-

Contemplations on an abandoned project: 2nd Gen 24v

Back in 2017, my 2001 2500 died in the driveway. I had just repositioned it so that I could load it up for a trip to the dump. An hour later, it wouldn't start. It would turn over, but not run. A friend brought a winch over, and we dragged the truck over to the side of the driveway. Five years later, it's still sitting there. It starts now, or it did in 2020, last time I tried. But I only get two positions on the throttle. Idle, and high-idle. (I think that indicates a toasted PSG5) If you look in my post history, you can see a few threads I made regarding my attempts to get it running again. Long story short, I drive a different truck now. But this one is still here, complicating my driveway. I wish I was still inspired to get it working.

-

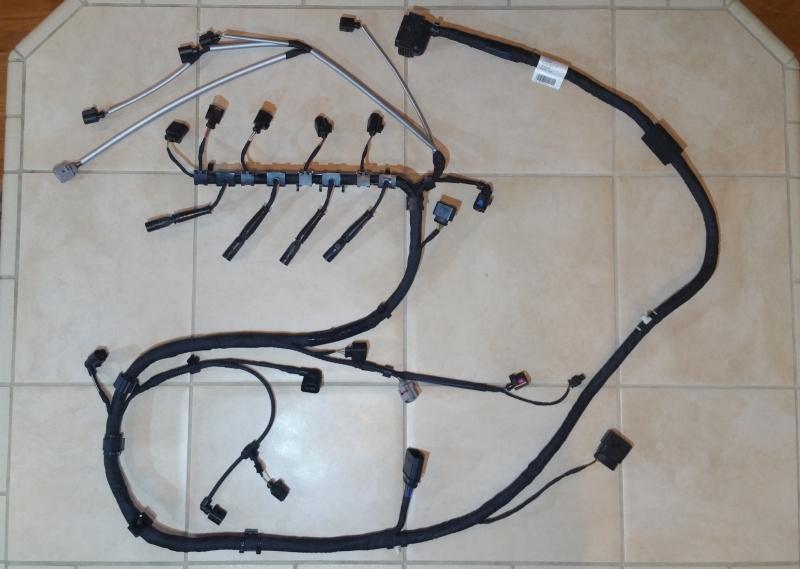

Show and Tell: 2010 VW Jetta TDI Engine Harness

I need to replace the engine harness in my TDI. I just thought I'd share some pictures: The reason I have to replace it is because there are a couple poorly protected areas of the harness where the wire jackets suffer vibration damage. This is one of those spots. The harness is wrapped with harness tape everywhere, except for here [below]. For this section, they stopped wrapping with tape, and substituted with this semi-translucent black fabric that kinda looks like really thin and very fine-pitch velcro. This section of wire is prone to chafing as it wraps around the oil-filter housing. In my amateur opinion, it makes no sense to "protect" this section by removing the protective tape and replacing it with this thin cloth. Until I saw this, I was going to add an extra layer of tape to protect it. But now, not knowing why they did this, I'm stuck wondering if that would make it worse. There's also this one additional section that has the same treatment. No Idea why.

-

Engine Harness Rebuild

I'm using Tesa 51036 tape. http://www.tesatape.com/industry/tesa-51036.html I bought three rolls on amazon. I only used one roll to do all that wrapping. I have no prior experience with harness wrapping, but I found this stuff was really easy to work with. It's not very sticky... just sticky enough. If you accidentally stick it to itself, you can separate it without fuss. If you need to back off a few wraps and then continue, it seems to re-apply confidently. It's a tough cloth with a texture that feels like you could use it as armor.

