Everything posted by JHFIII

-

Head Stud Install Question

The 1/2 turn was just how much to back the stud out once you bottom it in the block before you put the nuts on. The purpose of the mark on the stud was to keep track of how far the stud turned back towards bottoming once you started torquing the nuts.

-

Head Stud Install Question

I just did mine. As others have said, its a one at a time type deal. I used the glacier diesel method which is kind of a pain in the butt, but I do feel a little bit more secure about the install. Pro tip...grab a crosscheck paint marker so you and put a line on your stud and the nut so you can watch that your 1/4 to1/2 turn back off of the stud doesn't shift too much on you, and you can one on the nut to keep an eye on those.

-

Odyssey of the bucking and surging

I ended up sending out the email to Auto Computer Specialists (where the reman originally came from). Below are all the faults they found. I have no idea how it even drove at all. Releived they found the problems because I was tearing my hair out, but this was a unit that was about a year and a half old with maybe 40mi worth of driving. Strange thing as well was I had 5 volt ref, all gauges working, as well as proper lift pump circuit function. OUR FINDINGS: No Communication to Lift Pump, Lift Pump and APP Circuit in Short, No 5 Volt Reference, No 9.5 Volts and Lose CPU! REPAIRS PERFORMED: · Replaced Lift Pump Circuit · Replaced Flash Chip · Resoldered CPU · Replaced APP Circuit · Replaced 5 Volt Driver · Replaced 9.5 Volt Driver

-

Odyssey of the bucking and surging

Thats the conclusion that I'm reluctantly coming to as well. Im thinking the ECM the more likely culprit just because the vp is a DAP unit with new PSG. Obviously new parts can be bad though. Looks like I'll have to pop the reman ECM off and send it over to Auto Computer Specialist. As luck would have it, its just past warranty. No, I technically have not. When I did the ecm repair it was September last year. I was preparing to move across country, so I just installed it and idled and ran ok just riding around the neighborhood so I turned my attention away from the truck. For the record, the vp wasn't changed out of necessity, I just had an hrvp44 in it that had a lopey idle which I hated. Before the oem ecm went out, I never had a lick of trouble out of the truck.

-

Odyssey of the bucking and surging

What I dont get is, obviously thats a problem, but is it THE problem since it was misbehaving with the Quad can unplugged? Wouldnt it just default to stock timing?

-

Odyssey of the bucking and surging

Well, no joy so far. I unplugged the CAN cable from the quadzilla and its still doing the same thing. Worse tonight actually. Always nice when it acts up right by your house instead of 2 miles down the road. Surging under even very little throttle and at idle tonight. The one thing I did notice is that the thing at idle seems very high. It was 16.5-17deg at idle. I dont know if this makes any difference but when I did my short test drive tonight, I did have the quad on, pl0, with the can unplugged. Hers a vid of it struggling for idle. This is after I plugged the CAN connector back in so I could get some data logs.

-

Odyssey of the bucking and surging

Interesting...I havent noticed any funky behavior on the iquad, but that doesn't mean anything. Btw, I have the power and ground set up like you suggested. Actually, after the wt mod, I made a copper bus bar from the pdc b+ to the unused stud, so now I've got two. The ground is run to a blue seas common ground bar on the fender which is referenced to the body and b-.

-

Odyssey of the bucking and surging

Will do. I'll report back. I have no idea what firmware version the unit has right now. I bought it about a year and a half ago. Might have to give that a shot as well

-

Odyssey of the bucking and surging

Here is a video of how its behaving. This is just driving in my field in circles at 20mph, so in this instance it's at a lower speed than the original post, but it will for certain do this on the road, but rarely driving slowly. Sorry about the angle. https://youtu.be/Zc4xUhwguho

-

Odyssey of the bucking and surging

I just have the out of the box tune on it. I havent done any custom tuning at all yet. How can I tell what the stock v2 timing is set at? I couldn't find anywhere in the app with that info.

