Everything posted by eddielee

-

2nd Gen parts lookup tools

I think it is pretty cool. Only thing I did notice once I got to the diesel engine pages is that there are like 3-5 of the same page each with their own number. So far as part #'s go I didn't look too much at them as I am not sure if they would be right anyhow.

-

Lift Pump/ Fuel Supply Question

The lift pump is powered by the ECM only. The IP is powered off the relay in the PDC. I would double check that you somehow do not have a short. If this was the only problem presenting, I personally would supply power via a relay or a fuse that has power during cranking and running. Just have to remember to put it back if you put in a new ECM. And I recommend creating a signature with the year model and other specs of the truck so you don't get asked those things whenever you make a post.

-

New member introduction/reccomended maintenance

Welcome to the forums! The only maintenance I recommend going to your profile and creating a signature with the specifications of your truck and any mods that may be present. It will stop you from having to do so when you are asking for help.

-

Apps, Ecm, Pump, or something else?

Don't forget to check the AC noise issue, or you could kill another ECM!

-

Oscillating chirp noise

I would call the stealership and get their part#'s for them and then cross check to order from another retailer. Replace all there are. If your going through the effort to replace one it only takes 10 min to do another.

-

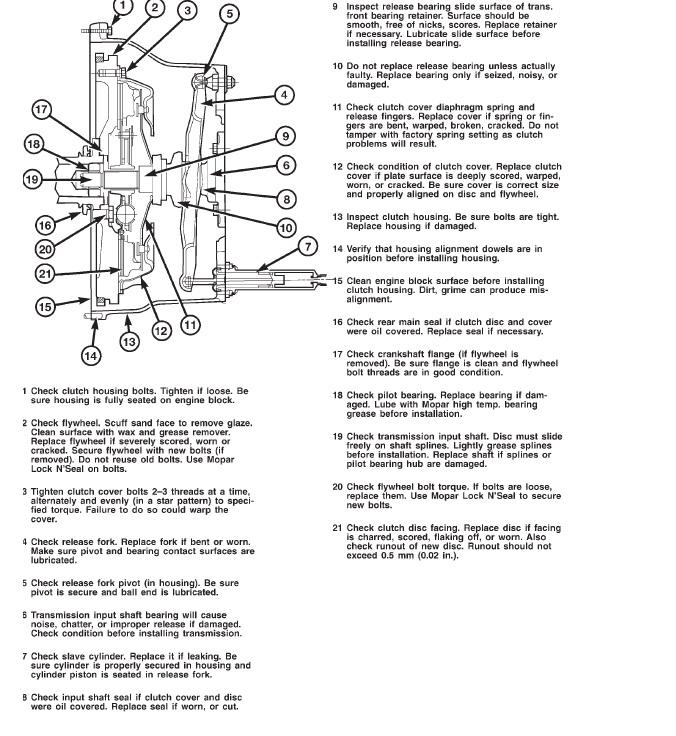

NV4500 Problem

You should look through the checklist and inspect everything you can to eliminate as many possibilities as you can. Each component has it's own affect on the way the trans shifts. Especially pay attention to the bolts holding the slave cylinder to the transmission and the trans mount bolts.

-

NV4500 Problem

Front seal on trans should be done with bearing.

-

Dead pedal issues!!

Have you ever performed the apps reset I just posted? If not do this first and see if issues persist.

-

Dead pedal issues!!

using multimeter (DVOM) stick pin in 6 idle on/ with ignition on check for voltage on the 20V setting, you should see voltage at idle. Then turn throttle manually to 25%-50% (driving positions) and hold to see if voltage goes away and stays away, or comes back. Pin 2 in that connector should be exactly opposite. Voltage begins when accelerator leaves idle and maintains Voltage without loosing Voltage. I would expect to see ether 5V, or 12V at pins 2 and 6 in the apps. To be sure which you should see check the voltage of pin 5 in the apps. Essentially what should be happening is the power comes in at pin 5 and switches between pins 2 and 6 to signal whether the idle is on (6) or off (2). once the ecm sees the idle is off it checks for the position of the apps petentiometer at pin 5. A potentiometer (aka: 'rheostat') is a variable resistor. When you reset the apps by using the following directions the ecm figures out where to expect the voltage to be: http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/26-engine-systems/258-how-to-reset-calibrate-apps-sensor

-

Dead pedal issues!!

