-

Blowby and miss

@Rotket for sure go after the miss.. you can also do a leak down test since you are going to have the injectors out. Pull each piston up on its stroke with all the valves closed on the cylinder. And apply shop air pressure with a leak down tester and then see if it holds. If you have a bad valve, seals, or rings that should tell you. The pressure will leak down very quickly and you will hear where it is coming from. ( make sure you have the crank held in whatever position you apply pressure or it will move.) I did this not long ago and found out number 5cyl had a broken ring even though it would pass a compression test.

-

High Pitched "Cricket" Buzz

The truck you have listed is a 4x4 right. It might sound far fetched but I have seen it before. The pinion bearing can make sounds like that and project up and sound like a belt or idler going bad. They usually act up when loaded and then quit when unloaded. Being that these trucks(at least from the ones I've delt with drive the front drive shaft all the time, when you accelerate it loads the pinion then when you let off it unloads and quits making noise. Check your diff fluid and play in the pinion could be a bad u-joint as well, but I have seen pinion bearing do crazy stuff on the big 4x4's I use to build.

-

No fuel pressure but Fass pump is working.

@the7t7 if you have high resistance in one of your ground paths it will drop your voltage, and give you the condition you have now. There is a good article on here about the ground mod that fixes alot of issues.

-

P0336 No Tach, Lack Of Power

The easiest thing to do is drop your starter and pull the CPS then with a mirror or borescope check the tone ring. I fought the same problem for a few months. It can be fixed without pulling the motor, as long as you have some patience. I'm working on a write up to detail the whole thing. Dodge no longer sells the parts but cummins has them for about $150 you will get the tone ring and 5 screws that hold it in. I have part numbers, torque specs and a tool list. Pics of the position the crank need to be for install.

-

No fuel pressure but Fass pump is working.

@the7t7 dumb question I'm sure but have you checked All your grounds. In my recent adventure pulling all the engine wiring harnesses. The grounds are junk they are just bundled together and crimped in a metal clip then covered with sub par heat shrink. I ohmed mine out and replaced all of them with solder sleeves then added adhesive aviation quality environmental sleeves. @Mopar1973Man said the ecm wont boot under 8 volts. I would check your power and grounds to the ecm and see if you can correct it there. Dont give up. If you have a power probe you can induce voltage and check circuits that way, just be careful there are some circuits that use reference volt of 5 volts and putting 12volts to them is not good. Power probe makes a 5volt adapter for there system.

-

P0336 / ECM trouble beyond standard troubleshooting

@int3man mine is a 98 3500 4x4. @Tractormanthanks for the comment. I'm starting a write up today that has the whole problem and procedure detailed. I learned alot with this issue. As a really good friend of mine who is one here said knowledge is power. If sharing can save someone the headache then it's well worth it. Plus I dont give up, I'm the type that will fight it till i get it fixed. @Mopar1973Man hit me up when you get a chance. Thanks to everyone for there input. You guys are the best

-

P0336 / ECM trouble beyond standard troubleshooting

All done and running. Tone ring can be changed without pulling the motor ?

-

P0336 / ECM trouble beyond standard troubleshooting

-

P0336 / ECM trouble beyond standard troubleshooting

To bad you guys aren't close enough to come help with this or at least give moral support.

-

P0336 / ECM trouble beyond standard troubleshooting

@Mopar1973ManWill do. This has been a huge learning experience. And I will gladly share anything I can

-

P0336 / ECM trouble beyond standard troubleshooting

Found it in the ram forum.... You have to pull #6 main bearing cap off, then pull #6 rod cap off. You might have to rotate the engine to get the cap off. The ring is in 2 pieces with 5 screws holding it all on. Take the small section out first, then rotate the engine so the gap where the small section was is facing up. Then you have to manipulte the large section out. Assemble in reverse order...The tone ring screws torque to 71 in lbs...and use blue loc-tite on them. Main bearing cap...45 ft lbs, 66 ft lbs, then turn bolts 90*. Rod cap...22 ft lbs, 44 ft lbs, then turn bolts 60*. Oil pan bolts 18 ft lbs. I'll let everyone know how well it works out hopefully will be up and running by lunch tomorrow...

-

P0336 / ECM trouble beyond standard troubleshooting

Yea I got all the parts in the bottom of the pan. Everything is accounted for. The issue now is getting it back on without pulling the crank @JAG1 I have tried to find a way around it with no luck. Destrocked diesel has a 35 minus 1 tone ring kit that mounts to the balancer but According to them it wont work as a replacement for the internal ring

-

P0336 / ECM trouble beyond standard troubleshooting

Do you have any suggestions on the installation. I'm trying install without pulling the crank. I've got the cap off but there doesn't seem to be a way to install it without pulling the crank

