Everything posted by Mopar1973Man

-

Getting on site

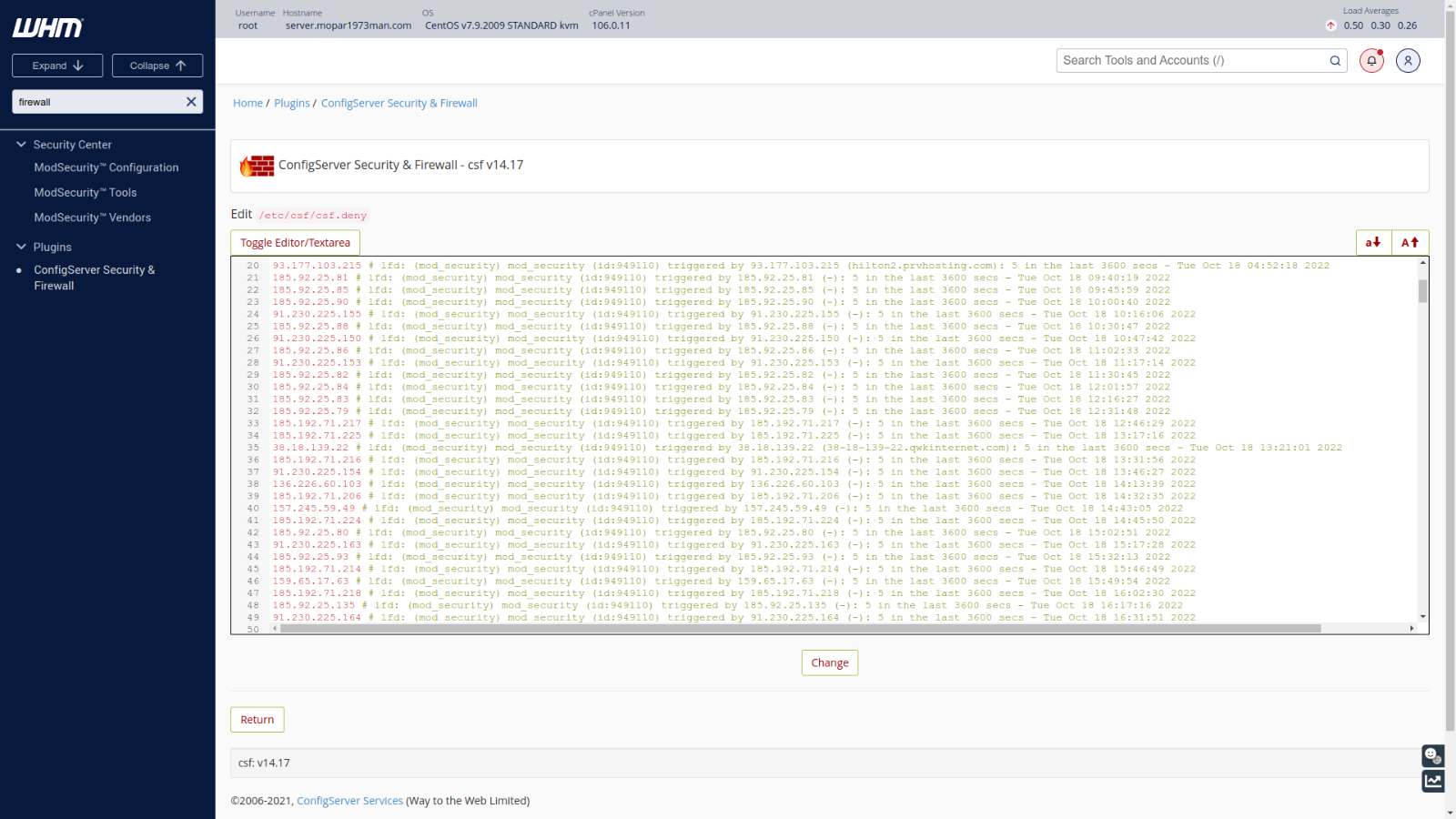

Nope your IP was not found in the 500 IP I've got blocked... It not the server at this point. Sorry to say most Microsoft machine tend to trigger it being then can infections that try doing malicious attempts to inject code into the URL of the browser or attempt to inject code into the pages. Some iOS will do it too not as much as Windows but it does happen.

-

Hey fellow travelin' campers...

