Torque Converter Issues and Alternator Noise Testing

Before Testing - IMPORTANT PLEASE DO NOT SKIP!

Before doing any testing of the alternator for AC noise, make sure to remove any and all wiring modifications. Return the electrical system back to stock. Make sure there is no extra grounds, relocation of ground wires or noise filters installed before testing the alternator. It has been brought to my attention that wiring mods can and will provide false passing grades for the alternator. The entire electrical system should be left stock and unmodified so you (the owner) are alerted sooner to impending alternator failure. Stock system will show AC noise issues much sooner than a modified system which will mask the issue and then typically cause damage to ECM, PCM or VP44 sooner.

2 Methods of Testing your Alternator for AC Noise

1. Remove the 140 amp alternator fuse in the PDC. Then unplug the field lead of the rear of the alternator. DO NOT remove the heavy charge lead. This was handled by removing the alternator fuse. Now go for test drive and see if the torque converter lockup issues occur. If no torque converter lockup issues then the alternator is at fault for AC noise issues. I highly suggest you verify by having the alternator bench tested and or do test #2 below.

2. Remove the turbo intake tube. Now using a high-quality digital volt meter like Fluke or Extech. The DVM should have an AC scale capable of reading down to millivolts AC. If not you'll see measured AC volts in the range of 29 to 31 volts which is erred.

AC Noise Voltage levels

- Normal - 0.01 to 0.03 AC Volts

- Marginal - 0.05 to 0.09 AC Volts (Some folks have reported random or odd behavior occurring at this low of voltage)

- Fail - 0.1 AC Volts and above.

NOTE: W-T ground wire mod will make the AC noise much lower typical reading around 10mV AC to 20mV AC is Normal past about 40mV is a fail. Factory wiring is going to remain higher. Highly suggested doing the W-T ground wire mod.

Here is another video explaining the AC noise even better...

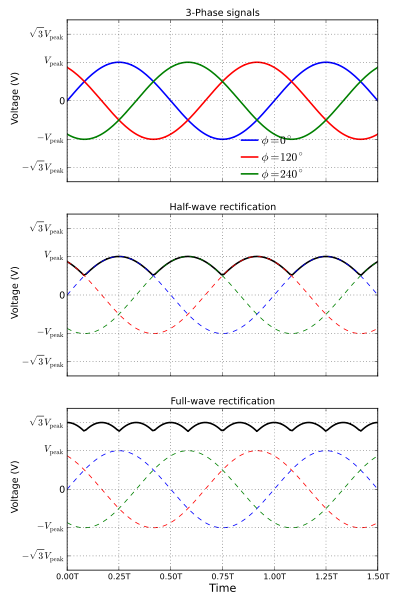

Failed diode waveforms will create some unusual patterns which will create the torque converter issues you guys are having. Here is a normal alternator output with good diodes.

Why am I going out and trying to fix this problem? Because the AC noise created by the alternator is being fed to all systems ECM, PCM, ABS, etc. So there is a chance that some of the random failures of ECM's and VP44 are caused by a failed alternator.

Replacement Alternators

I've been asked about what kind of alternator should be used. I've seen several folks buy brand new alternators and get several in a row that failed out of the box. I've seen personally several remanufactured alternators failed out of the box. Then some folks think that dealer alternator is going to do better but you not guarantee a quality alternator either. So, what is an owner to do? The best thing I can suggest is to buy what you can afford but before you leave the store have them bench test your new alternator for a passing grade. Some folks have now gone to upgrade alternators like Nations Alternators which are all brand new and upgrade to high amperage output. Again, it about what you can afford and brand new is not a guarantee that it's good alternator.

Replacement Diodes

If the diodes are to blame you can rebuild your 136 amp OEM alternator with this diode kit.

Another Member Results

As posted from craneop (AKA: Terry Quirk)

OK! Problem solved! Yippee!!!

