Everything posted by Timburrr

-

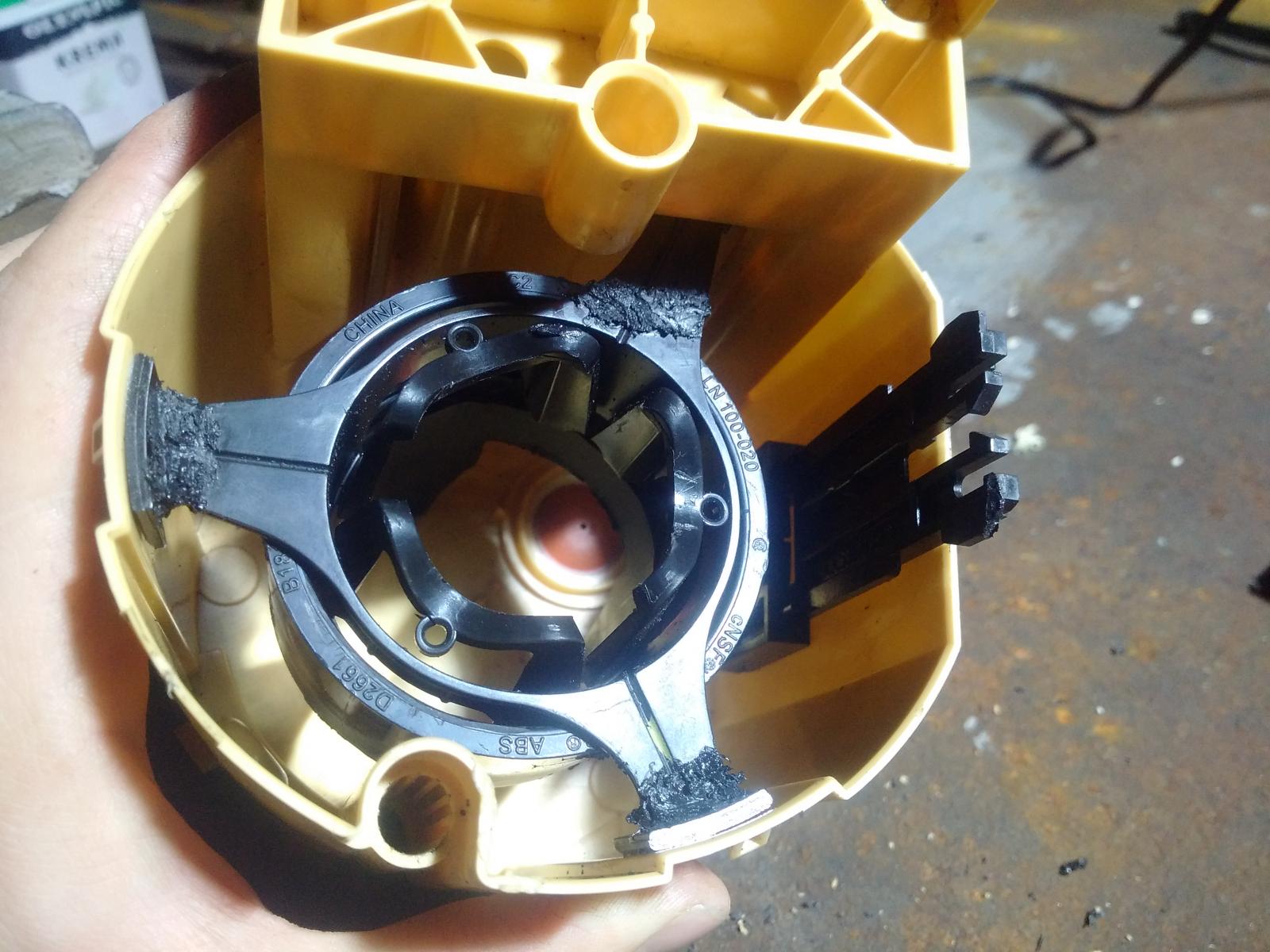

Is mild steel okay in fuel tank?