LOL... There is things like IP Blocker list. https://www.iblocklist.com/lists That prevents any agency from sniffing what your doing. The if you really want to get good then you use a what called a proxy server which moves your IP address all over the world every few minutes making it hard to trace. https://www.proxynova.com/proxy-server-list/ My best was doing things like this at public WiFi services like coffee shops because the only thing they can track back to is the WiFi provider. Linux is a wonderful thing, never had anyone sniffing around my machines ever. Being Linux machines already have a full firewall (closed all ports by default) on board and don't acknowledge anyone unless I open a port to talk other than that the only thing they can see is my IP address but if I'm running a IP block list my machine will not acknowledge anything to those block IPs. The only reason I know these things is I trained like a "hacker" to prevent others from attempting to hack into the website or my personal machine hence why I'm not worried... For all the Windows PCs and iOS (Apple products) since they are close source code of software hackers always attempt to go after those because the manufacture (microsoft & apple) are full of security holes and easy to hack into. Being Linux (Android included) they both are open source code and too many eyes on the code which means if there is a security issue its typically resolved in mere days not months like other software (apple and microsoft). Here is the blueprints to Ubuntu Linux all open to see... https://blueprints.launchpad.net/ubuntu Linux and Android both tend to keep all communication to the world closed till you open it. Being that you MUST log in every time to change any system stuff (root access) without my password you not going to be able to infect or communicate with any files till you do. Windows is huge security risk being EVERYONE logs in as a Admin (Root) which now make hacking very easy as long as your online. Linux you never logged in as ROOT unless you go to terminal and call out... michael@michael:~$ sudo -i [sudo] password for michael: root@michael:~# As you can see when using my system it in USER mode till I call the Super User DO command with -i switch now the system is logged in as ROOT. You should NEVER do this and opens the system for a huge risk! But you can see my prompt it shows michael@michael which is the user @ machine prompt. Also take notice Linux does not display stars for all the characters this prevent a hacker from seeing how many characters which makes it easier to filter down to find the password. Yes its a very secure system! Just to show how you would have to get a virus on Linux. First go out and get a virus infected file and download it. Then you would have to change the file permission to EXECUTE which by default any downloaded file is not given this permission. Then you would call out the sudo -i command to get to the root login and then execute the file. I still to this day love opening infected emails being even the files on email do not have the execute permission it will open up and show you the infected payload script that does the damage without running. Bring it on. This is why Linux & Android cant be infected. Matter of fact there is no anti-virus software provided for Linux because it never happens.

-

Diesel Price

We will see if the trend is real when I start seen the drop more so. Yeah it was 6.479 in McCall at the Chevron about 2 weeks ago. Yeah it slowly coming down but man its still steep. The only bonus right now since its been raining here I've parked the diesel and been running around with Minnie more so being gas prices have drop considerably. Soon as the snow returns I'll be stuck to using the diesel being those are my only 4WD vehicles at this time.

-

Insulating Heater Hoses?

Ummm... I made a trip to Donnelly ID with @Honey Badger she was getting her hair done. I waited out in the truck working on stuff on the website. It was a mere +9*F out and when she got back in the truck she was rolling down the windows because it was too hot in the cab. I can cook you in the cab of my truck at any temperature outside.

-

Getting on site

Do me a favor... Go to Google and do a search for "What is my IP" and then post up your IP address and I'll check the firewall for false capture. It seem Windows PC tend to trigger the firewall more so that iOS or Linux being it typically the most infected software in the world. I'll double check the firewall block IP to make sure you not snagged up. So post you IP for me I whitelist your IP so this doesn't happen.

-

Diesel Price

Just like Washington state from the border to near Seattle is all $5.209 to $5.509 roughly. Hit Seattle it drops to right at 4.999 a gallon for diesel. So state average doesn't mean much when just the bigger cities get the discount and us in the rural areas get the shaft. It is this way for most of what I've seen. I've seen gasoline drop like a brick every where in the mid 3 dollar range and rarely I've seen a few at like 2.99 a gallon for gasoline (87 unleaded).

-

Diesel Price

Yeah for Lewiston and Boise... Riggins One Stop is still 5.859 Chevron in Riggins is 5.499 Lewiston was 4.999 when I did my trip to Seattle.

-

Last minute prep for first measurable snowfall

Sad just a few days ago my power went out in the house and the heater heads where still fired up. Go down to find the Inverter shut down to a over current condition. Tried resting the inverter and trips instantly. I transfer back to city power and everything was working again. Few day later I found my issue is my step up transformer to create the 220V from the 110V inverter had burned up and shorted out. Now I'm hunting for a auto transformer to handle 30A to 35A service. As for my weather it warmed up the last few days and rained and rained. I've gotten over 3.00 inches of rain in the last 48 hours. Ugh... Please just go back to snow again I hate being soaked and laying in the mud.

