Everything posted by EcoRI

-

Re-priming problem after RP-100 install (sorry it's a novel)

Happy to see fuel and tired from not going to bed last night, I forgot about the high pressure... Before that I whacked the side of my face on the crossmember for one bump and half of a black eye, common sense was not present :duh:Air is worked out and that green machine sounds better than ever :woot:Fuel pressure gauge needs to be replaced for sure. The needle dropped past 30psi and pointed straight down, moved clockwise and counter-clockwise, it's toast. Then I'll be all about staying green!It was a relatively inexpensive fix, learned more about truck's wiring, finally have a scan tool and auto electrical diagnostic multimeter/tool, and feel more confident about working with electrical and fuel system components.Thanks for the support, I truly appreciate you guys!

-

Re-priming problem after RP-100 install (sorry it's a novel)

Thxy, glad to know!Cleaned grounds, cleared codes, checked connections and everything else, and put new batteries in. Cranking the engine was a thing of beauty! Started up with 3 injectors cracked and fuel came out of all of them in equal pressurized spurts. VP is alive :hyper:Ran rough as all heck, turned engine off to tighten the injectors up because the pressurized fuel hurt when it hit my forearm. Continuing to run it and hope it smooths out. To those with a RP-100, where do you have the pressure adjuster set? I don't know if my fp gauge is working properly now after new batteries. When I had it running the gauge went to 26psi, before that the cranking psi was at 6 (I believe this to be normal?) and spiked to 26 after it started. The pump adjuster is about a 1/4 turn shy of the most you can turn it towards "+". I'm going to lower it and see what my gauge does.

-

Re-priming problem after RP-100 install (sorry it's a novel)

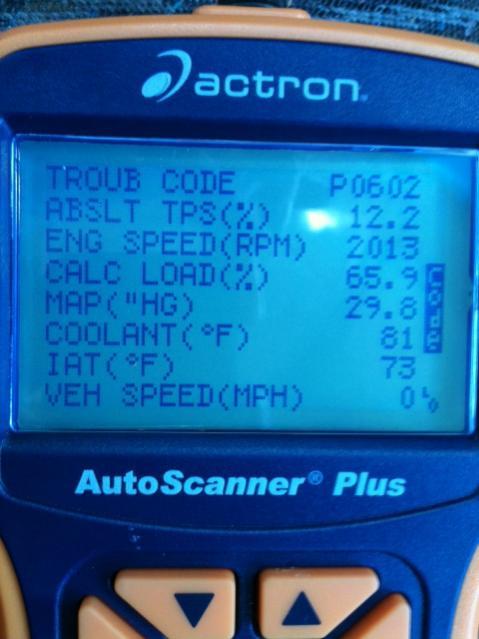

Thxy! I wondered if one is on its way out but didn't think to link the two things together, I'll pick 2 up this evening. I found a post @ CumminsForum.com <link>"Have you checked your batteries? ... with the battery being low the ecm suffers powerloss and you have truck issues." - I don't know this feller whatsoever, taking it with a grain of salt. CCD BUSS from PCM to connector over valve cover is good. (+) 0.5 (-) 0.4 Checking grounds now, working from engine wiring diagrams. I appreciate any suggestions from readers as to what compenents, wires, connections to check/test! Like to eliminate possibilities before dumping $$ into buying new parts if not 100% sure that's the problem. It's quality bonding time with my truck. Can't beat that.. [pic is the freeze frame of when the P0602 was sent, dunno if that's helpful or not]

-

Re-priming problem after RP-100 install (sorry it's a novel)

-

Re-priming problem after RP-100 install (sorry it's a novel)

~ thank you, your knowledge of these engines is crazy smart! Is it of any importance (i.e., would it help to determine the cause of P0602 as ECM or programmer) to know what program/chip/flash was used? I can find the previous owner on facebook and ask. Prefer not to unless it's valuable info for the situation.