Thanks to everyone for the help. Especially the info that ABS is safe for diesel, that saved my bacon. Made a sort of support using 2" ABS and a double female fitting, then used a soldering iron to hillbilly plastic weld the original pump bracket back in. Finally put on the bulkhead fittings and hoses and everything is back together. It took a long time, and that was with a helper. I did spend a lot of time chasing down my tools that got scattered all over the place. After its all said and done I think my batteries are in rough shape so I didn't get to start the truck, but they're charging overnight tonight. One thing that I have to say was embarassing was when I was tripping the pump to prime and get the air out I was losing my sh#$ when nothing would come out, but after a few tries I remembered to take the clamp off the supply line hahaha! I'll chalk that up to sleep deprivation. Thanks again!

-

Is mild steel okay in fuel tank?

It's regulated by a spring. They have different springs for different applications. For the 2nd gen its regulated at 15-18 psi. I have two fuel pressure gauges and have also used a mechanical gauge and its at about 12.5-13 at idle but comes down when I'm working the engine hard. Seems to be friction loss. When I deadheaded the fuel system it did 15.5psi if i remember right. The cummins dealer up the road says anything above 10psi is safe for the pump, but from what I have read 14+ is ideal but too much pressure can create the starting issues. Have gone through some problem solving steps and I believe the issue is in how they originally instruct you to remove and bypass the in tank pump. I'm putting in the vulcan 1/2" draw straw and eliminating the H manifold to have a separate return line to the basket and the 1/2" draw straw supply line. I went with BD because they have a good reputation around here and they're somewhat local (a ferry ride and 2 hr drive away) and support has usually been pretty good.

-

Is mild steel okay in fuel tank?

Thanks for all the replies. I'm trying to keep up but I had to take care of both kids while the wife was out and the struggle is real. The pump is pressure regulated at 15-18 psi. BD Diesel has a pretty good reputation for their parts around here, but since its made in Canada its probably not as widely sold south of border (I'm guessing). As soon as I get this silly bracket made up I'll probably drill the holes but I'm fairly confident I won't have issues either way. I definitely didn't want to do the sump because I don't like the idea of putting a hole in the bottom of my tank and I also don't like hoses down low where they can get snagged. I don't do what I consider "offroading" but I go on logging roads and spurs for hunting/camping etc and I'd hate to be in the middle of nowhere and have a branch kick up and tear off my fuel line!

-

Is mild steel okay in fuel tank?

you are correct only the return line from after vp44/injectors. my logic was if X amount of fuel is being consumed by the motor then X amount of fuel needs to enter the basket and any unused fuel being pumped by the lift pump (whether after going through the VP or straight from the airdog return line) going back into the basket doesn't matter, as long as it goes into the basket. Maybe another way to put my thoughts are that my understanding is the bottleneck is where the fuel enters the basket, and if it keeps up now, it should keep up with the new draw straw because my motor will consume the same amount of fuel. but maybe i'll just drill the holes just to be sure?

-

Is mild steel okay in fuel tank?

I have the BD Flow-Max. It's a 150gph pump with the water separator and donaldson filter. https://www.dieselperformance.com/shop/product/1050301df-flow-max-fuel-lift-pump-c-w-filter-separator-dodge-1998-2002-5-9l-24-valve-19641

-

Is mild steel okay in fuel tank?

015point9: i googled but didnt find a solid answer, thank you so much. this will save me so much time! Dieselfuture: thanks a lot for the pictures. that helps a lot. if you are low on fuel and parked on a hill, would it drain your basket? how low can you let your tank get? thanks. sorry for short reply, i have the baby on my lap and making sure she doesn't fall off!

-

Is mild steel okay in fuel tank?

That might make this very simple to use ABS pipe. Is ABS diesel safe? That could save me a bunch of time fabricating a metal bracket.

-

Is mild steel okay in fuel tank?