Took the recently purchased Alternator back to O'Reilly's where I got it from, had them test it on their tester. They told me they run the test 3 times and if they get a PASS all three times, its a good alternator. When I asked about measuring AC Voltage, they looked dumbfounded, so I asked them if I could hook my multimeter up to the alternator while they tested? They agreed! So now this alternator is reading .35 Volts AC as the first test PASS'S, they run the second test and we get a FAIL, the guy gives me a funny look, checks his wires and runs the third test and we get another FAIL. So the guy now tells me guess we have a bad alternator but they don't have another one on the shelf and I will need to wait till tomorrow to bring one in from the other store. I say I'm OK with that, but that I've learned my lesson and we are going to have to test the next alternator as well before I leave the store with it. The next morning (yesterday) they call me and let me know the alternator is in and I can come down and pick it up. We do the test like before, and this time we get a PASS, PASS, PASS, however, my multimeter is reading 0.3 Volts AC, and then I also notice that on their machine there is a box at the top that says Diodes and across from that box on the screen says N/A. So I ask the guy about it and he says their machine has no way of testing the diodes, it only tests for the overall condition of the alternator. Unhappy with what I'm hearing and looking at, I request my money back which they had no problem with at all, however the core I earlier took in was no longer in the store so the gave me cash in the amount of $215.00 (their core charge on that alternator $36.00 along with the full purchase price of $179.00.)

By this time I have no core, only to find out all the other auto parts stores around town are charging a $70 - $80 core charge for this alternator, and a lot of the places have no tester. Starting to get a bit frustrated, I decided to quit messing around and go to the most reliable place in town I know of, a small family owned auto electric and mechanical shop (Auto Electric, Anchorage, Alaska). I was hoping that maybe they had heard of this issue I am having with the TCL and get fixed up with a good alternator. They rebuild all kinds of auto electrical parts right there in house as well a run a full-service auto mechanic shop. Well,,,,I explained my problem to them and showed them a printed copy of the troubleshooting procedure I got from the Mopa1973Man website, to which they said...never heard of this before. However, these guys are real pro's and they didn't blow me off. They took my concerns seriously, brought two techs in out of the shop to talk with me about this, as I explained to them the 0.1 Volt AC upper limit thing. They genuinely got concerned and were pulling down alternators, checking them on the bench and checking outputs at vehicles in the shop. In all, I was in there for about two hours while they tested and discussed and in the end, the shop found me a NEW alternator and gave me a heck of a deal @ $239.00 w/no core charge. The NEW alternator was putting out 0.22 Volts AC on their alternator bench vise, and that concerned me cause I was looking for something under 0.1 VAC. However in further discussion, the techs I was working with concluded, (and BTW they turned out to be right),that the test machine itself was putting off AC Noise and that the Fluke Meter was picking up that AC Noise during the test, and that since the Voltage Regulator is on either the PCM or ECM, the only way to accurately read out the AC output on this alternator was to put it on the vehicle and measure it at that time. So,,,I took the alternator home, hooked it all up, and WALLA... measured at the batteries -0.01 Volts AC @idle, and 0.00 Volts AC @2000 RPM. Feeling pretty good at this point I take it for a test drive. Runs and shifts perfectly. NO MORE PROBLEMS!!!

Cory, I believe he's the manager or maybe owner, at Auto Electric said though he's heard and dealt with a lot of Dodge Cummins issues like this before, had never heard of this shifting problem being linked to + 0.10 VAC output on the alternator. He asked me to check back in with him to let him know how all this worked out. I will do that on Monday, as well as express my thanks for all the personal attention, efforts and concerns Auto Electric gave to me to address my problem.

In the meantime, my utmost gratitude to Mopar1973Man for sharing your knowledge and wisdom on this issue. I had tried all the band-aid tricks only to have them each work for anywhere to a couple hours to a couple days or so and then reappear. I believe what was happening was that as I fixed a ground or foiled a wire, it masked the problem just long enough for the diodes on the alternator to get a little worse and then BOOM, the problem is back!

Very good information Mopar1973Man!!!

Happy Holidays!!!

Update: November 19, 2014

Here we go with another blown alternator confirming without a doubt of the diodes being a cause.

Before any repair...

After the alternator is rebuilt...

The cause...