Posts posted by Mopar1973Man

-

-

-

-

-

The only thing I can suggest is contacting https://idahodrivetrain.com/ . You should be able to get information from them,

-

Edited by Mopar1973Man

Technically, the coolant sensor will control idle, but only in an OVERHEAT condition, it will drop existing RPM by about 400 RPMs. This is not the solution, but a normal reaction. I found this way back in the day by using a rheostat to vary coolant temperature. Just to let you know, this is a normal reaction to the sensor unplugged because it's a high volt code (+5V) and the ECM reacts accordingly.

Still, you have an APPS issue, most likely on the APPS sensor is not providing a proper idle validation signal. This will force the ECM to drop the APPS sensor signal and run the Cummins idle software, which is a perfect 800 RPM's.

Now the only other way to raise idle is bad injectors. If your injectors have over 100k miles you need to replace the injectors being as pop pressure falls and idle speed rises. I've seen trucks idling at ZERO percent engine load and idle speed of 900 RPM, being the ECM cannot cut fuel any deeper, and idle cannot be obtained.

-

3 minutes ago, Sycostang67 said: They sent me a lengthy email explaining everything they did and how all the issues I had were reflected in the condition of my ecm.

Could you bring that over here so I can review what is going on? I'd love to help I need to know what they found to help you out.

4 minutes ago, Sycostang67 said: Right now I need to borrow a truck to move some stuff around to make room for the ram in the backyard before my hoa notices it hasn’t moved in over 6 weeks.

Stupid HOA rules.

