-

Torque specs on injector hold down shoulder bolt

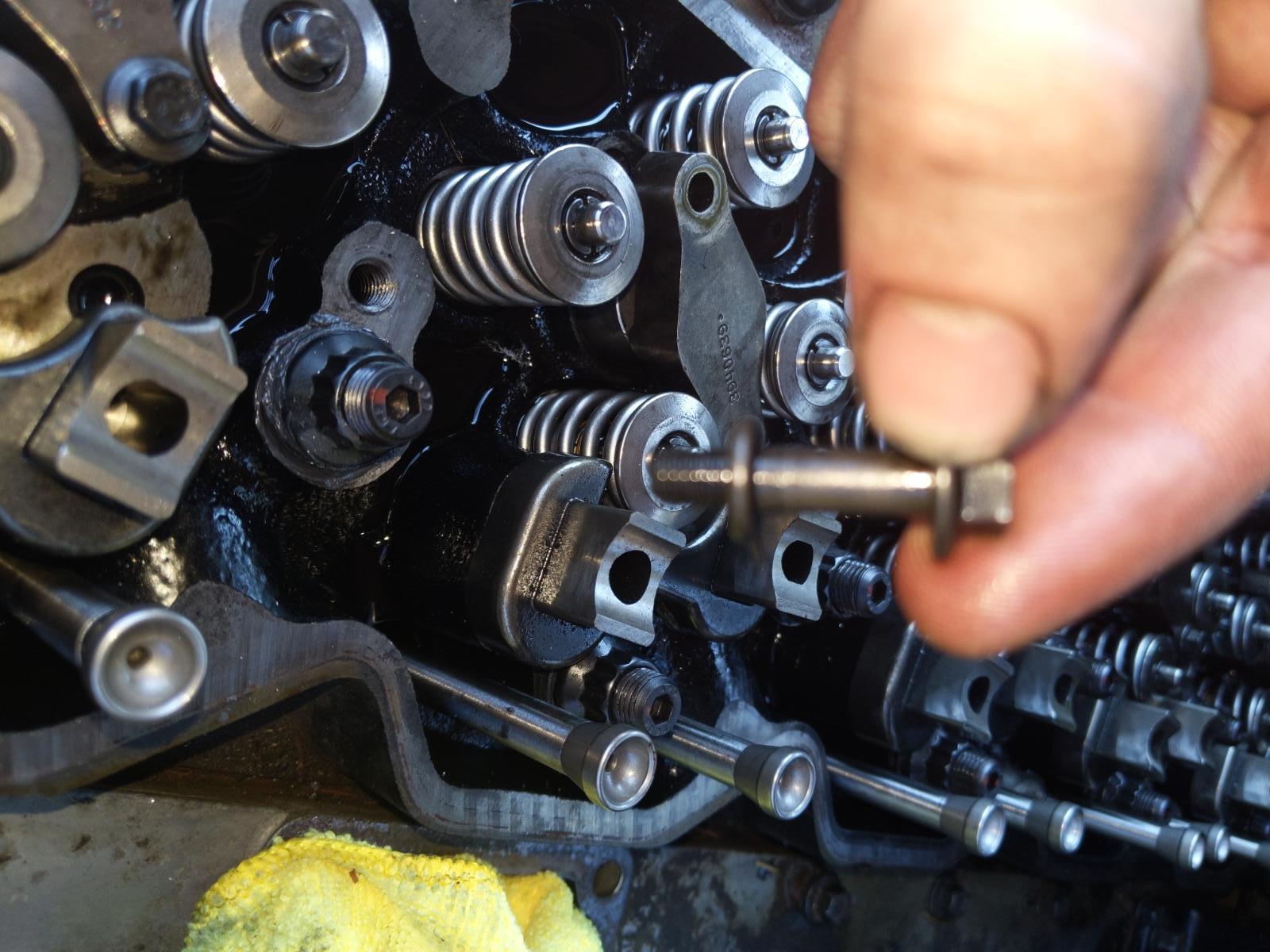

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainAnd is that shoulder bolt at 89 in lbs? Or just tight is tight kind of thing?

