Everything posted by Dumb A

-

Coolant leak at the back of the head

That may have been what that fellow was trying to tell me that sold me the PCM. I have kept every vehicle I've had clean just using WD-40 at the spray and wash places. WD-40 seems to be a better solvent then a lubricant for the really dirty oil soaked areas. This time I'm going to try some zep like moparman suggested.

-

Coolant leak at the back of the head

thanks buddy for your help.

-

Coolant leak at the back of the head

That's what I normally do, keeping my engine compartment and vehicle clean. That way you can see new oil leaks and things going wrong, hopefully keeping ahead of problems...

-

Coolant leak at the back of the head

Thanks.... The fellow who sold me the PCM was the one who said don't power wash/steam clean these units as it can kill the PCM, ECM and sensors. Made good sense but I don't like having a dirty engine and engine compartment. So off to the cleaners I go, then pressure test.

-

Coolant leak at the back of the head

Good info, I will get a pressure test tool and give it a test. There are oil leaks around the engine, dirty as can be. I haven't wanted to steam clean it as I'm concerned about the electronic components not working afterwards. Would it be smart to pull the engine, reseal it, clean it, replace all freeze plugs, bore the flywheel for the larger pilot bearing. This is if I find the freeze plug to be leaking. Is it a lot more work to pull the engine rather than the transmission.

-

Coolant leak at the back of the head

I don't know of any sensor on the back of the engine from the factory... your correct, I think someone has screwed that in there rather than a plug, why I don't know... I don't know if that is a coolant passage that it screws into or part of the intake manifold though. I'm guessing it is leaking from the freeze plug next to it, on the head. The coolant is coming from above the head gasket for certain. I took a long stick wrapped with many papers towels from the driver's side underneath and dried off the back of the head and block. I could then see coolant weeping down the back of the head to the head gasket and down onto the block. So I'm certain is coming from the head. Has anyone ever cut a hole in the firewall to access this area, I am going to look at that possiblity. Maybe moving the engine and transmission forward, possibly... I may pull the engine and replace all the plugs, pan gasket, front and rear seal, pilot bearing upgrade to the heavy duty one. I have the time to do it...

-

Coolant leak at the back of the head

The sensor is bad and needs to be replaced, yes and I'm going to put a plug in its place, sensor was evidently to plug the npt threads. My next question is the port with the npt threads on the back of the head, water jacket or intake manifold? Because I saw air bubbles escaping around the ceramic on the sensor. The coolant leak may be coming from the freeze plug and wetting the sensor??? Thanks for your input.

-

Coolant leak at the back of the head

It was difficult to see, I used a mirror and lite from the driver's side. I will have to get a better look at it tomorrow. I'm going to remove the rocker cover to see if this helps and run the valves while I'm there. It looks like it was leaking from the center of the sensor?

-

Coolant leak at the back of the head

Help from the wizards please. I have a coolant leak dripping from the back of the head running down the bell housing. I stuck a small mirror back there and I see a sensor bubbling around the ceramic center. I tried to identify the sensor in the service manual, no joy. This sensor is screwed onto the head, water jacket at the aft end of the head between the head and firewall, thanks!!!

-

Electrical questions/troubles

It took me about 4 months to finish it and was actually fun. This type of work I rather enjoy. I even made the aluminum extruded siding as I couldn't purchase it from the factory. They didn't make that style any longer.

-

Electrical questions/troubles

I did reseal my vacuum pump, Napa wanted 93 dollars for the kit. I got it on eBay, genuine Cummins parts, 19 dollars and free shipping. Also got the fan hub bearing SKF brand on eBay 28 dollars. I will have a category of spare parts onboard when I travel. I will shop for them and get the best price for quality parts as I will have time to shop for them. I'm in Oregon and had planned on being in Arizona playing on my claims this winter. As it turns out with the uptick of covid-19 I'm going to winter over in Oregon. Up to Alaska for the summer (if Canada opens the border) and down to Arizona next winter. This is pictures of my toy hauler, before and after. It was rear ended in fog on I-5. I had purchased it from an auction in Riverside. This is what I plan on pulling with my Dodge. Gooseneck style.

-

Electrical questions/troubles

Yes, I agree with you. I have to admit I don't really shop much and I know I'm paying a bit more then I should. I did see a Eaton Tru-trac for 935 after I had purchased mine. More then the cost savings was my frustration factor dealing with this truck. It had a lot more wrong with it then I anticipated. The previous workmanship was substandard. For example when I tore into the rear end the carrier bearing had the inner race welded to the carrier to prevent it from slipping. Who does this type of work??? I'm actually enjoying driving it and looking forward to pulling my toy hauler. I'm still performing road trials with about 600 miles on it. Changed my gear oil in the pumpkins rechecked all my torques on the axle, spring mounts, calipers, ring gear, carrier caps, drive line, all good. I couldn't have done this without all of your help. I thank all of you!!!! and look forward to helping you any way I can.