-

Re-priming problem after RP-100 install (sorry it's a novel)

Gut feeling I have an electrical problem as well... I'll clean the VP connection as suggested, I bought some electrical connection cleaner before I started my original project (Operation: Gut the truck and kill rust all over the floor panels). You aren't kidding, there are grounds EVERYWHERE! Definitely not buying a new VP until I pin point what's up. Tomorrow I'll do the test for the VP as outlined by Blue Chip Diesel (unless there are reasons I shouldn't?). You and me both. I have the diagrams he's posted and the Service Manual from the download page. I think it would be easier if the truck wires *looked* like the diagrams, all straight and neat and whatnot. Yup. I'm not liking electricity at the moment (as I type on my MacBook from the garage illuminated by fluorescent lights... hehe) ------ Battery questions: My batteries were getting low and cranking was waning, I hooked up the charger to the batteries (duh). Again forgive my ignorance with the electrical matters, but is it correct for the driver's side battery to show almost full charge, the passenger's side battery to show empty, and the dash lights not come on when the key is turned "on"? After passenger battery was charged a little the truck behaved normal with key in "on" position. What in the heck? That doesn't make sense to me. Second, the charger doesn't charge them all the way to full. Instruction manual said it should take 1.5 hrs to complete the charge and green light would illuminate. Hasn't happened for either battery over many hours of charging. The batteries not being charged is why I haven't dived in to the connector testings as of yet. I'll try to make sense of the electrical diagrams this evening and poke the engine in the morning. I need to take my happy to WV by Sunday because classes start Monday bright and early! Stressed a bit? Nahhhh....... --- Update to the previous post... ahh Scheisse yeah buddy!

-

Re-priming problem after RP-100 install (sorry it's a novel)

Ahhh that makes sense why my codes didn't show up right. I purchased a scan tool this afternoon! No worries, you have been a great help and it's much appreciated!!! Scan tool pulled the following codes, click the definitions to go to Marpar1973Man page for details: P0602 - ECM Fueling Calibration Error - Internal fault condition detected From cumminsforum.com (link here) "P0602 is generally an erroneous fault code, disregard the P0602 fault. Perform fuel system flow tests, reference TSB 14-03-06 revision A to diagnose the original engine performance problem" and some random dude said, "0602 essentially means unrecognized software, it comes with lotsa programmers". I have an unknown chip/program/thingamajig, maybe that's the cause of this one? But I had my truck scanned by Advance Auto a few weeks back just to see if anything was lurking in the shadows. There was something about the fuel level sender not changing over miles (P0460), but it went away and never came back. Maybe their scanner didn't do a great job and 0602 was there the whole time? (I hope) P1689 - No Communication between ECM & Injection Pump Module - Data link circuit failure between ECM and fuel injection pump. Low power, engine derated, or engine stops. Removing fuel relay can cause this code (link here). So for some reason or another the ECM is taking a nap and not telling VP what the heck to do. I removed my fuel relay (checking it, it tested good) however it wasn't when engine was cranked, key was in the "on" position. Don't know if that will send code or if it has to be cranking at the time (?) P1698 - No CCD Messages Received From PCM - Bus communication failure to PCM. A Companion DTC was set in both the ECM and PCM. PCM is monitored for receiving BUS messages with ignition on and engine off and with engine running. DTC may set if there is no communication with the PCM. I'm gathering from this the PCM and ECM are not communicating properly??

