If you have a 13-18 2500 or 14-18 2500 you are probably aware of this recall for the steering linkage.

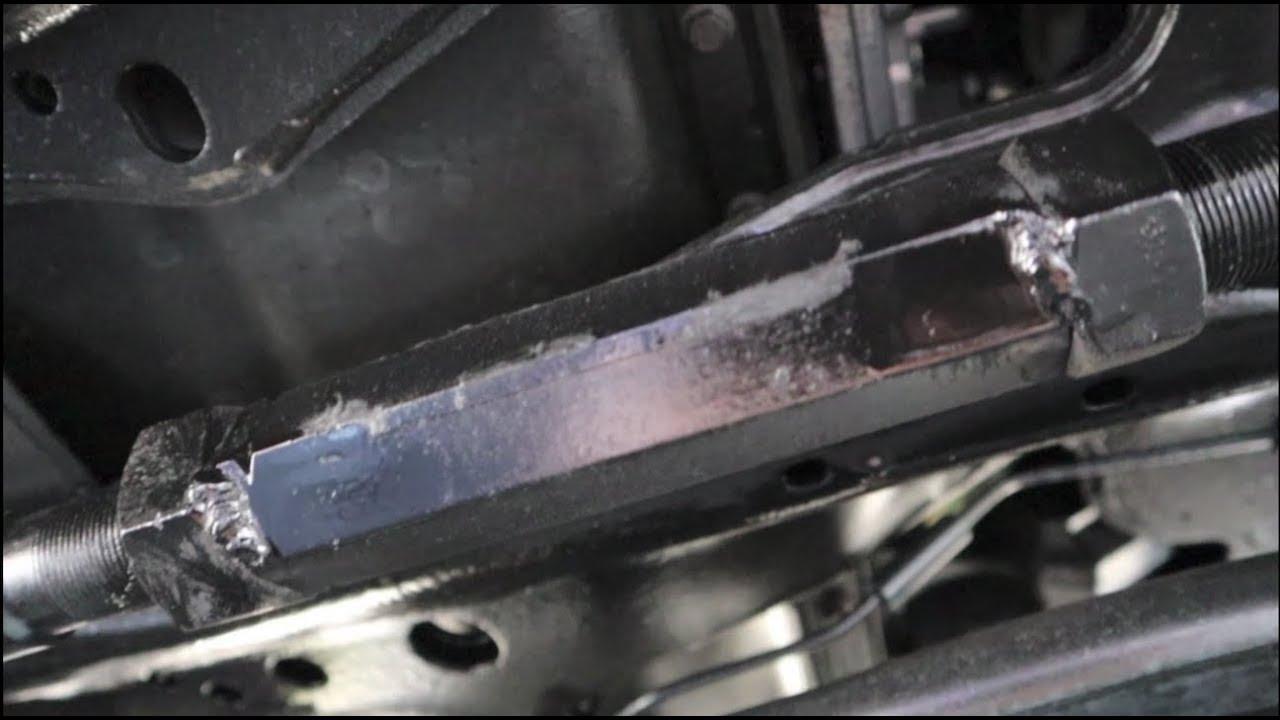

The standard fix is to weld the adjustment nuts, something I won't let them do on my truck. Example is in this image.

I have been trying to get FCA to just replace the drag link with the updated one... to no avail.

I recently learned the part number and have ordered the part and will submit for reimbursement. It's cheap too, $132 to my door.

68338342AB or 68338342AD

To install simply loosen the 2 nuts in red and remove the old trackbar then install the new trackbar. Get your truck aligned and you are good to go.

It's installed and ready for a test drive...

Removal at the spindle was easy, but removal at the pitman arm was a PITA.

So if any one else is in the same boat this is a better alternative to welding.