-

Truck Not Running Right

I'm still running just the 150A circuit breaker and never tripped the breaker yet. No fuses to replace or carry.

-

1965 Dodge Sweptline Powerwagon build

I'vew seen that very same truck on TikTok a bout a week ago. Amazing job that they did yo stuff the 6.7L Cummins in and all the interior into a old 1960's Dodge body.

-

Diesel Price

Still over $5 a gallon here in Idaho.

-

Where has Mopar1973Man been?

Well its been a crazy December for me. @Honey Badger and I made a trip over to Everett WA to go get her youngest son Jake. Jake wanted to move back to Idaho to be with his family. That trip was crazy getting over Snoqualmie Pass. Speed limit was set for 45 MPH I was doing between 45 to 50 MPH knowing what Katie told me of the road conditions. Sadly enough we watched a Jeep pass me at about 60 to 65 MPH rounded a corner and disappeared. I rounded the corner and Beast started to yaw a bit as I hit the pack snow floor. Looked to my right and there was that Jeep about 20 to 25 foot up the embankment stuck. Made it to Everett WA and got a motel room. Got up the next morning and grabbed the U-Haul trailer which took forever (1.5 hours). U-Haul set me up piss poor and not enough drop hitch (tongue was high). Boogied over to Jake's Dad's place and loaded him up and took about 0.5 hour to do. We opted to get over Snoqualmie pass before thinking of grabbing a motel again. 3 hours trying to get back over Snoqualmie pass. West bound side was closed right at the same spot where the Jeep lost it there was 3 semi-trucks piled up closing the west bound side. East bound side was just a crawl using 1st gear most of the way. Ugh! Once we got free of the hold up we all needed a bathroom break so we stopped in Cle Elum WA which was a freaking nightmare with everyone trying to go west. We ended up taking a detour to get back on East finding out East bound was closed behind us. Whew! We kept trucking all the way back to Lewiston ID to grab a motel and get some rest and food. Other than that I've been super busy with dealing with a 1997 Dodge with a alternator / PCM issues. Then a 2005 Dodge with a trans slipping issues which turned out to be a output speed sensor. Then another 2005 Dodge I just installed +50 HP DAP injectors in and now adding a Smarty Touch but the auto transmission isn't happy at all being the 35 inch tires are adding huge stress to the transmission (slipping in high gear). Then Mark my renter down in the guest house got hung up with a heater core that was barely 3 months old and blew out. Then myself trying to fix thing on Beast before making the Washington trip and be sure all my T's were crossed and I's where dotted. I've still got lots of work to do there yet for Beast. Replacing all my brake cables and get my parking brake working again. Still got work on Thor to do yet too. Then Katies Jeep is here in the yard needing a new floor pan on the passenger side. Beyond that I've been busy with bringing younger crowds to the website with TikTok videos. My last video I created was a good one and managed to get a few wanting to join the website. My TikTok profile - https://www.tiktok.com/@mopar1973man My Last video... Look at boost pressure and EGT's this a flat ground road highway 55 leaving McCall ID heading south toward Donnelly ID. Oh the speed limit is 55 MPH on this stretch of road. So now about Jake he might want to learn how to work on diesel engines as well I might actually have a good apprentice to teach being he's 19 years old and willing to learn about vehicles. So maybe I can pass on my knowledge to some one younger and might help me keep this ball rolling.

-

No cold start problem.....help

I've seen several cases where people got fuel from a farm tank or a drag tank locally and had water in the fuel. I've seen cases where the water has plugged draw straw and locked up the a fuel pump with ice in the pump housing. If your running a FASS or AirDog a heat gun will heat it up and thaw it out. If it was locked up check the relay and fuse. Stock fuel pumps well that might get expensive. It will most likely burn the ECM fuel pump circuit up being there is no fuse to keep it from happening. The tracer on the Mylar circuit board will burn and damage the ECM.