-

Engine Harness Rebuild

-

Engine Harness Rebuild

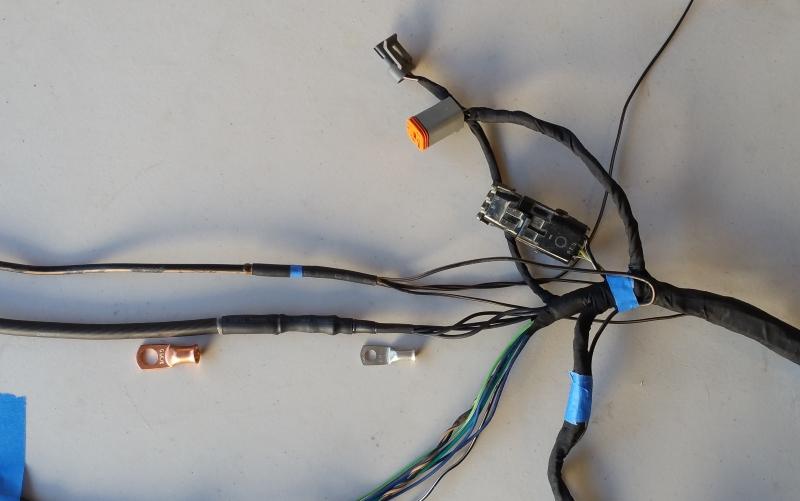

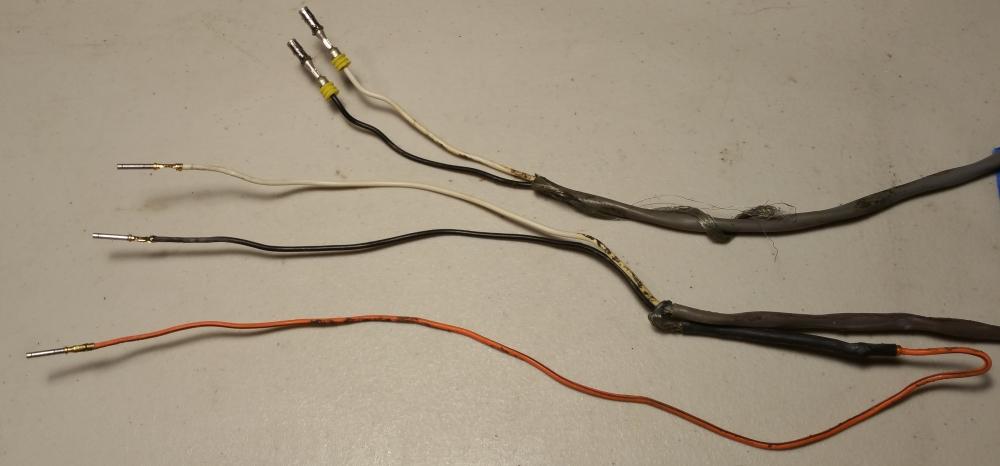

Ok... I unwrapped my freshly-wrapped harness to see how I could incorporate the W-T mod. This is my new ground wire sitting next to the stock ground wire. I tried to line them up so I compare the splice locations. Do I have enough length to the right-side of my splice, so that I can use the smaller connector? Or should I maybe use the larger connector and go all-the-way to the driver-side battery?

-

Engine Harness Rebuild

Tons of good reading from @W-T threads. Thanks for pointing those out. Now I have to reconsider my new ground wire.