-

Re-priming problem after RP-100 install (sorry it's a novel)

I'm more or less in a panic, feeling helpless, lost, and like I need to *do* something productive/proactive, and the warning light was a stretch. You're definitely right about 5psi being too late. I pondered that after I got home and left it in the bag, figured I wait and get input from the more knowledgable folks before doing anything with it Wires moved to the alt and ground --- Update to the previous post... (My train of thought can be discomboobulated sometimes, very ADD) Few days ago after new lp install I checked fuel-related fuses and relay. Swapped fuel relay with wiper relay & wipers still worked. Pulling fuel relay (key was “on”) tripped CEL, I ignored it for the moment assuming the comp was PO'ed I pulled the relay while it was on (maybe a be P1689? But I don’t know if that will only trip if engine is cranking or key being “on” after a 2-second prime by the lp). Anyhoo… I checked the codes a few minutes ago, " ----- P1693 ----- P done ----- 223,860." “a 1693 is never by itself... always wait for "p done" to flash twice to get codes from PCM and ECM” >>Mike's link<< I only have a companion DTC and one P done - can that happen on an otherwise healthy engine?? If either control module wasn't working would the other one have a code indicating such?

-

Re-priming problem after RP-100 install (sorry it's a novel)

dripley, your comment got my ole' brain-train a rollin’… I read something from/about Blue Chip Diesel and they said (I’m paraphrasing, here's the ~LINK) if upon cranking, one line flows but the others don’t or some only trickle the rotor has seized (the line rotor is stuck at flows, the other lines that trickle do so by pressure from the lp since the ip cannot hydro-lock). If that’s correct, it makes sense a seized rotor (Blue Chip’s example) and a VP without the ECM connection (dripley’s experience) would display the same air bleeding pattern. That’s exactly what my truck is doing, yet VP and that 9-pin thing are happily connected to ECM. I’m not big on the idea the VP seized at the same moment I swapped lp’s and tried to start it (unless I have poo for luck!). I know there’s plenty of fp in the low pressure lines. My train of thought is that the VP somehow isn’t getting the juice or proper instructions to do its darn job?? Bad ground? Some other connection loose or hooked up funny? ECM telling the fuel system a bunch of lies? I’ll find a map or diagram of the VP and whatnot to see where wires should go, ground, etc. and check my truck. Also bugging me, the lp doesn't do the 2 second prime each time I turn the key to "on", I have to turn the key off for a minute or two, then back to “on” for lp to run 2 seconds (doesn’t do diddly-squat if I turn the key to “on”, let it run for 2 sec, key off, then back to “on”). I mention it b/c my OE lp ran for 2 sec each and every time the key hit “on”. I miss my Cummins --> ~ Any and all input is welcome! I'm a giant with fuel and electrical stuff!! I need to get a solid handle on how ECM, VP, lp, solenoids, and relays work together, I hate not knowing and eager to learn!

-

Re-priming problem after RP-100 install (sorry it's a novel)

I don't know what's up with #1 and #3 because zippo fuel is present when those are cracked. I'm too chicken to try starting fluid!I don't know what to do - for Pete's sake, shouldn't fuel be gushing like it did from #6?? I'm open to any and all suggestions!!Side note: New fp sender isn't playing nice with old gauge, until I get a new set I'm going for a low fp warning light, in the event it starts at least I'll have some fp monitoring.

-

Re-priming problem after RP-100 install (sorry it's a novel)

dripley, I'm afraid something may be wrong. It's only cranking, not trying to start. The batts are low and I'm on way to pick up a new charger/starter (75 amp and 12 v is the largest in stock, I think that's ok? )A modest amount of fuel came out of 4 and 5, when I cracked 6 is *really* gushed out. I'm thinking that's how they all should look, so I went back to 3, 4, 5 being cracked. Cranked several more times, only a bit of leaking from 4 and slightly more from 5. Stopped when batts were low. It doesn't seem right to take so long, then again I haven't had to bleed from injector lines before. Low pressure lines were bled just fine, and plenty of fuel came out of hose that connects to VP when key put to "on". I'm worried. And a might bit scared.