-

Electrical questions/troubles

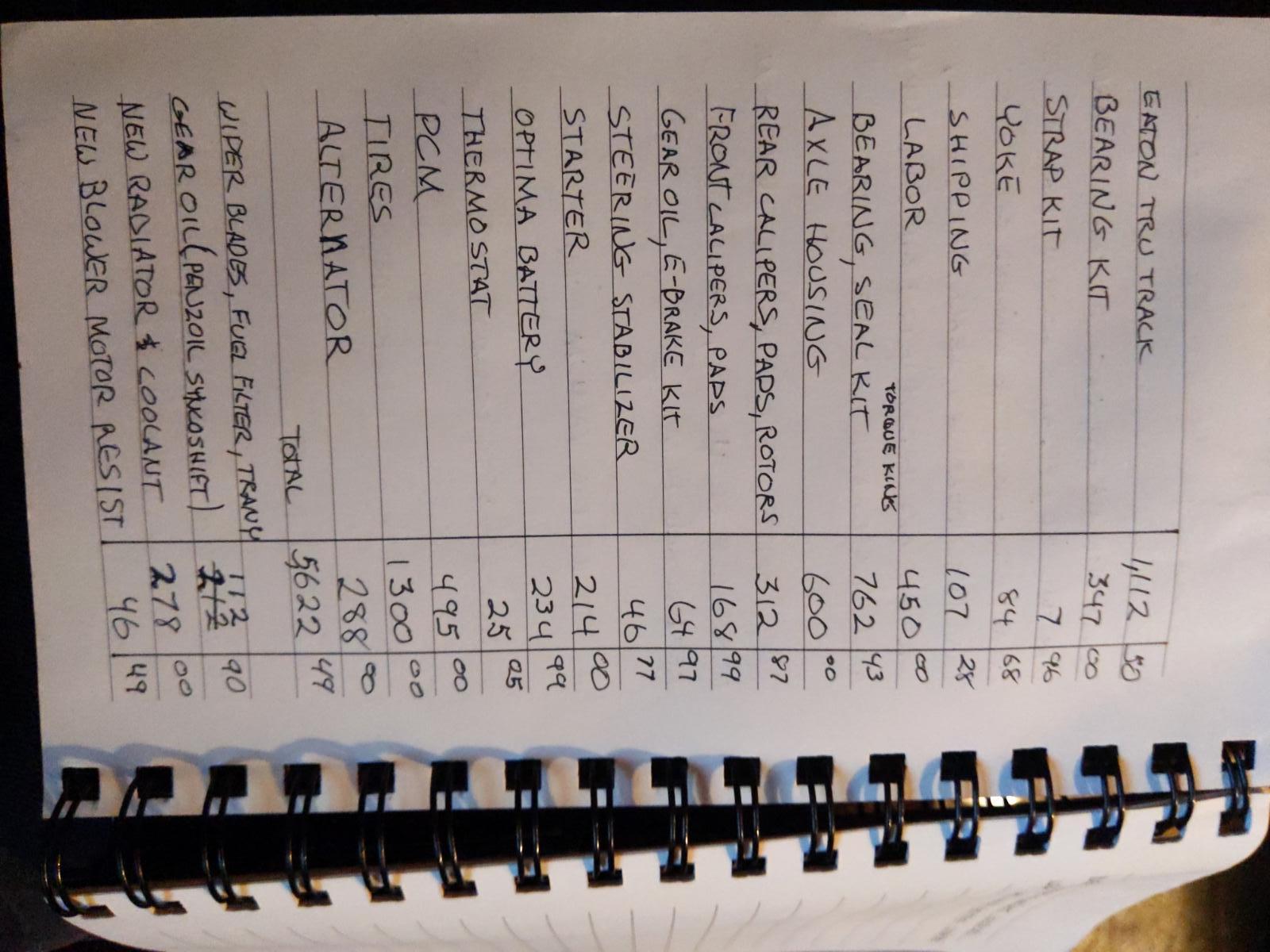

Yes JAG1, that's what that means. This is a common system in many vehicles "self regulated alternator" with one wire running to the battery from the alternator and no control wires for the fields of the alternator. Battery voltage is monitored through the charging lead. Moparman is correct in his statement about a smarter charging system controlling voltage regulation using the temperature sensor on one of the two batteries. In my case increasing battery life is a mute point as I was very close to launching a 50 caliber round through this Dodge. It was purchased as a project truck and in all my infinite wisdom "Dumb-A" I thought I was just going to build a new rear end for it and put it back on the road. Hahahaha.... I now have 400 miles on this truck and am getting use to driving it. It has lot of power and is getting around 14 mpg, seems like it should be better? Again I have no history with this truck!!! I don't know what had been done to it. Other than neglect. No blow by and after changing the oil it now has 400 miles on it and the oil still looks clean. This is what I've done so far. The 6 speed manual transmission was rebuilt around 4600 miles prior to me purchasing the truck. Time will tell how much more I'm to do on this truck.

