-

Power for the P7100 and lift pump on a 99 24v swap

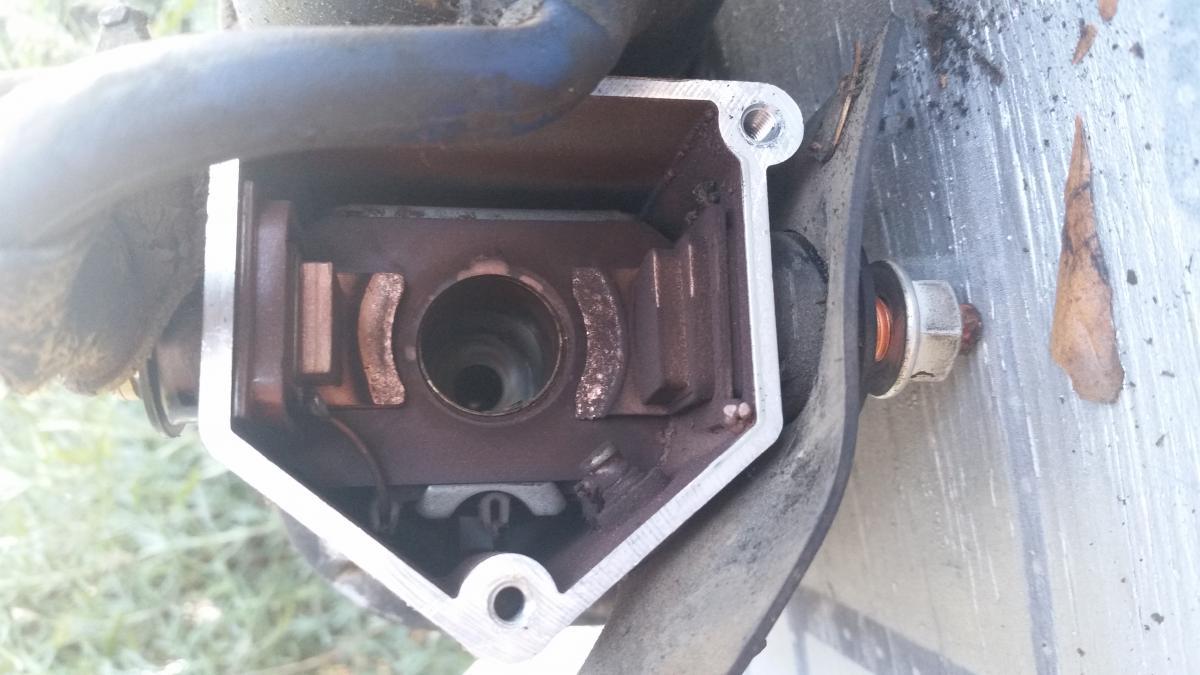

Morning and thank you for the response, the lift pump is an Airdog 2 165 and i will be upgrading to the G4 motor and pump as part of the project, while the old motor and pump are running fine, they are pushing 7 years old and about 80k miles. so it will be replaced. that said, it has its own relay that is already drawing from the battery directly, but using the ECM to trigger the relay. after looking at the diagrams, this signal is triggered from the VP44 directly, likely turning the pump on fire fire-up (you know the 10 sec bump of the lift pump) and thinking back when the VP44 crapped out 6 years ago, the lift pump would not turn on until the reman vp44 was installed and connected. I picked up the harness from larry b for the solenoid i have for the p7100. while i still need to look, it has at least one relay. I already am planning on running relays to power the solenoid and lift pump, I just need a signal source that has power at run and start position. the ECM will remain for now, I just need to figure out where i can secure it,. the p7100 is long enough to require ECM relocation, the harness does not have enough wire to relocate to the fire wall or frame rail. I will hunt down that wire you called out. I will also probe the vp44 harness, Worst case, I can run a simple hot wire but i know that is the last resort.

