- Replies 27

- Views 4.3k

- Created

- Last Reply

Top Posters In This Topic

-

yohon 14 posts

-

Mopar1973Man 13 posts

Most Popular Posts

-

OK so looking at my math I messed up twice but somehow got close. Lol cfm for a hx 35 is listed as close to 600cfm Instead of 900cfm. And my temp was off that output calc was really helpful. It's show

-

Will absolutely be careful with it. This is indeed my daily driver and If im being honest with myself at all I will be converting back to a intercooler when this doesn't work. But I have to try and fa

-

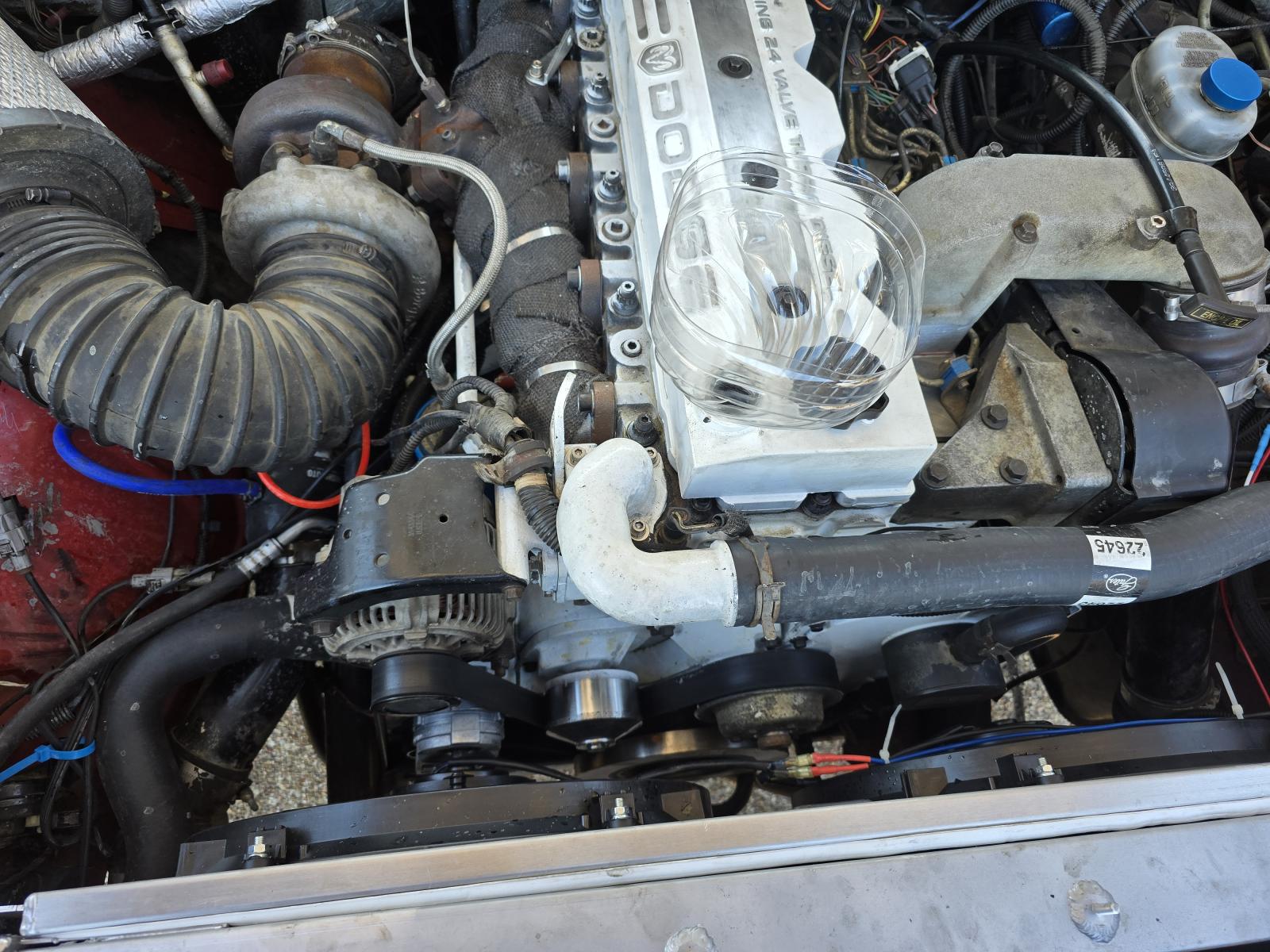

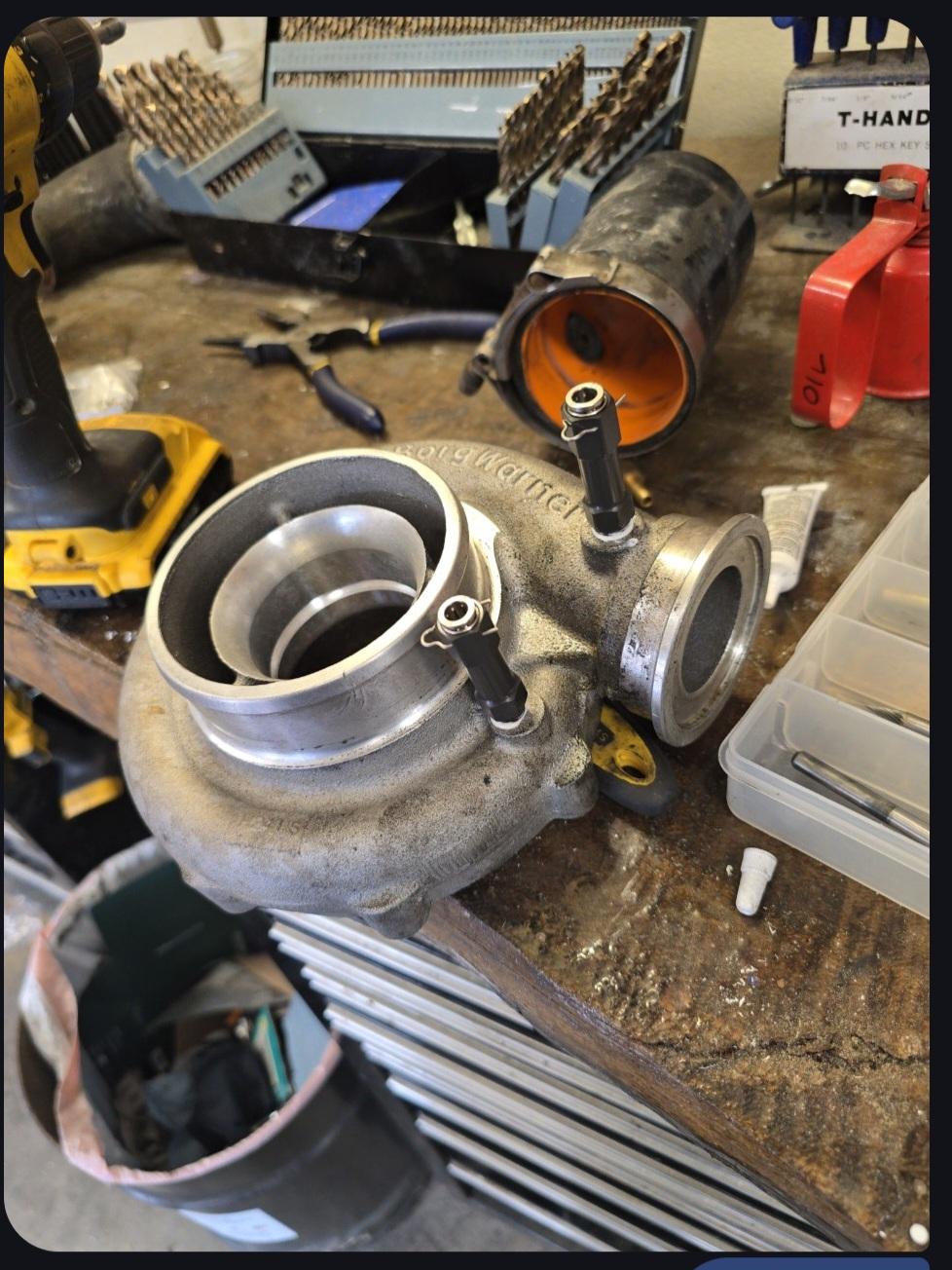

Build is progressing slowly then id like but trying to do it right the first time. Slow transferring all the parts to the new long block but got the turbo drilled tapped for water methanol and gasket

Looking for experience with water methanol. Done a lot of reading on it but haven't seen anyone do what I'm thinking of doing. (Probably because it's not smart for most people)

I would like to try and experiment with running no intercooler and using only water methanol to control temps.

Im hoping this will allow for higher inlet temps at low load and a shorter better flowing intake side netting some better mpgs. Im really curious how the quadzilla will play with water methanol.

According to my math the intercooler removes 3000btu per min at 30 psi of boost. Water removes 970 btu per lbs methanol a little less but flashes at a lower temp. So I should need about 1400ml worth of injection to keep 30 psi cool Im thinking of running 2 stages each 750 ml one at 10 psi one at 20 and drilling and tapping the volute of the turbo for the location. (Should be the hottest part of the system and it gives similar results as running pre turbo without the risk of destroying your impeller. Im hoping to incorporate a section of clear tygon tubing or plastic before the intake horn to see how much is actually flashing to gas. And I'll fab up a intake horn and clock the turbo to run similar to how 1st gens did it. Right over the valve cover. I'm not shure how cylinder distribution will work and might have to center or run dual intake horns to get air flow evenly distributed.

I know slead pullers run crazy pressure (I'm pretty certain pressure washers coupled to a starter motor) but I don't know how much they flow. Is their a saturation limit to how much I can inject? How do I tell when I'm getting close? Hydrolocking is not something I'd like to do lol. What inlet temp is the cummins most happy with?

Old non intercooled first gens made 10-15 psi with no intercooler so I'm curious with a more efficient turbo a better flowing head and quadzilla what's going to happen!

Let me know what yall think and thanks for reading.