-

Cracked manual trans mount

Good point.. I have had situations (on a telescopic forklift) where the exhaust bracket would continually crack from vibration or whatever, no matter how I tried repairing, replacing, or mitigating the factors causing the failures. So I suppose it’s plausible that vibration from exhaust over time could possibly result in this failure. When the new one arrives and I disassemble, I will be able to tell how much tension/misalignment, whatever, is affecting that exhaust mount portion.. having said that, I would expect to see many instances of a common failure in other trucks..

-

Cracked manual trans mount

Yeah... I have to wonder how he could’ve broke it. Could also be normal operation as you say, but the fact that it was never mentioned makes me wonder.. This was probably when the synchro was replaced in the transmission. Shortly after which, the fifth gear nut came off 50 miles out of town. When I saw the nut after, it was all beat up, like someone had used a large pin punch or something and a hammer and tried to beat it to the proper torque. There is a $35 tool for that as I understand it, which will allow you to install the nut and torque it properly. I would own it if I was the mechanic. Anyway... it’s water under the bridge now. Probably should’ve noticed the white makeup smeared all over everything when I got it back.. That’s why I like to do as much work as I possibly can myself. Hard to find anyone these days who cares about doing the job as it should be done... goes for lots of fields unfortunately, not just mechanics.

-

Cracked manual trans mount

I was crawling around under the truck looking for problems and I noticed this cracked mount for the rear of the transmission. I was wondering if anyone else has seen this on their trucks. I searched but didn’t see any threads on it. What’s more, it looks like someone has tried to weld it previously, but it was never mentioned. My dad had the truck for a couple years but other than that I bought it new. The trans was out for a synchro replacement and shortly after that, the 5th gear nut fix. (Whole other story of clown work by a local mechanic). Anyway, I ordered a new bracket and will replace, but just thought I’d post something on it. I was hearing a bit of a different kind of drone going on sometimes, seems more with the clutch disengaged than engaged, and this doesn’t seem like the culprit but in need of a replacement/fix nonetheless.

-

VP44 Electrical question

I think it’s all disconnected and returned to stock, I found the installation manual for the security system and reversed everything step by step, but whether the module(s) need to be reflashed, I’m not sure.. wish I could figure out how to bypass whatever is switching power on and off of pin 7 at the VP harness, I would just have it hot anytime the ignition isn’t in acc or off position. This seems like a security system type of interference; just cutting power to VP when trying to start.

-

VP44 Electrical question

Yes the wait-to-start comes on and seems to act as it always has. The ASD might be an issue, but not the relay itself as I have switched that one around too. I did have a key fob that was an aftermarket add with a mopar system, but I couldn’t get it to disarm so I removed it completely. There was a harness on the steering column that was intersected by the security system harness (original harness disconnected, security harness plugged in and other side plugged into security harness). That seems like where any interruption would occur from the security system, but all of that was removed and returned to stock, unless there was/is something present in the ECM no longer seeing the security system and disabling the truck somehow. I don’t know how integrated those systems are in terms of programming within the modules. Seems plausible since someone who had time, could get into a truck and remove the whole system as I have and drive off.. perhaps the security systems have accounted for this possibility. ??

-

VP44 Electrical question

Thanks Mike.. I will check fuses again, but having it vary consistently only between key positions makes me think it’s unlikely to be a fuse or relay. Automotive electrical is an area I don’t have much experience obviously, but I have a logical mind and I learn well, albeit slowly sometimes. I was thinking to test the brn/wht wire from pin 36 out of the ecm and see if the power is consistent there between start and run positions on the ignition. If yes, then problem between ecm and vp, if not then problem within ECM or ignition or between the two. I’m not sure what else can be eliminated from the equation? I hate to start replacing parts randomly without pretty good confirmation they are defective. Replace ignition switch, send modules in, etc. I read somewhere that someone had a crank but no start issue (but hotwired vp44 worked fine) and it turned out to be his cam sensor.. My brother has been bald for years and at this rate I’ll be joining him soon..

-

VP44 Electrical question

Thanks for the diagrams.. as simple as it should probably be, I’m a little lost still. I don’t see where the power to the VP would be changed between the run and start positions. There should be power to the VP in both key positions as I understand it from the diagnostic from BlueChip, and I guess, from the bottom illustration here. Is the suggestion that there could be a problem within the ignition switch itself? Relays seem to not be the problem (only because switching them all around makes no difference). Haven’t found any fuse issues so far. There are no fuses or relays outside of the PDC or the drivers side dash right? The fact that I have power at the pump in the run position makes me think there aren’t fuse or relay issues, but I’m not seeing why it wouldn’t be there at the start position.