-

Engine Harness Rebuild

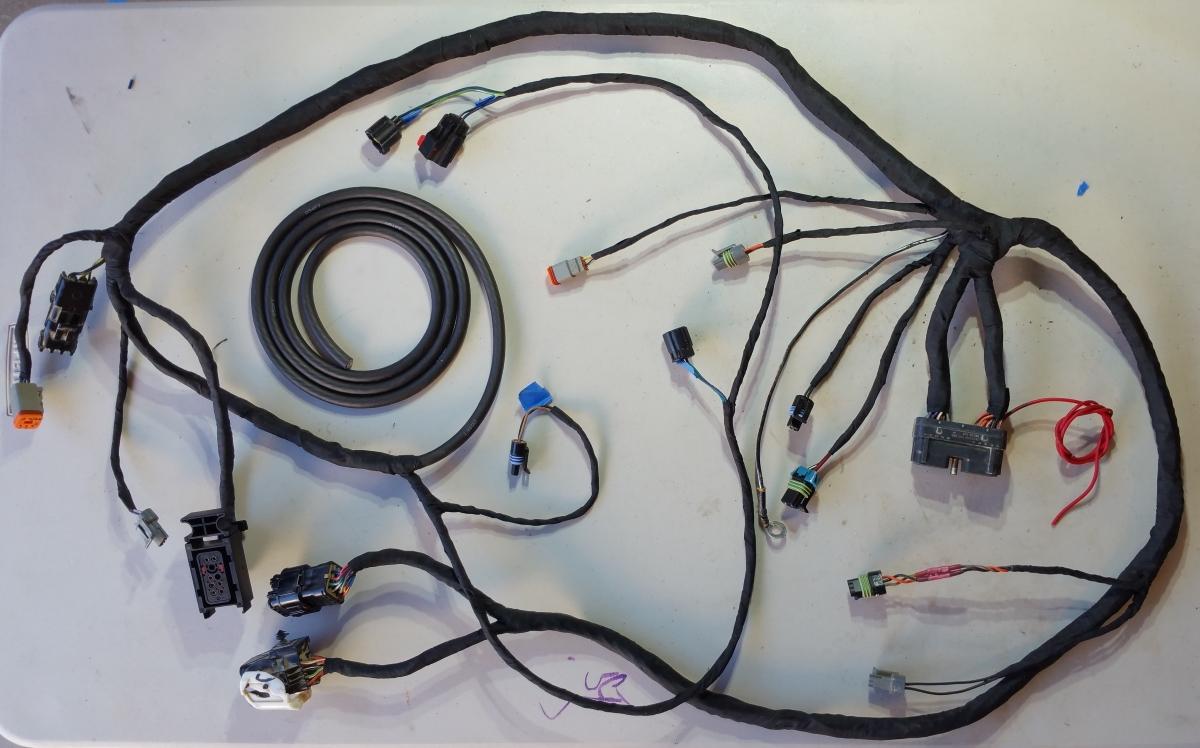

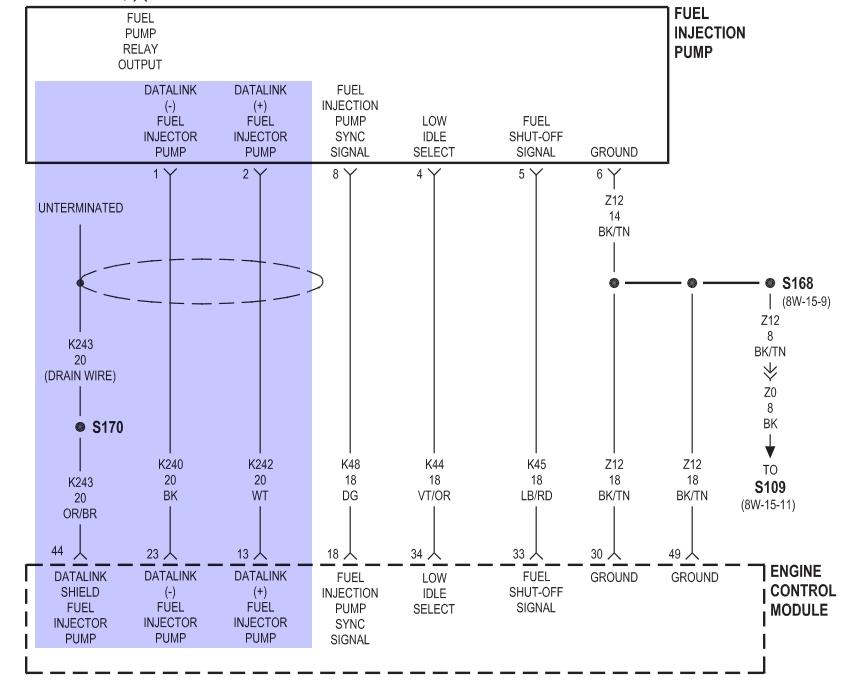

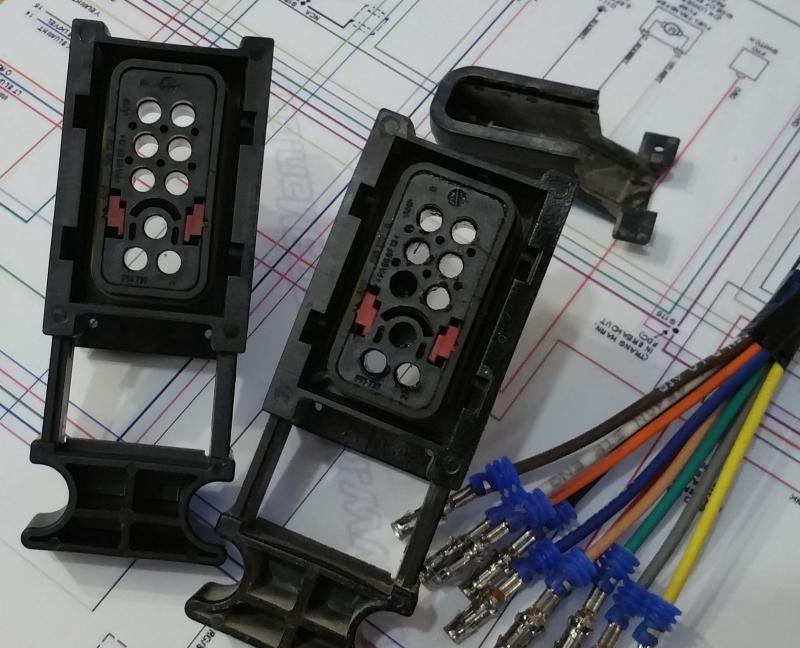

I've been ignoring this project for a few months, but I recently made some progress. So I'll share some pictures. If you ever have a hankering to rebuild an engine harness, this is your future: After several failed attempts to untangle that mess, I kicked the Camry out of the garage and set up some tables. I finally got a chance to re-wrap the harness this weekend. The coiled wire is the "computer" ground that connects to the passenger-side battery. I will cut it to length and crimp-on the end after the harness is installed. This entire ground-wire node was rebuilt from scratch using new wire and contacts. The VP44 connector shell is brand-new. I replaced the entire DATA (+) and DATA(-) shielded wire, that goes from this connector to the ECU. I replaced the contact on the #5 FUEL SHUT-OFF pin to repair the wire I damaged while troubleshooting. And the #6 GROUND, was replaced as part of the ground wire I mentioned above. I replaced the shell on the C126 connector. I wanted to do the same for the C125 connector but I was not able to find that shell. You might notice that the alternator-to-battery wire is no longer integrated into the same wrap. In an earlier project, I replaced all the battery wires. So when I took apart the harness, I removed the already abandoned B+ wire. I wanted to replace that red wire on the ECU connector, but I wasn't able to remove the pin from the shell without damaging the shell. So I'll just put that wire back together when I install the harness.

