-

Airbag light, seatbelt control module?

So, the seatbelt light comes on and then off at startup, so I believe that indicates functional. But its never beeped at me when the belts arnt buckled.. SRS isnt something Id like to backprobe to diagnose.. dont much like the dealer either. I guess if cant figure out, Ill work on getting a better front bumper.

-

Fuel Return To Tank (not basket) Question

@TractormanWow! That is great access! That cross piece have to be cut as well? Just start the pilot holes from the bottom? Mini writeup? Seems so much easier than dropping the tank if/when theres an issue. Appreciated.

-

Fuel Article - AirDog Draw Straw Installation

@jlwelding That does sound like possible minor air leak. If goes away warm, probably not straw.. Good video! My FASS was about 8 years ago, always had this problem. Hills or hard cornering would do it too. Im always a bit stressed when gets to about 1/3. My 150 failed and started leaking externally recently. Tried to rebuild but the bearing and seals are proprietary? Mark against Fass there. Has same blue hose I see with the airdog. Mines all surface cracked at this point bad. Ive replaced the runs I could reach with marine hose. Another reason for me to drop tank to fix. One other plus! I kept my original fuel pump, and added additional set of fittings for it. If the fass goes out again, I can use the OEM pump to limp home. Keep the articles coming!

-

Airbag light, seatbelt control module?

Ah, vehicle has RWAL, so explains plug. I plugged it into a modus or similar a while ago, recalling memory here, tried communicating with Airbag module, and was unsuccessful. Dont know if it was on me, or module dead. Module is plugged in and in proper spot. Any other thoughts for diagnosing it?

-

Airbag light, seatbelt control module?

Edit: whoops. can someone move this to non- powertrain? Thanks Hey all, Ive had this forever, but its been on the backburner. I figure some better minds could help. Airbag light, new clockspring fixed cruise control, no dice on light. Cant figure out how to pull codes for it. Dont know where to go. I looked at a 99? Wiring diagram posted here, showed the ACM hooked to something called a seat belt module. Supposed to be under center seat? Nothings there on mine, or harness, so dont know if was deleted? Mine is a 2001. Also theres this terminated plug under the air-filter. Dont know where that goes or what it does, any clues on that? Thanks for the help

-

Tire Size

First number is width in MM, second is ‘aspect ratio’ / R rim size example, my 275/65r18 are the same width and diameter as 275/75r16 Same calculator says I really should be running 3.73 gears. Although changing down from 275/70r18 made a significant difference.

-

Squeak/Screech noise in reverse only

Hi John, I got a shot of each side bot not a single shot of the bottom. Hope it still helps. I did them about a year ago, so thats how the previous set looked too. These were o’reallys shoes, not that great. Looking online it for sure looks like theyre two different sizes front and back..

-

Squeak/Screech noise in reverse only

-

Proper Final Ratio

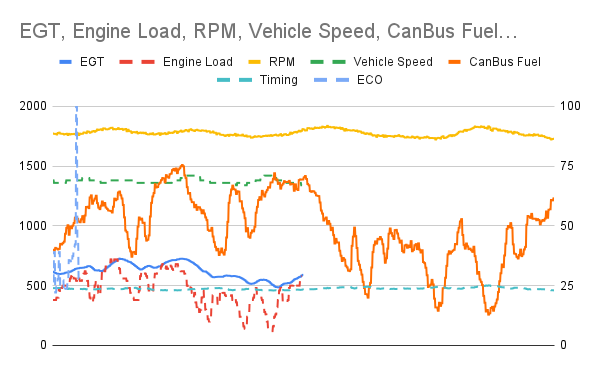

@Me78569Okay, thank you. Done, and put load timing reduction to 1 for now. Also can adjust base. Ill post another log later, or try another graph, if those sensors are most valid. Anyone want to take a stab at injection event in degrees from uSec? Ive read a lot of research from you all, its all been fascinating and helpful.

-

Proper Final Ratio

@Me78569 light SMALL grey/black puff for snap test. Then clears. Clear while driving, unless from stop go up hill or high load.