-

Odyssey of the bucking and surging

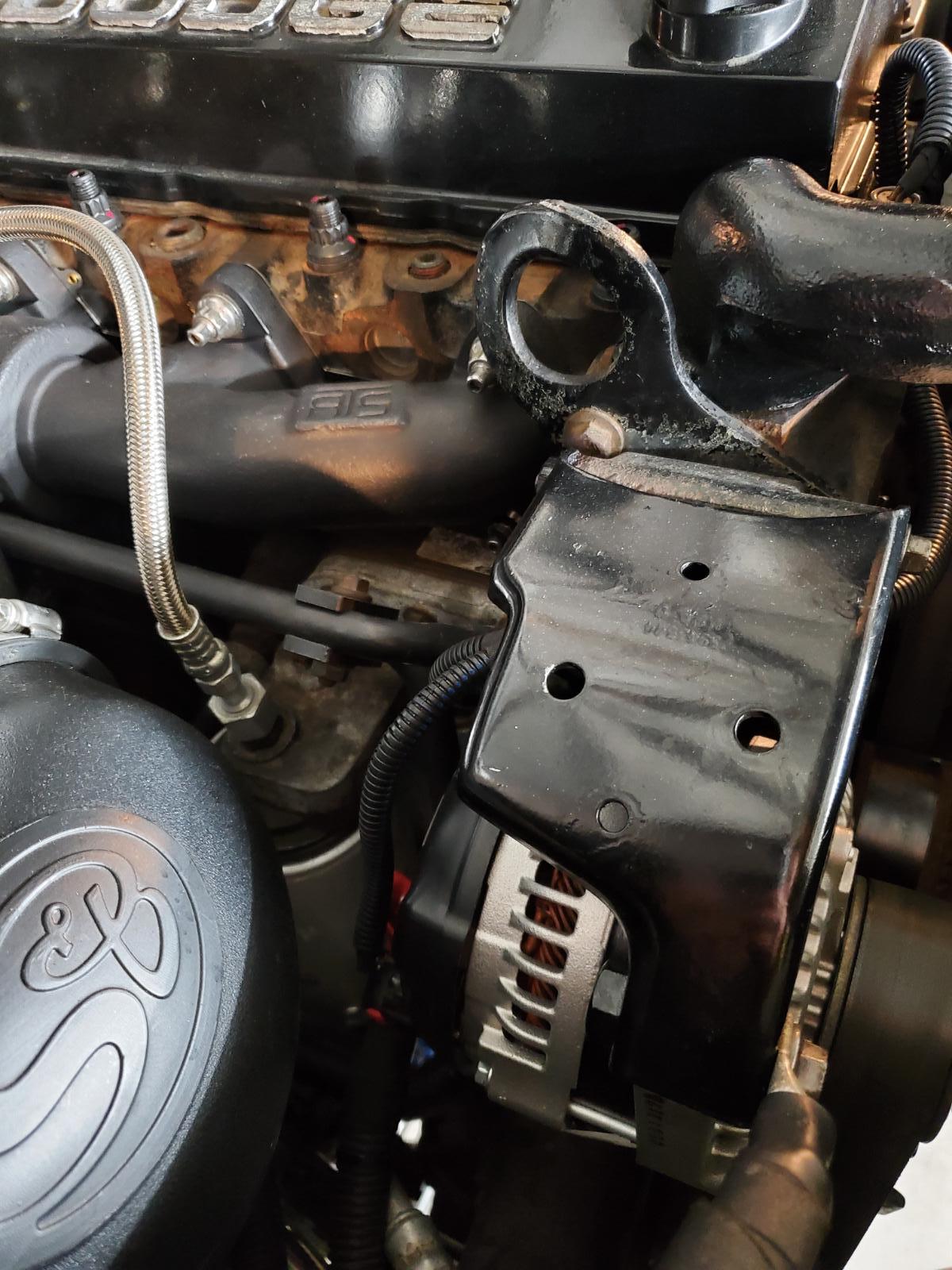

Hey guys, I've been fighting a heavy bucking and surging issue for some time now. My truck is essentially undriveable, and Id appreciate any insight on where to go from here. Symptoms: Ranging from light to heavy throttle input as long as the engine is under some load, it will develop a violent surge at about 35mph plus. It surges and bucks very badly and on my test drives within a couple miles of my house, its all I can do to nurse it home. It sounds like the footage youve seen of a WWII fighter getting shot down, when it starts to sputter before it catches fire. It idles just fine, and once I get it down to about 20mph it starts to behave again. It seems to worsen when the truck is warmer and the weather is colder. There are no error codes present. I believed I had fixed the issue previously, because the #2 injector line was not sealing correctly and air was getting into the line. I discovered a marred crossover tube which was replaced and now all the the lines are bone dry. I had one successful test drive about a week ago, where I went about 5 miles without issue. If I recall, it wasnt super cold that night (40's or thereabouts) Recent repairs and relevant performance modifications: Industrial injection Silver 62 turbo and II 120hp injectors Quadzilla Adrenaline Iquad running the stock V2 tune (I have a clue that the timing here could be low for the injectors, its about 13 at idle, and I have not been able to keep my eye on the phone while driving to see what it is at when it starts to miss) Newish ECM from auto computer specialists New VP from DAP All upgraded Battery cables and WT ground mod done Alternator testing at .03VAC Timbo APPS New Cummins MAP and Cam position sensors recently as preventative maintenence Fuel pressure rock solid (perhaps even a bit high) at 22psi with the fleece dual intank system and fresh fuel filter Fresh fuel All ECM VP grounds etc are new and clean I have checked and rechecked power and grounds to the vp and ecm many times. Id greatly appreciate any ideas on what to test next. I miss driving my truck!