QuoteDealer Service Instructions for: Safety Recall V06 / NHTSA 19V-021 Drag Link NOTE: Only 2017 and 2018 MY vehicle remedies are available at this time. Part requests for 2013 through 2016 MY vehicles will be rejected until further notice. 2017-2018 (DJ) RAM 2500 Pickup 2017-2018 (D2) RAM 3500 Pickup 2017-2018 (DD) RAM 3500 Cab Chassis 2017-2018 (DF) RAM 3500 10K LB. Cab Chassis 2014-2016 (DJ) RAM 2500 Pickup 2013-2016 (D2) RAM 3500 Pickup 2014-2016 (DD) RAM 3500 Cab Chassis 2016 (DF) RAM 3500 10K LB. Cab Chassis NOTE: Some VINs in vehicles above may have been identified as not involved in this recall and therefore have been excluded from this recall. Remedy Available Remedy NOT Available Safety Recall V06 – Drag Link Page 2 The drag link on about 795,000 of the above vehicles may have been built with an outboard steering linkage jam nut that could loosen allowing one end of the drag link to separate from the adjuster sleeve. A drag link separation can result in a loss of directional steering control, which can cause a vehicle crash without prior warning. Inspect the torque values. If the torque values meet requirement, the nuts will be welded to the adjuster sleeve. If the torque values do not meet requirement, the threads will be measured. If thread engagement is acceptable, the link will be reassembled, the vehicle will be aligned, and the nuts will be welded to the adjuster sleeve. If the thread engagement is not adequate, the drag link assembly will be replaced. Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if inspection determines that a drag link assembly is required and the vehicle must be held overnight. IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. Subject Repair Alternate Transportation Safety Recall V06 – Drag Link Page 3 No parts will be distributed initially. If a replacement drag link is needed, after performing Sections A and B, please contact the STAR Center for additional directions. Part numbers listed below are for reference only. Very few vehicles are expected to require drag link replacement. Part Number Description CSZHV061AA Assembly, Drag Link 06505623AA Hex Lock Nut, Tie Rod (2 required) 68317791AA Paint, Black (MS-PF-1-25) (Each container of paint will repair approximately25 vehicles) NOTE: If any part of this procedure cannot be performed during disassembly or assembly, a STAR Case must be submitted. NOTE: A STAR Case must be submitted, then contact the STAR Center to request parts. Please provide the VIN, Model Year, Mileage, PN, Dealer Code and measurements from Steps 4 and 5 in section B. If approved, STAR will place the order for the Drag Link part. The Drag Link part will be shipped from your facing PDC. Once STAR has confirmed parts can be ordered, Dealers must place order for the Hex Lock Nut and black paint, as necessary. Hex Lock Nut will be shipped from your parts distribution center and the black paint will be shipped SSD. Parts Information Safety Recall V06 – Drag Link Page 4 Do not scrap the part, if the Drag Link Assembly is replaced, the Star Center will initiate the process for returning to the Quality Engineering Center for review. All returned parts and associated claims will be reviewed and are subject to charge back. The following special tools are required to perform this repair: NPN Lincoln Powerwave 350 - Flux Cored Arc Weld (MIG) or equivalent C-3894-A Puller, Tie Rod 2069400190 Crowsfoot Wrench, 41mm (SCOM41) Parts Return Special Tools Safety Recall V06 – Drag Link Page 5 A. Inspect Drag Link Assembly 1. Inspect the drag link assembly for drag link to turnbuckle separation. If no evidence of separation is observed, continue to Step 2. If the vehicle was towed in and separation has occurred or any evidence of separation is observed, continue to section D. Replace Drag Link Assembly. 2. Using a .020” feeler gauge, confirm jam nut contact to drag link turnbuckle. If no contact is noted, proceed to section B. Measure Drag Link Assembly Threads (Figure 1). 3. Using a paint pen or equivalent, mark both jam nuts and turnbuckle with lines (Figure 1). 