Pricol Fuel Gauge Fluctuating

- Replies 18

- Views 5.5k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 5 posts

-

BART 5 posts

-

Prowelder 3 posts

-

Rhagfo 2 posts

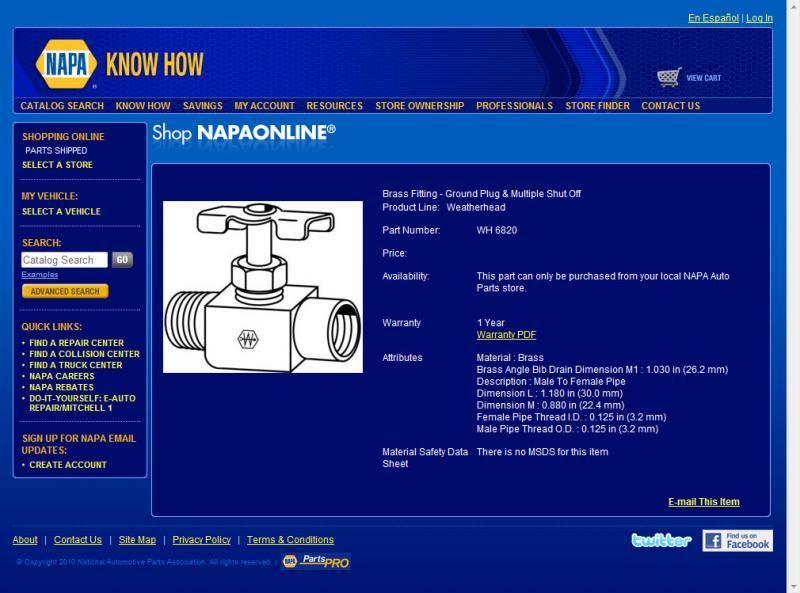

Put a Pricol 0-30psi fuel gauge in when new and it's been fluctuating, especially in hot/warm weather, and pulling hard. The engine runs perfectly without a miss. I have a FASS installed and it produces 15psi steady. I'm suspecting the "isolator", the thingy that's filled with antifreeze. I'm about ready to remove the isolator and run the line directly to the gauge or just bite the bullet and change to an electric gauge. Do these "isolators" have a reputation for failure? Kind of makes me wonder when the pressure jumps around but I'm relying on the FASS to give steady pressure. Thanks. This is my first post here...