-

Re-priming problem after RP-100 install (sorry it's a novel)

#5 and #4 are bled and tightened. #1 and #3 are cracked. I can't reach #6 to save my life and #2 of course is hiding behind the intake horn. It's taking a while... Technically I did run it out of fuel when I tried to start it but (unbeknownst to me at the time) lp wasn't getting enough power to do anything (test light showed current when key turned "on" but didn't run). Okidoki back at it!! --- Update to the previous post... Edit: #6 is cracked. It's taking a lot of cranking. No more than 25 seconds at a time, 3+ minutes between each crank (except for this last bit because I fought with #6). I've read other posts about it taking a while, but I'm still worried about the stupid thing

-

Re-priming problem after RP-100 install (sorry it's a novel)

I read Mike's instruction page for re-priming the engine, and still have questions, which are likely dumbs ones at that...After lines 3, 4, and 5 are cracked, crank the engine (less than 30 secs w/ 2 min between each time) - do the lines have to be tightened up as the engine is being cranked? (in which case I would need a helper) Can I do the cranking and then hop over to tighten lines that leaked out fuel? I did my own "bump" business three times (after getting fuel @ the VP's inlet line) and #5 had fuel. I tightened it up and bumped several more times. No more fuel present at 3, 4, or 1 (I cracked 1 after 5 was tightened). If I read the instructions correctly, I am to actually crank the bad boy over for >30 seconds while lines are cracked, not just a "bump"?Can I hurt the VP just by cranking the engine to bleed the lines? If/when the engine starts and runs rough, will this hurt the VP? As you may guess... I'm afraid it will go kaa-poooey

-

Re-priming problem after RP-100 install (sorry it's a novel)

Before I set up the red and black wires I texted a mechanic buddy and asked where he thought they would be best (ASE Master Tech dude). He advised I connect them to the positive and negative connections going into the fuse box (the positive comes directly from the battery). I tested power at the lp and it was there... I wasn't hip on putting them at fuse box because the directions didn't mention that as a possible location, but heck he is the mechanic, not me, so I rolled with it. Electrical... BINGO! I moved the wires to run directly from the battery... flipped the key to "on"... and dang it all if I didn't hear the pump!!! I need to run to the store for my mother and once back I'll bleed air and whatnot and hopefully get this bad boy running!!

-

Re-priming problem after RP-100 install (sorry it's a novel)

Gotchya. I'll do this once the first two lines are bled and I reattached inlet line on filter. Yup, I've had that page bookmarked on my laptop and iPhone!! Line going into filter from lp is loose. I just double-double checked lines and connections... and found a kink in the line from tank to lp, out of sight behind the frame next to pump... :banghead: the lines from Raptor are extra long (to also work on extended/mega cab applications I assume?), I made a wide loop on each line and secured away from road debris thinking it was smooth (FAIL). Straightened line out & "bumped" five more times - no fuel @ filter inlet (the connection which is loose). Instead of cracking the lp outlet line as I did yesterday, I just completely it out, only has traces of fuel. Pulled inlet line out and it leaked fuel (never been so glad to see diesel fuel my entire life). Reattached both lines. Bumped starter twice. Removed lines - no fuel at inlet or outlet. I'm afraid to ask... that kink in the line - could it have killed the lp?? Side note: the OE lp made noise when I turned the key to the "on" position, I could hear it from the cab. The Raptor hasn't made a noise which I can hear at all. I turn the key to the "on" position (through the window) and duck under the truck to listen. I hear a "click" (sounds like a relay sorta), no pump-like sounds. Same when I bump the starter, I jump out (while key is still in the on position) and stick my head next to the lp - can't hear a hum, bzzzz, nada.

-

FP sender location - snubber won't fit! Help...