4. Hold the drag link turnbuckle with back-up wrench (Figure 2). 5. Using a 41 mm crowsfoot, such as Special Tool 2069400190 (Snap-on SCOM41) or equivalent, set a torque wrench to 20 N·m (15 ft. lbs.) (Figure 2). Service Procedure Figure 1 – Mark Jam Nuts and Turnbuckle DRAG LINK TURNBUCKLE JAM NUTS MEASURE HERE TO CONFIRM JAM NUT TO TURNBUCKLE CONTACT Safety Recall V06 – Drag Link Page 6 NOTE: If using a digital torque wrench during the inspection, observe the torque wrench digital reading to determine if minimum torque of 20 N·m (15 ft. lbs.) is achieved. NOTE: Some jam nut movement may occur when tightening from 20 N·m (15 ft. lbs.) to 148 N·m (109 ft. lbs.). DO NOT replace the drag link if initial 20 N·m (15 ft. lbs.) is achieved. 6. Rotate each jam nut in direction as shown (tightening direction) until wrench clicks or 20 N·m (15 ft. lbs.) is achieved (Figure 2). If paint lines do not show nut rotation, continue to section C. Weld Turnbuckle Jam Nuts. If either paint line shows nut rotation, continue to section B. Measure Drag Link Assembly Threads. Service Procedure Figure 2 – Inspect for Jam Nut Movement BACK UP WRENCH ON HOLDING TURNBUCKLE JAM NUT TIGHTEN DIRECTION CROWSFOOT JAM NUT TIGHTEN DIRECTION TORQUE WRENCH SET TO 20 N·m INSPECT PAINT LINE ALIGNMENT TO SEE IF JAM NUT ROTATES NOT OK Safety Recall V06 – Drag Link Page 7 B. Measure Drag Link Assembly Threads 1. Back off both jam nuts enough to paint mark threads. 2. Paint mark threads of outer drag link at turnbuckle (Figure 3). NOTE: Turnbuckle end with notch marks on hex goes toward the outer drag link. 3. Remove the turnbuckle from the inner and outer drag links (Figure 4). Service Procedure [Continued] Figure 3 – Paint Mark on Threads Figure 4 – Remove Turnbuckle JAM NUT NOTCH MARKS ON TURNBUCKLE OUTER DRAG LINK PAINT MARK ON TURNBUCKLE THREADS TURNBUCKLE OUTER DRAG LINK INNER DRAG LINK Safety Recall V06 – Drag Link Page 8 4. Using Vernier Calipers, measure and record the inside diameter of the turnbuckle (end with notch marks on hex) (Figure 5). NOTE: Measure the inside diameter at two different locations (90° from each other). Use the largest measurement. Service Procedure [Continued] Figure 5 – Measure Inside Diameter of Turnbuckle at Notched End NOTCH MARKS ON TURNBUCKLE MEASURE INSIDE DIAMETER VERNIER CALIPERS IN TWO PLACES Safety Recall V06 – Drag Link Page 9 5. Using Vernier Calipers, measure and record the major outside diameter of the outer drag link threads 5mm (0.20 in. - approx 3 threads) from paint mark denoting end of turnbuckle (Figure 6). Be sure to measure using the flats on the calipers, do not measure inside the thread pitch (Figure 6). NOTE: Measure the outside diameter at two different locations (90° from each other). Use the smallest measurement. Record smallest outer thread diameter (Step 5): Record largest inner thread diameter (Step 4): Subtract (smallest outer – largest inner): If the result of the subtraction is 0.6 mm (0.024 in) or less, continue to section D. Replace Drag Link Assembly. If the result of the subtraction is greater than 0.6 mm (0.024 in), assemble the turnbuckle and continue to section C. Weld Turnbuckle Jam Nuts. Service Procedure [Continued] Figure 6 - Measure Outside Diameter of Outer Drag Link MEASURE OUTSIDE DIAMETER IN TWO PLACES (THREADS THAT WERE ENGAGED WITH THE TURNBUCKLE) VERNIER CALIPERS PAINT MARK OUTER DRAG LINK MEASURE THREE THREADS IN FROM PAINT MARK USE FLAT SECTION OF CALIPER Safety Recall V06 – Drag Link Page 10 C. Weld Turnbuckle Jam Nuts NOTE: DO NOT WELD COLD, allow the parts to warm to room temperature, above 65° F (18° C). NOTE: DO NOT LOOSEN JAM NUTS if steering wheel is centered and toe adjustment is not required. 1. Adjust the toe if required and center the steering wheel. 2. After adjustment, using a backer wrench and a 41 mm crowsfoot, such as Special Tool 2069400190 (Snap-on SCOM41) or equivalent, tighten the drag link turnbuckle jam nuts to 148 N·m (109 ft. lbs.). Make sure the toe setting does not change during tightening (Figure 2). 