-

Please Please Help

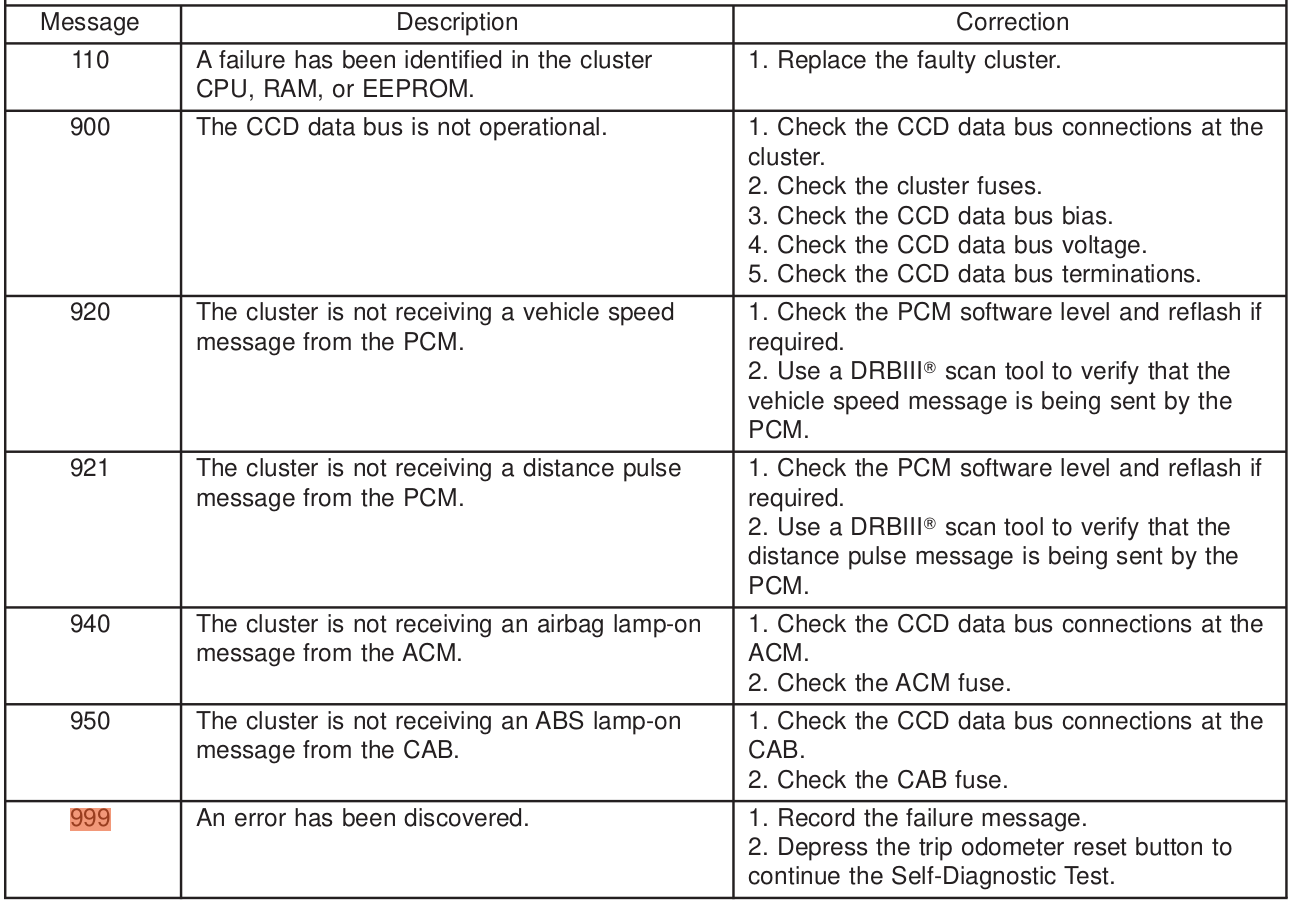

Do me a favor and check the blue wire on the alternator for +12V power while the engine is running. Also make sure your tach is working. If there is no tach signal the PCM will not turn on the alternator field. If the PCM is for sure dead head over to @Auto Computer Specialist and they can rebuild the PCM voltage regulator I just had a 1997 Dodge rebuilt last month for a local rancher. Gauges are get there data from the CCD network and could stem from the PCM problems being the PCM is having issues. If there is a cluster problem for sure there is Module Masters in Moscow ID that rebuilds the dodge clusters and ABS computers. Most likely there is a issue with the PCM being the PCM is not responding but double check the pins in the OBDII plug I've seen it on my truck and few others after a few thousand cycles of being plugged into it might of push a pin out of the plug under the dash. It doesn't take much to push it out and double check the pins. I'm kind of doubting its happened being there is other issues pointing to the PCM. This is going to be tough without the OBDII socket working and might have to return back to it after the repair. So the blue and green wires. The blue is +12V from the PCM that powers also the trans relay in the PDC. The green wire is a variable ground. If the blue wire shorts out it will fry the PCM quickly. You want to ohm test between the blue wire and ground to verify this. Make sure the PCM is unplugged and alternator is unplugged too for the test. Neither blue or green wire will be active till there is tach signal sensed by the PCM. Again back to a PCM problem. I do have a PCM protection fuse mod that will keep this from happening again. Oh yeah make sure to load test your alternator on a test stand. Automatic or manual? Manual is just a 2 wire switch typically near the shift tower. Automatic does the switch action inside the transmission. Might also check the fuses in the dash on the driver side for a blown fuse.

