Proceed at you own risk, this is not something that is approved by anyone as a safe to use device. Parts that are used to make this are only that, parts and we're not designed for this kind of project.

For those that don't want to spend thousands on expensive units and don't quite trust china special sold at many places, you can make your own out of bottle jack. I've also tossed the idea of buying hydraulic cylinder type pump made for body work. It already has a hose that would be easy to adapt to fittings or just adapt right at the pump as it's threaded.

But since I had this 4ton jack for last 10 years not doing much I decided to use it. Keep in mind not all jacks are going to be put together same way or have same size internals. One thing you need to make sure is that it can be disassembled, most new seem to be welded now, probably cheaper to make that way.

There are more than one way of making this work, some use a tap on the main cylinder where all the pressure is built and not even using the part that travels (piston?), then use a bushing to reduce to 1/4" pipe and go from there. To me it seemed that you would need to machine the top nut that holds jack together so your bushing can get through, you would also need a bigger tap, in my case it would of been a 1" they don't give good ones away. I had a 1/2x14 tap already and the inside of the piston that travels in my case was hollow and pretty close to tap size, a little on the lose side but it worked, later I decided to weld it to be sure. I suppose you can drill it so the fitting just fits inside and weld it in to begin with, so no tap required.

Some actually thread the nut that holds it together on inside where oring is and reduce it from there to 1/4" npt so no inside piston needed at all. Like I said there are plenty ways of doing this. You may come up with one that works best for you.

As you can see in picture above I cut off few inches of the piston, these parts aren't used just showing where a tap would fit. Here it is already tapped with 1/2-14 npt.

I also drilled 2 holes on the sides of main cylinder and went in to piston a bit then filled it with weld make sure to have a good welder that penetrates and makes a good seal. The actual piston is an inch below the holes, it still has the rubber sealing ring on it. One thing I didn't mention, you have to drill a hole all the way through the piston so fluid can make its way in to top part where the threaded part is. Here is what it looks like after it's welded with the 1/2" x 1/4" npt male on both sides fitting. Then I ground off excess weld and tapered it some so the big nut can go right over.