-

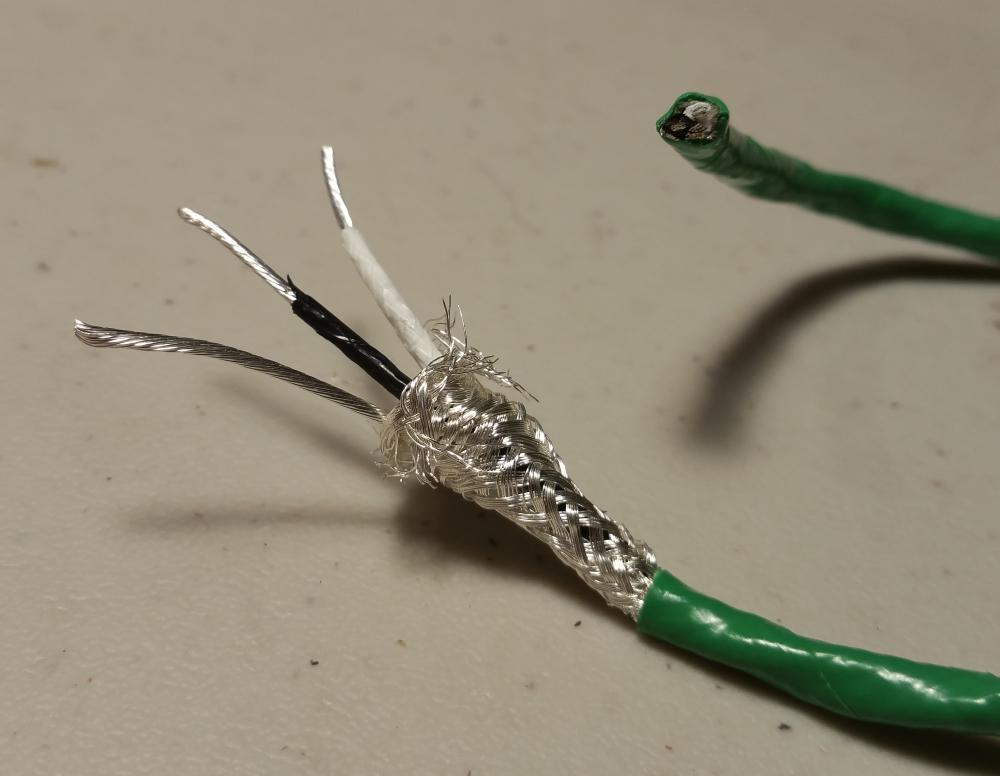

ECM <--> VP44 Canbus wire replacement

I'm replacing this wire: The wire is a shielded twisted-pair with a drain (SAE J1939/11). The wire seen here is the stock wire. It's comically unkempt. Note that the orange wire is about five inches too long, so that it must be doubled-back to make it the proper length. Also, the shielding is missing from the first six inches, and the last four inches. Neither of these is a problem from a functionality standpoint. I mean, it probably doesn't hurt anything. It's just sloppy. That loose twist of shielding provides no benefit, so why did they leave it loose like that? This is what I made to replace it. All new wire and connectors. It was hard to find a short length of J1939 wire. I found a few sources that were happy to sell me a 250ft spool, but I wasn't happy enough to buy it. I found a guy on ebay selling teflon/silver shielded twisted pair. $35 bought me 25ft. I wasn't trying to get silver. In fact, I wouldn't have bought it if I had realized that this is what it was. However, this is remarkable wire, so I'm going to give it a try. It's temperature rated to 200ºC. I don't know if it's oil rated.

-

ECM <--> VP44 Canbus wire replacement

I'm replacing this wire: The wire is a shielded twisted-pair with a drain (SAE J1939/11). The wire seen here is the stock wire. It's comically unkempt. Note that the orange wire is about five inches too long, so that it must be doubled-back to make it the proper length. Also, the shielding is missing from the first six inches, and the last four inches. Neither of these is a problem from a functionality standpoint. I mean, it probably doesn't hurt anything. It's just sloppy. That loose twist of shielding provides no benefit, so why did they leave it loose like that? This is what I made to replace it. All new wire and connectors. It was hard to find a short length of J1939 wire. I found a few sources that were happy to sell me a 250ft spool, but I wasn't happy enough to buy it. I found a guy on ebay selling teflon/silver shielded twisted pair. $35 bought me 25ft. I wasn't trying to get silver. In fact, I wouldn't have bought it if I had realized that this is what it was. However, this is remarkable wire, so I'm going to give it a try. It's temperature rated to 200ºC. I don't know if it's oil rated.

-

Found source for VP44 connector

@GSP7 I've chewed up my existing connector doing a bunch of tests to diagnose my VP44. I cut the Pin-5 wire too. So I got this to repair the damage I did. I'll replace all the contacts, while I'm at it.

-

Found source for VP44 connector

I found a source for VP44 connectors, and pigtails. http://americadiesel.us/ $13.20 for the connector shell $2.20 for each pigtail (I ordered 10, to allow for a few mistakes) $57 shipping My total was $92. Even with International Priority FedEx fees, that's still cheaper than other sources. It's a genuine AMP 965734, new. Our stock connector has two holes blocked. This one has all nine holes open, so I'll have to plug two. It did not come with the wire-cover back-plate. I ordered 10 pigtails. I was expecting them to be all one color, but I was happy to see that they randomized the colors for me. They aren't the factory colors/stripes, but any color is better than all-the-same.

