Everything posted by KATOOM

-

Replacement fuel level sending unit...?

Wow...modules arent cheap. At 1/3 the cost, I'll certainly try replacing the sender itself first. Thanks dripley

-

Replacement fuel level sending unit...?

Well I'm getting tired of my fuel gauge reading 3/4 tank with 300 miles on the clock... Its been acting up for some time but getting worse as half tank is about as far as it will ever get to. If this was a true representation of some amazing fuel mileage then I'd feel a bit different.....but sadly its not. So I guess I'll drop the tank, or lift the bed, and see whats up... I'm thinking the fuel sending unit on the module is toast. I see Geno's sells them but I was wondering if anyone has any suggestions on who else does? Just for reference, the module is stock because I've never needed to modify the fuel module system. Most video's and information about the fuel modules are because someone was trying to install a Drawstraw, remove the intank pump, or perform some other possible concocted modification. I just want to fix the fuel level since driving by the odometer is kind of a pain. EDIT: Not sure what I was thinking but lifting the bed isnt an option because of the 5th wheel hitch. Guess I'll be dropping the tank...

-

Not starting after warm

Without being there to diagnose in person, I would question whether or not the engine was getting fuel. Meaning, was the AD even pumping before you realized it wasnt starting..... Did you confirm the FP gauge was working before the engine didnt start? Maybe the AD fuse wasnt getting a good connection from you messing with it before. Then there's the off chance that you could be experiencing more than one issue, like a possible fuel leak which would cause the prime to be lost. At this stage of understanding whats going on, you need to establish if the VP is getting fuel, then establish if the injectors are getting fuel. If fuel is being delivered then it "should" start.

-

Upgrades for Towing

I wouldn't count on the stock clutch holding up with anything over 75 hp, especially towing. The HO clutch is notorious for holding slightly less hp than the SO clutch merely because of the smaller material surface area.....even though its larger in diameter. Yes, I understand that goes against the logic of the HO clutch design but ask the clutch companies and they'll tell you they use the larger HO diameter with the SO plate material size. I ran my SO stock clutch on the Edge EZ for many miles of towing until I added the 4" straight exhaust. That was apparently the straw..... So when I upgraded the clutch I got some RV275's. LOVE the combo.

-

Not starting after warm

Did you change anything on your truck after starting this thread?

-

Not starting after warm

Even though it's very rare for that to be a problem, there's a TSB pertaining to this exact issue.

-

Not starting after warm

I've considered whether the lack of fuel pressure to the VP during engine cranking also lessens or removes the electrical load on the PSG during engine cranking. If the solenoids arent placed under resistance then the electrical load is minimal. No.....?

-

Not starting after warm

Everything's too loud for me to hear my relay click but I've confirmed with a 12 volt test lamp that the open pin on the delay relay will flash when cranking, proving the cycle of voltage to the relay during engine cranking.

-

Not starting after warm

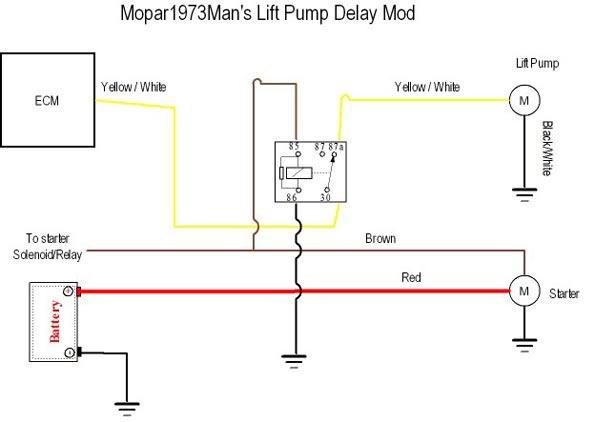

Yes, makes perfect sense. And to fix your problem you simply need to install that delay relay using the diagram I posted for you. The VP does not like fuel pressure during engine cranking and you're feeding it 17-18 psi.....

-

Not starting after warm

Correct... The ECM fuel pump circuit simply tells the fuel pump when to pump. Most recognized aftermarket performance diesel fuel pumps come with a relay which removes the amperage load to the ECM circuit by becoming that "on/off" switch for the aftermarket fuel pump. Still though the ECM is dictating when the fuel pump runs. As Moparman just mentioned, if the aftermarket fuel pump does not come with a new wire loom and relay then the ECM circuit must absorb the additional amperage to power that stronger fuel pump. The delay relay mentioned is merely an "additional" relay added into the aftermarket wire loom which further interrupts the signal from the ECM to the fuel pump relay when the key is in the START position. It does nothing else.....

-

Not starting after warm

Why do you think so?

-

U Joints

I stopped installing greasable u-joints years ago..... They just didnt hold up for very long, and they throw grease all over the place. Real Spicer non-greaseable packed with high quality synthetic grease are what I use. That said, strangely there are knockoff versions out there which look like the real quality u-joints. I attribute most u-joint problems to shaft balancing issues, poor grease quality, improper installation, or overall angle issues. At least from what I've seen over the years.....

-

Vacuum test?