2001 diagram shows pin 1 at ecm to pin 6 at apps/ idle on pin 16 at ecm to pin 2 at apps/ idle off pin 31 ecm power in at pin 5 apps pin 32 ecm ground to pin 4 apps pin 25 ecm to accelerator position to pin 3 apps and pin 1 from apps appears to be ground to the potentiometer of apps attaching to other sensors like IAT, oil press, water in fuel and the MAP sensor

-

Dead pedal issues!!

I find with this style plug that it is difficult to put a wire in the plug for a jumper. The little gold safety pins can usually stuck along side the wire and tested for continuity with the plug unplugged to ensure connection. Reconnect plug and leave two little safety pins facing away from each other so there is no contact. touch black to ground and red to either safety pin to see which has voltage. diagrams are here: http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/26-engine-systems/87-dodge-ram-turbo-cummins-24-valve-engine-wiring what year is it? looks like pins 2 and 6 in the plug are what you need to test. 2= idle off 6= idle on Stick pin in 6 and test to ground on 20Vdc setting. without throttle there should be voltage and when the throttle picks up it should no longer be energized. pin 2 should be opposite. Intermittent issues are the most difficult to localize too.

-

Dead pedal issues!!

Here is the info you should know about the APPS: http://www.cumminsforum.com/forum/98-5-02-powertrain/54322-anatomy-apps-sequel.html I usually use little safety pins to stick in along side the wires for testing.

-

Dead pedal issues!!

sounds like an intermittent short or broken wire somewhere beings all the symptoms, could be the idle on/off circuit cutting in & out. I would triple check the Timbo apps for proper function and the apps wires to ecm for breaks and shorts.

-

Dead pedal issues!!

Okay, Describe exactly the dead pedal you are mentioning, is it like Dripley and Moparman are saying "idle only," or is it lack of throttle response "lack of power"? And have you tried with fuel cap loose and venting?

-

Help!! not sure if grid heater is working properly

Along with what Moparman and ME78569 said, the brake and ABS light staying on could have an affect on the situation as well. Testing the grid heater relay manually: First test the resistance of the grid heaters to ensure they are good. Mine show .001 ohms resistance. There are two studs on the right side of the heater, test each to ground to be sure they are good. If they are good go to the next step... Make a jumper wire from battery to the signal side of the relay, test for 12V to the supply lines of the Grid heaters with DVOM. If you are getting 12V to the grid heaters, the relays are working.

-

Intermittent voltage

I, myself, would say to double check your battery connections and be sure they are clean and making good contact. This will ensure there is no unnecessary resistance to the electrical system. As said before, it is common to have the voltage drop due to grid heaters cycling. Seeing the voltage dropping is no issue so long as you ensure good contact at the battery. I had to clean mine again the other day because the dimming of my headlights. Essentially the electrical draws as much as possible from the alternator while the truck is running, sometimes it needs a little more and the battery supplies it. My voltage was dropping as low as 10V-11V with dirty battery clamps. Cleaned the clamps well and it hasn't dropped below 12 since. Lights are brighter too.

-

Dead pedal issues!!

Curious, does it do this when it fires up or does it start after driven/ run a bit? Try leaving the fuel cap loose and see if it has a vacuum at the tank which is stopping fuel leaving the tank. Be sure to check the pressure when you have the dead pedal too.

-

Curious what others think of installing a blocking diode to prevent AC Noise

I ordered 4 of these nice little rectifiers so I can play and test the results of this little project.. I am getting a little excited about it too.