-

So, I got gauges for Christmas!

Don't bother tapping... The previous owner did this to Thor and tapped the intake horn. Looks rather cheap having a ISSPro EV2 sensor and wiring off the intake horn. There is a 3/4" pipe plug in the manifold just behind the MAP sensor that you can bush down to 1/8" and hook up your boost gauge. Boost bolts are easy to snap off and the tubing doesn't last long there either. Seem like every truck that has a boost bolt I end up breaking the tubing at the boost bolt or end up breaking the boost bolt off getting it back out (rusted). The pipe plug is super easy to remove and just grab a few few pipe bushing and presto boost access.

-

It's always something

NAPA has a full assortment of plastic fasteners typically just take an old fastener with you and match them up. Like I did big bags of the door panel fasteners from Amazon.

-

So, I got gauges for Christmas!

I've had the steering column pod it does block a few things. 25 MPH down to zero you can't see. The brake light on the dash you can't see. The 4WD light you can't see. Wait To Start you can't see either. I relocated mine to below the dash near the transfer case lever. (Trans Temp).

-

Huge puddle question

I've managed once to get water in the front differential from just running deep snow and mushy snow. Yeah its possible to draw in water in the differentials. Double check the vent hose to be sure they are as high up as possible. Just pull the plugs and dip a finger to check if you have a milkshake in the differentials.

-

Hey fellow travelin' campers...

I've gotta say if there is all this big brother watching and know our every move... They would of busted every criminal, drug lord, etc. Sad truth it never happens. My whole life is on the internet even the fact I use cannabis. Never had any cops show up. I don't even worry about it. Heck my address is even on Google. Come and get me. Been here in Idaho for 32 years never been arrested. Second off I have clean devices no windows or apple. I'm fully Linux and android which doesn't have the issue like Windows or Apple products.

-

Insulating Heater Hoses?

Nope. My vent temp at ZERO degrees outside I'm still 160°F. Just had a period of 3 hours of sitting in my truck at 0°F out and comfortable 70°F to 80°F inside at an idle. Just using a NAPA 190°F thermostat.

-

Big Bad Blizzard on Its' Way...

I'm heading to Seattle WA tomorrow. Not looking forward to the haul but hopefully we can make it before the storm. I'm going to be hauling my girlfriend's youngest son back with me and all his personal stuff. I'm renting a Uhaul trailer and going to use Beast to do the trip back and forth. Let's see if I can at least do good on the MPG's there and back. Still 5.589 here for diesel. Ugh..

-

Hey fellow travelin' campers...

Better yet live in a area without cell service. All I gotta do is pull the plug on my Verizon Extender and no cell service. Then walk back to the bedroom pull the WiFi router I'm no longer connected. Where I camp normal there is zero signal and services for at least 50 miles. Go back country problem solved.

-

Truck Not Running Right

Should only buy VP44s from Bosch certified sources. There is a lot of rebuilders that don't have a test stand nor do they replace the PSG on top which requires a 3 hour run on Bosch test stand to calibrate and flash the PSG. Like @dieselautopower is a good vendor sells only certified VP44s.

-

Good rear 2nd Gen bench seat covers to hold up to dogs?

I created my own solution back when I had Diesel the Dobbie. I just covered the seat with like a nylon fabric and then cut a piece of plywood the shape of the seat and then screwed carpet to the board. That way Diesel had a way to hang on and get grip without damaging the cover. Then the board could be hosed off to get the hair and pet accidents off. The cover I just threw in the washer once a month. I just seen another version in a customers truck that in the yard that is the same kind of fabric as well and it drapes from the back of the front seat to the rear seats but easy for a pet to tear up being there is no board or carpet for the pet to hang on too.

-

Wood Heat

Hard wood is always better than soft woods. Should try coal, one time in the stove it will burn for a very long time too. Burns clean in a wood stove as well. Like Myself I've got that maple limb that broke off and it dry and we having be burning it as well.