Thanks for the reply. I have a stock motor, and the return line runs right back into the basket, so with the motor not drinking fuel any quicker, and not having issues with running the basket dry now, would I probably be okay not drilling the hole? Or maybe just drilling one hole? I don't know why I'm so against drilling holes, but I don't think it would benefit me. I'm not a rocket surgeon though. I've already dropped the tank twice, another time coming up soon, whats one more to put some holes in it if needed? lol. but holes i'm guessing to be drilled evenly spaced?

-

Is mild steel okay in fuel tank?

Long story short, I am doing the vulcan draw straw mod in my fuel module and i have to make a bracket to hold the supply and return lines in place. Is mild steel okay to use for this? It would be 2-3" from the bottom of the basket of the fuel module so it would basically always be covered in diesel (I don't imagine it would corrode). It would be incredibly cheaper and easier for me to make it out of mild steel vs aluminium or stainless. I'd enjoy hearing thoughts on this. While we're on the topic, they mention drilling holes in the side of the fuel basket, but this seems like it would be more prone to let fuel out than in. Is it necessary to drill the holes?

-

Oil leak in turbo

It's funny because its not super remote, just remote enough to not have anything available. I'm about an hour away from Victoria. It seems like even in some bigger cities in Canada selection and inventory are slim because there just isn't the same population for businesses to make scale. I have worked in remote areas all over BC when I was a forest fire fighter and then as a production faller and I really like small towns. I think If I could have chosen my future I would have been a farmer in a rural town but you basically have to be born into a farm it seems. Don't know how anybody could pay one off buying one and working it! Yeah I don't like the idea of a runaway. I have a manual transmission so I can always put in the clutch and let it pop. probably have a hard time stalling it out unless I was going up a hill slow... but knock on wood anyway. I'm leaning towards just getting the modified HX35. I looked at the Super B too but its a lot more money and I don't really want to be pushing tons of boost. My long term plans are like 50hp injectors and enough turbo to keep it happy and cool. Maybe a real gentle tune but not sure. Basically just enough to make towing a little nicer. So if I get that turbo now I save myself some time, don't have to put on a new downpipe or anything like that and don't have to worry about ramming tons of boost into an otherwise stock engine. I'm not really sure what exactly the mod is but I assume its similar to an hx35/40 hybrid or maybe just one of the more aggressive wheels on the compressor....I'm going to get the details as to how fast it spools up and what it puts out for boost before I pull the trigger.

-

Oil leak in turbo

None available locally. I live in a smaller town in Canada which means everything has to get ordered in lol. On top of that I'm on an island so everything is a ferry ride away too.

-

Oil leak in turbo

So I'm weighing my options right now. I really need to go pick up this trailer next week. I've talked to a couple mechanics I know, They both don't seem concerned about imminent failure. I don't think I can get the rebuild kit mailed out to me in time, and have time to install it before I go. I'm also worried about parts being seized and doing all that for nothing. Still considering it. What I"m leaning towards is: BD upgraded HX35 for $1500ish. Its a performance upgrade, which I was hoping to do in the future anyways, I'm just not sure if its enough of a performance upgrade. I'm not looking for crazy power, probably just 50hp injectors and enough turbo to keep things cool and make towing a little easier. Not sure what it puts out for boost. Other option is a reman turbo from ADP turbos which I haven't heard much about. Parts store says they are good. $800 and *SHOULD* be here before I go. Simple swap in and out. But could potentially be money spent that would be replaced in a couple years on an upgrade. Would you guys feel okay going on a trip to pick up a trailer with it as is (new air filter in obviously) and get the upgrade, or is this like a do not fly situation... FYI all prices are in Canadian Pesos.

-

Oil leak in turbo

I see the filter itself at DAP but there must be a housing to mount it which I can't seem to find? MoparMan, did you do a write up or take pictures when you did the rebuild?