-

Curious what others think of installing a blocking diode to prevent AC Noise

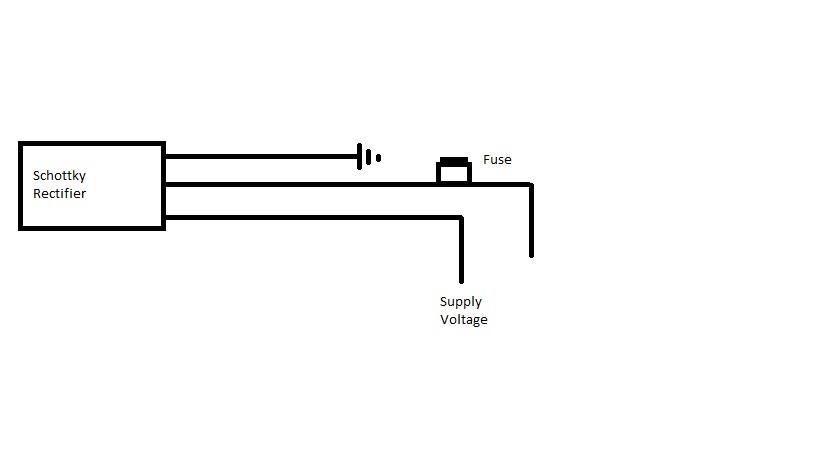

The diode will not have to handle the 140A charge current as it is only supplying the ECM, PCM, IP and lift pump with power. Pull the FMX fuse at #3 in PDC tie into the power there, run out of fuse box to the diode attached to the truck as a heat sink, through a 20A fuse and back to the #3 fuse to supply power.

-

Curious what others think of installing a blocking diode to prevent AC Noise

I agree that i was looking at the Zener the wrong way. It can be difficult to find information about some of these diodes. After a lot of consideration and a few discussions with an electrical friend of mine, I have come up with a Schottky rectifier. Say the left leg is connected to the power supply for the components at the fuse block and the right leg is connected to the ground, with the middle leg supplying the component with power. Stick the appropriate fuse inline with the rectifier and you have a rectified current. This rectifier is rated 40A bypass with .61V to .77V drop @ 20A with 1.25mA to 15mA reverse leakage current. 15/1000= .015A maximum leakage which is half the alternators allowed leakage. So from the power to the fuse #3 20A in the PDC where the ECM, PCM and IP get their power supply to the Schottky rectifier to a fuse back to supply the components with rectified power. The third leg will be grounded, preferably to the alternator minimizing resistance. This will rectify AC current, however, the main purpose is to maintain any possible AC voltage to be within specs of .03V or less to the sensitive electronics. https://www.westfloridacomponents.com/T621APL03/40CPQ100+40+A+100V+Schottky+Rectifier+Diode+International+Rectifier.html

-

Curious what others think of installing a blocking diode to prevent AC Noise

It doesn't seem to me that slight forward voltage spikes are bad. The alternator has a variance in the first place. A Zener diode is designed to regulate the supply voltage in power supplies, If I were to install one in the power supply line to the sensitive equipment with a value of 12V-13V it would only allow forward direction current and regulate the voltage fluctuation to the component. Stabilizing spike current and limit flow one way. Just need to know the wattage and compensate, or minimize, for added voltage drop.

-

Curious what others think of installing a blocking diode to prevent AC Noise

The reason I was looking into inserting one or more diodes is to protect the sensitive electronics in case the Alternator goes out of specs, not to replace the alternators diodes without repairing the alternator too. Makes sense to me that if these electrical components are so sensitive to AC noise, then why not add a layer of protection. A zener diode is capable of doing just this, however, I have not found any large enough to carry the full load of the truck. Therefore, I would be limited to individual diodes for components. Added resistance is not so much of an issue at the voltage and load of the components. When Moparman says that some trucks failed with such a low noise volume over spec, I start trying to find ways to protect myself from such costly repairs using inexpensive sensible measures.

-

trouble codes p0237 and p0112 limp mode

Check the resistance of the positive and negative posts in the MAP, should be around 1.5

-

Curious what others think of installing a blocking diode to prevent AC Noise

So I have been having difficulties if I have a Bosch or Denso alternator. What are the real tell tales? The Larry B's rebuild kits only cover Denso and say something about small wires going to 2 posts on the back. I looked for Denso alternators and the ones I find look like mine. I also find Bosch that look like mine. http://www.partsgeek.com/t11c86m-dodge-ram-2500-alternator.html?utm_source=bing&utm_medium=ff&utm_content=MP&utm_campaign=PartsGeek+Bing&gb=pp&utm_term=1999-2002+dodge+ram+2500+alternator+denso+99-02+dodge+alternator

-

Curious what others think of installing a blocking diode to prevent AC Noise

Using a DVOM what is an acceptable AC reading?