Everything posted by daav544

-

1999 24v cummins changes engine tone while keeping steady speed on highway

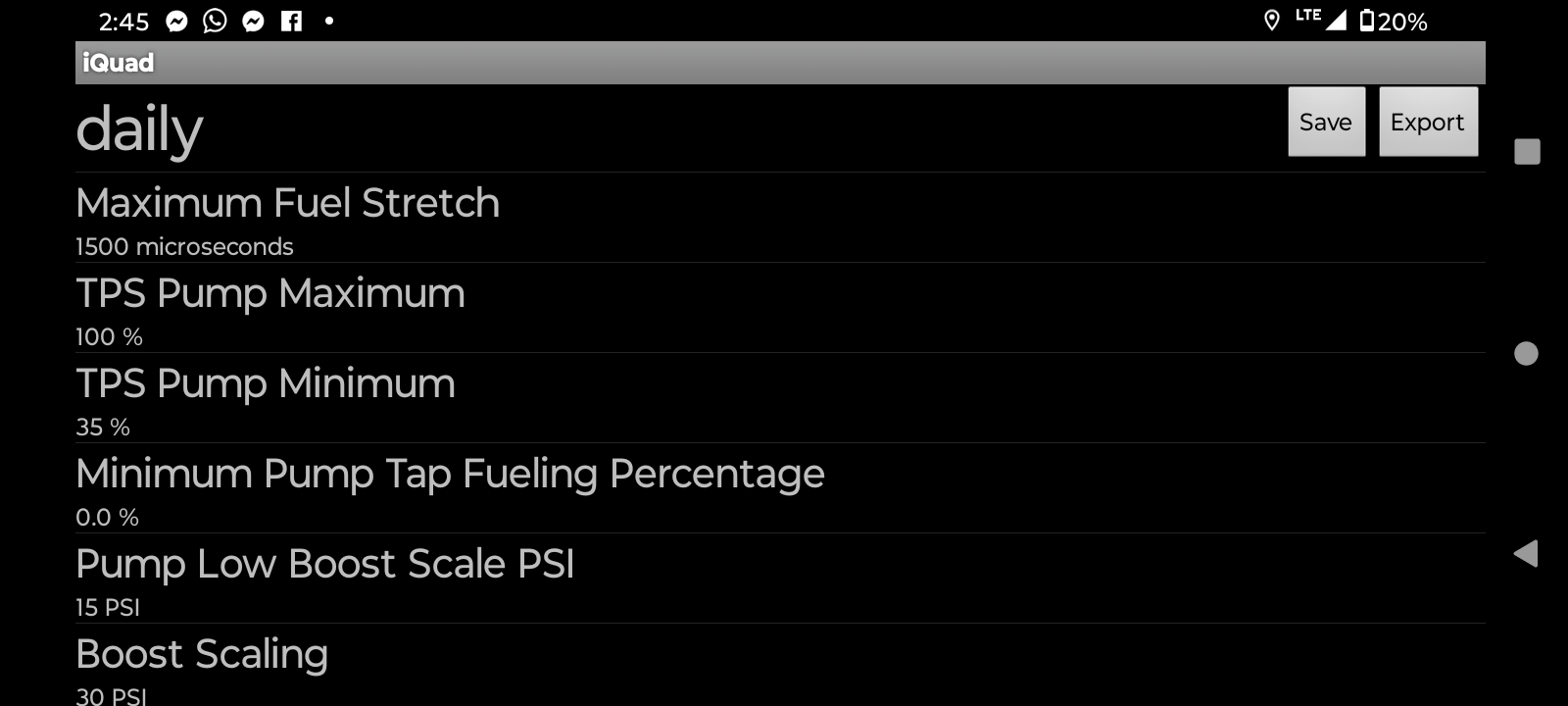

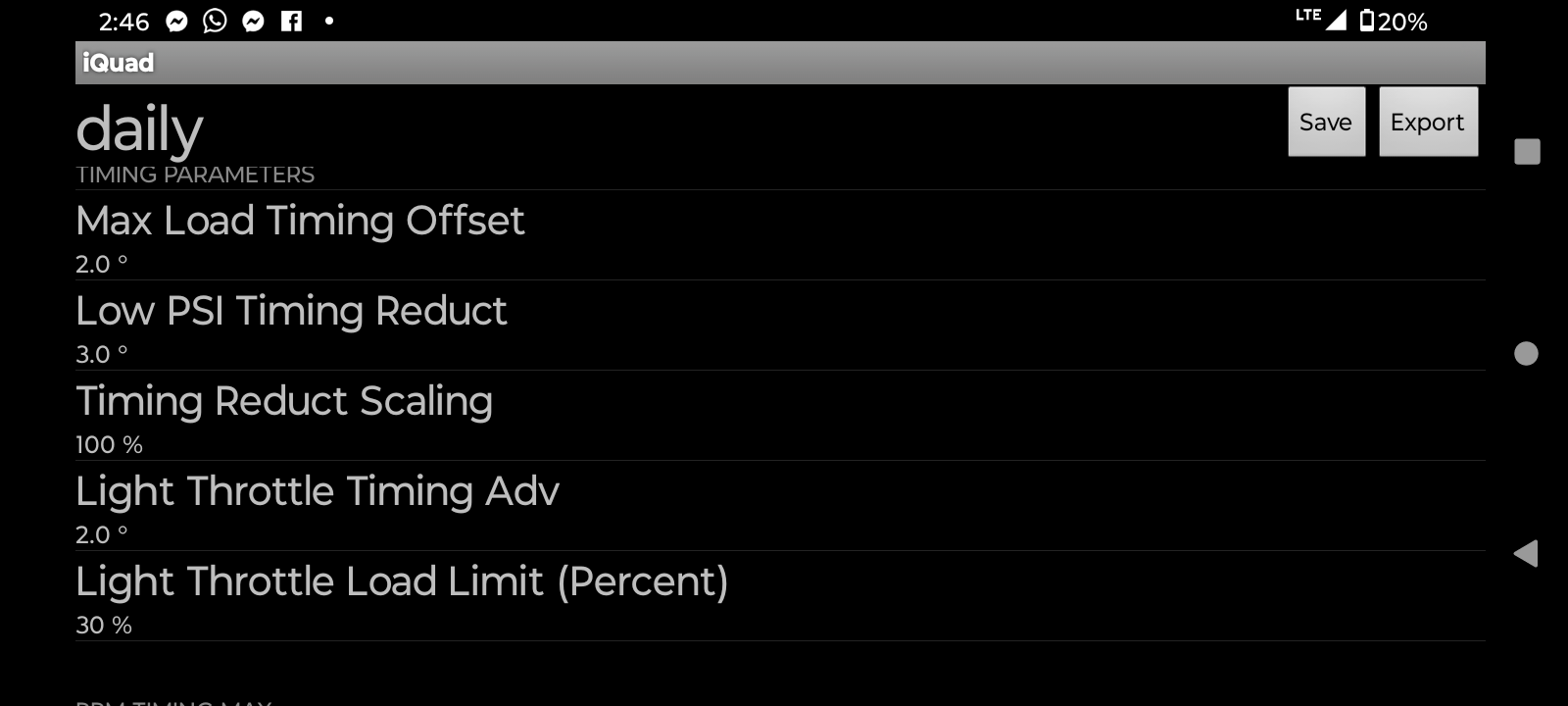

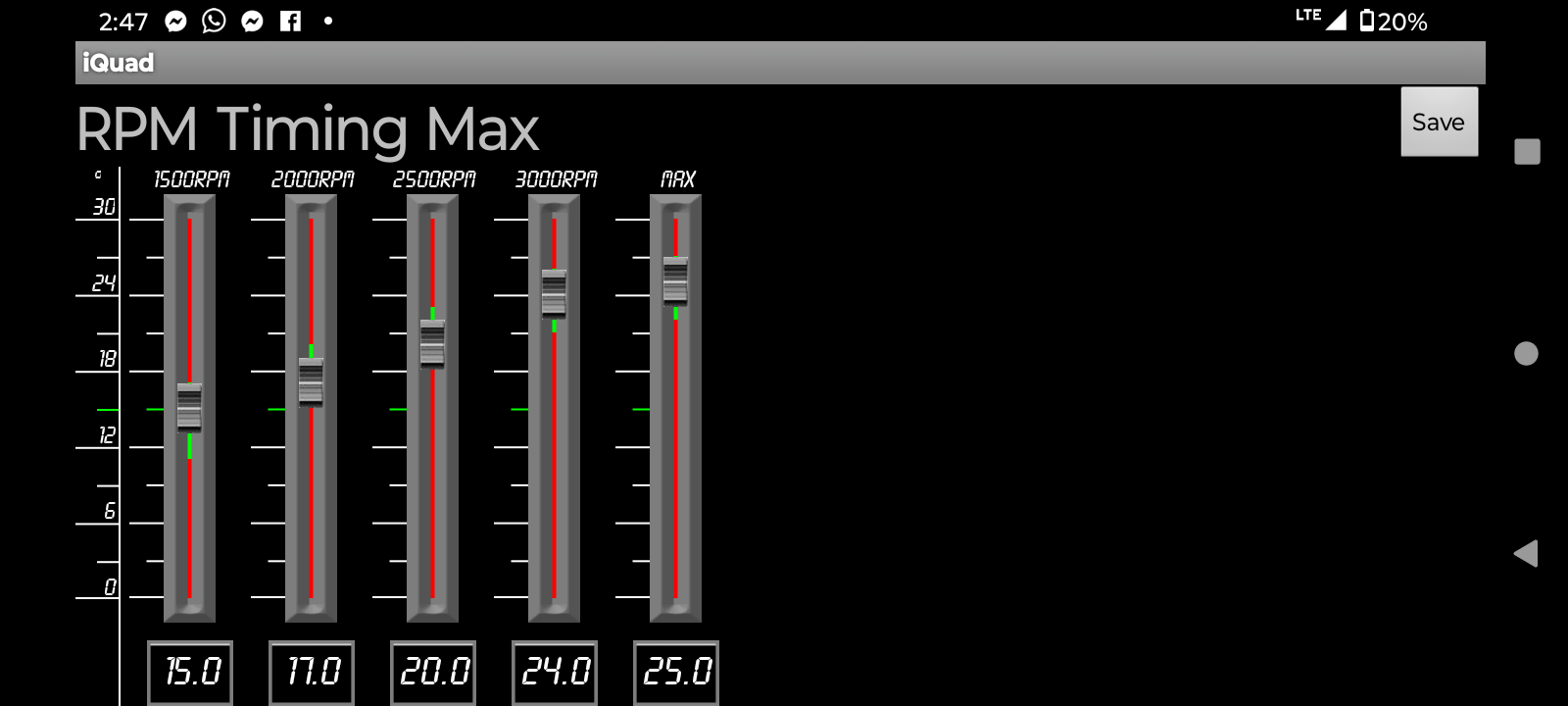

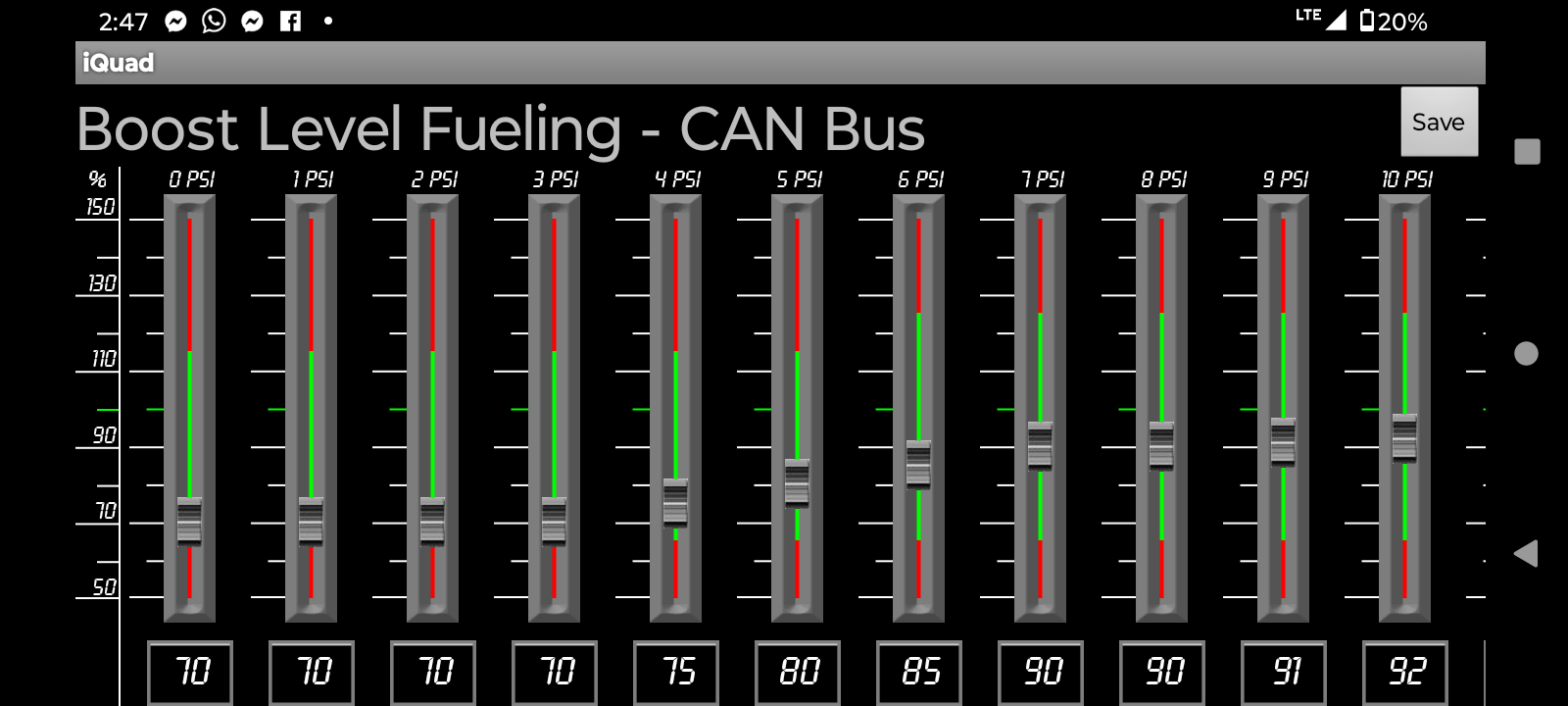

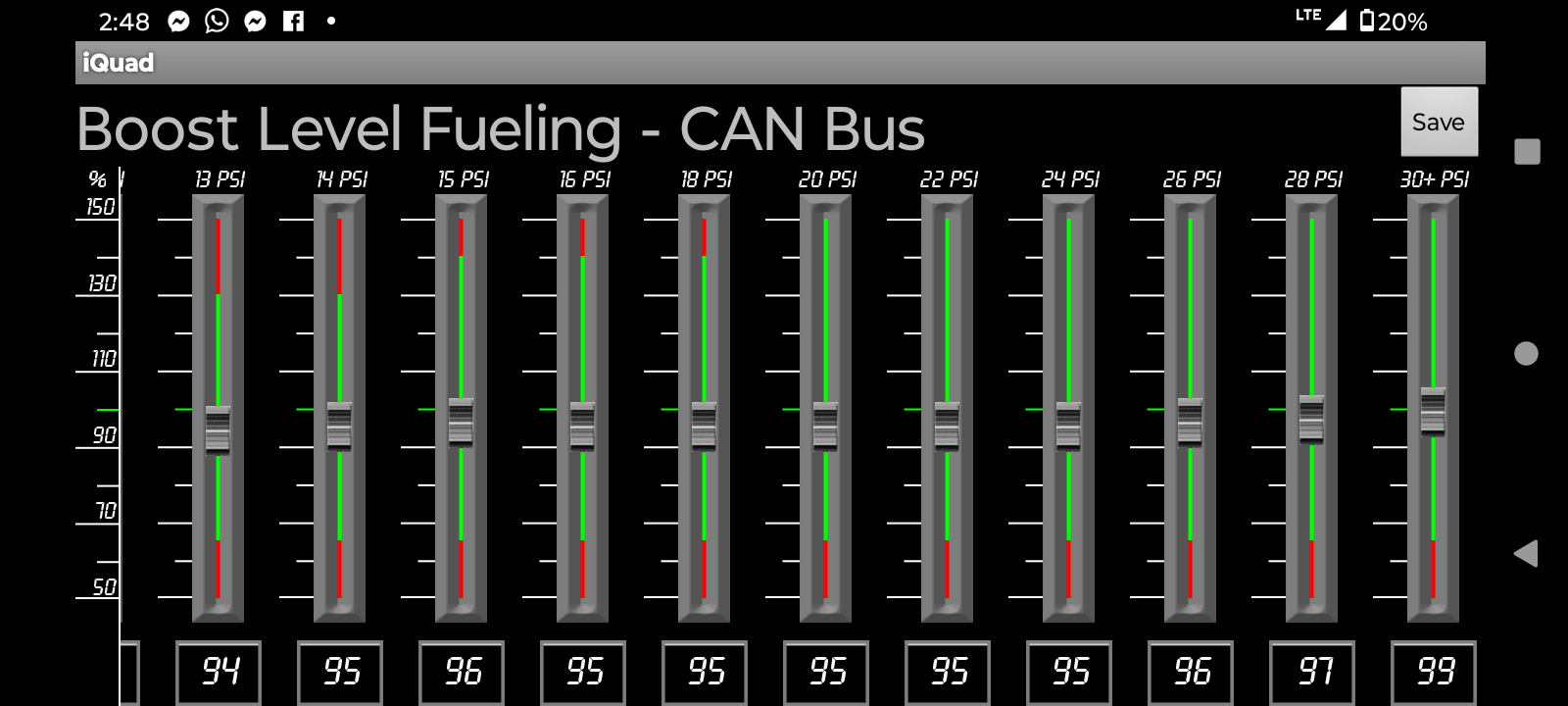

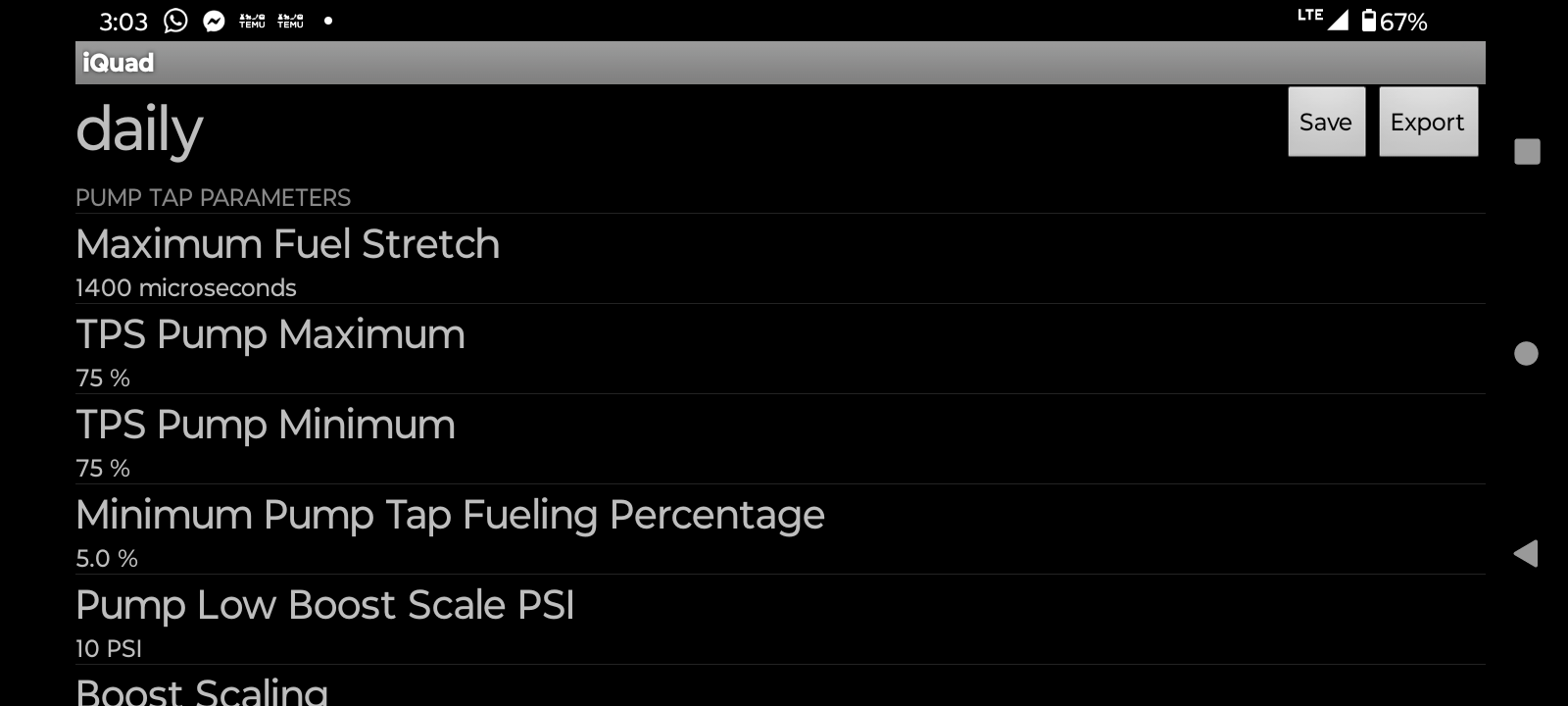

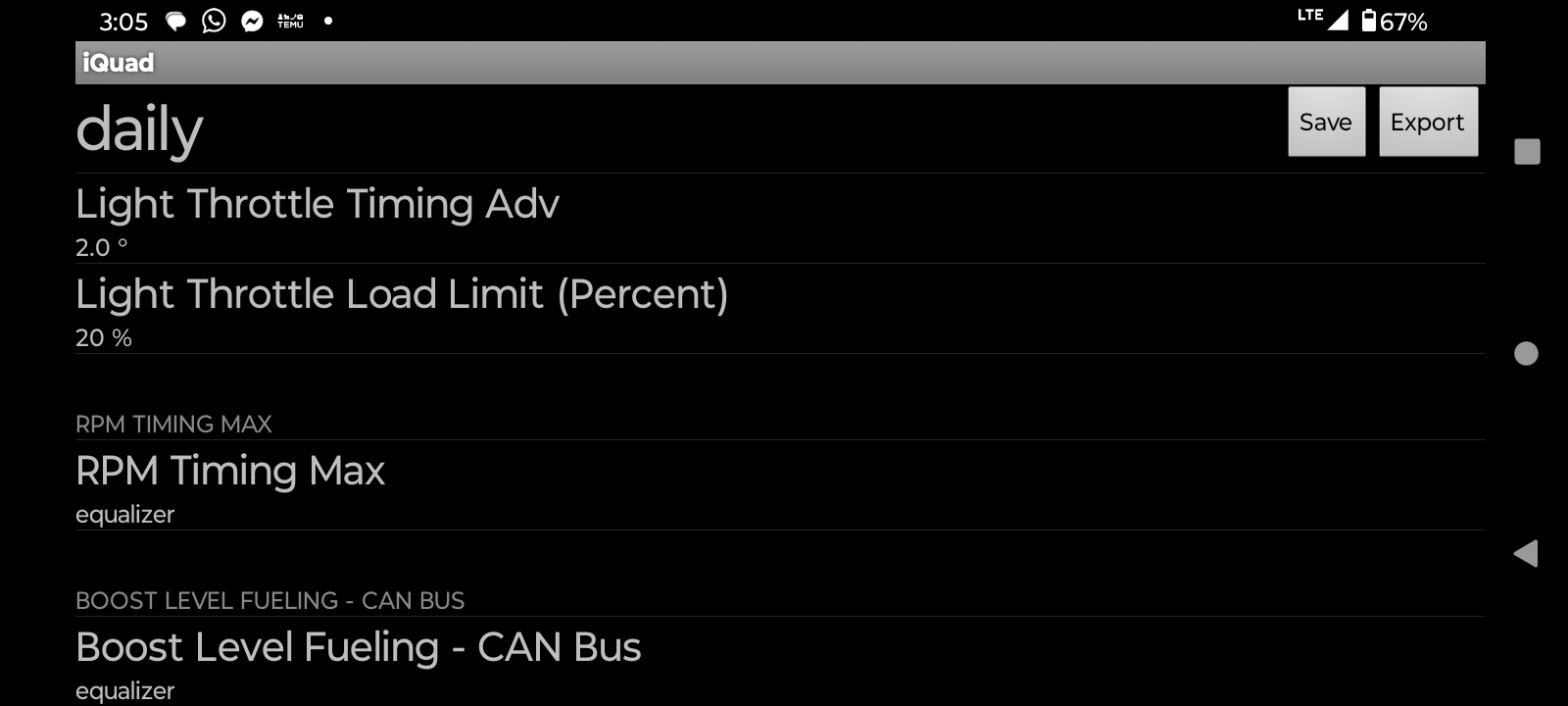

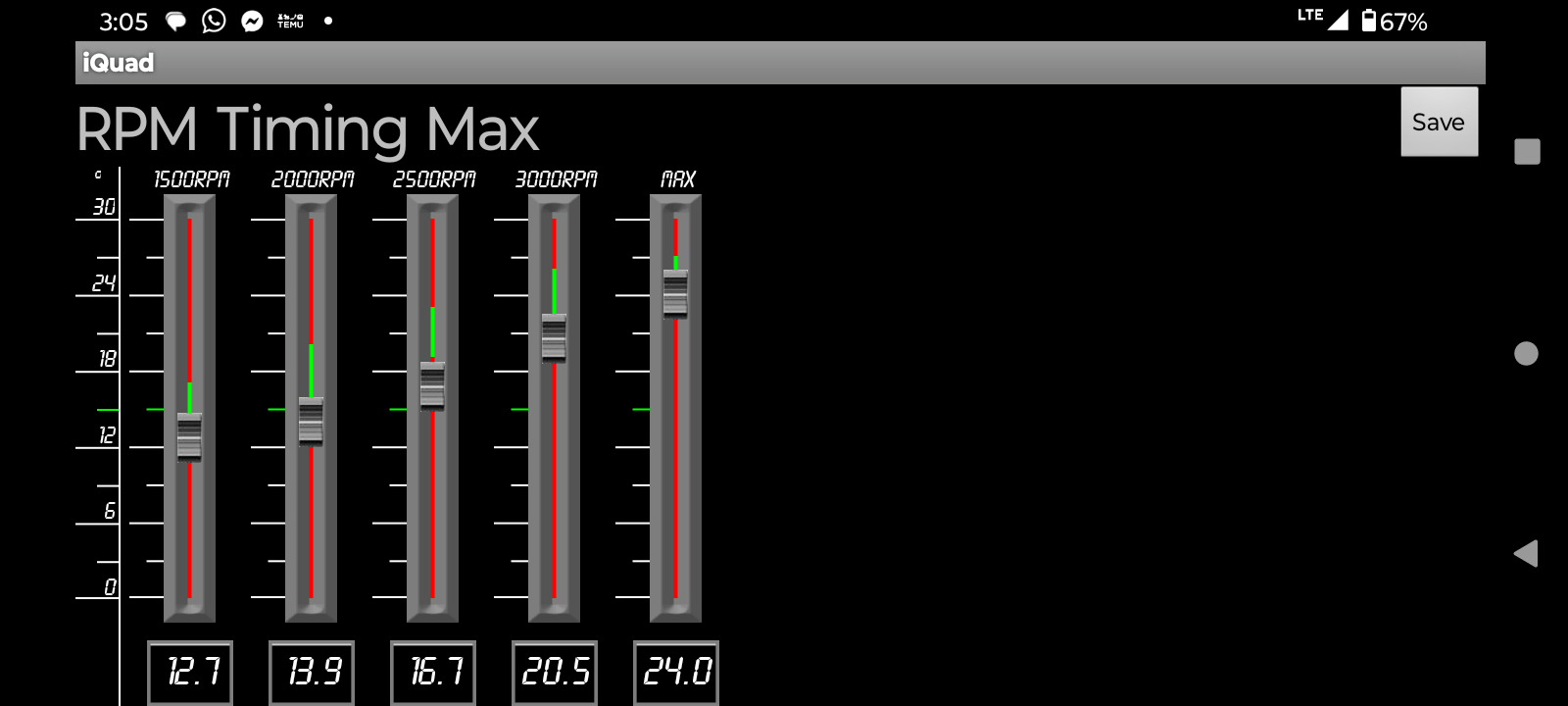

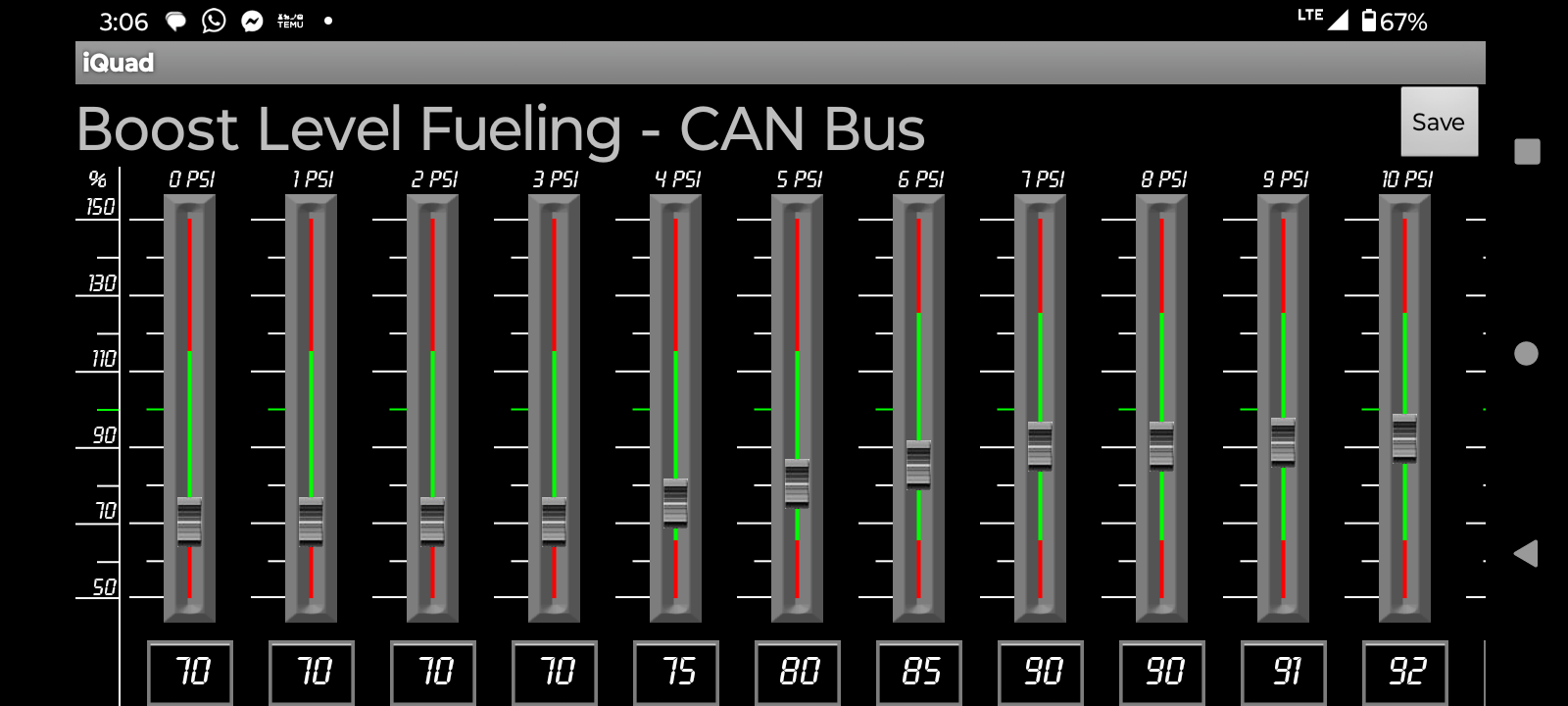

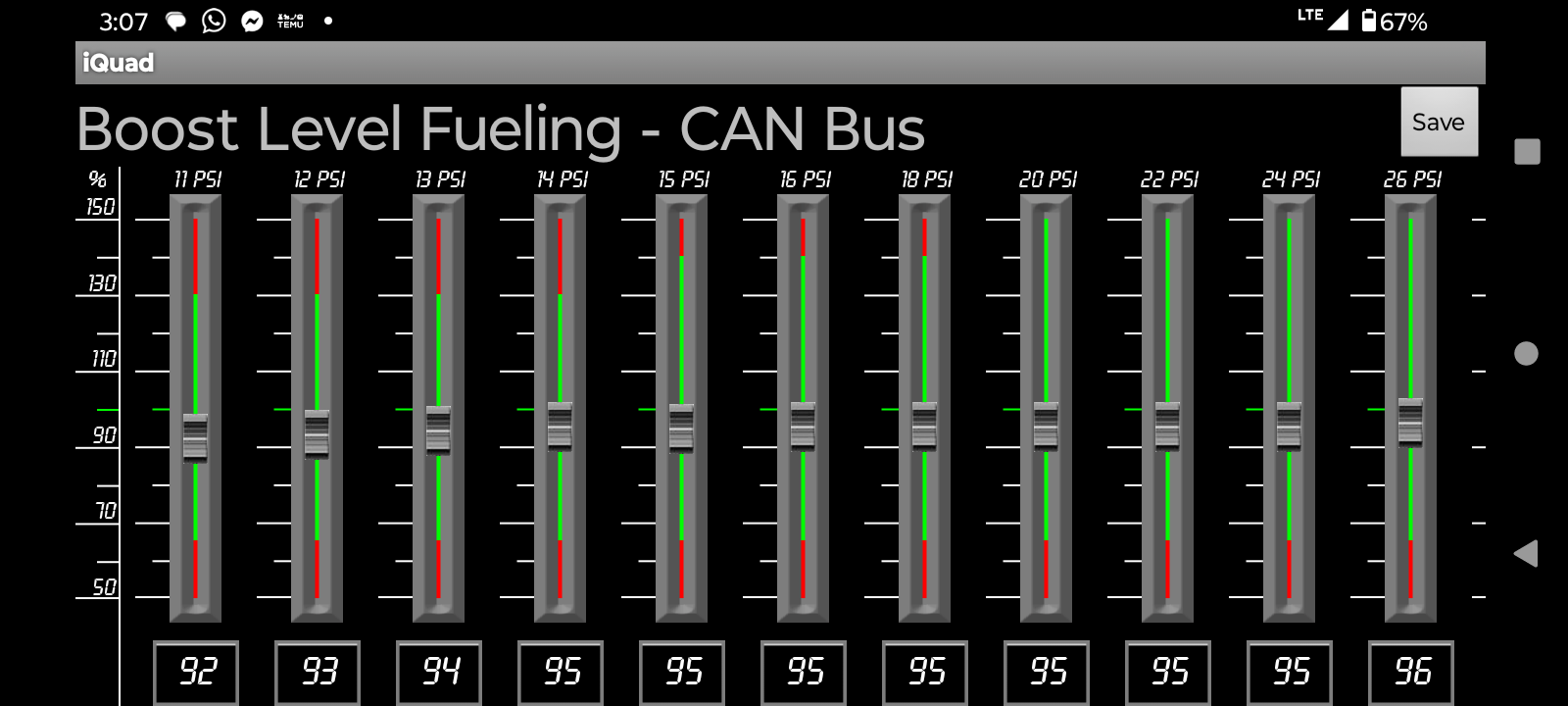

