Everything posted by VMac822

-

Fuel Level Sender Resistance

Thank you Michael. In the end I may try to crawl under there and take a voltage reading when it's empty next and after a fillup, should be able to get me close to what I need to know. I'm going to call Centroid as well since they've done a few 2nd Gen applications.

-

Fuel Level Sender Resistance

I'm trying to find out what the resistance range is for the fuel level sender in my 98.5. It works okay, but I seriously dislike the typical alinearity. Amazingly it is the original, just under 298,000 miles, but it is dangerously low on fuel by the time it reads 1/8 tank. You will be walking before it hits E. I want to switch over to a capacitive fuel level sensor for greater accuracy and no moving parts. I searched this forum and online and one source says 3.8 ohm full, 103.8 empty, but not sure I trust that. I found for a 2001 it is 20 ohms full, 220 empty. I know there are differences in fuel modules & fuel level senders at least between older and newer 2nd Gens, I think mainly between 12V and 24V, but I'm not sure. My truck is an early 98.5, manufactured February 11 (engine built January 27). Some capacitive senders are spec'd in volts, generally 5V range, but it looks like Dodge used 12V as signal supply. I have to drop the tank to fix a major fuel leak that happens when I top off my tank. So I would like to figure out what to order and have it ready to install at that time. http://www.centroidproducts.com/ https://www.reventec.com/product/ls200-liquid-level-sensor/

