- Replies 28

- Views 13.3k

- Created

- Last Reply

Top Posters In This Topic

-

webbrenda 13 posts

-

Tractorman 9 posts

-

Great work! 4 posts

-

IBMobile 2 posts

Most Popular Posts

-

The engine wire harness part numbers for model years 1998.5, 1999, 2000, and 2001 with manual transmissions are all different. 1998.5......05611436AA 1999..........05014177AA supersedes to.

-

Pin #15 and #35 provide power to the transfer pump. One is for run mode and the other is for crank mode - not sure which is which, but it doesn't really matter. The wires are both connected at splic

-

Is the ECU that's installed now present when the shorting with the test leads happened? Have you tried the old one again? Probably damaged the relay driver circuit in the ECU. There is a dirty fix for

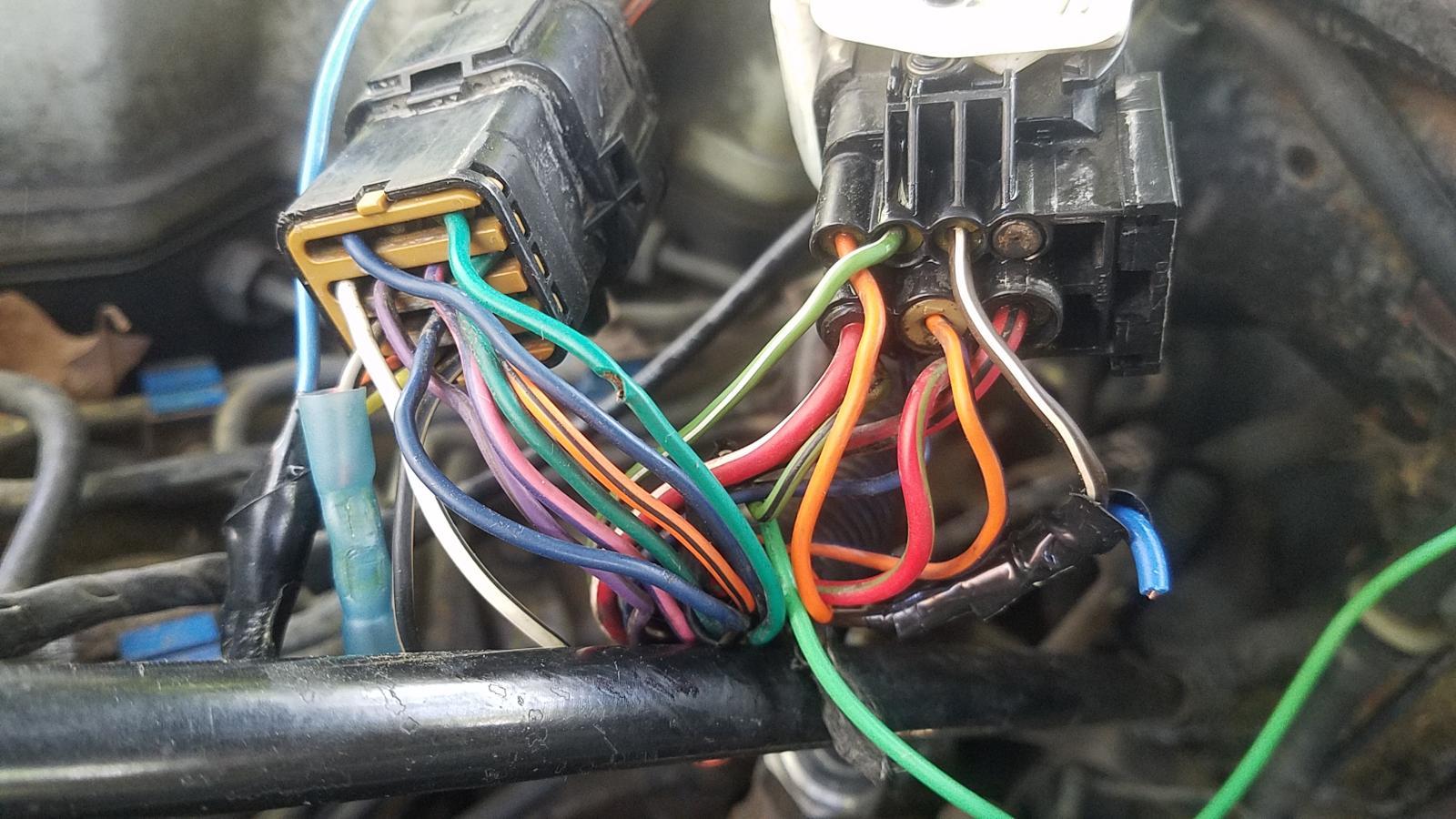

.jpg.767e9c243c3aa142765bdfc95f9129d8.jpg)

.jpg.01eb915604979dccc3199dc42e043332.jpg)

Hey guys. I have a 99 Dodge 2500 quad cab 4X4 5 speed. I was having an ongoing issue with WTS light either being delayed or not coming on at all and LP not cycling so I replaced ECM with a known good one and replaced ECM wiring harness with a new one I found at Firsttruckparts. When I was troubleshooting LP not running( before I replaced ECM and harness) I pulled the fuel system relay and got a P1689 code and truck wouldn’t start. So now, after replacing those I still had code and no start. After a lot of troubleshooting and wire checking I figured out on the fuel system relay that I have 12 volts to pin 86 from ECM until I plug the relay in and then it drops to about 1.8 volts. I sanded and dielectric greased all the grounds. I finally ran a dedicated ground to pin 85. Same thing. I have the plug unplugged from VP 44. I have checked resistance on wire from pin 86 to the ECM plug and it shows 0 resistance. I’m lost at this point. I don’t think it’s the ECM as it has 12 volts until relay is plugged in. Any help would be greatly appreciated.