks from the rubber connector, putting them in a ring, bolting them into the case. Got that. The big black wire that used to run to the alternator hot pin, I'm "deleting" this..it looks like it runs into the fuse box on drivers side. Am I just unbolting this, right?

-

Grounds and electrical stuff.

I cannot seem to get a wire off the alt with this red tab business. I can't seem to push it out to save my life. I knew I'd get it the second I posted that. Next question..I've got the loom unhooked on front, alt unplugged..but I've got this loom shooting straight down that's connecting to something? Is this normally there? Drivers side view..does this look right too? It almost looks like previous owner scratched the hole by vp44..and I see another ground coming along side loom to body ground?