-

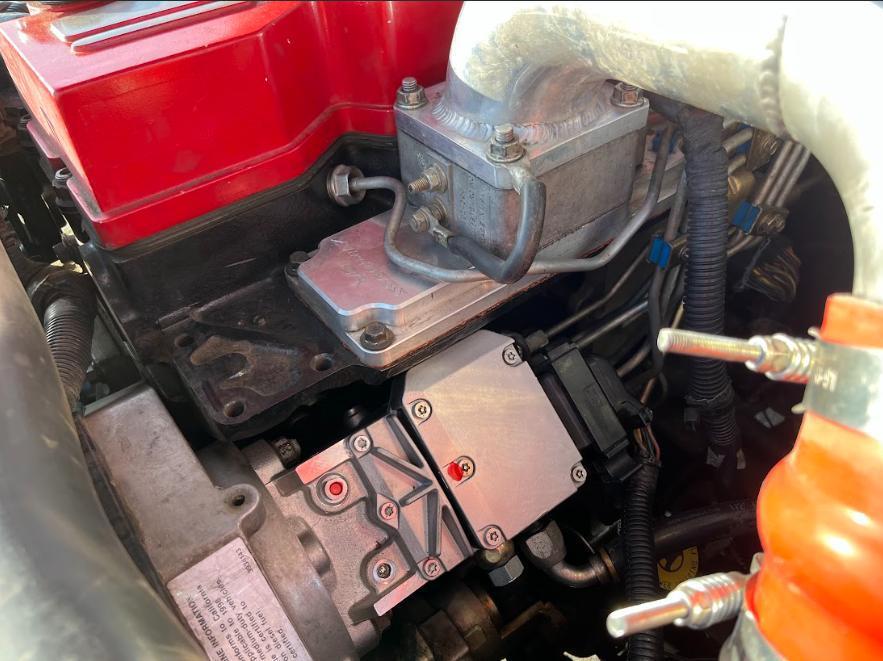

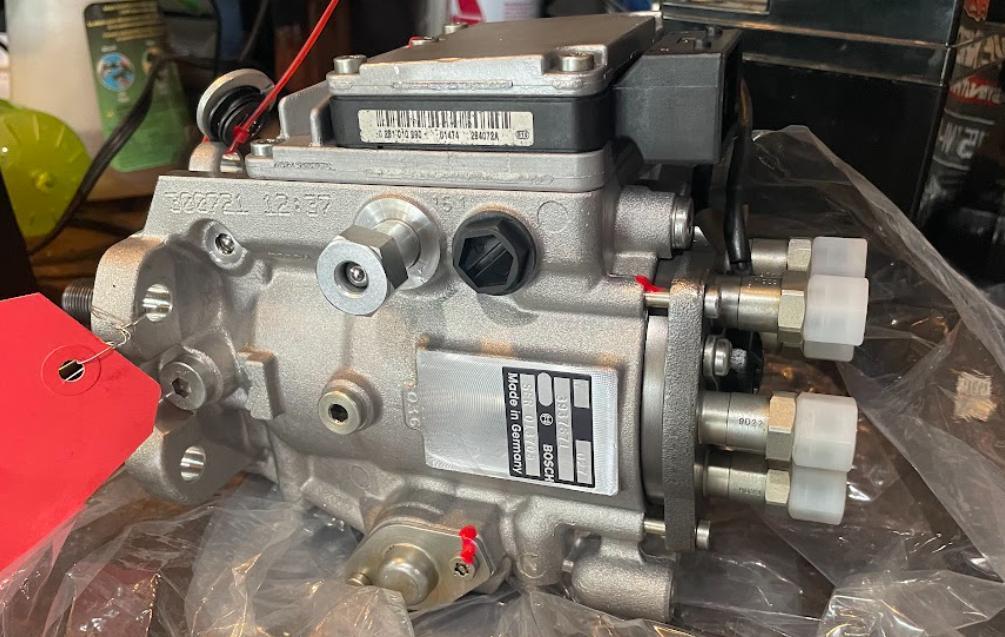

Having my VP44 Rebuilt versus reman/exchange

So I ended up getting a cheap core VP44 and bought an off the shelf rebuilt from Advanced Diesel in Spokane. They said they have the Bosch 815 test stand and they run them in and have a 3 year warranty. I got a 027 pump and they always do the steel liming sleeve, but as far as new computer goes Caroline at Advanced said you have to be careful when a vendor says "new PSG" because some rebuilders supposedly pull out unused but outdated/old generation PSGs. But Advanced doesn't always use a new PSG if it's the latest version and they are reflashed and thoroughly tested. Since they warranty it for 3 years I felt that was acceptable. I got the pump on last week and it's running good. Well to be honest the old pump was fine so it drives pretty much identical to the old but seems to have a bit more low end & midrange. I've put about 200 miles on it so far. It runs and idles smooth.

-

Having my VP44 Rebuilt versus reman/exchange

That helps, thank you Michael. I found a couple of older threads discussing it on this forum as well, and the VP44 teardown thread is a good read.

-

Having my VP44 Rebuilt versus reman/exchange

In looking a little further some rebuilt VP44s are upgraded to steel housings and come with 2 year or 1 year "wire tap" warranty It sounds like most off the shelf rebuilt pumps don't come with the steel housing, I would think it would be worth going for if you want durability and plan to keep the truck for a while. What is a steel housing?

-

Having my VP44 Rebuilt versus reman/exchange

I was wondering if anyone has sent their VP44 out to be refreshed/rebuilt versus doing the typical purchase of a rebuilt unit and sending the old one in as a core. The pump on my truck has basically been running fine for 130K miles even though it was a reman of unknown origin installed by the previous owner in 2011. I thought it would be interesting to have whatever shop rebuild mine and send it back and let me know what it looked like at teardown. . .is my filtration working effectively, does it show signs of low quality fuel, was the timing piston scored, etc. I have been having an odd starting issue intermittently for about 4 yrs/50k miles where sometimes it won't fire when cranking. The solution is to turn the key off and try again, it usually fires instantly. It doesn't matter if it's cold or hot start, if it's sat for days or 10 seconds. I believe my fuel system is sound with Fuelab 100 lift pump and spinon 7 micron filter and consistent 13-18 psi pressure, fed from a Beans under-tank pickup. Other than that the truck runs good and gets good fuel economy. Has anyone done business directly with any of the Bosch certified shops Michael listed in this post?