-

VP44 Electrical question

So I finished the W-T ground mod and was finally able to rule out the injection pump as my no start problem. Sort of. I followed the diagnostic from Bluechip Diesel and others to do some basic electrical testing at the VP harness. I verified that pin 6 was grounding, and pin 7 had power at the RUN position on the ignition but NOT on the START position. I didn’t check the power situation on the wire to pin 5 after reconnecting the plug because I didn’t have power on 7 at the start position. I also ran test leads to pin 6 from battery ground and pin 7 (fused) to battery positive. Truck fired right up. I couldn’t find anywhere on a forum so far where someone explains what might be the cause of pin 7 having power at RUN but not at START. Does anyone here have any ideas? I’m still looking at the PCM having failed as I posted in another thread. Although I thought the ECM was responsible for fueling and so maybe the pin 7 issue is an ECM problem? Thanks for any thoughts..

-

Strange Scenario; PCM?

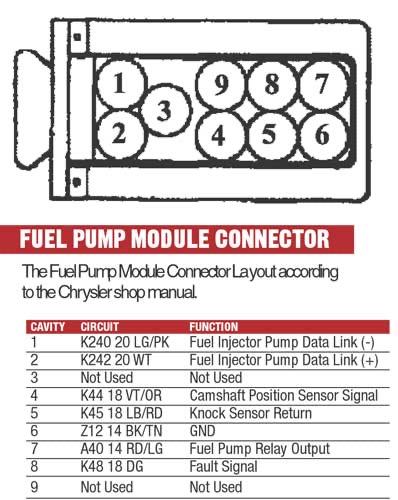

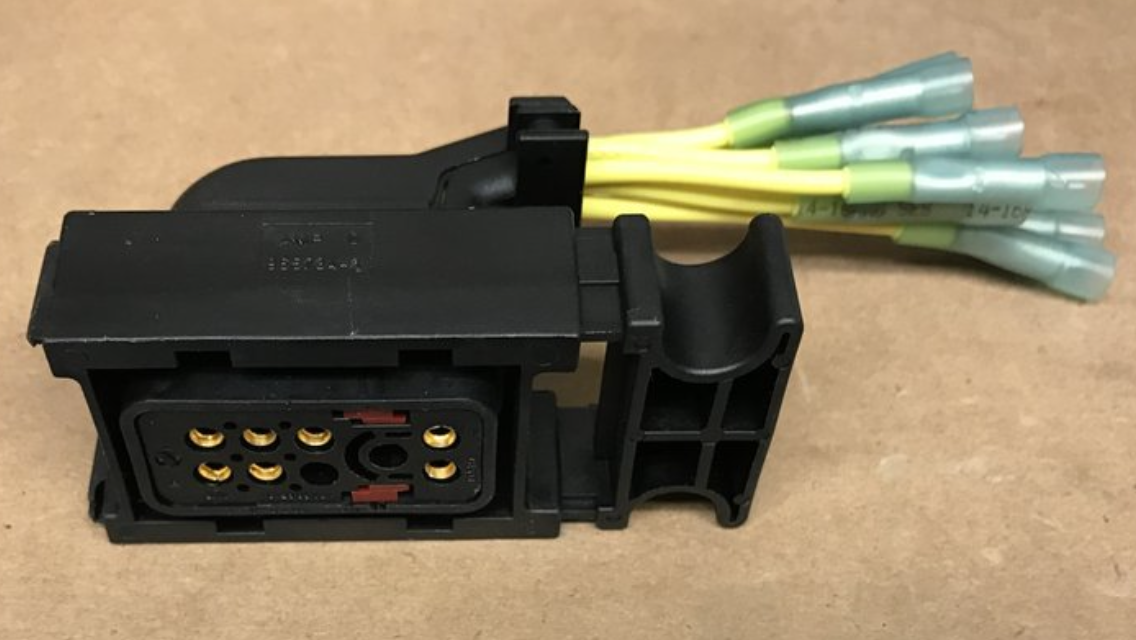

I think it’s pin 9... also not used. And in looking at this repair harness.. it would seem mine is fine. Pin sleeves missing at both 3 and 9..

-

Strange Scenario; PCM?

I don’t know if I should post this as a separate topic, but it does fit in to my scope of potential causes.. Here is a picture of both sides of my injection pump harness. There is a female side sleeve for one of the pins missing. I don’t know if this pin is just unused or what the function would be. The truck was running in this condition previously so my guess is maybe it’s not used? I will research this further, but I know it’s a quick answer for some of you guys who have changed a few of these out. I don’t have a second truck around to compare to at the moment. I think there is an aftermarket solution for about $200; a new harness you can wire in I believe in the event the truck side has a failure..?

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

Thanks Dripley.. Yeah I have the 98.5 so I have the “bonus” ground from the alternator to the block just below the Tstat housing. I pulled the loom apart over to the VP and found the splice. As mentioned by another member with a 98.5, mine is shrink wrapped with I believe a metal crimp beneath it. Probably significantly better connection than some of you have discovered on your newer models. Not sure if this is present on the 99-02 models, but the charge wire drops into a large loom just below the VP and snakes down under the power steering pump, up over the motor mount and around to the inside of the wheel-well.. the lazy in me wants to consider just cutting that cable at the VP area and seeing if I can pull it through to the PDC. Probably not possible given the likelihood that it’s taped throughout. I then thought well, maybe just cut it off at both ends and leave that section in the loom. That looks to be a great deal more work to remove it completely. Not that I’m afraid of work, but time and mobility are becoming factors as well in my projects.. Just wondered if anyone else might have taken the err umm... shorter route on this cable as well.. I guess it’s irrelevant.. I can’t think of any danger in leaving a disconnected section of that cable in the loom.. only if it could become energized somehow which seems pretty unlikely. I’ll tape up the ends just in case.