-

Electrical questions/troubles

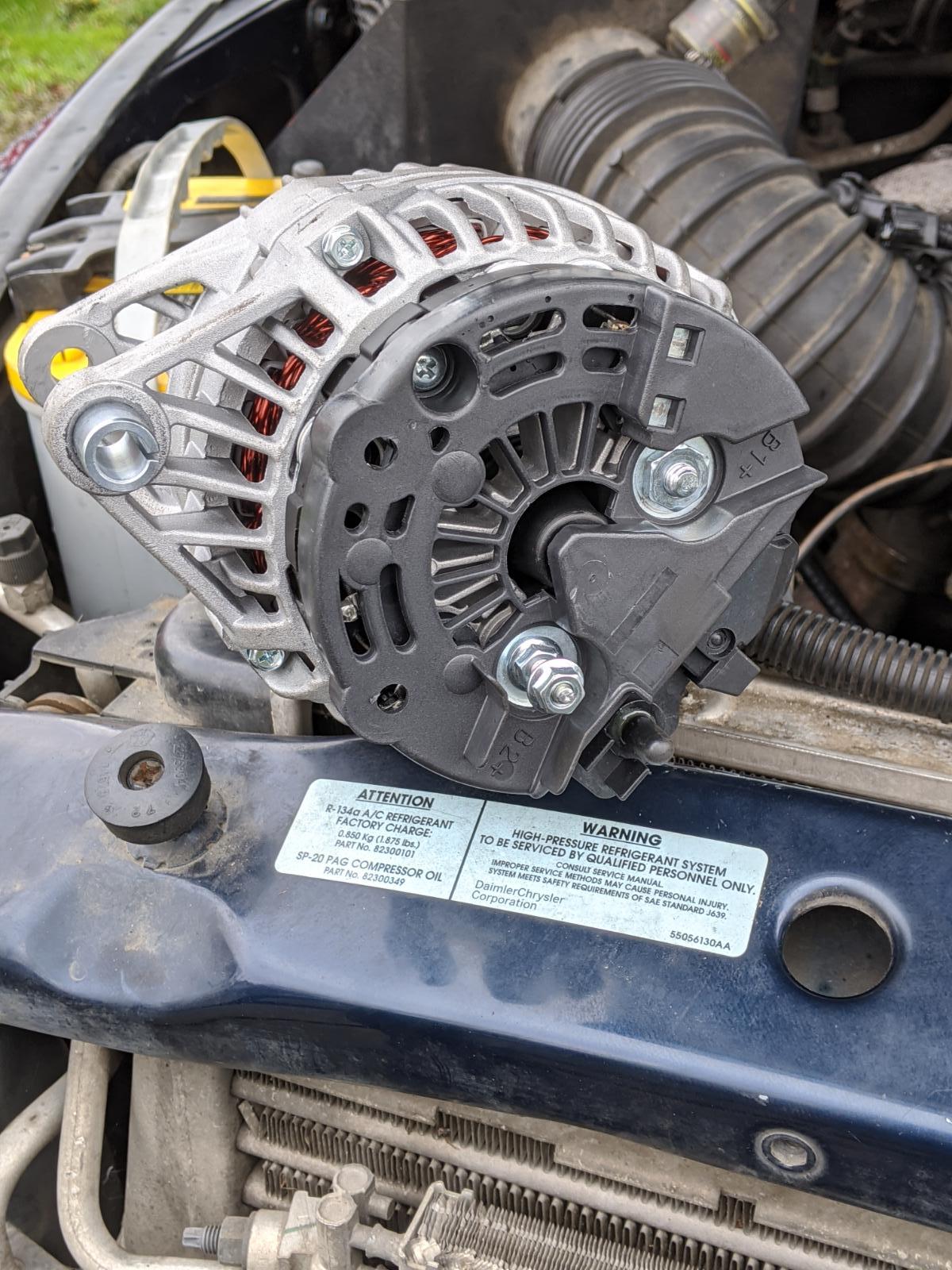

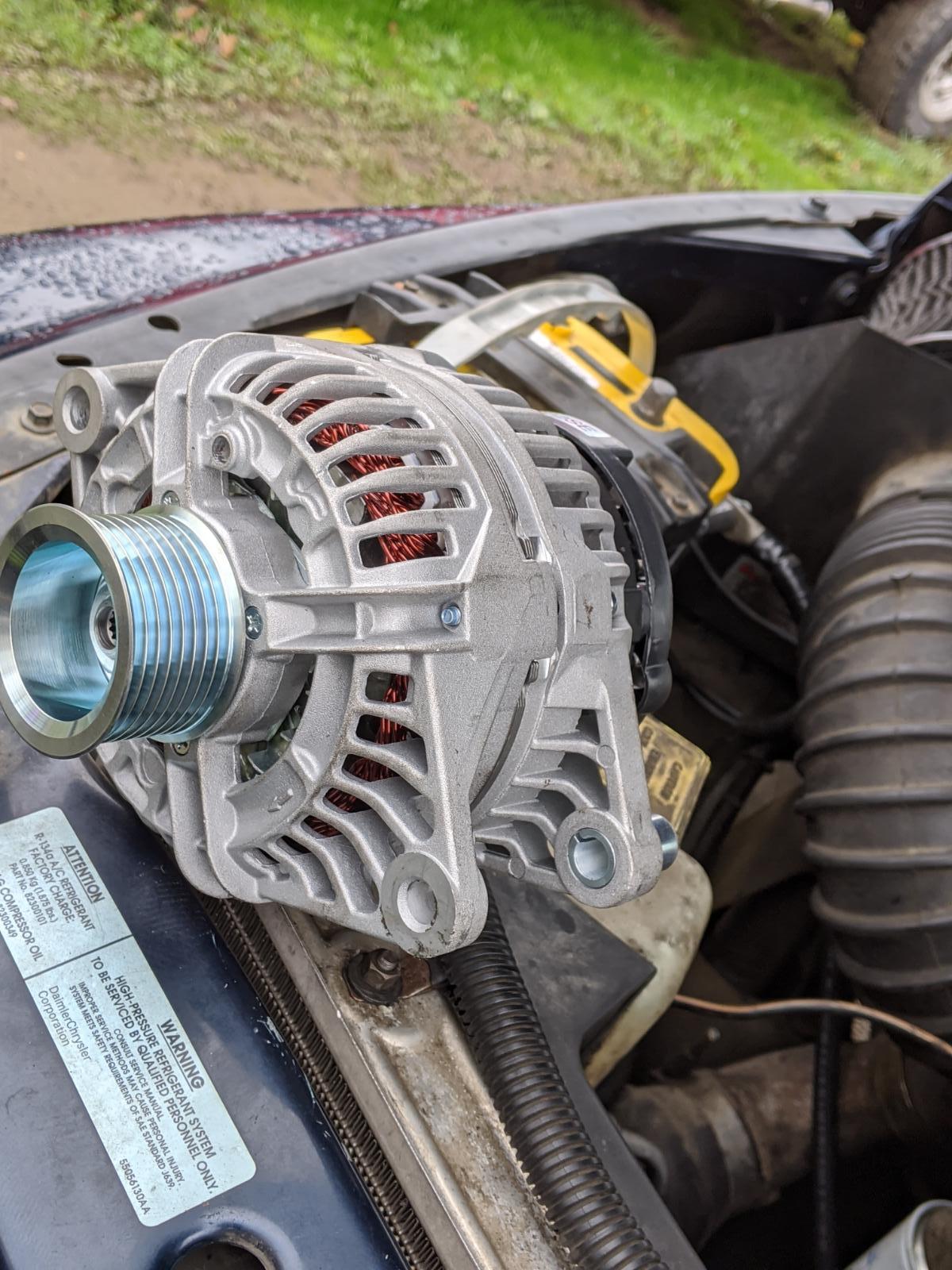

I did get my charging system working and got my "no bus" fixed as well. The "no bus" was an open ground because one of my connectors by the passenger battery came apart. The charging system was fixed by purchasing a single wire alternator from HEI in Oregon, 288 dollars free shipping. It has been 14.2 at idle or WOT. This is a Bosh alternator and a direct bolt in, no mods. The two control wires are now capped and secured to the upper alternator bracket with a zip tie, in the unlikely event I may want to go back to a stock system. I had gotten a refurbished PCM and it had the same problem as the one I sent in for repair. Rather then arguing with this company in Florida I just decided to go with a one wire alternator ( self regulated) hope this answers your question.

