- Replies 46

- Views 1.6k

- Created

- Last Reply

Top Posters In This Topic

-

kbf98520 25 posts

-

Tractorman 13 posts

-

Mopar1973Man 8 posts

Most Popular Posts

-

On my truck the tee at the back of the head started to leak fuel about 15,000 miles ago (at 390,000 miles). At the time I had the transmission out while doing a clutch job and I noticed the leak. Th

-

@Tractorman Those o-rings are square cut and you would need to order from Cummins for replacement. Might be a good idea.

-

Give details of your bucket test. Have you ran the engine while drawing fuel from the bucket with a separate power source to the lift pump? I'm having a hard time with believing it to be a VP44 overf

Good afternoon, I put a titanium fass lift pump along with a Fleece sureflo sending unit on my 2001 pickup about a year and a half ago. It’s been flawless for a few thousand miles. I had been noticing some slow starts when warm. Not bad just a few more revolutions than what was normal. I put some NAPA cross referenced fuel filters on because I didn’t have FASS replacements and didn’t have the time to wait . I started to take a trip recently and fuel pressure dropped significantly. I got the truck home and parked it for a month . I wasn’t real confident about the NAPA filters so i replaced with the direct replacement FASS filters. Test drove the truck for an hour or so and all seemed fine. Today it did the same thing again. I had gotten 17-19 psi at idle and 15-17 WOT. Today it dropped to 15 idle and drops significantly at WOT.

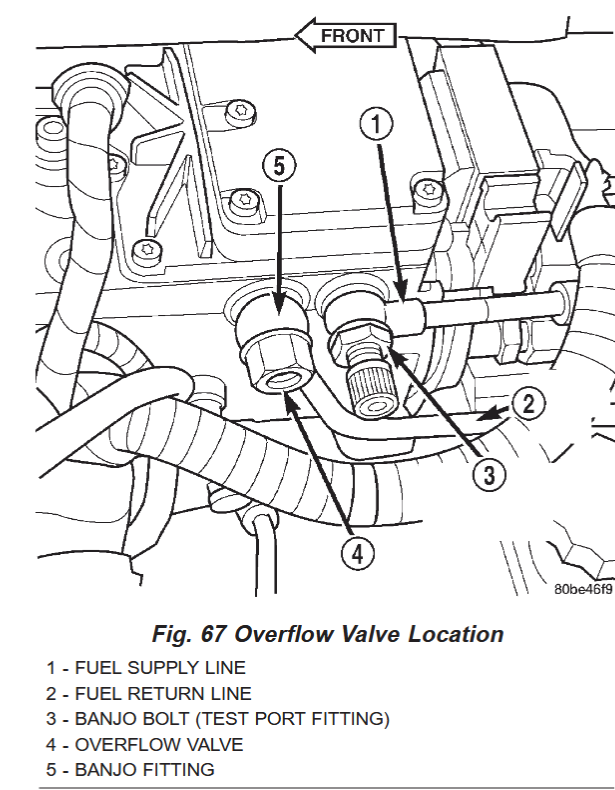

I talked to tech support at FASS and he mentioned something about a valve in the VP 44 might be a problem. Now when I turn the key on PSI jumps to 17 and drops to zero momentarily when I start the pick up. I’m in the process of putting a mechanical gauge in line to verify that the brand new auto meter pillar gauges are not the problem. Does this sound like a VP44 problem? Truck only has a 160000 miles, but I assume VP44 and everything beyond is original equipment .

Thanks, Kevin

Edited by kbf98520