The sealing ring indexed the fitting at a different angle and snubber/sender fit! The gauge is clearly receiving steady info But... the needle tries to move counter-clockwise New gauge as well I suppose. Was originally installed 2005 so not out of line for it to be bad. Perhaps working with the faulty sender messed it up or the new sender has different wiring than the original one. This stinks --- Update to the previous post... Guys, I went with the raptor series pump, thank you for your input The fuel sys isn't re-priming and I've followed the posted instructions by Mike. New thread for this problem here I pretty much feel like a dumb-butt and want to cry

-

Re-priming problem after RP-100 install (sorry it's a novel)

Cliff notes for Raptor 100 and Autometer fuel pressure sending unit and snubber install, just in case I screwed something up along the way I’ll thoroughly explain, main questions will be in bold font to make easier to read (I hope): FP Sender - Removed lines going in and out of filter housing (½” ID 35psi fuel/emissions hose from Goodyear, worm gear hose clamp attaches over male fittings). Removed old fp sender which was smutted into filter drain valve and fitting. Reinstalled fitting with additional sealing washer (per Autometer) to index port at an angle away from drain tube, installed new sender and snubber. Bolted filter back into place and reattached hose from filter to VP. Removed fuel filter from canister, wiped out most debris. Began filling with diesel fuel, slowly pouring down the sides to wash any debris I missed to the bottom. Filled housing about an inch, covered with clean rag and let sit for 20 minutes to allow any floating debris to settle at bottom. Slowly filled canister ¾ of the way and inserted filter (3 weeks old). Pump - Removed OE line from tank to pump and ½” line from pump to filter housing. Installed new ½” blue lines from Raptor kit, bolted pump to frame, installed new wiring, connected and secured hoses. - Checked for power to the pump - the black ground wire is solid, the positive yellow receives a brief flash of power when key is turned to the "on" position. Double checked fuel line connections. Set flow setting on Raptor to fully open hoping this would get the lines bled faster. Stupid move - I was going to bump starter to bleed… forgot to disconnect a line to allow air a way to escape, held key in “start” position too long, truck turned over and ran for a few seconds then died. I’m going to go out on a limb here and guess air in the lines killed it Bleed air from lines - removed line going into filter (those “quick connect” lines are fabulous!), wrapped a blue shop towel around the opening so I’d know when fuel came out (working solo here), bumped starter, allowed key return to "on" position, waited thirty seconds, turned key “off” and removed from ignition. Repeated more than 20 times (do not remember the # exact). No fuel present. Cracked the outlet line at pump, fuel was present at that point. I tried the bumping-bleeding business five more times and stopped afraid to cause damage (?) - How many times can I bump the starter? How much fuel does it pump for the 25 second interval? Could it be taking so long because of the length of the lines from the RP kit, they look to be long enough for an extended or mega cab (they are secured in a wide loop away from possible road debris)?

-

Mystery chip installed ... ?

hahahaha!

-

Mystery chip installed ... ?

Shoot! I'll look around under the hood and dash once more. If no luck then I may dig put his email add and ask. I feel kinda like a tool for not knowing what's up with my vehicle. El Raptor-o ... I'm still torn between the two options and haven't taken the FRRP out of the box yet. Don't want to regret FRRP in a year or whatever. I welcome feedback on the following logic: - 235 stock hp + injectors 105 and intake 24-30 = 365-370, of course + mystery-chip-programmer-doodad (under or about 100 if I recall correctly) so hp is in the ballpark of 440-470, so my hp is close to the cut off for the 100gph pump - I rarely haul/tow since I returned to school (towed a four horse trailer on occasion years ago) - the original Carter is still alive and kicking down on the frame, perhaps the longevity is partly due to not being hard on the truck? - if the Carter can handle it, would the 100 gph be able to as well? - I don't have interest to upgrade mods/add hp to the truck, rather I want to improve the supporting systems to maintain my old boy in good shape - like with the Amsoil remote bypass, extra cooling to #6, etc. That's my rationale for the 100gph over 150gph. Maybe I'm overthinking it... ignore me if I am --- Update to the previous post... Thank you Mike, excellent and important food for thought! I don't have the resources for the tank drop and draw straw install. and I sure don't have the cash to pay the shop to do so! I really appreciate everyone's so far!! It's great to have folks to bounce ideas off of and such!!

-

Mystery chip installed ... ?

