Everything posted by lcattin

-

TRUCK VIBRATION FIXED !

I finally found the vibration that has been eluding me in the truck for the last 10 months. I went through all possible things to check and found that it was a bad brake drum. I think that it was a deformed casting from it's conception. I had to go through 3 new brake drums to finally find a good one but now the truck rides on the interstate as good as my wife's Town and Country. I am doing my happy dance and now it is time for a cold one. Thanks to all who offered suggestions along the way. Many times you never hear what the cure was when someone has a problem so the reason for this message will help others who may be trying to find the vibrations problems in their trucks.

-

Dually bed fitmant

Is it possible to mount an 03 dually bed on a 99 truck?

-

Rear slide window

I never open mine either so to replace the latch I just drilled the screw holes in a piece of plastic to attach and hold the window shut. I always run A/C when it is summer here in AZ so don't need the open window.

-

ABS Question

When the temp outside is below 40 deg or so my ABS light will stay off. I drive 50 miles to work daily. If it gets above 50 degrees or so then the ABS and Brake light will come on. Anyone have any ideas as to why this might act this way? I have replaced the rear wheel sensor but not the front wheel sensors. Thanks in advance.

-

How much play?

According to what I read in the factory service manual, it says to pack them. My Haines repair manual said the same. Oh well, if I have to change them later so be it.

-

How much play?

Well, still have vibration at speeds above 66 mph although it not as bad as it used to be. I had the drive line balanced as it was out of whack a bit but still shakes a bit. Just found the lower pass side ball joint is not tight in the control arm so I have a new Moog control arm with ball joint and bushings already installed. Thanksgiving weekend project to get that put in the truck. Going to try to get the transmission mount changed this weekend. I've had it for a while but just haven't installed it yet. I am kinda throwing parts at it but it is things it needs and besides I now know what has been done and what shape it is in mechanically.

-

Dana 80 Wheel Bearing nut torque

Thanks. I'll give that a try.

-

Dana 80 Wheel Bearing nut torque

I have the Haines manual and the downloaded factory service manual for this 1999 Ram 3500. The two publications contradict each other on the setting of the nut for the rear wheel bearings. the factory manual states to back off the nut 1/8 of a turn after torquing to 120-140 ft lbs and the Haines manual says to back off 1/3 of a turn. I went with the factory manual and backed off 1/8 of a turn. One hub runs warmer that the other. Any advice. Thanks

-

How much play?

I got it all done. Bearings were in good shape, just needed repacked. Brake shoes were good also so while I had things apart I had the drums turned, one was slightly out of round. A propane torch did the job getting the axle bolts out. Made a drill guide bushing and drilled the broken bolts before removing the axle then with an easy out and a T handle and a small amount of patience until the propane torch did its job the broken ones turned easy also. I haven't driven it yet but after I adjusted the pass side last week my vibration diminished some. I hope it is all gone now. Thanks for all the suggestions. I'll let you know how the truck feels after I drive it to work tomorrow.

-

How much play?

Does anyone have a good source for the axle flange bolts for the Dana 80. I now have 3 broken bolts that I'll have to remove. Didn't know they had red loctite on them.

-

How much play?

I just pulled the tires and axle out of the pass side and the inner bearing is sloppy with the outside one tight. Gotta find a wrench to get the nut off now. I don't know if this has ever been apart. Red loctite and black paint still on the bolt heads.

-

How much play?

How much play in the rear wheel bearings on my 99 3500 2wd Dana 80 would it take to create the vibration I have been working to eliminate for a while?

-

EGT Probe alternate locations

Well all the gauges are installed and are working great. I immediately had to bump the regulator on the FRRP to get it where it wouldn't drop drastically under WOT. With the gauges installed we were ready to make the 3 hour drive today to hook up the 35' Travel trailer and tow it to our home here. Well it didn't happen as planned. On the way running 65mph my left front tire just exploded and had me heading toward an oncoming semi. With some fishtailing and the Hand of God the truck was gotten under control enough to get to the side of the road and stopped so I could clean my shorts and get the spare put on. It ripped out my plastic inner fender liner and ruined all the plastic on the front bumper which I had to rip off so I could attempt to drive once again. After finally getting to our destination I immediately headed to the local DT for a complete new set or rubber. Now I think I may have to get another alignment also. After all that I was not up to towing a 35' trailer so we drove home and the new tires did fine. What a day!!