-

Torque specs on injector hold down shoulder bolt

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainYeah I put the connector tube in and they popped in like a glove. I guess I'm going to just torque both bolts at 89 in lbs. And the reason I had to pull that shoulder bolt is because I put #103 springs in it. Or else I would have just slid it out

-

Torque specs on injector hold down shoulder bolt

Having a little trouble finding this answer. My service manual says 89 in lbs for the clamping bolt but nothing for the shoulder. I'm assuming it's the same but I just want to make sure. Pic for reference but I'm sure y'all know what I'm talking about Also, just realized I forgot my in lb torque wrench that goes up that high at my house an hour away. And I don't have a torque wrench that goes to 8 ft lbs. So either I can torque it to 80 in lbs or 10ft lbs with what I currently have. I'm assuming it's not going to hurt anything giving it a little more on my inch lb torque wrench or going up to 10 ft lbs on my other torque wrench. Any insight would be appreciated

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainYeah thouroghbred. And I'll double check it when I get it back. I sent it out this morning

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainI've definitely had issues since I put it on. Once it's set correctly with a new key I'll be able to see what it changes. And that key was horrible to extract. They told me to take that thing out and chuck it before I sent it. I'm pretty good with stuff like this but in the end I had to notch each side of the smashed key perfectly and pull it with some ear clamp pliers. They said they'll put the right key in it so I'll double-check it when I get it back. Thank you

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainI'm curious what those issues would be. It's always been a little sluggish for all the parts I have on it. And I always thought it was a turbo/air in fuel line type deal. Everyone says it should be waaaaaaay faster than it is. My idles always been a little crappy as well

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainI'll definitely be buying some of that thank you ? So update; pulled the pump and the woodruff key was smashed one one side and flattened, so it needed to come off anyways. Sending the pump back today and going from there

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainWhen I first got my diesel I didn't put any in because I didn't know about adding lubrication to the fuel system. I've been running Howes it but I think I'm going to try something new. Any suggestions? And it barely drops under 14 at WOT - around 1500 on my egts

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainNone that came back. I thought it was super weird I got a speed sensor code though. I haven't spun the tires on it in a while and I just replaced it 600 miles ago as it is

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainMy V2 tune is on level 3 out of 5 on a medium tune. I'm assuming I have the turbo timer set. I started it a few times after it was fully warmed up and it was fine. Waited 20 minutes and started it up again and it took a good 3-5 seconds to start. And it feels like my idle has a minor miss, or it didn't idle like it usually does. I'm going to go over all my grounds on Sunday (had to take one of my other trucks for tomorrow) and unplug the quad and see if anything changes. If it doesn't then I'm pulling the pump

-

Question about my VP44

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge 24 Valve PowertrainI did. I only had a rear speed sensor which I replaced like 600 miles ago. Everything else of my scanner was clear. No injection codes or anything like that Sad thing is I only have 6000 miles on this pump and the 2 year warranty expired yesterday. Horrible timing I was able to upload a video I took of it. I already emailed thoughbred and hopefully they can still honor the warrenty. We shall see VID_20200904_172757.mp4

-

Question about my VP44

Hello, So I went to run an errand with my 01 earlier after washing it and it fell on its face while driving down my street. Had a random speed sensor code that I cleared, but it wouldn't shut off even with the key pulled. I'm assuming it's the VP but I'm trying to find different opinions on the matter. I let it sit for 30 minutes and started it back up no problem. Everything came back to life. Turned it off again and re started it 20 minutes later and everything is fine. The pump is barely 2 years old and I'm reading 15 psi on my FASS. Any help would be appreciated.

-

Yet another injector and turbo question

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge Reliability / PerformanceI feel like a kid at Christmas haha. As soon as I get back from Vegas I'm putting it all on and going to buy one of the tunes on this website to start playing around with it! Thanks again everyone!

-

Yet another injector and turbo question

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge Reliability / PerformanceThanks everyone for the help! I ended up taking y'alls advice and calling up DAP. Talked to Lenny there and he set me up with what I needed. Got hooked up with 150s, 62/68/12, studs, pushrods, springs and a new downpipe. Hurt the wallet but I'm excited for the power increase! Thank you for this information! I'll definitely do this method ?

-

Yet another injector and turbo question

Rather Be Wheeling replied to Rather Be Wheeling's topic in 2nd Generation Dodge Reliability / PerformanceSorry but what does it mean when you say 320 bar?