Question - does the chip matter when deciding between 100 and 150gph lift pumps? - If so, is it possible to figure out which chip/hp rating is installed? I took ownership of my truck in 2007, it belonged to my ex since 2005. He put a non-adjustable chip in the truck while we dated and shame on me for not remembering which one it was... I desparately need a new lift pump and afraid to buy the wrong one!

-

cracked dash

Please let me know how you like the product if you get it. More than one-half of my dash has fallen through and I'm not liking the fabric cover on there now! I clicked through the shipping costs and the total is $247.70 (which includes a $20 oversized item surcharge). There's a cheaper alternative, a dash pad cover for $124.95 (includes shipping) ~here. I don't know anything about its quality and haven't purchased either one... new lift pump comes first

-

FP sender location - snubber won't fit! Help...

I cannot agree with you more! I read many of Mike's posts on the cumminsforum.com, was very impressed with his knowledge, and made my way to his forum. The diagrams and detailed explanations are perfect for my needs. Varying information on other sites has me sixteen kinds of confused. For example, the Cummins shop suggested I simply add a second Carter to my existing Carter. Another diesel shop said my only option is a the $600 complete AirDog kit. I'm lost and do not like feeling this way. Mike's forum (so far!) has the most even keeled sensible approach to repairs and things. I haven't finished all of his articles yet, not many more to go. I'm sure I'll have a couple more questions when I am done. Definitely appreciate the members at this forum, and Mike of course for his time and efforts! I emailed Vulcan and the gentleman responded within 24 hours, excellent service! He suggested adding another washer (part SW12) to the fitting under the filter so it will index at a different angle (hopefully one which will work for my snubber!). ~Here~ is a link to the mobile gallery w/ a pic. I'm optimistic about this fix!

-

FP sender location - snubber won't fit! Help...

The fp averaged 15-17 psi, 11 psi WOT. Autometer gauges, I'm generally happy with them. They were installed before they were aware of the problem with the senders going out prematurely due to the fp spikes on start up. My gauge totally went out a few weeks ago - this big dummy didn't fix it until now.This week I'm going over the truck with a fine tooth comb before I move. Yesterday I went under the bed to check on things... and there's the stock, rusty old Carter politely sitting on the frame I refuse to drive it until the new fp sender is in. Shame on me for assuming the lp was replaced when the ex installed the reloc kit when we started dating (I adopted truck in 2007 after we split). I've taken care of it, added to it, watched my fp like a hawk, randomly checked codes for p0216, etc. like a responsible owner of a vp. I haven't made any further fuel mods or inspections because pressure is good, I don't tow/haul a lot, and the crappy Carter was already replaced, right?I pretty much feel like a huge (insert colorful words here) dummy for driving a modded truck on a stock lp @ 222k without a working fp gauge for several weeks

-

FP sender location - snubber won't fit! Help...

Thxy for the link! I'll definitely contact Vulcan and see what's available. I'll also send some pics of the current set-up because my explanations aren't super great sometimes. I hoped to reuse the current tap fitting somehow because I'm in a time-crunch, the fixer-up and clean-er-up list keeps growing, and I'm rather slow and these repairs and things!! (looking up everything before I do it, going slowly, double checking, you get the idea )

-

FP sender location - snubber won't fit! Help...

Hi there, I've searched Google, this forum, Cummins forum, and TDR without luck - if this is a dumb or repeat question I apologize in advance! The previous owner of my Dodge put the Autometer FP sender between the fuel filter and the line to the VP. The sender failed, I ordered a new one plus the snubber to prevent the premature wear on that part. Problem: the FP sender is angled such that the back butts up against the drain valve and the snubber definitely will not fit. I'm pretty scared of messing up the VP and don't want to tinker around without the advice/recommendations from more experienced folks! Can I rotate the sender/fitting so it doesn't stick out into the drain valve? Or is it fitting threaded such that this angle is necessary to achieve a tight seal? Thanks in advance!! -Tiffany