-

-

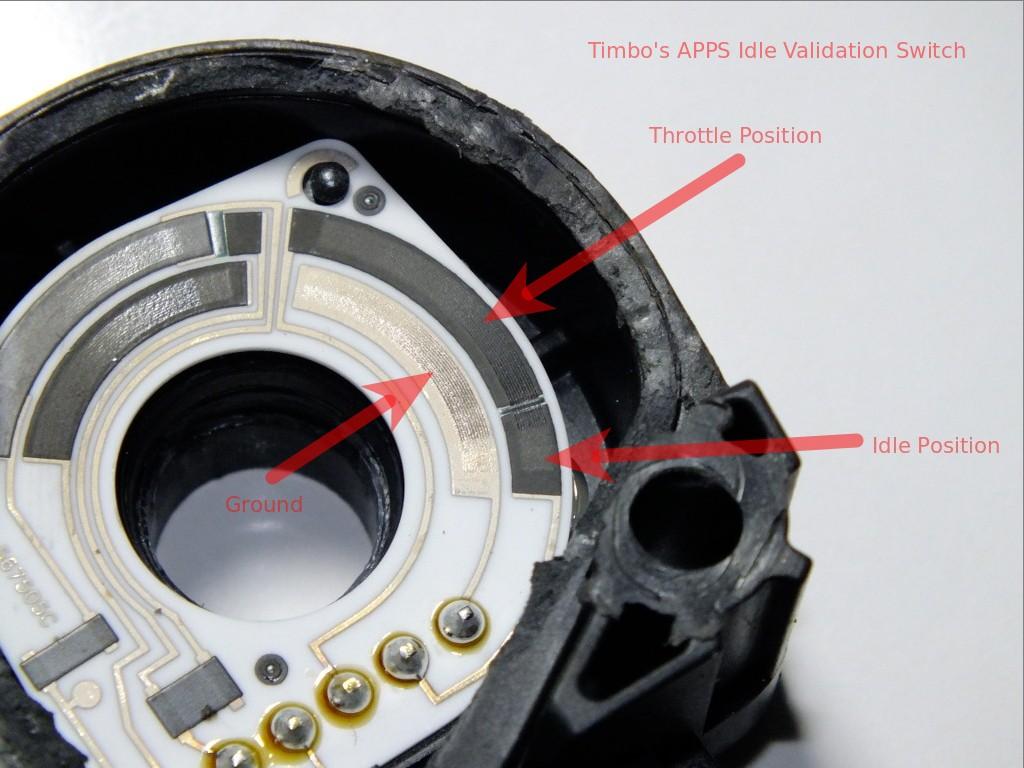

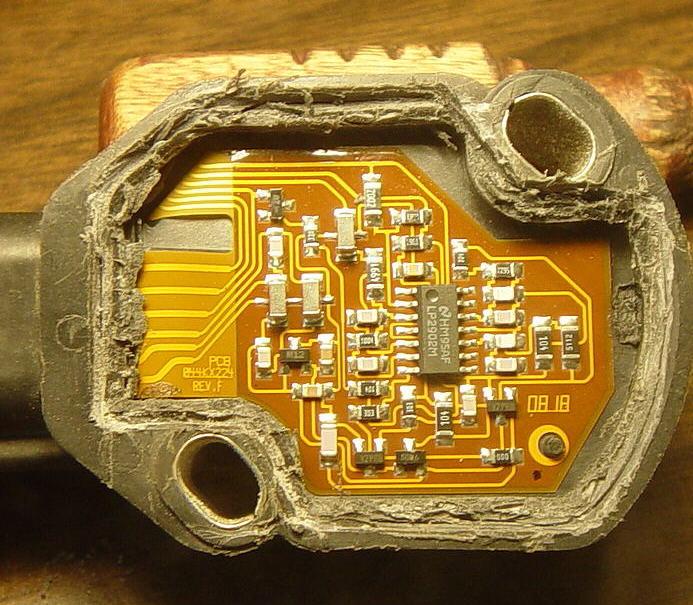

Most likely a bad APPS sensor. The is a idle validation switch inside the APPS sensor. So if you have mess with or adjusted the sensor its possible you are stuck in throttle mode and idle will not happen. I suggest getting a Timbo's APPS and replace your APPS sensor, this should fix your idle issue.

No ELECTRONICS the Timbo's APPS is fully mechanical.

Now stock APPS. As you can see it requires electronics to make the idle validation work and misadjustment can and will affect idle speed.

-

@Sycostang67 I'm sorry that you're stuck with your ECM not working.

I know you're upset, but calmly call ACS and find out what information you can about the repairs they have done and any other process or testing BEFORE the ECM is hooked up again. There is a solution, but we have to make sure the truck is ready and does not have another issue in the wiring or another device that will cause the same damage over again.

-

-

Edited by Mopar1973Man

My only problem is this test was designed for home person to test. If you pull the alternator and bench that is done under full load.

Either way excessive AC noise will cause...

VP44 damage (PSG, P1688 or P1689)

ECM damage (P0606 but could be a all hi or lo volt codes of all sensors)

PCM damage (P1698 code typically but also code have hi or lo volt code of sensors)

AC noise puts a lot of stress on transistors and IC chips.

On my truck it made the cruise control to wander +10 or -10 cycling past it's set point of 65 MPH. Either way AC noise pollutes the AC signals from HAL effect sensors like crank sensors or speed sensors like ABS.

-

-

it seems like it's mostly fuel related issue. You can't obtain the speed you are requesting of the engine. The idle speed is lower. Be aware idle speed will change with coolant temperature, but typically when it's way high, like above 225℉. I've played with a rheostat and varied the resistance of engine coolant to see what it controls. IAT will change the aspect of the timing of the VP44. The higher IAT is much more stable for efficiency. (80 to 140℉) is optimal.

I'll keep thinking on this why I'm working here on the site. I'll dig for an answer.

-

Edited by Mopar1973Man

What is your lift pump pressure to the injection pump? Optimally, you should see 15 to 17 PSI of fuel pressure to the injection pump. Sounds like it's starving for fuel. Measure this at WOT (Wide Open Throttle) at highway speeds to be sure you have plenty of fuel pressure under heavy demands.

Here in Idaho, I just got back from camping up in McCall, Idaho, and it was about 100℉ (37°C) outside for the last few days. Remember, I'm running Beast with a 200℉ Thermostat from a 2012 6.7L Cummins with zero issues, even towing my RV. With my Quadzilla I rarely see above 140℉ fuel temperatures, 175℉ engine oil temperature.

The only device capable of failure without codes is the VP44. There is several cases where the VP44 just no longer will fuel properly and just not throw any codes being its consider failed within specifications. Sadly its true. ECM will typically have a series of low/high volt codes and P0606. PCM will typically throw P1698 IIRC.

This combo is roughly 17,600 pounds (7,983 kgs) rolling up grades of 7% no issues.

-

-

-

Look for anything with looseness...

Shocks - remove and check for gas charge and suppression. Weak shocks can allow the the axle to bounce.

Tie Rod Ends - look for any loose tie rod ends.

Ball joints - Check for vertical movement by prying upwards on a hanging tire.

Tires - Any deformity? Properly balanced?

Wheels - Are your wheels true and now bent or out of true?

Steering shock - It helps, but it's not a cure-all fix, either like some websites mention. Some people omit this shock.

-

-

@Sufarry It was a great conversation on the phone. Sorry, I've been missing in action for a while between the landslide, clearing @Tweety Bird place out, and moving here, and then my bladder cancer.

My notes on this after this hour-long phone call. It is not mechanical that we can find it's a bad signal being created by the ECM and feeding the VP44 the bad information, which makes it knock. I know he is waiting for a Cummins crank sensor to arrive. I've got a few ideas, but I just have to wait for the sensor to arrive for the owner to reinstall the starter and give it a try.

-

-

-

-

-

Edited by Mopar1973Man

Just one in the fuel tank about 300 dollars for a quality pump. One of the few reasons I ditched stock in my 2006.

Even with a new lift pump in my 2006 I was able to pull fuel pressure into a vacuum state. The in tank pumps are low quality and should be replaced with an AirDog (suggested).

Flashing WTS light

in 2nd Generation Dodge 24 Valve Powertrain

·

Edited by Mopar1973Man

Just remember just one wire pinched in behind part, bolt, or bracket could do it. I had one where the PCM burned up because one wire was rubbing on the trans dipstick tube and fried the voltage regulator.