-

Acceptable AC voltage with grid heaters on

Thank you and Dieselfuture for the kinds words. It took a little bit of work. I can assure you there are plenty of rusty, oily and sharp things still there! Awesome pics Tractorman! Down here in Nampa we just have the bracing wind and light snow dustings. Sunsets are pretty sweet though. Alas, my misfire/bucking issue persists. Im going to start another topic on that.

-

Acceptable AC voltage with grid heaters on

Wow, Thank you guys. Never ceases to amaze me the amount of experience and effort people on this forum put out. I tested my new alternator full warmed up with no acc on and she holds solid at .03. That seems acceptable. Just to add some detail, I was having a bad misfire when I got up to about 45mph. Previously I had changed out a bad vp44 for a DAP unit, and I also had a totally blown up ecu just prior to that, most likely from either a bad ground or the bad alternator I just switched out. In any case, I had been chasing my tail because I had no codes whatsoever and was beginning to doubt the new ecu, or think the apps was going. It almost felt like the vp44 was turning off and on. Up to this point I had -Done the WT mod -Changed the apps over to a timbo -Verified wiring integrity ad nauseum -Changed alternator (The apps and the alt needed to be changed regardless, so I didn't waste any money) And my whole charging cable system is pretty bomb proof, all marine 2/0 tinned lugs, mil terminals etc. Welp, yesterday I found the culprit. See pic below. The #2 injector tube got buggarred somehow. Some junk mustve got into the line nut the when I changed the vp. Dont know how, I'm pretty good about cleaning things that touch sensitive things. It was hiding behind the air horn and weeping just enough fuel to not be noticeable. Luckily I had a spare set of injector tunes and sanded the flare very lightly with some 1300 grit. Sealed right up and runs like a raped ape now. The irony of the whole affair is if someone had the same symptoms and asked for my advice the first thing out of my mouth would've been, "you're getting air in your lines somehow" So, thats my Slingblade moment. "It aint got no gas in it" Btw, Mike, I did consider Durability in Nampa. There is usually a pretty decent fish and chips food truck parked there, too! I just wanted to try thr off the shelf option of the 160a Durango hairpin. Seems to be working pretty well so far!

-

Acceptable AC voltage with grid heaters on

Understood on the fully warmed up truck. Ive been dealing with some other issues, but it should be ready to test drive now. The alternator should be the last piece of that puzzle. The old alternator was causing some wicked tcc cycling issues and simultaneous apps issues. Ill test it on a warm truck no acc and update.

-

Acceptable AC voltage with grid heaters on

I did have them test it at the store. It "passed" with .36vac. For reference, there were no accessories on in the vehicle during the test in the video. Only the grids cycling. In the vid, I think it was down to 1 grid cycling at that point bc with 2 cycling it was at 1.65vac vs the 1.0 seen in the vid.

-

Acceptable AC voltage with grid heaters on

Just to be clear, the spike is only when the grid heater cycles on. Should there be no vac spike when that happens?