3. Road test to verify the steering wheel is straight prior to welding. 4. Disconnect the battery negative cable(s). WARNING: • When Welding or working with Adhesives always wear safety goggles and gloves to prevent contact with chemicals and to prevent weld spatter, sparks, and sharp metal from causing bodily injury. • Wear an approved respirator while welding and during the application of adhesives to prevent inhalation of harmful vapors. • Always remove NVH (Noise Vibration and Harshness) foam from welding repair area, as material is flammable. Service Procedure [Continued] Safety Recall V06 – Drag Link Page 11 WARNING: Failure to follow these instructions may result in possible serious or fatal injury. Welding • Comply with all federal, state and local regulations to avoid any injuries due to shock, fires, fumes, sparks and liquids. • All flammable materials or liquid should be stored in tightly sealed and labeled containers, and used only in well ventilated areas. • No spark producing equipment should be permitted in any area where flammable materials are being handled or stored. 5. Clean the areas to be welded. Areas must be free of dirt, oil, water, salt, undercoating, or any signs of moisture then wire brush area to be welded (Figure 7). Service Procedure [Continued] Figure 7 – Clean the Areas to be Welded AREAS TO BE WELDED Safety Recall V06 – Drag Link Page 12 6. Following the weld procedure values in chart below (Figure 8). 7. Using a Lincoln Powerwave 350 Flux Cored Arc Weld (MIG) or equivalent, apply a 17mm long weld the length of one turnbuckle flat on each jam nut (Figure 9). Service Procedure [Continued] Figure 8 – Weld Procedure Values Figure 9 – Weld Both Jam Nuts to the Turnbuckle WELD JAM NUTS TO TURNBUCKLE IN TWO PLACES Safety Recall V06 – Drag Link Page 13 8. Wire brush the slag from the surface of the welds (Figure 10). 9. Allow to cool to room temperature. NOTE: Each jam nut must hold a breakaway torque of 105 N·m (77 ft. lbs.). 10. Using a backer wrench and a 41 mm crowsfoot, such as Special Tool 2069400190 (Snap-on SCOM41) or equivalent, set a torque wrench to 105 N·m (77 ft. lbs.) and attempt to loosen each jam nut (ref: Figure 2 for set-up). If both jam nuts do not rotate (breakaway), continue to step 11. If either jam nut rotates (breakaway), repeat Steps 5 through 10 on a different turnbuckle flat. 11. Paint the area to prevent rust using MS-PF-1-25 black paint or equivalent. 12. Remove the supports and lower the vehicle. 13. Connect the negative battery cable and return the vehicle to the customer. Service Procedure [Continued] Figure 10 – Prepare areas for Paint BRUSH SLAG FROM WELD 17MM WELD WELD THE LENGTH OF ONE TURNBUCKLE FLAT Safety Recall V06 – Drag Link Page 14 D. Replace Drag Link Assembly 1. Raise and support the vehicle. 2. Remove the right front tire and wheel assembly. 3. Remove and DISCARD the outer drag link to tie rod nut (Figure 11). 4. Remove the outer drag link tie rod from the knuckle using C-3894-A (puller shown in Figure 12). 5. Remove and DISCARD the inner drag link to pitman arm nut (Figure 12). 6. Remove the inner tie rod end from the pitman arm using special tool C-3894-A (Figure 12). 7. Remove and RETURN the drag link assembly. See Parts Return section. NOTE: Prior to installing tapered end suspension components, clean male and female surfaces with brake clean. Service Procedure [Continued] Figure 12 – Inner Tie Rod Figure 11 – Outer Tie Rod OUTER TIE ROD NUT INNER TIE ROD PULLER Safety Recall V06 – Drag Link Page 15 8. Position the NEW drag link assembly to the vehicle. 9. Install the inner drag link tie rod end to pitman arm using a NEW nut and tighten to 37 N·m Plus 180° (27 ft. lbs. Plus 180°). 10. Install outer drag link tie rod end to the knuckle and tighten the NEW nut to 60 N·m Plus 105° (44 ft. lbs. Plus 105°). 11. Install the right front tire and wheel assembly and tighten to proper torque specification (Figure 13). 12. Remove the supports and lower the vehicle. 