-

Carrier bearing shot

Hey everyone, my silly years of being a machinist working with bearings on machine tools has taught me a lot. When applying grease to a slow moving item like ball joints and wheel bearings you can typically pack them full. But caution is the word for over greasing a high speed bearing, that may see 3000 rpm or more. The shearing of viscous grease between the balls will create excessive heat, destroying the bearing. The balls are rotating at rpm's 3, 4, 5, times faster then the bearing is. The leading edge of one ball and the trailing edge of the next ball are going in opposite directions, shearing the grease. Now multiply that by the number of balls. Most ball bearings have both sides shielded or sealed and are pre-lubed in a clean room setting, no dust or particulates of any kind. They are typically greased very lightly. If you pop a seal off of a new bearing it appears it has no grease, but it really does. If that bearing is kept clean and ran within it's design parameters it will last millions of revolutions. Add a contamination, poof gone. Probably more then anyone wanted to know about a bearing...

-

Battery temp circuit question

I was able to take the truck out for a test drive, seemed to go ok. It did set a 0120 code and the throttle did have a hesitation when it set this code. I measured the ac volts as described and got .043, engine hot, at an idle. I cleared the code and will see if it returns. You folks are a great help, thanks. Mario As for alternators, I will have one of each, Bosh and ND one wire converted by Heielectric in Oregon. That way I have a spare for when I'm up Alaska way having fun....

-

Battery temp circuit question

Update, I just installed the one wire Bosh and the system is charging at 14.2 volts at idle and wot.

-

Battery temp circuit question

Hey buddy, thanks for your help!!! So I had read about this mod, adding the fuses link to the blue wire and performed this mod prior to installing the refurbished PCM. I will change the 7.5 to a 5 amp fuse. I got this PCM from Auto Module Source, I feel it didn't work from the moment I plugged it in, but not having much experience with this truck and lack of knowledge is a good recipe for self inflicted oh #@&$ moments. Thanks again for all your help and support. I will order a new PCM from Auto Computer Specialists. I wish for you and your family a healthy happy future... Mario

-

Battery temp circuit question

I don't have any history with this truck, unfortunately. Many of the fuses were missing in the PDC and I was able to figure out from the skematics which fuses I needed. Everything seems to work now except the charging. I double checked green and blue wires for shorts and opens, they checked out good. I have ground on green and no voltage on blue. When I replaced the PCM and checked voltage on blue, it was 8 volts. Batteries were 12.2 volts. An odd thing I noticed today was after running the truck for 10 minutes or so the bolt meter dropped to 0 and the warning "check gauges" came on. At that time I had the charger hooked up to the batteries and battery voltage was 12.4 volts. Very odd!! I will double check the battery temp circuit tomorrow to make sure I had the correct pins as the numbers are wonderfully small.

-

Battery temp circuit question

I just ordered a one wire Bosh retrofit for this truck from HEIELECTRIC. Has anyone use these folks, they are located in Oregon.

-

Battery temp circuit question

No codes.

-

Battery temp circuit question

02 ram 3500-6 speed manual 4x4. If the battery temp circuit is open will this prevent the PCM from charging/regulating? I checked ohms between C1 pin 4 and C3 pin 15 on the PCM and found this circuit to be open.

-

Electrical questions/troubles

Thanks tractorman, I am easily confused when it comes to new things like posting and didn't want to start on the wrong side. I'm kinda good at that!!!

-

Electrical questions/troubles

I will clean up these ground splices as you've described. I like doing these upgrades as preventive maintenance rather than along side the road (crisis management style). I still don't think the PCM is correct as it's not supplying 12 v on the blue wire to the alternator? Hey JAG1, I'm a bit of a dumb A when it comes to posting as I've now posted a total of 4 times... Did I highjack this thread? I'm a little confused when you stated the two rules as maybe I broke both of those rules?

-

Electrical questions/troubles

Thanks again, yep it was pin 30/31 no ground, connector doesn't have a lock when closed and worked loose. I taped it up for a short term fix and will replace connector as soon as I find one. Now my instruments work but I'm not charging. I un-plugged alternator blue and green wires, started er up and checked voltage on blue=0, green had ground. I have put a 7.5 amp as described, to protect PCM from an alternator short. I checked it and it's good. I am assuming the PCM is bad???