-

EGT Probe alternate locations

I took the plunge and got a set of Isspro Gauges - Mechanical Fuel pressure with an isolater - Mechanical Boost and EGT. I am partially through the installation. I was able to drill and tap the exhaust manifold just next to the weld and it worked like a charm. Now to finish the install tomorrow.

-

EGT Probe alternate locations

Thanks for all the comments. I really want to put it in the right spot. I may be pulling my wife's 35' to Florida soon and would feel more in control if I can monitor the EGT's and boost.

-

EGT Probe alternate locations

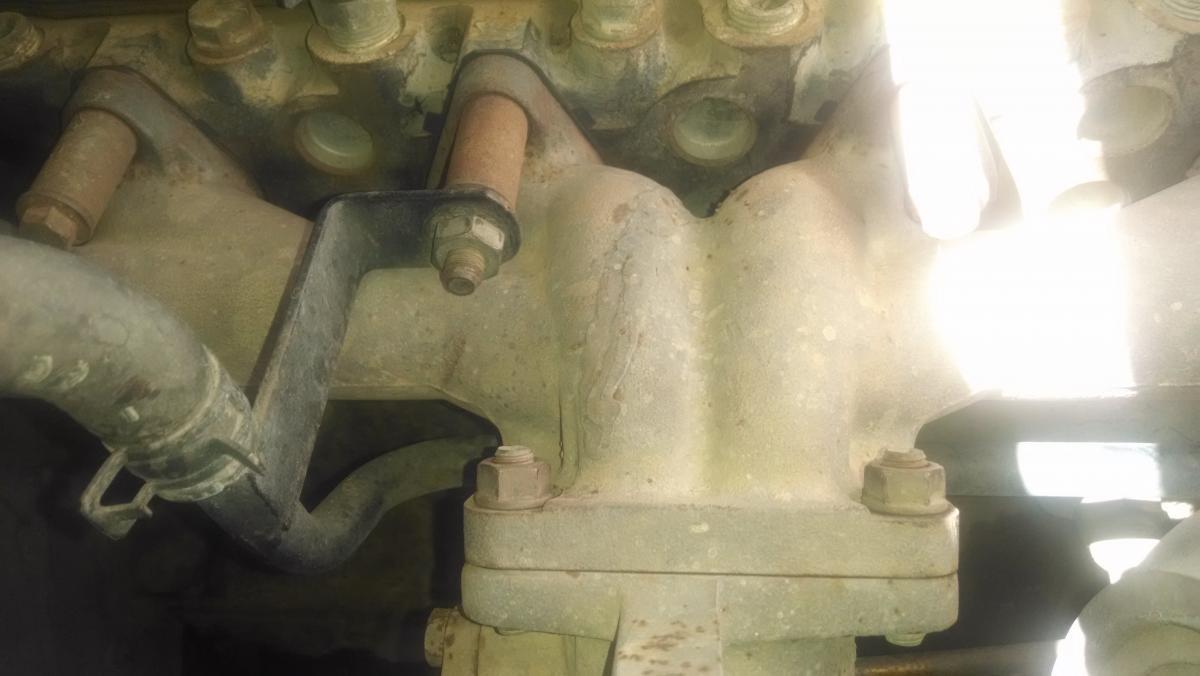

No. I had the manifold off a while back to replace the gaskets and it had definitely cracked almost all the way round.

-

EGT Probe alternate locations

I have a 1999 dodge 3500 1 ton cummins. I would like to add an EGT gauge. The problem is that at one time the exhaust manifold cracked. The PO had it welded ( it apprears they did a good job). The weld is right through the center of where the recommended spot is to drill and tap for the probe. Is there an alternate location where the probe could be located? I really don't know if I want to take the chance of drilling where the crack was.