-

Acceptable AC voltage with grid heaters on

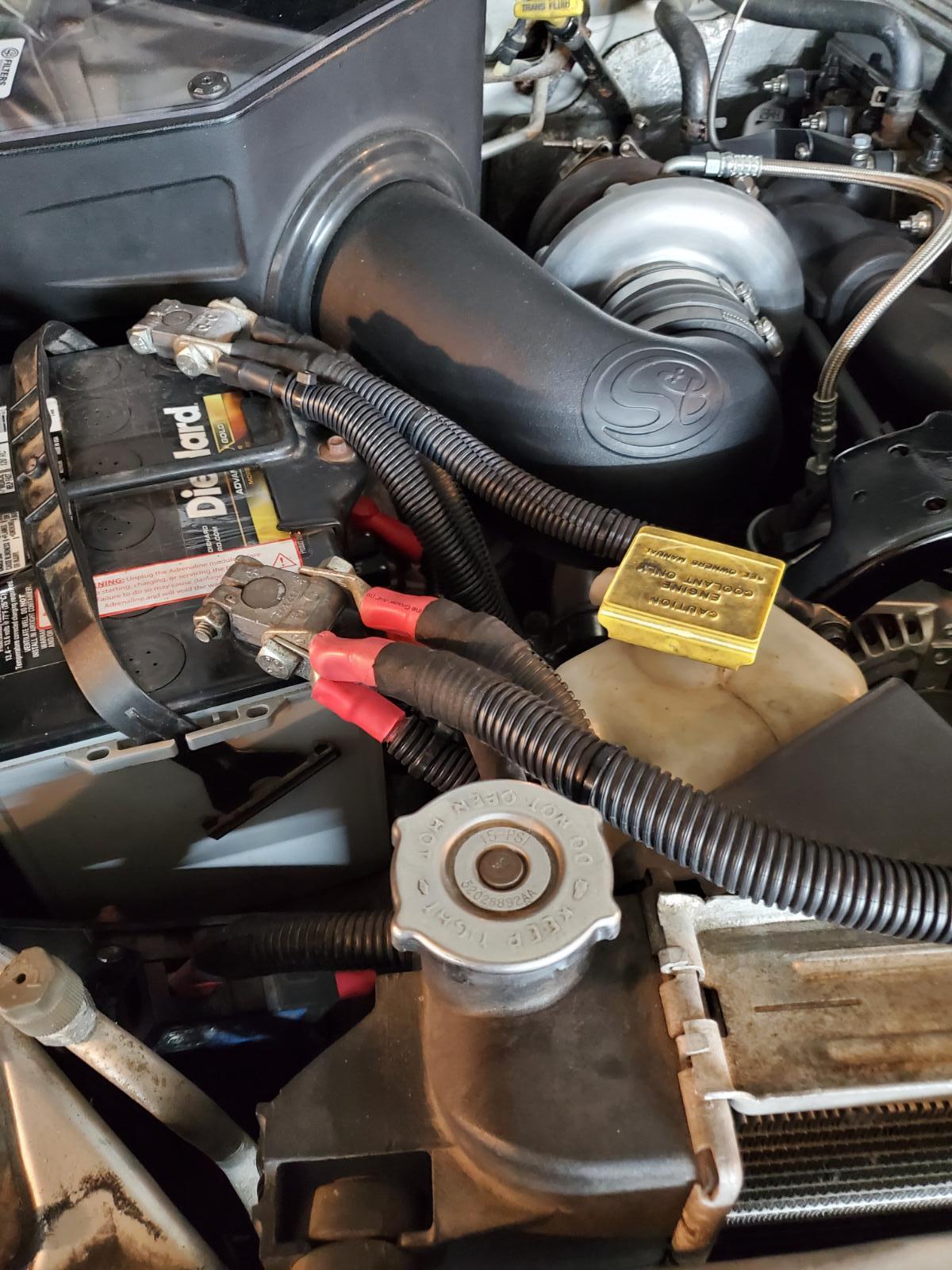

Hey guys, After a long saga of chasing my tail, I figured out that my alternator was shot. I had previously measured it with cheapy multimeter and it was holding a .02vac so I sort of put it at the back of my mind and kept on going. Anyway, I realized that my power probe had a true rms setting and remeasured and saw some pretty bad numbers. I picked up a 02 Durango 160 amp hairpin alternator from O'Reilly today. I had them test it before I took it and it tested at .36. They couldn't get another until next Tues so I took it. I installed it, and at idle its pretty much what it tested on the bench at the store. When the grids cycle on, Im seeing about 1.65vac. I couldn't find a reference for what is acceptable. It settles back around .03vac once the grids turn off. Id love some input to whether that's normal and acceptable. Here's a quick vid you can see the spike near the beginning when the grids turn on. John