The 75% 75% was supposed to be at 25% 75%, but any way i got some recommendations from some people on a 1badvp44s form on facebook and this is the tune i loaded its not half bad, deffinetly better than the default tunes for the 150s. Still bucks slightly but alot better my valet mode is 80% and it seems to like that aswell defffinetly room for improvement though. I wana get something dialed in thats tame down low, not a ton of smoke up top, and just all around daily/ pull my 4k pound camper

-

1999 24v cummins changes engine tone while keeping steady speed on highway

I found out the part number for the pressure sensor for the quad fuel sensor its a gm sensor lol. Any way i got the 150s in this thing and it hauls the mail and then some but i wana start getting into the custom tuning side im already sick of how much it will smoke and now it likes to buck when i take off from second i use to be able to let the clutch out no gas and take off now i have to give it some pedal so it wont buck. Anyway this is what i did on the custom tuning ill most likely stay on level 0 most of the time but i wanted to see if you think i should change anything to make driveability better with the 150s

-

1999 24v cummins changes engine tone while keeping steady speed on highway

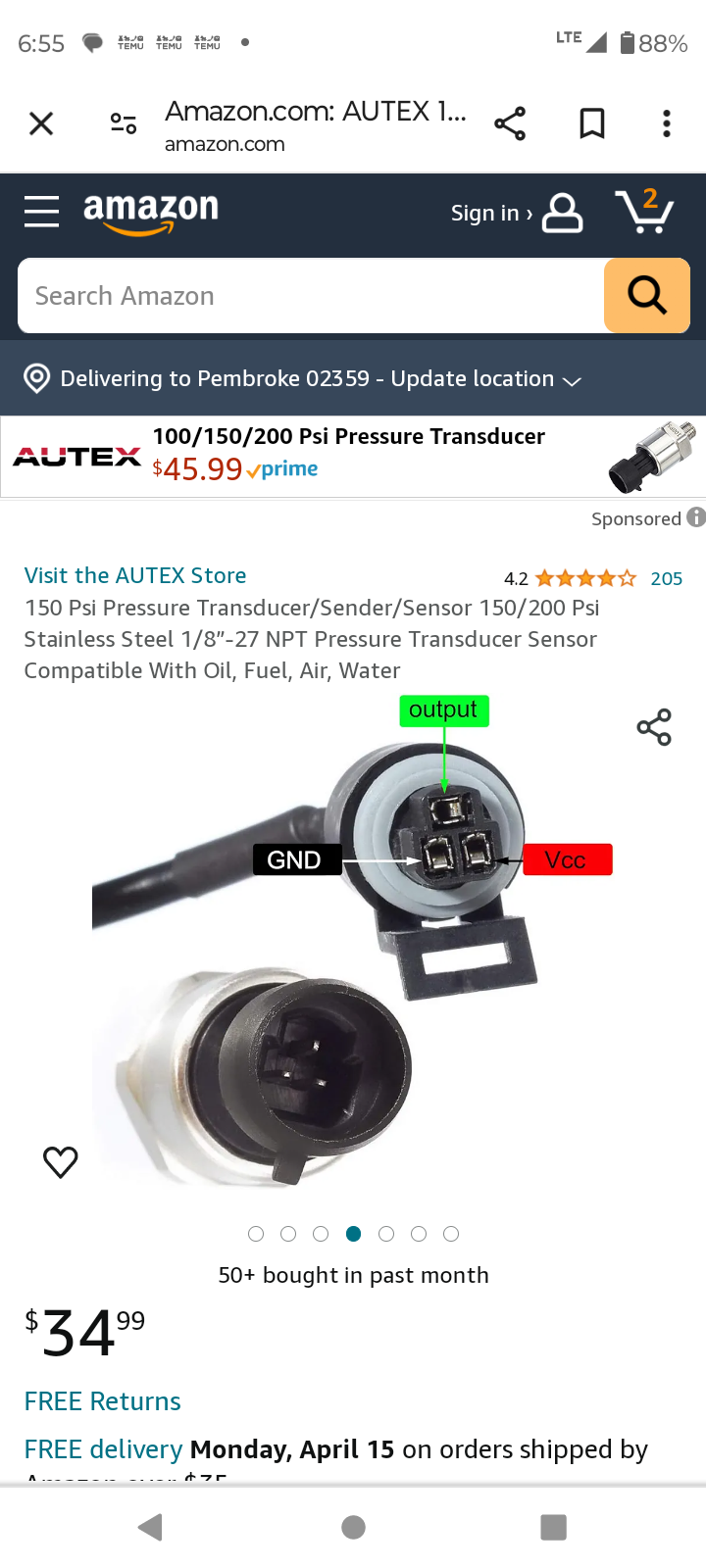

@Mopar1973Man i ended up making one for it found the thread size of the set screw and got an allen head cap screw threw it in a drill and spun it up and grinded a perfect point on it with a flap disk, worked mint. Now im trying to see if i can buy a cheaper fuel pressure sensor than quadzillas. Im trying to find out the pin orientation so i can find one with the same specs, theres so many with the same plug type but not sure on pin orientation

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Never heard of a rod with copper in it like that, i always used the 56% silver **** expensive af though. And @Mopar1973Man so i threw in my 150hp injectors yesterday and boy does this thing run good like a raped ape. Idles at 799-800 rpm and load at idle is 7% anyway when i had the throttle linkage off i notice my pump already has a pump tap cover. Its a bd pump that my buddy who had the truck before me put on. They must put them on from factory theres a small set screw in it. I just need the long pointed set screw, any idea where i could get one?

-

1999 24v cummins changes engine tone while keeping steady speed on highway

@Great work! Ive done the vacuum pump before, it does suck to get off buy i got it done. And thats a great idea for the cover, if i didnt have a gasket ordered i would deffinetly do it that way but now that ill have an actual gasket and not just rvt i should be good. @IBMobile yea brazing would probably be the best bet i have a little lincoln 140 welder i could probably trigger and build up some tacks but brazing would probably be easier. What rod do you use? Like the 50%+ silver stuff used for brazing copper to steel and other dissimilar metals? I went to highschool for hvac so im very familiar with brazing and brazing copper to aluminum, copper to steel ect.

