Everything posted by VMac822

-

Colt Cams Install

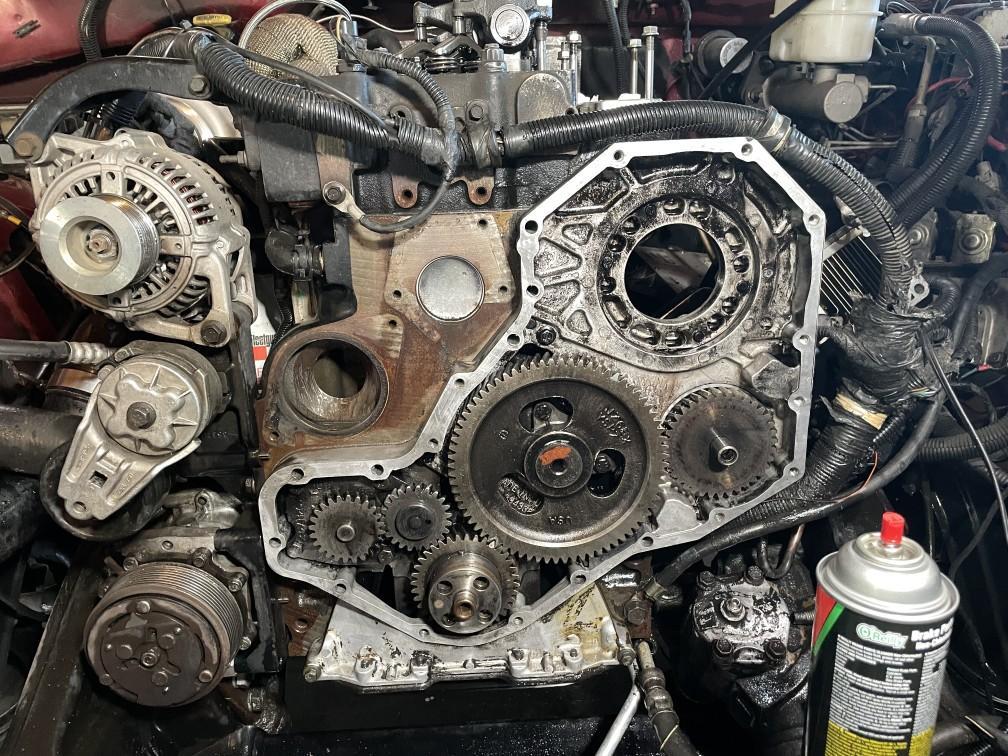

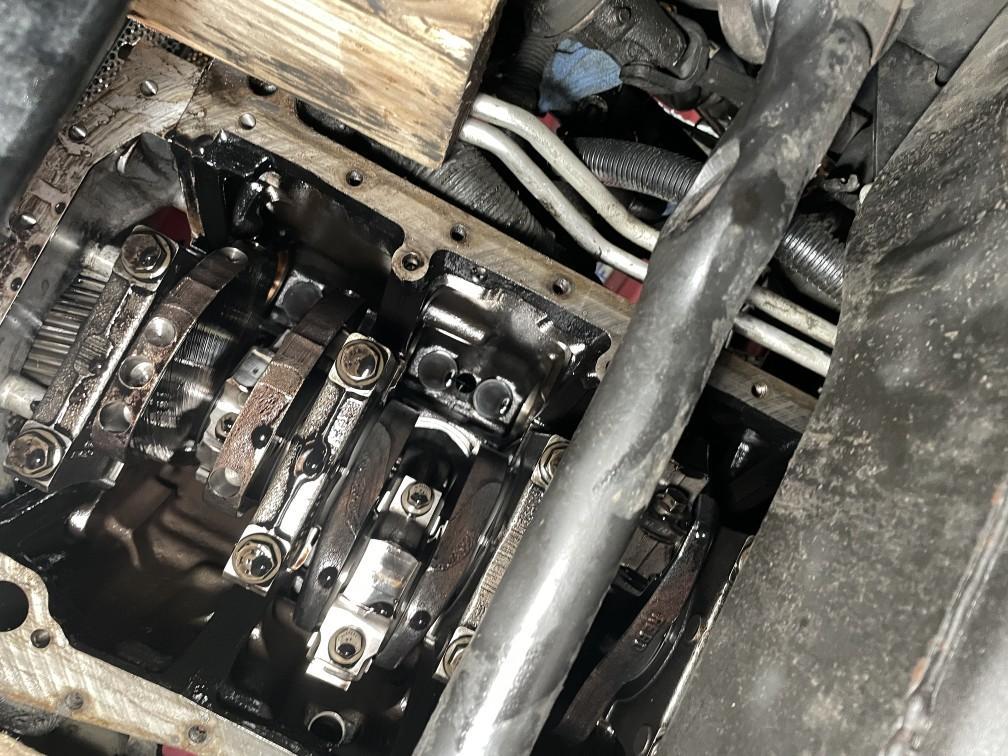

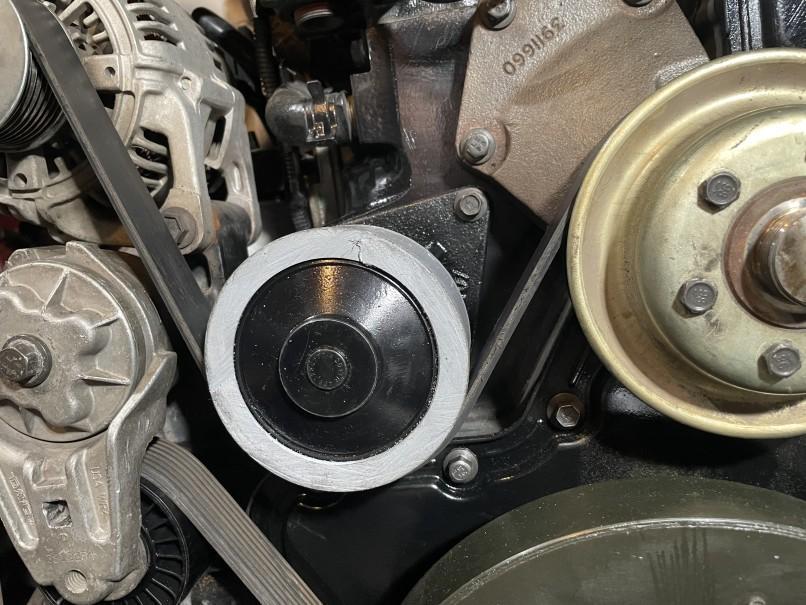

Got started on my Big Stick III install a couple weeks ago. This cam is comparable to Hamilton "tow" cam 178/208. Mine came out of my 96 which I Colt reground. Pulled it at 494,400 miles, but they said it was good to go and gives me the mechanical lobe if I decide to convert to mechanical lift pump. During the project I did a couple things on the side- installed a block stiffener from Cummins, modded the water pump, and threw in a different set of injectors. The block stiffener is one they use on their Tata engines in India (Tata Cummins are a bit of an amalgamation of Cummins parts, built out of 2nd Gen 24V blocks with early CR pistons and VE injection pumps). It is part number 3941556 and around $300 if you shop around. Clipping water pump vanes is a thing these days, because of the pressure they build in the cooling system at high RPM. I blew a heater core once redlining my truck racing someone from a light. Supposedly it reduces stress on the 53 block. But I decided to give it a try. I didn't clip nearly as much off as you see guys doing on YouTube. But I also took a piece of heavy PVC and fit it over the pulley to reduce RPM a little. By calculation, it increased from 3" to 3.5" diameter, pi says that is a 15% reduction in RPM. Don't know if it's worth the effort but figured it wouldn't hurt. When clipping the vanes I set up the water pump in a vise and mounted the grinder so I could ease it into the vanes while turning it by hand. That ensures even grinding. I went with Colt's tappets. They recommended them over refaced 24V tappets or brand X, since they have seen issues going with either route. When it came to replacing the tappets I took a different approach. . .jacked up the engine and pulled the oil pan. It was pretty fun popping out the dowels and hearing the tappets hit the floor, lol. Actually I let them land in a box to prevent damage. Sticking in the new ones was real easy. Overall, this approach was probably more involved, but this is a good alternative for those not interested in fiddling with hooks and strings. I had to loosen the bolts on the motor mounts and remove two trans mount bolts, and then disconnected the downpipe from the turbo. It took close to 4" to gain enough clearance to wrestle the pan in and out. Overall not too difficult. When removing the oil pickup tube you remove 4 bolts, 2 for the connection and two support bolts. I am ready to reinstall the cooling system, intercooler, and bumper. Hope to get it wrapped up by middle of next week. Here's some pics.