I know its not a blowby discussion but you mentioned seeing "lots of white smoke or vapor...". So I thought it worth showing how important it is to understand that a vacuum leak can increase venting. That said, in answering your question, the complete vacuum system as it sits on the truck does not hold vacuum. It will slowly bleed down releasing vacuum when the engine is off. But if you're trying to test the vacuum lines/pods then you can connect a tester with a manual pump and check that way since everything post the main vacuum pump line should hold vacuum under testing.

-

Not starting after warm

I've had this additional "delay" relay setup on my truck for a long time. Around a decade if I'm remembering correctly..... I chalk it up there with one of the most important changes/upgrades I've done to the truck since I know its beneficial to have very low to zero fuel pressure placed on the VP during engine cranking, as long as fuel supply and prime is intact.

-

Not starting after warm

- Not starting after warm

Thanks... Glad I explained it decent enough since I know I can get a little wordy. It makes sense to me when I'm typing but that doesnt mean anyone reading is following my logic. Anyways, yes this is a problem for most people with aftermarket fuel pumps. Doesnt have to be a problem immediately either, but it will eventually most of the time. Understanding that the factory ECM fuel system circuit is even programmed to alternate ON/OFF voltage to the lift pump during engine cranking in order to reduce the cranking fuel pressure to about half delivered to the VP before the engine starts. So thinking about that... If the OEM Carter lift pump was hardly capable of 15 psi while engine running, the factory fuel pressure should have been no more than about 7 psi while engine cranking. Your VP is receiving 18 psi no matter if the engine is cranking or running. All that said, after you get the AD connected to the factory lift pump pigtail connection with a relay to remove any additional amperage to the ECM, you can add a 5 pin relay which when wired into the hot lead and triggered by the starter solenoid circuit, the fuel pump is prevented from pumping at all when the ignition key is in the START position. But all other fuel pump function is retained. If you want I can upload a wiring diagram Moparman created years ago showing how to wire this relay in. Lastly, what you could potential find out when trying to rewire your AD is that the previous owner wired it up direct to key ON because the ECM fuel system circuit has been burned out or is no longer working. This sometimes happens when people wire their new aftermarket fuel pumps directly to the lift pump pigtail unknowing that without a relay removing the additional amperage placed on the ECM the circuit cant take the additional load. Especially when the AD 150 pulls something like 6+ amps over the factory lift pump. So what happens is when that circuit no longer functions they'll wire their fuel pump directly to a keyed source and there ya go..... The option of wiring directly while using an additional keyed relay is still something they can do but they either fail to know or forget that they can go that route too.- Not starting after warm

Whats happening then is the AD is running at a full 18 psi (your setting) when the key is ON. This means the VP is receiving fuel incoming pressure while the engine is cranking, which then increases the pressure load on the timing solenoid and fueling solenoid. This can prevent starting of the engine until the fuel pressure is reduced internally in the VP. And in your situation it sounds like its not allowed to bleed down. A common problem with fuel pumps that are more aggressive than the stock lift pump.....which was rarely capable of putting out its regulated 15 psi. Addressing this electronically as well, those solenoids require a minimum of 9 volts to function properly. When you start the engine the load placed on the batteries is immense, and combine this with grid heaters and possibly batteries which arent great or corrosion or poor connections/grounds and you have a scenario where the solenoids arent getting 9 volts during engine cranking. Same thing can happen during the hot summer heat too. So again, I'd reconfigure the AD wiring setup, even though it did work. And you might want even consider adding a delay relay so that the AD isnt running at all while the key is in the START position. Very easy to do and it removes all pressure on the VP when engine starting. Much better..... Then check the batteries and all major connections, grounds, and cables for tightness and corrosion. Especially since one of the codes is possibly coming from ground issues.- Not starting after warm

Just to recap so I understand..... Is your fuel pump wired utilizing the stock lift pump connector but using the aftermarket wire loom with relay? Because I thought I read that it was wired direct to the key so that its running fuel time whenever the key is ON.....which would be bad. Also, if thats how its wired up then correct the way the fuel pump is wired and it may possibly correct the starting issue. If not then there's other suggestions but checking the most obvious and cheapest first is always best.- Vacuum test?

I made a video some time ago showing what the normal amount of blowby (engine venting) should be and what happens when you get a leak in the vacuum lines. Maybe this will help.- Installed a Nations alternator - results

Ground to the alternator body otherwise you can get false readings depending on the battery. If the results are the same then you might want to give Nations a call.....- Installed a Nations alternator - results

How exactly are you testing it?- Installed a Nations alternator - results

Other than slightly less voltage drop when the grids cycle, everything works normal.- Installed a Nations alternator - results

No need to change anything with the 180 amp upgrade- Lets talk backhoe's

Yeah them full size toys are serious workers which is my fear for anything smaller. Thats not to say a 50ish HP tractor/backhoe would be a slouch. I do like that extendahoe though..... But renting is never an option since I'm the kind of person who attacks things when I have time. Renting means not stopping until the job is done.- Lets talk backhoe's

If I could get this 580 Super D for $10k I'd feel a whole lot different since I dont know how much things cost to fix on these old machines. I've been scouring the Internet and I think I just ran across something saying that Case no longer has parts for the transfer cases on these 580's. If thats true then I'm not sure I want it..... - Not starting after warm