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Lol i try to do things right, i just ordered a gasket so once that comes in ill pull the cover back off(carefully not to damage the new front main seal) and clean it all up again and throw the gasket on with a thin layer of the permatex on both sides and hopefully ill be golden. Then next step wil be the vacuum pump im friggin sick of that god damn thing. Ill have to get genuine cummins gaskets for that. Oh and my god damn power steering resi is rotted a little bit and has a pin hole so ill be welding that friggin thing up too or covering it in jb weld

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Anyone happen to know the pin orientation for the fuel pressure sensor for the adrenaline? I know i should probably just get the adrenaline sensor but im cheap and want to see if this sensor would work. Also the leak is pretty much stopped did see any drips. Next will be the vacuum pump for the second time. I think it might have started leaking prematurely cus i didnt put the stiffener bracket back on that goes from the power steering resi to the block

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Welp seals dry as a bone its the damn cover i must of over tightened it or not let it set up long enough before i tightened i gave it about and hour and a half 2 hours with the grey great stuff. So i cleaned all the oil residue off( it actually slowed leaking from the other day) and then i slathered on some more of the great stuff all over the seam where the cover meets the engine. I even took out 4 bolts on the bottom and pryed the cover a tiny bit so i could smoosh more sealant under the cover. Now im letting it set up. It will probably be a bandaid or it might stop it enough to where i dont give a **** lol. Also next task is vacuum pump seals for the second time in 8 months....

-

1999 24v cummins changes engine tone while keeping steady speed on highway

The groove on my crank was really miniscule nothing id think woulda been a huge deal, and i really dont think i ****** the seal up with how easy it went on with the plastic bottle neck installer. And could it be that i didnt use any loctite on the outer rim? I couldn't see that area leaking a drop evert 15 seconds like it is, its a decent leak. Well ill find out in the next hour or so when i dig into it.

-

1999 24v cummins changes engine tone while keeping steady speed on highway

What do you mean a traditional style seal? And tonight when i get home from work i plan on taking my harmonic balancer off and making sure its the seal that is leaking then i have a mahle sleeveless seal just like the one i already put in the truck and im guna drive it in while the cover is on the truck. Another form im on on facebook people are saying the seals go in from the back which i tried at first but it wanted to cockeye alot easier than from the front i ended up driving it in from the front fairly easy. So ill take the plastic bottle neck tool thats for slipping the seal over the crank and ill get the seal on the crank then drive it in like i did the first time and hopefully the seal will sit on a better part of the crank i think my first one ended up in the same spot as the one i replaced landing it in the groove

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Ok cool ill double check its the seal, and i think i just happened to bang the seal into the same exact spot as the old one so its sitting in the slight little groove my crank has. I have plenty of room behind the seal to tap it in a little more do you think thats worth a shot? Also i have plenty of room infront of the seal for a second seal. Ive read of guys running 2 seals and having success im thinking of slipping on a second seal and tapping it in while the cover is on the truck i really dont wana pull it apart if i dont have to. And im damn near positive that i didnt mess up the first seal i used the plastic install tool and it slipped right on like butter and the plastic piece came out with little effort

-

1999 24v cummins changes engine tone while keeping steady speed on highway

I know for sure i didnt tear the seal lip i used the supplied plastic install tool it slipped right on easy peasy. I installed it dry and i used permatex great stuff grey gasket maker on the cover used a generous amount but not a crazy amount l, installed cover and put bolts in hand tight and let it set up for over an hour and a half before tightening the cover down. Can i start the truck with the harmonic balancer off for just a minute or 2 to verify its the seal and not the cover leaking?

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Havnt noticed it yet, but also havnt had à long enough stretch on the highway to cruise at 80 for a while but for the couple minuets i did keep steady speed it kept the same klunky tone the whole time wish i could figure out how to get it to have that smooth tone, it really quiets things down in the cab a bit. And @Tractorman idk if it was ptfe but said install dry so i did. Ive heard of people installing 2 seals one in front of the other so atleast one seal will be out of the groove. Also i read that the majority of the wear sleeves are used with stock size seals. And the cummins brand ones have a larger sleeve? So i ordered an aftermarket seal with a sleeve that im guna take the sleeve from and use the plastic install thingy and slip the plastic under the seal thats installed on my truck already then press the wear sleeve on so it slips under the seal. Decent plan? I really do not wana have to do it all over again so id like to try that before tearing it all apart again

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Oh and i forgot to tell @Doubletrouble with the adrenaline hooked up the engine load at idle is right at 5%

-

1999 24v cummins changes engine tone while keeping steady speed on highway

@Mopar1973Man adrenalines hooked up and working great, dont have the pump tapped yet. But any way i did a front main seal today and the mfer is leaking i should have gotten one with a wear sleeve but any way i had seen a video on installing a front main and the guy said to hit the seal in a little deeper to get it out of the groove , have you heard of this? Should i try that first before ripping everything back apart And or do you think id be able to slip a sleeve in the existing seal? Im hoping i could do that i really do not wana do this all over again

-

1999 24v cummins changes engine tone while keeping steady speed on highway

I stuffed a tiny bit of wire into the pin just to see if it would make a difference and ease my mind that its just the plug and thats all it was, ill deffinetly have to keep an eye out on future plugs for that. Easy to miss and start chasing ghosts