-

Beast - Misc small repairs

It's a labor of love keeping these older trucks going on the road. When I'm tempted to complain about the long list of maintenance and fixit items I remind myself I'm grateful for a truck that's paid for, I can work on myself, and isn't laden with emissions control equipment. And to top it off, take all the road trips you want because racking up the miles has nil effect depreciation.

-

Final Ratios

On your chart how does it work with the different transmissions? ie Automatics you definitely want smaller tires or go with 4.10s sooner than you would with a NV4500 or NV 5600. I do like bigger tires and I'm right on the cusp of crossing over into the "red zone." I have a G56 (later version) in my short box 4x2 98.5 Ram, 3.54 axle with 275/55R20 tires. Being a lighter truck (scales right at 6000) and lower ride height I think I can get away with it. EGTs are fine, it's snappy on the highway. I have my speedo corrected and show about 2020 RPM at 70 mph I generally get 22 on the highway doing 70-75. I had two tanks right at 24 mpg driving to Wisconsin last fall. Running just under 80 across S. Idaho and Utah netted 21. Running some 75hp injectors Weston Shupe modified and Smarty CO3, as well as Colt Stage 3 cam and exhaust header with ball bearing 63mm turbo. Towing my 24' Airstream Argosy I get 13.5 to 16 mpg. Swapping over to the G56 from the auto sure made it nice for towing!

-

VP44 replaced, Injectors replaced, now P0112

Just to make sure, you used the woodruff key that came with the new VP44?

-

Higher flow exhaust manifolds?

Hey Silverwolf, I missed this before but I can give some feedback on the header. Yes it does change the sound some, smoother for sure. I like it! The main reasons headers didn't gain popularity is the cost versus benefit, plus concerns about durability and killing low end spool. Mine was manufactured around 2009 and I grabbed it used for $700 in 2012. It was made by Polydyn the coating company, and it is well built. The original owner ceramic coated it. He hammered pretty hard on it, raced his truck. Since I put it on it has had a pretty easy life. I've driven around 130k miles. I don't think the header provides much practical improvement over a stock manifold until you're in the 450+ HP range, and at that point I'd say do a steed or similar manifold. I think a header should be beneficial when you get into competition level performance though. Firepunk built a header for a race truck and it competed well. . . t looks a little intense and too many bends IMO. Anyway I have a larger turbo on my truck now, it spools well and the header may even help. I think it's a S363 with 73/80 turbine (14cm housing) dual BB. I have no data to speak of, I've had a lot going on and don't even have gauges in the truck at the moment. But it starts spooling around 1200 and very good daily driver. Now that I have the Colt stage 3 cam it pulls great in the midrange through redline, the cam/header/turbo is a good combo. I have a lot going on but I can't wait to get my Adrenalin installed (likely Spring) and tune it up. I have 75ph generic VCO injectors and Smarty C03. I took a road trip to Wisconsin via Kansas in October. My 2wd short box turned 20-21 MPG rolling in the high 70s, later on driving slower the last 2 tanks headed east were right at 24 mpg. Driving home with headwind and some winter blend it dropped to 20.0 to 21.5. I have a G56 6 speed, 3.54 axle, 275/55R20 tires. Below is the video you may have been looking for, there are 2 that will give you sound clips. I need to do some new ones now that I have the manual trans! I am thinking about redoing my exhaust again. . .make it louder. LOL

-

Pennzoil with TC-3

I haven’t done 2-stroke oil to speak of, I think I’ll give it a try. Do you use it in winter as well even with frigid temperatures?

-

Pennzoil with TC-3

How much two-stroke oil are you guys adding to a tank? I’m guilty of running quite a true gallons of used motor oil through my current truck. Not a lot, maybe 50 gallons over 50,000 miles. When I had to head off there was a little bit of light deposit on the valve faces but very insignificant. There was some on the injector tips too. some caveats: best to do it during warm weather, and long trips. I would generally limit to 2 gallons per tank. Doing it in cold weather and short trips is asking for trouble. And shy away from synthetics and ATF. I run very little used motor oil anymore.