-

Oil leak in turbo

Would you guys ground the truck for now? I have to go pick up a trailer about a 10hr drive away next week and I don't know if I'll have time to get to the turbo before that. I will see how much a shop will charge for a rebuild, but if its a lot or they can't get to it soon, would you feel safe driving around for a while?

-

Oil leak in turbo

Thanks, I had just found it!

-

Oil leak in turbo

I'm tyring to find your thread, but you have so many posts! do you know what the thread is called? Thanks for the help.

-

Oil leak in turbo

Arg. How easy? I'm trying to find a good walk-through to see... Also, mine says HX35W. Is this different from the HX35?

-

Oil leak in turbo

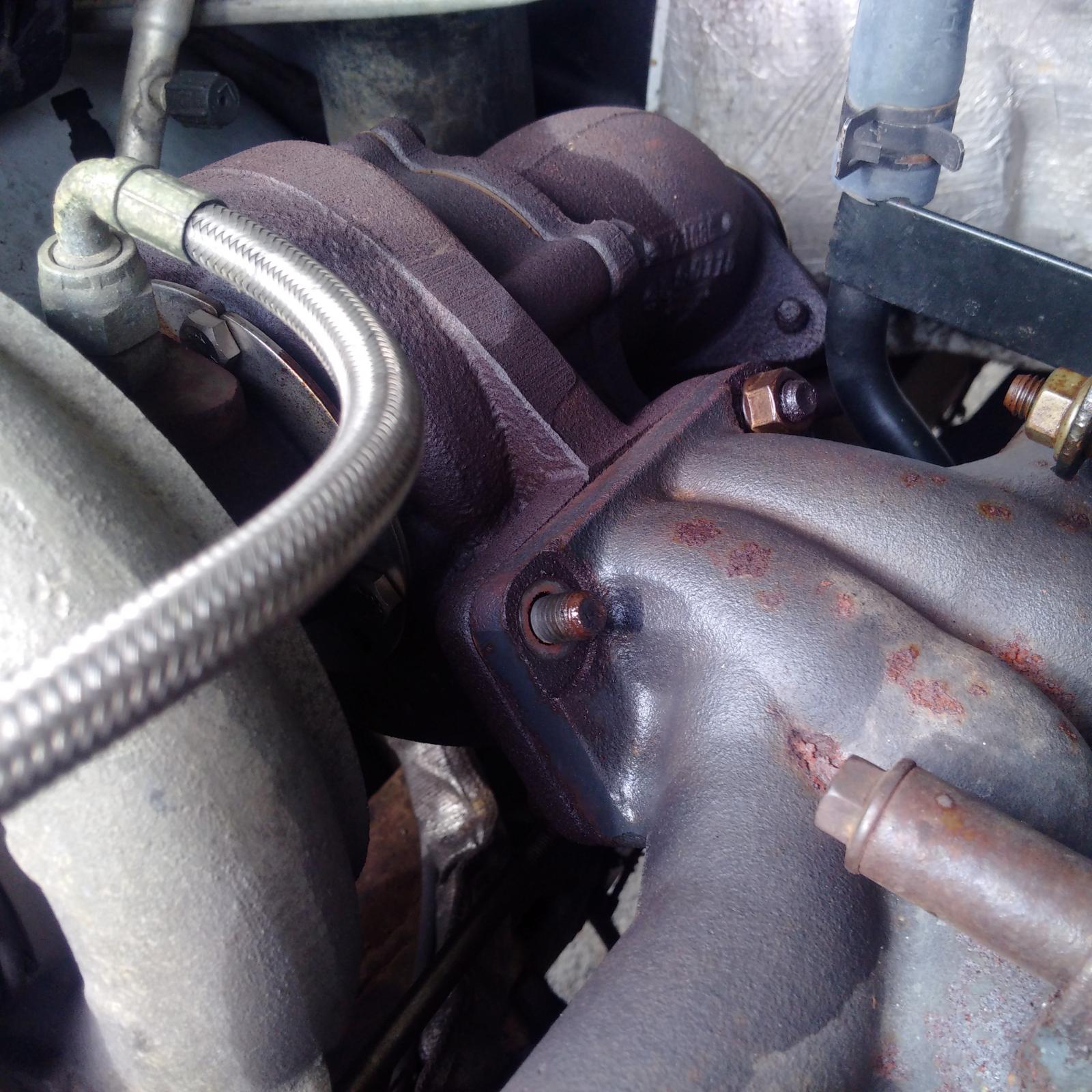

So I'm installing a new exhaust manifold (you'd be surprised how many issues you can run into doing this simple job) and this is what I find. Is this enough oil for me to be concerned?