-

P0336 / ECM trouble beyond standard troubleshooting

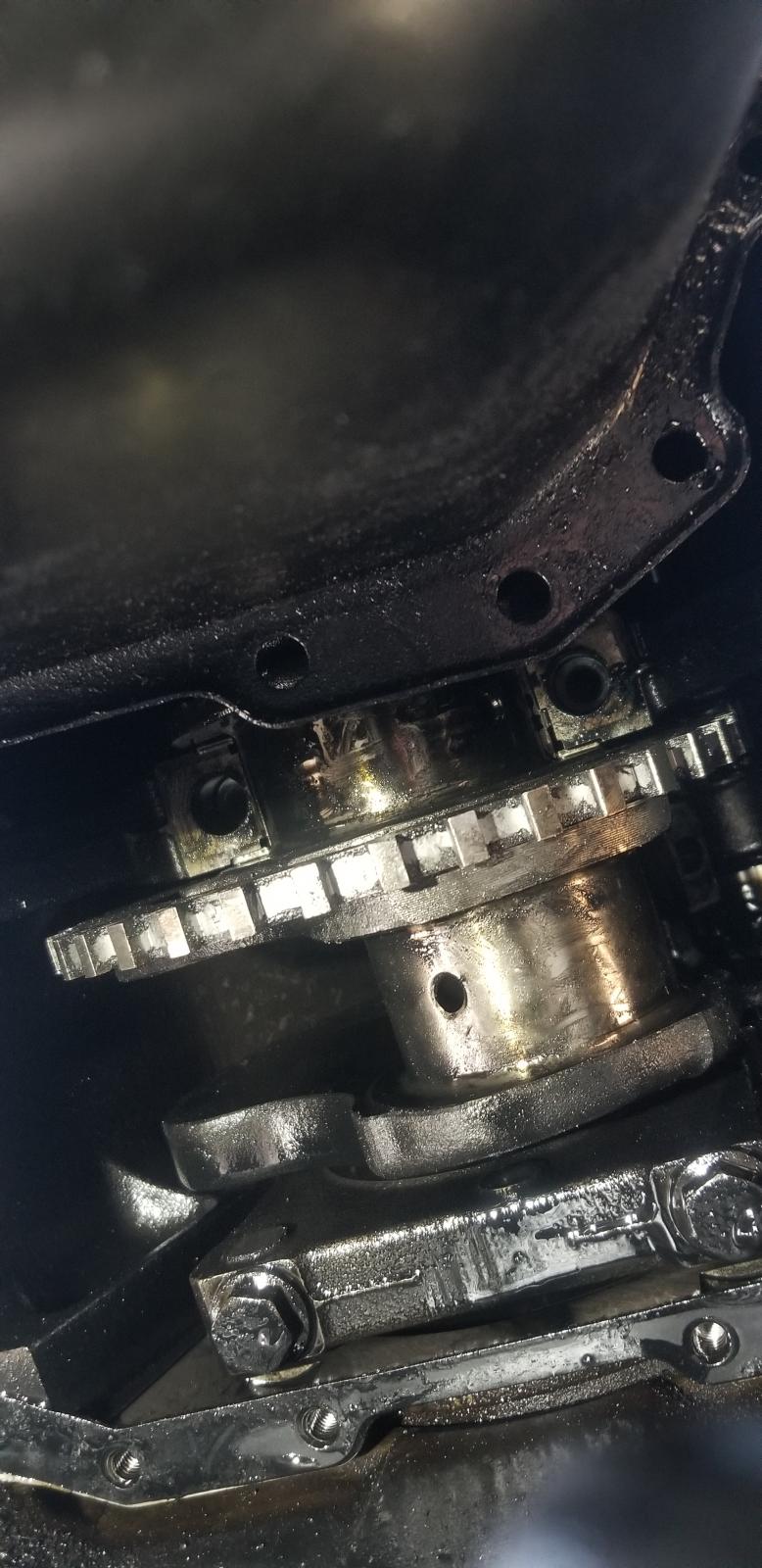

Old tone ring out. I'm not sure what happened and I am very lucky that there is zero damage to anything inside. I hope this is a one and done deal.

-

P0336 / ECM trouble beyond standard troubleshooting

@JAG1 first off all input is much appreciated. I know sometimes as a life long mechanic we tend to dive right in and overlook the obvious. To answer your question yes sir all connections have been checked cleaned and "bond checked" to their respective components. All the harnesses have been removed disassembled inspected cleaned checked end to end for any failures, then reassemble to aircraft specs all bend radius of wires have been set to 6D or better. Then everything was loomed up and taped all the joints that could have been an issue have been changed out for solder sleeves then adhesive heatshrink on top of that. It has come down to the last thing in the equation, which is the tone ring. I wasnt aware it was a bolt on ring until @mopar1973man brought it up. But with the logic of the ECM and a signal that doesn't agree with the other inputs. I'm confident that once I drop the pan I will either find pieces of the ring in the bottom or the small removable section sitting there. I will post pics and updates once I get into the bottom end. Once again thanks to everyone for all the information and input Ok everyone so after getting the oil pan loose enough for me to see inside the tone ring is broken. It has sheared in half. So got a new tone ring and will post pics once I get the pan off