-

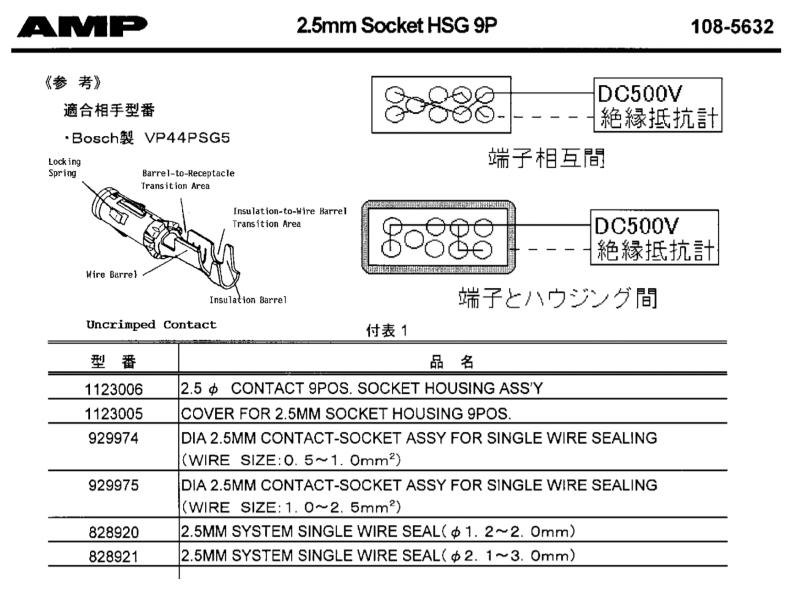

How to extract terminals from a VP44 connector

I found some AMP documents that show the terminal and part numbers. I pieced together the relevant bits. The 929974-x is for 17ga to 20ga wire. The 929975-x is for 13ga to 17ga wire. The heavier gauge is used for power +/- (pins 6 + 7). The rest are all the lighter gauge. I kind-of expect that the stock part was -3, but you'll never find any to buy. -8 seems to be the only gold variant that is available. -1 CuNiSi pre tin -2 CuNiSi silver plated -3 CuNiSi gold plated -4 CuFe2 pre tin -5 CuFe2 silver plated -6 CuFe2 gold plated -7 CuNiSi silver plated -8 CuNiSi gold plated <<< Choose this one. As seen here: Master Electronics 929974-8 Master Electronics 929975-8

-

How to extract terminals from a VP44 connector

@Bobalos, Is that tool used from the front, also? I tried to make one to extract the pins in that kind of connector. I couldn't figure it out. I'm looking for a source of the terminals for the VP44. I found some that have pigtails, but I want to do my own crimps, to avoid butt connectors. Those look close, but they don't have the big stop-flange at the back.

-

How to extract terminals from a VP44 connector

Maybe you've followed the VP44 diagnostics instructions over at blue chip... there's a point where one of the steps involves cutting the wire for pin 5. If you really need to do that experiment, don't cut your wire. Pull the terminal. I made a tool to extract terminals from a VP44 connector. It's just a bit of brass tubing. I put it in a drill and sanded it down until it was small enough to fit into the front of the connector. You need to move the little red tabs. This releases the lock that holds the terminals. But it's not the only lock. Insert the brass tube over the front of the terminal. It should go in about 1/4" or so. The tube will cover the barbs in the terminal... releasing the second lock. Then pull out the terminal. . Good times.

-

How to extract terminals from a VP44 connector

I wasn't really meaning to endorse those diagnostics instructions. I was just using that as an excuse to talk about one of the reasons you might want to extract pins from a VP44 connector. Nevertheless, here it is: https://www.bluechipdiesel.com/vp44_diagnostics.html I cut my pin-5 wire, and I wish I hadn't. It didn't do me any good. So knowing how to extract a pin might save somebody some grief.

marked23

Unpaid Member

-

Joined

-

Last visited