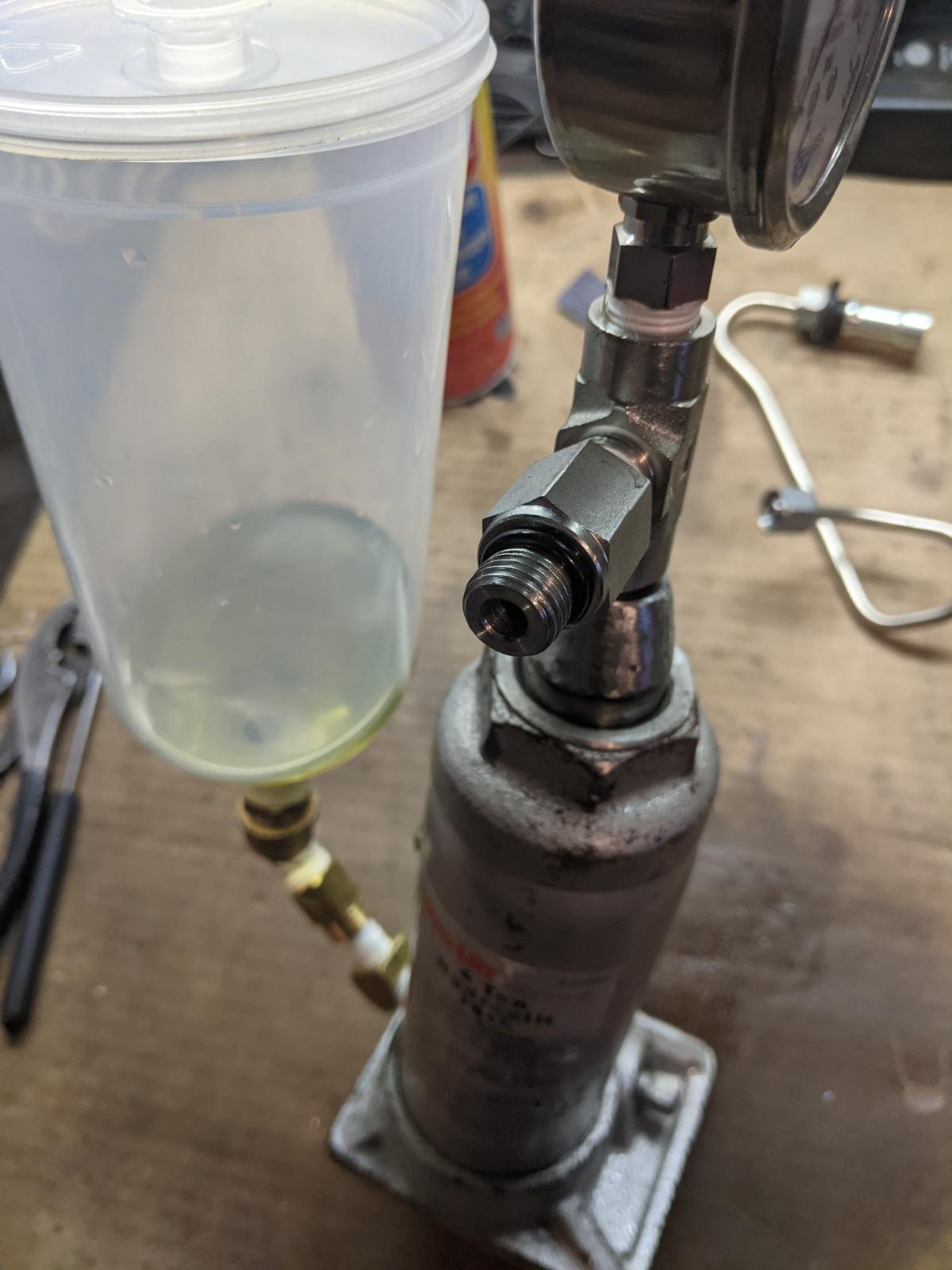

Now you got 1/4" mnpt sticking out that you can adapt a 1/4" npt T. One side of a T is a male that I put a 1/4" npt female to metric male 14x1.25 the other is for the guage. I used a Carbo guage form eBay, says carbousa but it's made in china. I believe it's a decent guage for the money, I may get a better one later that's also bigger for accuracy. The metric thread where you see oring needs to be slightly tapered inside so the injection line seals, oring is not used. I used a drill bit to put some angle inside, worked for me.

I plugged the original oil fill hole and tapped another one down low with 1/8"x27 tap, then used some local hardware store fittings to go to a paint cup that I got from harbor freight, comes in a pack of 5 really cheap for what they are. They are threaded with female 3/8" npt, so you need a reducer to go to 1/4" then to 1/8" npt. I suppose you can tap a 1/4" npt in the housing and just use 1/4" all the way. I didn't use a filter like I planned to, maybe I will in future, for now I make sure fuel I put in is clean.

I got a fuel line from a local CAT dealer, guy I know works at parts counter and he was able to get me a free line that is 14x1.25 metric. It was a used line that apparently they don't reuse on jobs just toss them and always put new ones on, at least that's what I was told, ether way it worked out for me.

As for the adaptor for 24 valve vp44 injectors, I went with accuratediesel made in usa. I'm sure you can find others.

https://www.accuratediesel.com/5-9l-dodge-cummins-vp44-24v-injector-pop-test-adapter-fixture.html

Guess that's about it, like I've mentioned this can be done more than one way, maybe simplified too.

One thing to remember is to clean everything very well before final assembly, this even goes for if you decide to buy one on line, I would highly recommend to disassemble it and go through it. It won't take much with that kind of pressure to ruin something. I also used teflon tape for sealant, make sure to stay back with it on threads so it doesn't get inside. Now that we're talking high pressure, it is very dangerous if you get injected with diesel fuel you can get seriously hurt. So make sure you are comfortable in your building skills and wear proper ppe when working around high pressures, a good respirator is not a bad idea. This project is not for everyone. Good luck if you chose to go this route.

-

2

2