-

Advice on Exhaust Manifold/System/Brake

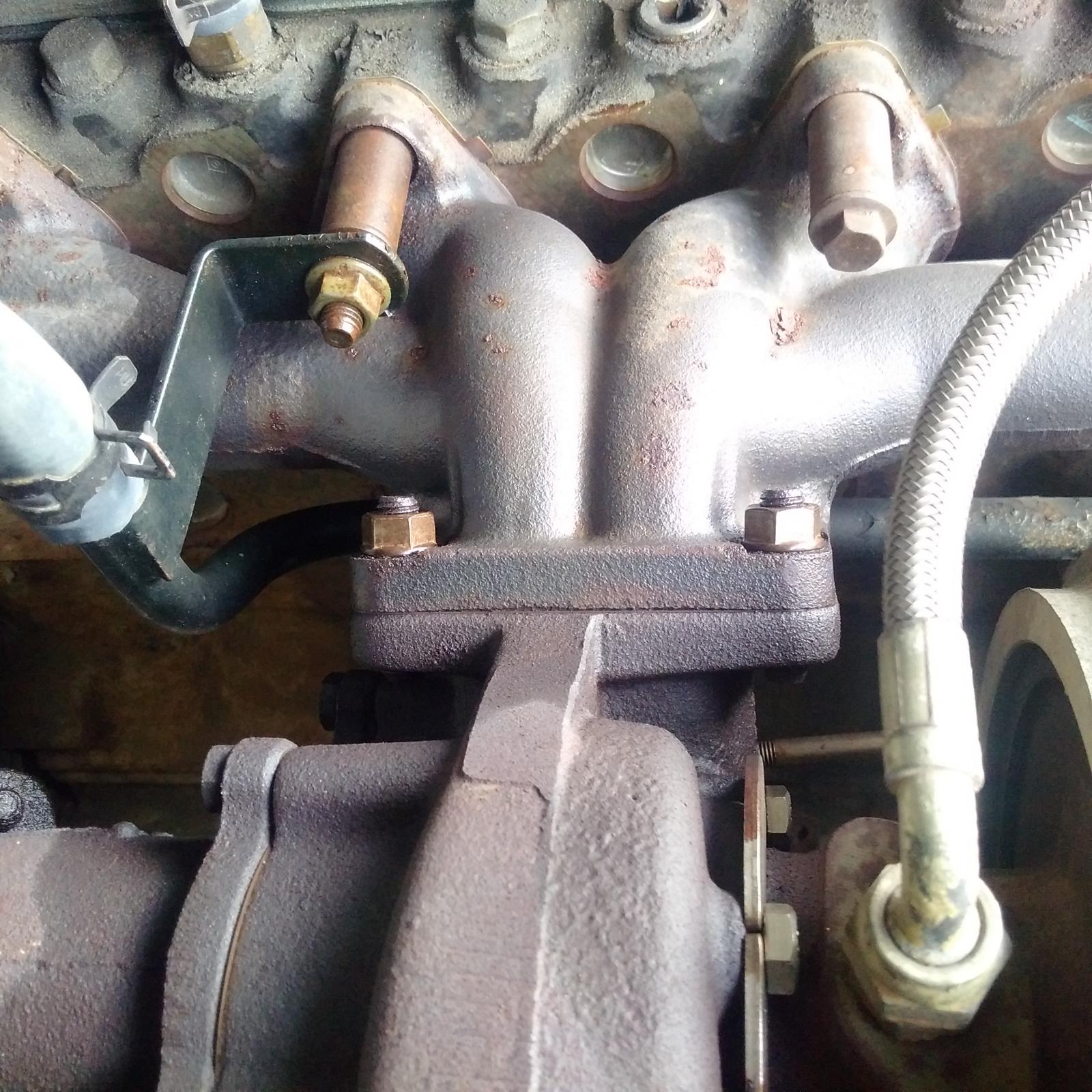

I guess I'll call DAP tomorrow to see what the program is because all 4 holes in the new manifold are tapped so the turbo won't mount up as it stands now. I guess I will also look into how the aftermarket turbos I may get in the future are set up because it would be a shame to have to replace the manifold again for a new turbo application. Upon further reading i think I have the wrong manifold. I think this one is for 3rd gen swaps maybe.

-

Advice on Exhaust Manifold/System/Brake

So i'm about to get started and something funny is going on. Everything in manuals and that I have found online shows the turbo to manifold studs threading into the manifold and the nuts threading on the turbo side. On mine the bottom studs are in this orientation and the top are reversed (studs thread into turbo flange and nuts on manifold side). What the heck is going on here? The exhaust manifold is threaded on all four holes so i'm obviously going to have a problem when I go to mount this.... should I drill out the threads on the turbo???

-

Advice on Exhaust Manifold/System/Brake

Cool! Thanks man! Is that remote or turbo mount?

-

Advice on Exhaust Manifold/System/Brake

Arg. Looks like it's behind VP and not easy to splice into!