-

Harmonic Balancer

I put one on my 98.5 a few years ago. It made a noticeable difference, smoother at higher RPM. They will last longer than the OEM unit, and quells 1st and 2nd order crank harmonics over a much broader range.

-

New theme for Mopar1973Man

Looking good. I like the changes. Only one minor drop back, reading on my phone with the black background/white text is a bit more difficult. Is there anyway to reveet back to white background?

-

Engine Article - Engine Oil Pan Gasket Replacement

I pulled the pan on my 98.5 this spring when I did a cam upgrade. I wasn't sure if I wanted to fuss with strings and stoppers fishing in new tappets, so I pulled the pan which made it super easy swapping tappets out. After pulling the stock cam it was kind of fun popping the old tappets off the dowels and letting them hit the floor! I then pushed new tappets in place and held them while my kid shoved the dowel sticks in from above. Then slipping the new cam in was easy too, my kid guided it in from the front while I supported the end from underneath and guided it through the cam bores. It's a tossup which method is easier overall, but I think dropping the pan does save some hassle and lets you take a look at the lower end.

-

Traction Bars for short box 2wd

Yes. That cost a few bucks to put together but it turned out great. Was hard giving up the lightweight aluminum one piece but I know it wasn't up for the extra torque. I didn't make any effort to phase the driveshaft, I just threw in a bracket from a 4x4 2nd Gen Ram and bolted it all up and knock on wood it's super smooth on the highway. On the tire pressure subject, I run about 55 front 45 rear. My effort on ride quality was more focused on reducing unsprung weight, versus simply making it "soft." Converting to disk brakes and eliminating overload leafts knocked a lot of weight off the rear axle, and the Dana 70 is quite a bit light than an 80. Makes a pretty noticeable difference. I'm thinking about that. I decided to kind of start at the bottom and see how it did with mostly ATF then go up if needed. I have heard some have issues in cold weather shifting into 1st with 50 weight. Right now I have a mix of 5.5 qt ATF+4, 1 quart Amsoil manual trans lube, and a bottle of Bestline transmission additive. Seems to be pretty happy at the moment and isn't that noisy. For other options was thinking about Royal Purple, Amsoil MTG, but that is spendy stuff. Do you run the Mobil or Valvoline? I hadn't looked at those. Thought about Hotshot's but it's expensive too. I Googled and found Mobil Delvac Transmission Fluid 50, and Valvoline Synchromesh MTF. Both are pretty affordable compared to the likes of RP, Amsoil, and Hotshot's. Not much higher than ATF+4. I'm a little leary of Royal Purple since I've heard of it breaking down badly a couple times in NV5600 transmissions when towing heavy, that was in the early 2000s. But that may have more to do with how the truck was driven versus the oil itself. Do you ever have shifting issues in winter? It seems to be a roll of the dice with G56s, some work great on 50wt and some aren't so happy.

-

2001 Dodge 2500 Heat Exchanger Replacment

Vinster I just switched my truck to manual and will sell you mine for cheap like $50 if you pay shipping. It's not rusty since my truck has always been in a mild climate.

-

Thanks to the forum!

Welcome! You can definitely learn a lot here and have a setup you're really happy with. You could do injectors before turbo if you can live by your gauges and have mild tunes on your Quadzilla. DAP injectors are pretty common, would also recommend Infinite Performance (Weston) if you are shopping. Have fun!

-

Traction Bars for short box 2wd

Tractorman it happens in 1st, 2nd & 3rd when towing, you can feel the driveline vibration from excessive pinion angle. I removed my overloads and one spring from the pack and they have been gone for years, it made a nice improvement in ride quality and I would rather not go back. I have a Valair street dual, it works very well. Mopar1973Man I've had a couple NV4500s and they were good. . . I do skip shift quite a bit when empty, take off in 2nd. Often shift 2-4-5. I drive in town quite a bit and G56 ratios are spot on for town cruising, unlike the constant lugging or revving of the ol 5 speeds. My only gripe on the G56 is it's a bit noisy.