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

So the factory alternator charge cable runs through the 140 amp fuse in the PDC. The short wire on the other side of the fuse to the battery also supplies power to the PDC right? So nothing is being changed or upgraded here? Do you think the factory ran it this way simply to have the charge cable fused and they didn’t want the fuse outside of the PDC? Do you think there is detrimental noise/fluctuations/surging running through the PDC because of the factory design and re-routing the charge cable to the aux battery is safer with regard to the integrity of the PDC? Finally, does anyone have any of the pics from W-T’s post on page 2 of this thread? Presumably these were lost in the server changeover that I read about elsewhere? I believe I’ve read everything available here on the W-T mod (with the exception of any coverage in the high-amp alternator thread, I plan to stay stock for now but good to know it will be prepped for a better alternator in the future). I’m psyching up and getting ready to tear into getting the W-T mod done and the PCM ground improvement done as well. Already fused it. Has anyone done any protective fusing or other measures with regard to the ECM (aside from the ground improvement)? Oh.. also it sounds like a lot of folks are perhaps not doing the additional 2/0 cables from battery to battery. It was mentioned that it was possibly not necessary without going to higher output alternator.. but it seems it would be important when switching charging heirarchy from the primary battery to the auxiliary battery given the temp sensor is beneath the primary battery? Also does this temp sensor go bad in anyone’s experience or is it pretty reliable? Worth replacing proactively? I had an O3 that I have since sold, but it blew a passenger side battery once for reasons I do not know. I loved that truck except that it was an automatic, otherwise I would’ve kept it. Thanks to all for all the informative reading. Brandon

-

Strange Scenario; PCM?

Thanks John, Yeah.. I think this time I did not disconnect the batteries. I left town quickly, did not plan to be gone nearly as long as I was and so I almost certainly did not disconnect them. Normally I would do that when I know I’m not going to use the vehicle for several months.. or alternatively I would put a charger on it every month or two. I’m actually glad to be rid of the security system, I just hope it wasn’t tied into the computers in some way that would disable the truck if the entire system was removed.

-

Strange Scenario; PCM?

Yeah, I wasn’t really surprised they were discharged, but they were completely gone and also not recoverable which I haven’t experienced on a vehicle before and I’ve had others in storage situations without ever losing a battery entirely. I wonder if there might be a parasitic load on them though and that would seem possible.. I wonder if that could have been a result of something happening in the PCM/ECM. I had read through that 1389 article you posted, and I read through it again just now. Thanks for that post. I don’t have the scanner that gives those messages, freeze frames, etc.. it’s just an inexpensive Innova scanner from Autozone. Also, I have not ever dug deeply into the truck wiring as described here. It sounds like I need to unbolt and somewhat take apart the PDC so that I can identify specific pins and wire locations. I don’t think there were markings on the top side that would indicate where to place the test leads. I’m not really familiar with using an ohmeter although I have an inexpensive one of those as well. I’m not afraid to jump in and learn and figure it out though. I will probably dig into this tomorrow and take the PDC apart or look into checking the wiring coming out of it, etc, and see if I can find anything obvious.

-

Strange Scenario; PCM?

The WAIT TO START seems to work as normal. Although I noticed before I changed the transfer pump, during a period of cranking and trying to bleed the fuel lines and get it to start, the “intake horn” I believe it’s called got pretty hot and it seemed like the grid heaters might have been over active. However while in storage I’m not sure how the grid heater circuit would become active on it’s own and take the batteries out. Hmm... Maybe it’s worth replacing that solenoid... or putting some kind of manual shut off in-line somewhere. Thanks for the schematic... I am a little inexperienced when it comes to wiring diagrams and such but I’m a moderately quick learner (I think..). The EVS II was a dealer provided security system with keyless entry, alarm and anti-theft module. I think they phased out in the next few years after I purchased it. It had always functioned perfectly until this storage period. After replacing the batteries, the EVS was all out of whack. The keyless function wasn’t working right and the alarm could not be disarmed so it would go off as if I were breaking in no matter what i tried. So I removed the whole thing. It’s just very curious to me how a truck just sitting had something spontaneously happen that caused the battery failure, EVS problem, and possibly the PCM and/or injection pump issue if it’s involved. Are the ECM and PCM not within the same device/box on this truck? Any thoughts on how to further isolate where the problem might be located? At this point I was thinking about doing the jumper wire test on the VP44 although I don’t know if that will positively point to the ECM/PCM. After that, I’m out of ideas... maybe just send the PCM in and see if they find anything? I sure appreciate the welcoming to the site and your comments Mopar1973man.

Cummins5.9

Unpaid Member

-

Joined

-

Last visited