-

1999 24v cummins changes engine tone while keeping steady speed on highway

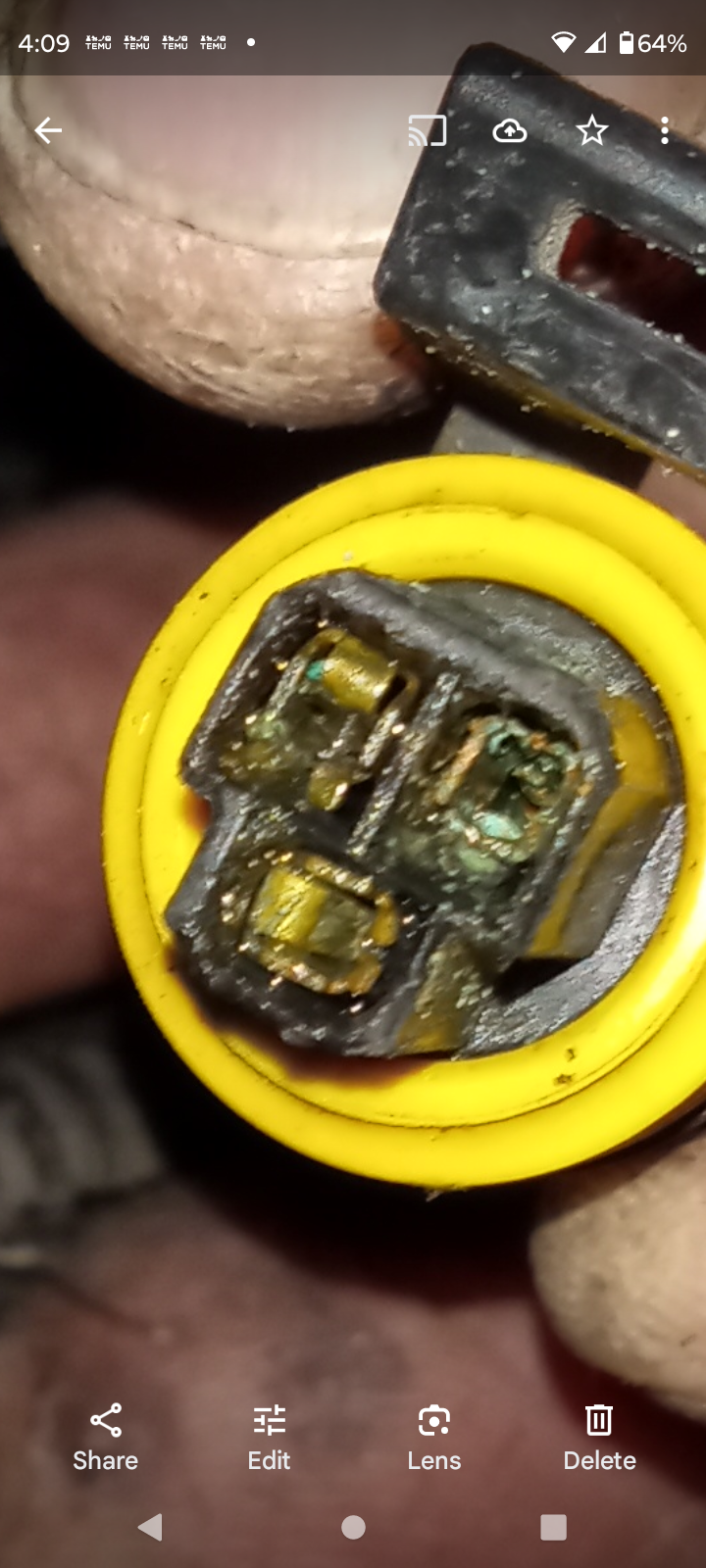

Yea i ordered a plug from orileys it will be here tomorrow, lucky i got a good eye for **** like that or id have thrown a map sensor in it and been pulling my hair out @Mopar1973Man you think thats deffinetly the issue? Thats the 5v supply pin so id deffinetly assume it would frick things up. My scan tool would only read 29 in/hg which is 14psi it wouldnt move from that reading. I belive it reads 14psi being thats atmospheric pressure so really would be zero

-

1999 24v cummins changes engine tone while keeping steady speed on highway

@Mopar1973Man pretty sure i found my map sensor issue if you look close one of the pin tabs broke off my truck connector plus its filthy

-

1999 24v cummins changes engine tone while keeping steady speed on highway

@Mopar1973Man so i hooked up the adrenaline, everything aside from fuel pressure, Oil pressure, and the pump tap, i put the truck on the default v2 tunes on level 3 (can bus only) and the truck ran like a dog didnt feel like it was building any boost so i disconnected it cus i didnt want to harm anything. Now the truck every so often feels like it wont make any boost then all of a sudden kicks in and will take off like normal. Im assuming this is a map sensor issue or map plug issue, any ideas?

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Yea i thought 250 was a great deal especially with only like 5-6k miles on them. Cant wait to feel this thing really make some power, whats you guys out look on head bolts or studs for the power level ill be at(stock turbo mind you) i saw a video power driven diesel made about these affordable head bolts i forget the brand but they seemed like a good option for my rig . And whats your opinion on doing them one at a time and what would be the best way to do them one at a time like follow the regular head boly torque sequence and just change one stud at a time?

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Yea i seen those collar fittings. To be honest though i might just pull the trigger on some 150hp injectors, the dude that sold me the adrenaline has some used DAP injectors with only 4000 miles on them, hes going larger cus hes got compounds and has a set of 200hp ones waiting to go in. I can probabily get them for like 250 bucks and with the adrenaline you can set the percentage of injector you want to be used (idk the actual terminology for that setting on the tuner) but i saw you van dial back larget injectors incase you have a stock turbo and dont wana just smoke out each intersection

-

1999 24v cummins changes engine tone while keeping steady speed on highway

So one of those little diesel injector testors would suffice for doing the pop pressure test like the one pictured? And i most certainly will make a little write up on it. Would just be easier for me to do it and be able to have my truck back and running that day, plus you know the saying if you want it done right you gota do it yourself sometimes lol

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Would it be possible for me to do a pop pressure test with one of those table top diesel injector testers that are a couple hundred bucks? And can these be rebuilt and i throw a set of 100hp nozzels on them, im pretty mechanically inclined i rebuild that 6.7 soip to nuts myself at the last company i worked for when it needed injectors and dropped an injector tip cus my boss wouldnt listen to me when i said it needed them, also rebuilt an allison 1000 myself. If its possible on one of those table top machines id like to go that route and get it done in a day as this trucks my daily and i couldn't have it down for more than a day or 2 borrowing my g mas car or something

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Jesus im gone for a few hours and the whole thread blows up, but to awnser on my injector life i dont think they have that many miles on them, the truck fires so fast hot or cold, even when my grid heater was not working(which i fixed) at like 10 degrees out the thing barely cranked at all fires immediately then sounded like a bag of bolts cus the lack of a grid heater. And ive always kept good filters and ran good injector cleaners either hotshots or motul. And to awnser on the scanner question it says calculated load value and on every vehical ive ever used it on even a 2011 cummins with brand new industrial injection injectors it would say 0% at idle i dont think its very accurate on the true load value being at idle and not moving the shitty scanner probabily thinks theres no load cus its not moving, i could have a family friend of mine plug it in with their snap on or autel scanner. And how come 815 rpm is high? And how are quadzillas injectors i saw a set of 75hp injectors from them for like 7 or 800 bucks, i was surprised at how cheap they were are 24v injectors alot cheaper than 6.7 injectors, the set we got for the 2011 work truck were like over 3grand

-

1999 24v cummins changes engine tone while keeping steady speed on highway

The one i got links by bluetooth and the guy said it was updated to v2 so it was probabily the older one at one point but with the iquad i can see everything on my phone and tune it right?, and i plugged in my scanner and truck idles at 815-820rpm i didnt see any fluctuations higher than 825 it stayed right around 815-820 majority of the time. The load i dont think is true every vehical ive ever had it on at idle was 0% it says "calculated load value" and while driving it didnt give the best readings fluctuating weirdly and glitching almost its not the best scanner its a OBDlink MX+ I saw this guy got a flip out pioneer radio and was able to link his iquad to it ill probabily end up doing something like that I didn't even realize that there was an iquad and iquad plus lol i just read that the iquad plus will work with any adrenaline module. Its like 200 bucks so maybe ill just end up getting that instead of the radio. Either way atleast ill be in the adrenaline family now and be able to monitor and change things. The guy i got it from did say it had the v2 software