- Replies 8

- Views 2.4k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 5 posts

-

5akman 2 posts

-

Scarecrow 1 post

Most Popular Posts

-

When you have too advanced timing the fuel is lighting off and starting flame front on the cylinder walls which in turn heats the cylinder coolant jacket. Now the engine oil temperature will rise beca

-

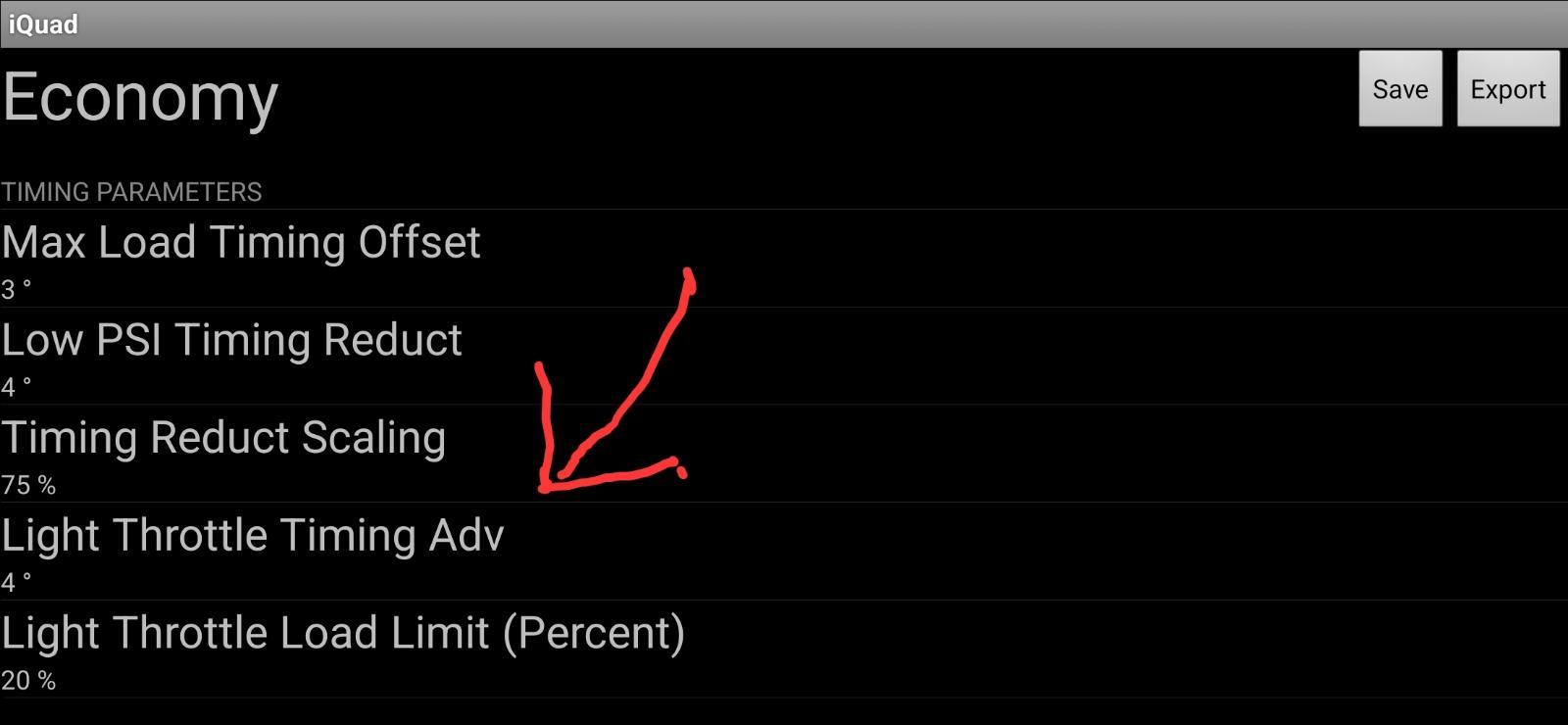

There are many secrets I've found regarding tuning on a Quadzilla or using custom injectors which is the tough part finding proper timing where your engine load drops lower, EGTs drop lower, and engin

.thumb.jpg.9c48aa8f6cc163d8202f09ef46255c5f.jpg)

Just got my Quad, and have a few questions, forgive me if I say something stupid. After a whole lot of reading on this site a couple of things are making me look for answers.

First, it seems to me that I need to add timing because my injectors are DAP 7x.009 and popped @ 320 bar. My question here is I know that as they wear, they will drop in pressure. Has anyone worked out a table based on mileage/hours of when to start taking that advance out?

Second, what is fairly simple, can I just tap into my existing gauges for the fuel pressure and pyro to the Quad?

Again, sorry if I'm asking stupid questions, but I like to understand what and why I'm supposed to be doing something and not just because someone said so. Kind of weird for someone who spent 24 years in the Army, right?

Mark