-

P0252 and not firing

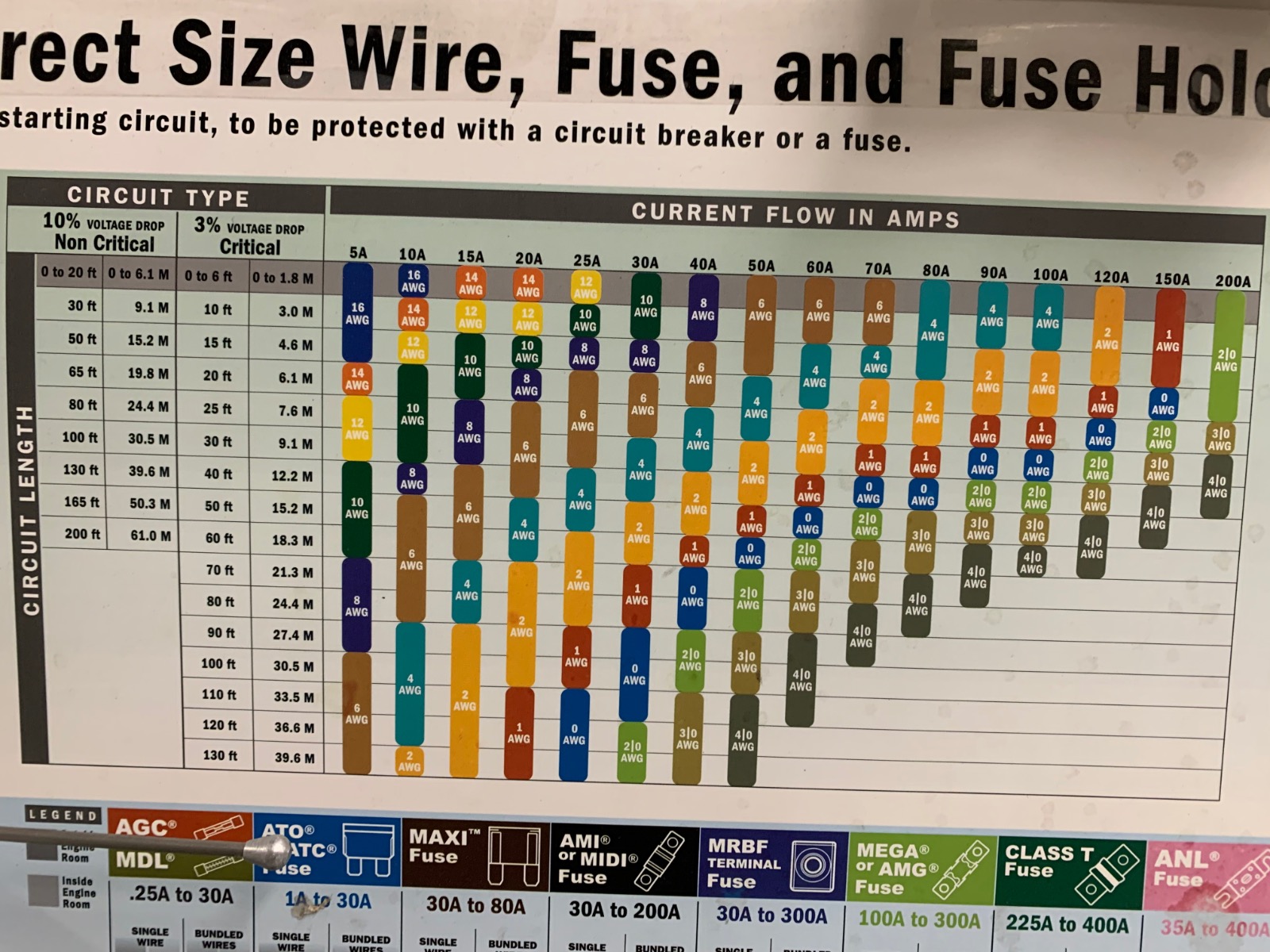

Batteries not fully drained. And wasnt full fielding alternator, saw peak of 90 amps. 4awg is fine for a short run up to about 100 amps. edit: probably wouldve went for a 150 amp breaker if had one lying around. But dont see any issues, only 5A difference than stock fuse.

-

Proper Final Ratio

@ThreadzyI am totally, 100% open to suggestions. Had quad less than year now, so still new to me. Before that was the original edge JWA! When I went down in tire size, I didnt see the load decrease much. But could definitely notice it with other gauges, and acceleration/gearing.

-

Proper Final Ratio

Thanks for taking a look. Im figuring with this setup is only 1 step larger on tires and injectors, shouldn’t be too hard to find something good. The larger turbo may make it trickier. I thought there was some good info posted here. From 2019 and back then 2.99$ was ‘high’! When running .010 about 82% where was starting. Theres no smoke @ 115%. The truck doesn’t take off well for sure though, @LorenS. One thing Im fighting is load, or perceived load. Data time cruise was about 22-25 with the 150s. I have to put load limit up high for these.. Id start lower on the 1500 timing, but big jump to cruise.. I find it ‘bounces’ between 16-22*. Ill start with lowering the CANBus.

-

Proper Final Ratio

2000 RPM is close to 75 for me. Not great with wind drag. This is with 3.55 275/65R18. (Essentially a 275/75r16) 47re. RV275. Already stepped down a tire size, and it improved, but don't want to go much smaller. Would consider 3.73 but lots of work for a 4x4. First attempt at graph, wish could get 2nd axis as a bar instead of line. Didnt include boost, its mostly 0-1 psi. A 64/64. I dont think its bad, but unsure where to try tweaking or improving. Any pointers would be greatly appreciated! Current daily, Levels: 6 Timing Fuel Load Timing: 0 Low PSI Timing Reduct: 4.5 Timing Reduct Scaling: 90 Light Throttle Timing Adv: 6.0 Light Throttle Timing Load Limit: 37 Timing vs rpm 1500: 16.5 2000: 19.5 2500: 23 3000: 25 Timing Max: 26 Wiretap Pump Stretch: 1900 TPS Pump max: 100 TPS Pump Min 50 Minimum Pump Tap Fueling Percentage: 0 Pump Low Boost Scale PSI: 15 Boost Scaling: 40 RPM Limit: 3400 Power Reduction: 0 PSI %:115 1 PSI %:116 2 PSI %:117 3 PSI %:120 4 PSI %:122 5 PSI %:124 6 PSI %:125 7 PSI %:125 8 PSI %:125 9 PSI %:126 10 PSI %:127 11 PSI %:129 12 PSI %:131 13 PSI %:135 14 PSI %:137 15 PSI %:140 16 PSI %:145 18 PSI %:150 20 PSI %: 22 PSI %: 24 PSI %: 26 PSI %: 28 PSI %: 30 PSI %:

-

Proper Final Ratio

So 2 part question. As this best relates to economy. What numbers do you look for in your data log and then which parameters are then adjusted? Timing vs egt, etc? Ill post a datalog just took, as HW try to do a doc graph, still not great at it. Also the ECO is quads way of tracking MPG? 2nd part relates to the larger injector theory. Read a lot about the .010 with the higher pop pressure. Shorter duration, precise fuel. Im trying to calculate that to crankshaft degrees. Microseconds is a small unit. For (rounded) max canbus and wiretap (~6000us). Im getting 1.2*. Does that sound right? When adjusting the timing parameters, the event STARTS at the desired value, and ends when duration complete? Sv275 ii.csv