-

Power for the P7100 and lift pump on a 99 24v swap

Hi All, I have a question, I am in the home stretch of swapping my 24v i am needing to tap for key on power for the lift pump and fuel shutoff, those that have p pump swapped their trucks, where did you tap in for key on power? just looking for ideas before i get to that step Thanks.

-

Starter Hung,

the LarryB kit arrived, it was time, $35 and change to my door step and i have a starter the kicks like new

-

Starter Hung,

i just placed the order for the contact kit, if it needs more, i will order the rest of the parts and drive the First gen

-

Starter Hung,

ok Thanks

-

Starter Hung,

so you all just thinking the contact kit to start with? i see the contact kit, http://www.fostertruck.com/dodge-denso-starter-solenoid-kit-89-2006.html easy kit http://www.fostertruck.com/cummins-dodge-denso-starter-easy-rebuild-kit-94-06.html and the complete kit http://www.fostertruck.com/cummins-dodge-denso-starter-complete-rebuild-kit-94-06.html

-

Starter Hung,

I am ordering the kit tonight. I have new cables on the way so i will do the repair at the sametime, i looked over the starter and shes starting just fine. So i think the risk is low to continue until parts arrive

-

Starter Hung,

Ok great. Thanks i will get one ordered

-

Starter Hung,

That is an option. I just checked the starter. It is tight. I will start searching for a rebuild kit.

-

Starter Hung,

ok, well i am getting ready to inspect it, just so i know its not lossed up on me, i am looking at 200 bucks for a new starter and able 150 for a reman, I will budget it in. truck is at ~160k

-

Starter Hung,

Question, what is the normal or usual reasons for a starter to hang? I walked out of the office, fired the truck and it was the strangest damn noise, once i realized what it was, I shut it down, restarted normally, home now, tried to reproduce it and it seems to be fine now. I have the truck on ramps cooling at the moment and going to inspect the starter to make sure its not lose etc. it was the damnedest thing FYI, i just replaced the batteries and the truck has a very brisk start to it now. is the starter getting worn?? Thoughts?

-

Alternator not charging, PCM not sending signal?

have you run a continuity test on the field coil ? you should have 12v on one pin of the field connector (Blue wire IIRC) but its a 50 % chance if the two above are true, then i would look at the bridge again

-

Lift pump issue?

your right, good, then i dont need to worry about my ECM. which makes more sense with the unit i linked from the autoparts house I stand corrected,

-

Lift pump issue?

the built in regulator failed and instead of failing open (killing the alternator) , it started applying full power to the field and proceeded to cook it. it was funny, I was dropping my wife off, nothing seen out of wack, right after pulling away i started smelling burning/hot wire, and i saw a wave of smoke from that side of the hood, pulled over and the alternator was cooking pretty good by then, at idea the voltage stay around 15 volts, i decided to move truck and just off idle the voltage started climbing. so i had to sit for a few minutes to let the process complete, when the voltage dropped to 12.8 volts, i drove the ole girl home. just figuring / hoping something was screwy with the old alternator, I through the new one on and with in 30 to 45 second the voltage started climbing and once it pasted 15.5 volts i shut her down. looked everywhere for bad grounds broken wires, etc. nothing. the best i can think of is the circuit path with in the ecm for the reference voltage broke so as far as the regulator circuit knew, it was not charging to spec and kept increasing the output. so after taking the article i found here for the external conversion, I applied a few changes, shes been rock steady at 14.4 volts at the batteries with less then .020 ripple voltage not the best solution because i lost the battery temp system and i am sure that is what finally took out my 13 year old batteries. (over charging with the heat we have had this year. (not the hottest on record) )

-

Lift pump issue?

yeah, very likely, I was searching when my ECM decided to burn up my alternator. i have been using the external regulator setup with great success. I would like to have mine rebuilt, but i want to find a local provider (unlikely) the ole 12 v is looking better and better LOL