13. Adjust the toe and center the steering wheel. 14. After adjustment tighten tie rod adjustment sleeve clamp bolt to the 75 N·m (55 ft. lbs.) (Figure 14). 15. Return the vehicle to the customer. Service Procedure [Continued] Figure 13 – Wheel Assembly Torque Specifications ADJUSTMENT SLEEVE CLAMP Figure 14 - Adjustment Sleeve Clamp Safety Recall V06 – Drag Link Page 16 Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments. Use one of the following labor operation numbers and time allowances: Labor Operation Time Number Allowance Inspect Drag Link for Separation, Replace Drag Link and Set Toe 19-V0-61-82 1.1 hours Inspect Drag Link and Jam Nut Gap (Not OK), Measure Drag Link Assembly (Not OK), Replace Drag Link and Set Toe 19-V0-61-83 1.5 hours Inspect Drag Link and Jam Nut Gap (Not OK), Measure Drag Link Assembly (OK), Set Toe and Weld Jam Nuts 19-V0-61-84 1.6 hours Inspect Drag Link and Jam Nut Gap (OK), Jam Nut Torque (Achieved 20 N·m (15 ft./lbs.)), Set Toe and Weld Jam Nuts 19-V0-61-85 1.4 hours Inspect Drag Link, Jam Nut Torque (20 N·m (15 ft./lbs.) Not Achieved), Measure Drag Link Assembly (OK), Set Toe and Weld Jam Nuts 19-V0-61-86 1.6 hours Inspect Drag Link, Jam Nut Torque (20 N·m (15 ft./lbs.) Not Achieved), Measure Drag Link Assembly (Not OK), Replace Drag Link and Set Toe 19-V0-61-87 1.5 hours Completion Reporting and Reimbursement Safety Recall V06 – Drag Link Page 17 Floor Plan Reimbursement 95-95-95-97 Calculate See Below Floor Plan Reimbursement represents the vehicle’s average daily allowance (see table below) multiplied by the number of days the vehicle was in dealer inventory and not available for sale. This reimbursement is limited to the number of days from the date of the stop sale to the date that the remedy was made available. Note: If the vehicle was received by your dealership (KZX date) AFTER the stop sale date, you will use the KZX date instead of the stop sale date. For this Recall, the stop sale was initiated on 02/01/2019 and the remedy was made available on 03/20/2019, therefore, the number of days cannot exceed 47 days. Vehicle Average Daily Allowance 2017 (DJ) RAM 2500 Pickup 2017 (D2) RAM 3500 Pickup 2017 (DD) RAM 3500 Cab Chassis 2017 (DF) RAM 3500 10K LB. Cab Chassis NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions. To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification. All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached. Completion Reporting and Reimbursement (Continued) Dealer Notification Owner Notification and Service Scheduling Safety Recall V06 – Drag Link Page 18 All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed. GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission. To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence. Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair. Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use. If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager. Customer Services / Field Operations FCA US LLC Vehicle Lists, Global Recall System, VIP and Dealer Follow Up Additional Information This notice applies to your vehicle, V06/NHTSA 19V-021 YOUR SCHEDULING OPTIONS 1. RECOMMENDED OPTION Call your authorized Chrysler / Dodge / Jeep® / RAM Dealership 2. Call the FCA Recall Assistance Center at 1-866-220-6747. An agent can confirm part availability and help schedule an appointment 3. Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App. Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above. DEALERSHIP INSTRUCTIONS Please reference Safety Recall V06. IMPORTANT SAFETY RECALL Drag Link Dear [Name], This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2014-2018 (DJ) RAM 2500 Pickup, 2013-2018 (D2) RAM 3500 Pickup, 2014-2018 (DD) RAM 3500 Cab Chassis and 2016-2018 (DF) RAM 3500 10K LB. Cab Chassis] trucks. It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers. WHY DOES MY VEHICLE NEED REPAIRS? The drag link on your truck [1] may have been built with an outboard steering linkage jam nut that could loosen allowing one end of the drag link to separate from the adjuster sleeve. A drag link separation can result in a loss of directional steering control, which can cause a vehicle crash without prior warning. HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE? FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will inspect the torque values. If the torque values meet requirement, the nuts will be welded to the adjuster sleeve. If the torque values do not meet requirement, the drag link assembly will be replaced. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit. Your time is important to us; please be aware that these steps may require more time. The estimated repair time is two hours. We recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership. TO SCHEDULE YOUR FREE REPAIR, CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED? If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed. We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter. Customer Assistance/Field Operations FCA US LLC [Model Year and Model] VIN XXXXXXXXXXXXXXXXX LOGO VEHICLE PICTURE QR Code [1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information. [2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424- 9153), or go to safercar.gov. [3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement. Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days. Mr. Mrs. Customer 1234 Main Street Hometown, MI 48371 This notice applies to your vehicle, V06/NHTSA 19V-021 YOUR SCHEDULING OPTIONS 1. Visit recalls.mopar.com to sign up for email or SMS notifications for when remedy parts become available. You will be asked to provide your Vehicle Identification Number (VIN), provided above 2. Scan below using your smartphone or tablet to sign up to be notified when remedy parts become available 3. Wait for FCA US to contact you again, by mail, with a follow-up recall notice when remedy parts are available 4. Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can sign you up to be notified when remedy parts become available, or answer any other questions you may have DEALERSHIP INSTRUCTIONS Please reference Safety Recall V06. IMPORTANT SAFETY RECALL Drag Link Dear [Name], This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2014-2016 (DJ) RAM 2500 Pickup, 2013-2016 (D2) RAM 3500 Pickup, 2014-2016 (DD) RAM 3500 Cab Chassis and 2016-2016 (DF) RAM 3500 10K LB. Cab Chassis] trucks. WHY DOES MY VEHICLE NEED REPAIRS? The drag link on your truck [1] may have been built with an outboard steering linkage jam nut that could loosen allowing one end of the drag link to separate from the adjuster sleeve. A drag link separation can result in a loss of directional steering control, which can cause a vehicle crash without prior warning. HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE? The remedy for this condition is not currently available. We are making every effort to finalize the remedy as quickly as possible, and will service your vehicle free of charge (parts and labor). FCA US will contact you again, by mail, with a follow-up recall notice when the remedy is available. Once you receive your follow-up notice, simply contact your Chrysler, Jeep®, Dodge or RAM dealer right away to schedule a service appointment [2]. Additional options for your next steps are included on the left side of this notification. We appreciate your patience. WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED? If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online [3] . Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed. We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter. Customer Assistance/Field Operations FCA US LLC [Model Year and Model] VIN XXXXXXXXXXXXXXXXX VEHICLE PICTURE LOGO QR Code [1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information. [2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to safercar.gov. [3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21- 8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement. Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.