-

P0232 help, kind of an emergency

Hey guys, Im set to move across the country in 2 days and I have been finishing up work on my 01. I took it for a shake down drive last night and everything was going well until (fortunately) right when I got back near my house. It starts to surge and stutter and wants to and does shut down. I took it for a short drive the other day and I had the same issue. I chalked it up the Hot Rod VP that WAS in it, because it was giving me a really hard time loping at idle and low load. I went ahead and switched out the VP for a DAP SO unit, since I had wanted to switch back to an SO anyway. I finished that up along with a new cam sensor, and she started and run beautifully. So as I got home it was surging stuttering and shut down. I could get it to turn over and catch for a second but not run. Fast forward to this morning, I pulled the VP connector off and put it back on and it started right up. The codes, which have not returned since I cleared them were a p1689 p0232 and p1693. I ran the diagnostic for the p0232 and I am getting odd readings. The voltage fluctuates between .09 and .5 volts My power probe says that somewhere I am getting a 13-14v spike but its so fast I cant see it on the meter. I probed the wire at the VP connector and back probed it at the ECM as well. Same readings. The diagnostic says you need between 9 and 14.5 volts. The diagnostic seems pretty conclusive that if you dont have that voltage, the ecm is bad. I just got a new ECM from Auto Computer Specialists. I thought maybe since I had pulled the VP connector and reattached it that maybe I just had a crusty connector or bad wire, but the readings are the same at the ECM as mentioned. At this point in time all codes are cleared and not returned. I just cant risk going out on the road without knowing whats up. 01 qclb auto No tuner right now apart from a smarty update for abs (37s) New DAP VP44 New Fleece in tank lift pump (20psi)