-

Advice on Exhaust Manifold/System/Brake

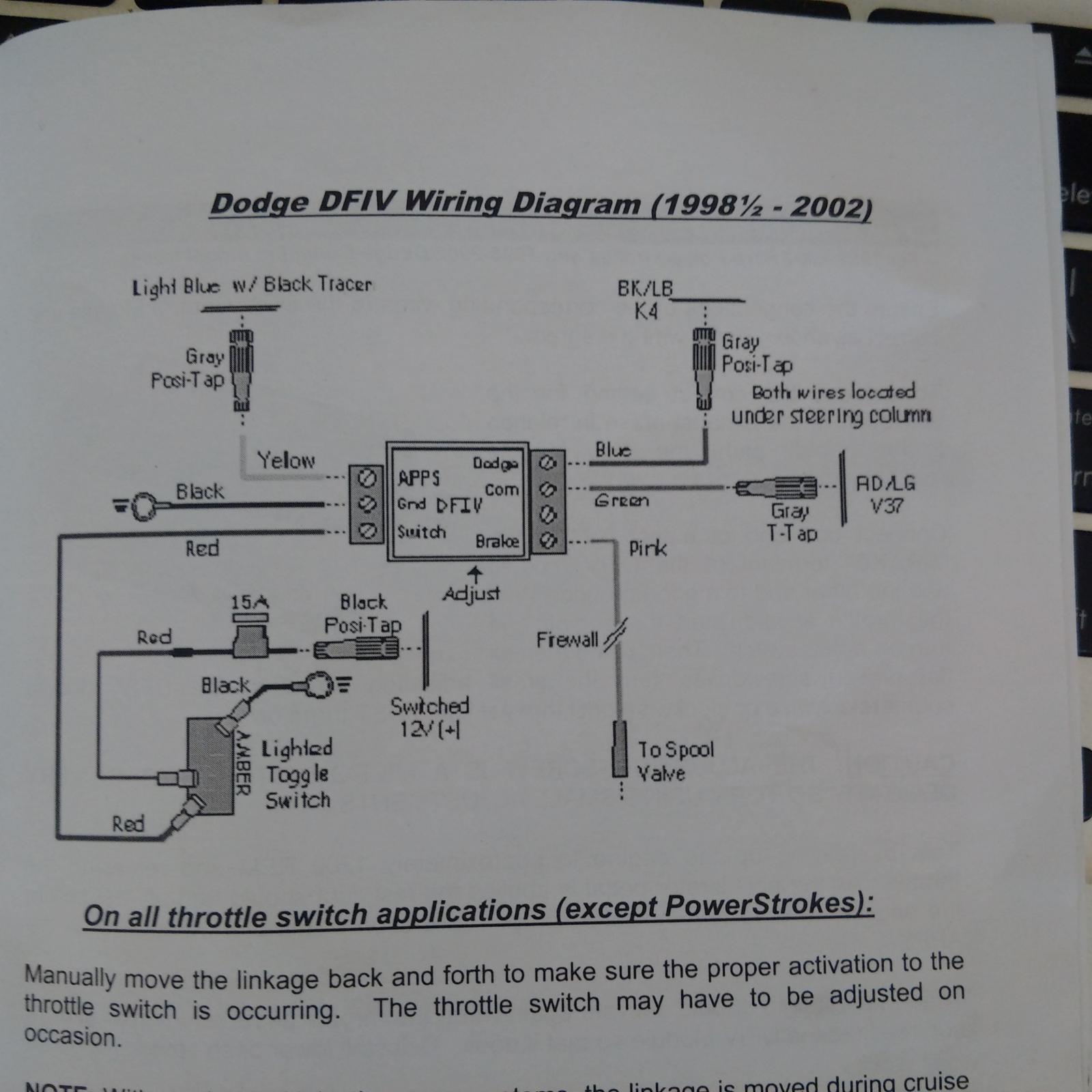

For the BD I have to tap into a few wires. Two I can find (the BK/LB and RD/LG that come down from the steering column) but I'm having trouble finding the Light Blue/Black that goes to the APPS sensor on the control switch. Should be on my side of the firewall somewhere. Any idea which cluster to fight through?

-

Advice on Exhaust Manifold/System/Brake

Well the exhaust brake has arrived and I'm going to get started on the stuff I can install before the manifold and exhaust system arrive. I'm looking for the wire the hooks up to the APPS sensor of the brake control. It's a Light Blue w/ Black Tracer. Any help on which bundle to look for? I'm going splice into the wires (with butt connectors, not those cheesy tap n' splices) and want to get as much done before the other parts show up as possible. I'm surprised that the main vacuum line that runs to the control valve is 3/8" and the main line coming from the vacuum pump is maybe 1/8"...I called tech support and they said the vacuum pump is adequate to run it. Any thoughts on this? In hindsight I'm starting to think the Pacbrake might be a better option for the remote mount because it comes as a compressed air actuated model that is smaller, faster to engage/disengage, and gives you the compressor that you can use for other upgrades. I'm also a bit disappointed that the exhaust pressure gauge kit doesn't seem to be mountable at all unless I mickey-mouse it with zap straps or something...which will make me lose sleep. I can get a different gauge in the future for a clean mount but I was hoping to have everything done right the first time. Any thoughts on blipping the throttle to double clutch on downshifts? My understanding is the exhaust valve should activate fast enough to not damage anything (the same as you can leave the brake on and it disengages whenever you have throttle applied).

-

Advice on Exhaust Manifold/System/Brake

Thanks for all the help. I think I'm going to go with the Diamond Eye. Looked up shipping weights and its 10lbs heavier, which to me likely means more metal. 73 lbs vs 83 lbs. I thought about getting a bottle of gas for the stainless and some wire, but I think this would be a one-off job. 409 is ferritic stainless steel and uses different gas and wire than austenitic stainless and if i was to do anything in stainless down the road it would almost certainly be austenitic. I usually do the "why buy something for $50 when I can build it for $100!" but money is tight with another kid on the way so I think it would be cheaper to have a shop do it and just be done with it. If I remember right it would be about $250 Canadian Pesos for a small bottle of gas and most of the shops here only sell Mig or straight argon in the small bottles and anything else is usually big bottles. All the help is appreciated greatly!