-

Long Time Cummins Fan- Tri Cities

Thanks everyone. Been off for a while, busy with foster kids and doing a cam upgrade on my truck. Lot of work for an older guy LOL. I have the Big Stick III installed, now to getting everything buttoned up. Did the first test fire Tuesday, she's sounding good. I replaced the tappets using a different technique. I jacked up the engine and pulled the oil pan. Probably more work than the conventional method, but it was fun to take a look at the bottom end and swapping tappets is super easy that way. And putting in the new cam was really easy, while my son pushed it in I laid under the truck and used a dowel to push up on the end so it could hit the holes on target. Since I had the pan off I went ahead and threw in a block stiffener, Cummins PN 3941556. I thought with a 53 block why not, but I was going more for possibly reducing some noise. It does not tie in the mains, that is a lot more involved since they require studs and align-honing the mains, but the price was right. . .$306 from Source One in Los Angeles. Anyway will create a new post once I get my truck back on the road and give overall impressions. https://s1partscenter.com/brands/cummins/cylinder-block/cylinder-block-stiffener/3941556

-

DIY vp 44 and ECM. It runs, very happy

Hey all, been super busy lately. Yes the starting issue I tried disconnecting the lift pump, but the issue only happens occasionally. So disconnecting the lift pump I wasn't able to repeat it (which could mean that's it, but this issue occurs maybe 5% of the time). I have a Fuelab pump, it does not like the 50% pulse signal at startup so I have it key-on. I have a delay relay I'm going to set to 15 seconds and pop in there soon. The startup behavior is odd. If I begin cranking and it doesn't fire, it will crank and crank and nothing happens. If I shut the key off a moment then try again it usually lights right off. Also, it can sit for days and fire instantly. Other times, I have literally turned shut it off after driving a considerable distance, only to have it crank and crank when starting back up less than 30 seconds later. This problem started about 5 years ago, with my previous lift pump, a Holley, controlled by the ECM. That pump was about 5psi at startup. Anyway back to the idle subject. It was much discussed 20 years ago, why the VP trucks idle fairly high compared to 12V trucks in general and Powerstrokes at the time (around 600 as I recall). To me 800ish has always seemed high. But not a big deal, more of a curiosity more than anything. I am most of the way through a cam swap on my truck. I decided to chicken out on tearing into my PSG, for now. I may pick up a core sometime for cheap and make an attempt at replacing the chip, keep the pump for a backup. We'll see.

-

Long Time Cummins Fan- Tri Cities

Hello all, Vaughn MacKenzie here. Probably know or have met some of you guys over the years. Been on NW Bombers and Turbo Diesel Register for 20+ years. A few years ago something interesting happened. We were in S. Idaho chasing the UP 844 steam engine and stopped to grab a bite to eat at a restaurant. When we were there we spotted a Ram in the lot with a big Mopar1973 window sticker. Hmmm. Sure enough we found out it belonged to the man himself! It was great meeting Michael, we had a really nice visit. I have owned quite a few trucks, all 2nd and 3rd Gen. Let's see, in order: 1998 24V LB CC 4x4 5-speed (1999-2000) 2001 QCSB 4x2 6-speed (new Mar 2000 to 2003) 2003 CCLB 4x2 6-speed (new Mar 2003- 2004) 1996 CCLB 4x4 5-speed (2004-Current, 494K miles) 1998 12V CCSB Auto (2006-2011) 2001 QCSB 4x2 sport Auto (2009-2012) 1998 24V CCSB 4x2 auto (2012-current) 2007 5.9 CCSB 4x2 6-speed (2019-2021) Next month will mark 10 years since I picked up my current truck, which I drive quite a bit. Love the truck and have no plans to part with in. It shares daily driving with my Mercedes. I've done quite a bit to it over the years but the wish list remains very long. Currently have a Smarty on it but I have an Adrenalin in a box that will be going on soon. Next project is the Big Stick 3 cam I have in my garage. Hope to get started on that in a few days!

-

DIY vp 44 and ECM. It runs, very happy

This is so fascinating! Going back to around 2000 guys were wishing someone could "crack the code" on these trucks in hopes of manipulating them better performance. As far as I know you have gotten further than anyone else with this. The starting-up process intrigues me. I have always wished VP trucks could start a little more softly, less aggressive fueling and puff of smoke. For whatever reason the VP pumps seem to totally fall off the table when pulled below idle RPM. May be why VP trucks are the hardest to start in extreme cold. The very early 98.5 5-speed I had in 1999 would die easy letting out the clutch if you didn't give it a little fuel. The reflash they did back then fixed it, by making it fuel far more aggressively. I have wished the idle could be set a little lower on these, 650-700 versus 750-800. More power to you. I am going to be pulling my VP44 off mine fairly soon and attempting to replace the main fail-prone chip in the PSG. I've had intermittent long crank issues for the past 3 years and am suspecting the chip. If it cranks and cranks I just shut the key off then it will fire instantly when I retry it. The VP is a reman of unknown source (previous owner) with about 140,000 miles on it.