-

Rebuilding the G100 ground

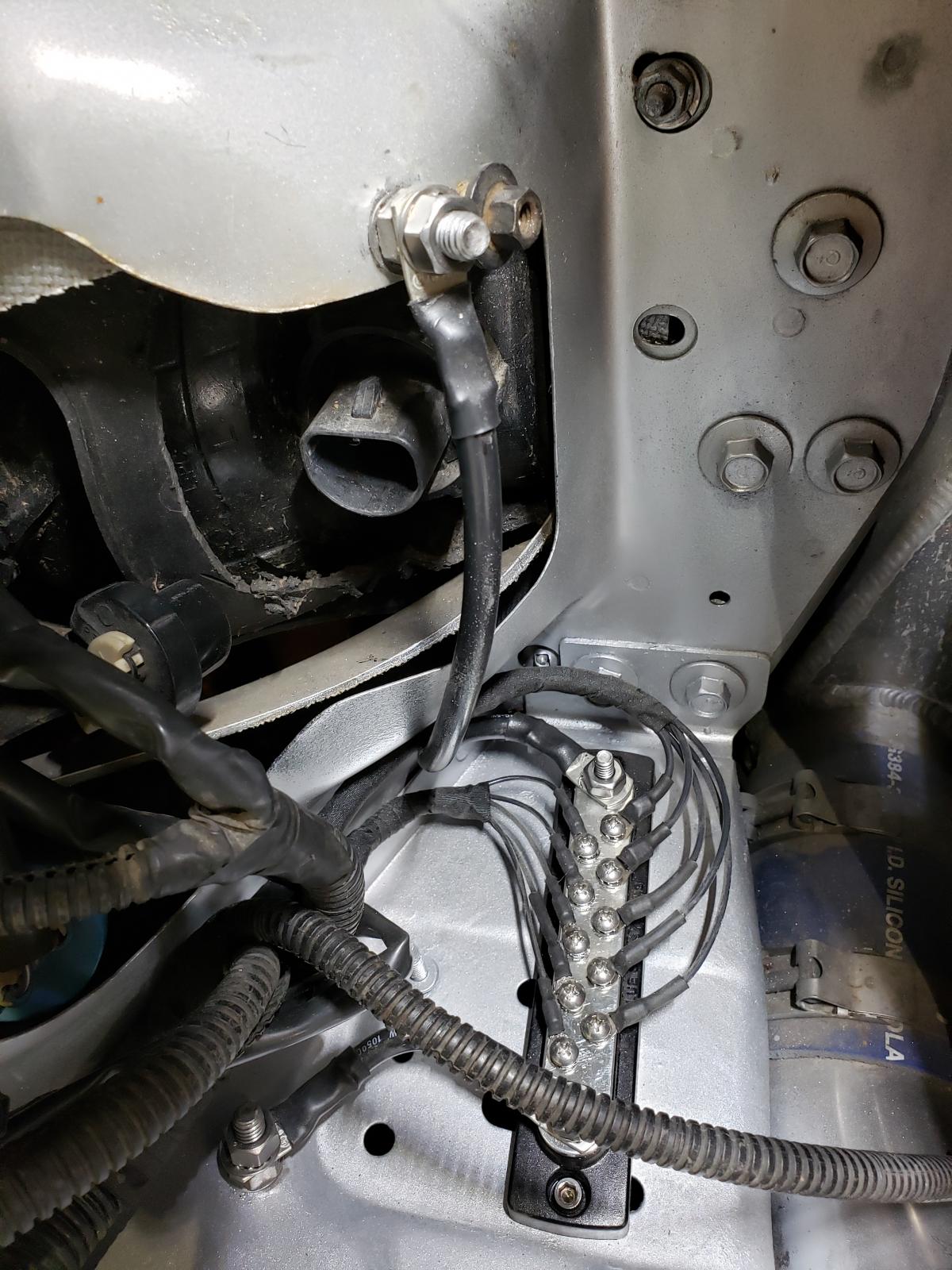

I should have enough slack where if I decide its ridiculous I can just go back to the stockish setup. That large open barrel with no weather protection just rubbed me the wrong way. Im pretty confident in the weather protection as it is now, though. The ring terminals are nickel and the 6a wire lugs tin plated, and the wire is all tinned. I think the strip is stainless. it has a cover as well.

-

Rebuilding the G100 ground

So my G100 ground was in very sorry shape. I believed it to be the problem causing a no start issue I have been experiencing. Unfortunately it wasnt the proble, but I thought Id share anyway. The picture shows how I set it up. The materials I used were a Blue Seas bus bar (2300, included cover not shown), tefzel wire from mil spec wire 16, 14, 12, ancor marine cable for the 6ga ground cables, 3M High temp butt and ring connectors, and DSG heat shrink, tesa tape. The ground hardware is stainless steel 5/16 (bolt, washer, fender, star washer, nut, lug, star washer, nylock, nickel anti sieze). I put the new ground "studs" right next to the old for the top one, and back a little and on the slope of the fender for the original g100, to encourage drainage (one major reason my oem ground was so badly corroded was because water would pool there when the hood was cracked for the trickle charger and it rained) One interesting item of note is that where the wiring harness Y's from the G100 to the top ground, one of the larger 12ga wires that attaches to the top ground simply runs back down to the Y and to the g100 spot. I was able to simplify it a little with this set up. I wanted to be able to diagnose each of the ground wires separately. Let me know if I should change anything.

-

Chassis Ground Question

Am I correct with the WT wire mod, the stock 140 amp fuse on the PDC becomes useless? Circuit protection has already been added to new charge cable.

-

Chassis Ground Question

I read your write up before on that. I really like it. My truck is a sport model and I impulse bought a set of the hikari LEDs after seeing lot of positive reviews on them when they went on sale on amazon. If they dont pan out, I will do something like you have done. I have an space in my winch bumper for lights, and I recently busted on of my older baja designs HIDs. I am going to replace them with another set of Baja Designs (Im partial to them) LEDs when I get a chance. So point taken on reducing the load. Ive had to fix some stuff wiring wise and I cant resist overbulding the wiring (Plus Ive got a bunch of spare material). May as well address those when I do the W/T ground mod. I already had that half done unknowingly because my higher amp alt required a charge wire to the aux and fuse.

-

Chassis Ground Question

Which sensor ground are those? I making a mental list of things I should take care of. That list is getting long. Wiring with OCD can be a time sucker. I think what I might do it take the OEM block grounds I have in the garage and cut them down and make one ground from the body to block on one side and to the frame on the other, piggybacking to the same mounting bolt as my new battery to block grounds. Also, I have been rebuilding my G100 ground using a blue seas bus bar. I will make a thread about it in the next couple of days. I found a couple interesting things.

-

Chassis Ground Question

I recently built new battery cables when I changed to mil style battery terminals, 2/0 everything. Both neg battery grounds go to the block on my 01. Unless I totally misunderstand auto circuitry, anything grounded to the body or frame must come back to the battery somehow. I have to assume there is some path to the block, back to the battery negative. I cant imagine it all comes back through the small body to battery grounds.

-

Chassis Ground Question

Thanks for the replies guys. I am familiar with all of the stock cables coming off the battery. I made some 00 marine cable ground to upgrade the stock battery to block grounds, as well as one from the alternator body to battery negative on the passenger side, as well as the two body grounds on the driver side battery (again from marine wire, sized up one from stock). I also have a 16.5k winch, but that goes straight to battery (+ and -). What is confusing me is that the large cables go to the block, but I assume that the motor mounts isolate the block from the frame and body. So how does the grounds on the body and frame get back to the battery, apart from the small body grounds connected to the battery? Im admittedly shaky on auto circuitry, so this may be totally obvious. This is more of a theory question, Im not experiencing a specific problem. I just want to know how this works. Thanks for the FSM link, and I will definitely do the W/T mod soon.