-

Traction Bars for short box 2wd

I recently tossed the automatic and installed a G56 manual in my 98.5 short box. Love the trans but now I have too much axle wrap. My rear springs are on the soft side because I took a leaf out of each side to improve ride and offset it with a pair of coil springs. I have had traction bars before, on this truck and two previous trucks. Each set sucked. The last set I paid something around $700 because they were supposed to be good and beefy, but the heim joints quickly wore and rattled and clunked like mad. . .heims at both ends (bad idea and not quality ones at that). Also it seemed to bind suspension travel, ride quality wasn't that good. On another 2wd truck I installed a used set of Caltracs for a 2500 Ram, but after endless fiddling and adjusting the ride was not that great either. Generally the ride was okay except railroad tracks or large bumps caused the back end to have nasty rebound effect, made the back end of the truck to buck badly. Looking for suggestions or options. The disadvantage of a 2wd is less leverage to combat axle wrap because of not having the spacer blocks. I have thought about a large single bar, mounted to the topside of the pumpkin or a special cover, but there isn't a good spot on a frame crossmember to mount the other end.

-

TC not fully unlocking on 1998.5

So I spent most of the day working on the truck, having all kinds of fun bathing in ATF and fighting with the shifter and kickdown levers, the rod thingy inside with the C clip, wiring connectors and so forth. Installed the new TC lock solenoid and nada. . .did not solve the problem. Didn't help (or hurt) one bit. Any speculation what is going on? Electrical issue? What is happening mechanically? I don't believe it is the TC is locking, I have been driving it like this for a few days and there was no burnt smell or any metal on the pan magnet to speak of. I looked over the wiring at the APPS and reseated it, and checked grounds. Should I remove the Trans relay and see how it acts? As I mentioned, the TC lock/unlock is working normally per programming, the truck acts like the torque converter is running at 95% plus efficiency. Anyone know if it will hurt it to keep driving it? I need to get this figured out soon, because I have a camp trip planned for the coast in a couple weeks. If I need to rebuild the trans I need to make sure it's not an electrical problem outside of the trans, I would hate to rebuild it in a rush only to have the same issue when I put the trans back in. Once my trip is over I can have some down time and get it rebuilt.

-

TC not fully unlocking on 1998.5

Great, thanks guys, will get in touch!

-

TC not fully unlocking on 1998.5

So, after 278,800 miles, my virgin 100% stock automatic has had its first hiccup. A couple days ago when I came to a stop it kept wanting to lurch forward, dragging the engine down. It doesn't kill it but it is lugging. I did some Googling but am not finding anything with the exact symptoms I'm having. I think it's the TC solenoid so I ordered one and will try replacing it. During normal driving the trans essentially operates normally, when the TC locks at its usual time the engine RPM drops, and it unlocks and relocks as I let off and back on the throttle. Basically, everything works normally but it acts like the torque converter suddenly went from 80-whatever percent efficiency to like 95%. It's great to drive and has nice snappy solid shifts when accelerating from a stop. But, I'm sure that's hard on the torque converter. So I parked the truck to avoid possible damage. In my investigation, if I unplug the multi pin cable from the trans and start it, the problem clears. Once I reconnect it and begin driving the it's fine until it locks again, then it is stuck like that until I repeat the cable unplugging process. I drained some of the trans fluid to look at it, it's nice and clear. I need to do some digging but I need to look at doing a proper trans rebuild/upgrade. I want to have mine rebuilt versus swapping in a built trans and using mine as a core. It's survived towing many tens of thousands of miles and handled some power upgrades for 120K miles (100-150hp over stock). Does anyone know a good trans builder in Eastern WA or NE Oregon? Vaughn

-

DIY vp 44 and ECM. It runs, very happy

Thanks for the tip, I’ll pay attention to the WTS light.

-

Colt Cams Install

Dang it!!!!! Just kidding! KDP was rocksolid, could not even move it a nanometer. Smacked it good with a punch to deform The surrounding metal, that should keep it locked in for good. Also snugged up the bolts securing the timing case. They were not loose and I don’t have leaks. Truck has 278,900 miles.