Everything posted by Wild and Free

-

worthwhile hiatus.

Make sure you demo the ZT mowers on side hills, some ZT mowers do not do well at all on side hills and some do, the position and type of casters makes a difference as does the hydro drive. Make sure you can drive one sideways on a hill to make sure you get one that will work for your needs.

-

Oil Sample tooling

There has been a lot of discussion about oil samples lately and another member had a sample with high Silicon in his sample and after a few questions found he had a good chance of contaminating the sample with dirt while taking the sample the wrong way. I took some pics of a couple different tools to do it the correct way to eliminate the chance of dirt in the sample. There are 2 different tools to get this done and I will attach pics of both here. - - - Updated - - - Here is a pic of an oil sampling gun with hose and sample bottle attached, also in the picture is an oil sample port that Cat uses on all of the component on their newer equipment, I also have one of these installed in my system for easier and cleaner sampling than the sample gun. Also as you can see the sample port fittings come in either o-ring boss or pipe thread to accommodate different places you would want to pull a sample from, Cat uses almost 100% o-ring boss fittings. In another pic shows the yellow rubber cap that covers the fitting and as you can see it is labeled as engine oil, on the Cat equipment different components have different colored caps and are labeled hydraulic, transmission ect.

-

Screaming Beavers

What I have mostly cut up has been dead and dry for a while already, rarely do I cut up fresh trees mostly already dead and dried before I cut it up. It smells very musty like when burned. If I do cut some up it is camp fire wood only.

-

BBI injectors from Smarty source?

From their own web forum. http://smartyresource.net/forum/showthread.php?17-US-or-them I am still waiting for replay from them on the BBI which I do think is way out of my league for what I would spend, but in the mean time the guy said he would accepted my offer of 1100 for Brand new stockers with 30K miles on them he said he changed the factory filter every oil change at 5k miles and had a Fass system with dual filters which he changed every 10k miles so they have had good filtration, anyone think this is not a good deal? If I decide to get them who would everyone recomend I send them to for cleaning check up and calibration and possibly 50 hp nozzles installed?

-

BBI injectors from Smarty source?

I sent them an e-mail and tried to call but got the answering service so waiting for a return to see if they accept cores and what the best price would be either way. Either way...............4K OUCH!!!!

-

BBI injectors from Smarty source?

Have you heard if they charge a core or if it is 4K out the door only?

-

Screaming Beavers

I quit cutting box elder a few years ago, usually half rotten inside, it doesn't spit worth a crap and it stinks something awefull when burned in the stove in the house.

-

Tires: Treadwright

I have found through my last several sets of 10 plys that I get really good miles out of them running 55 psi all around and am religious about airing up and down the back when towing, depending on the load I run either 65 or 70 psi and back down right away again. No matter the brand I always get at least 60-80k or more. My last stock factory BFG's went 85k but still had tread left, had a set of 285/75/16 BFG,s 8 ply on a 1/2 ton go well over 100K miles.

-

BBI injectors from Smarty source?

OK so I have not followed the performance end of the Cummins crowd for a couple of years and especially since selling my 02 last year I seem to have fallen off on new stuff. I saw a post by Mike yesterday with mention to Smartysource.com which I had never heard of. Went there and checked it out for a bit and did some reading on the BBI injectors they have developed and sell. Question is does anyone have any input on them? I see they want 4K for a set but do not show what or if there is a core included in that price, if no core I can't believe anyone would spend that kind of money on a set. I am looking at doing an injector swap on my 05 as it has never idled real smooth when cold since I bought it with 18k on it but it getting a bit more hickuppy at first start up. I found a set of new Bosch stockers locally with only 30K miles on them but am in the process of dealing on them, guy is asking 2K or offer so I offered 1100 and have not heard back yet.

-

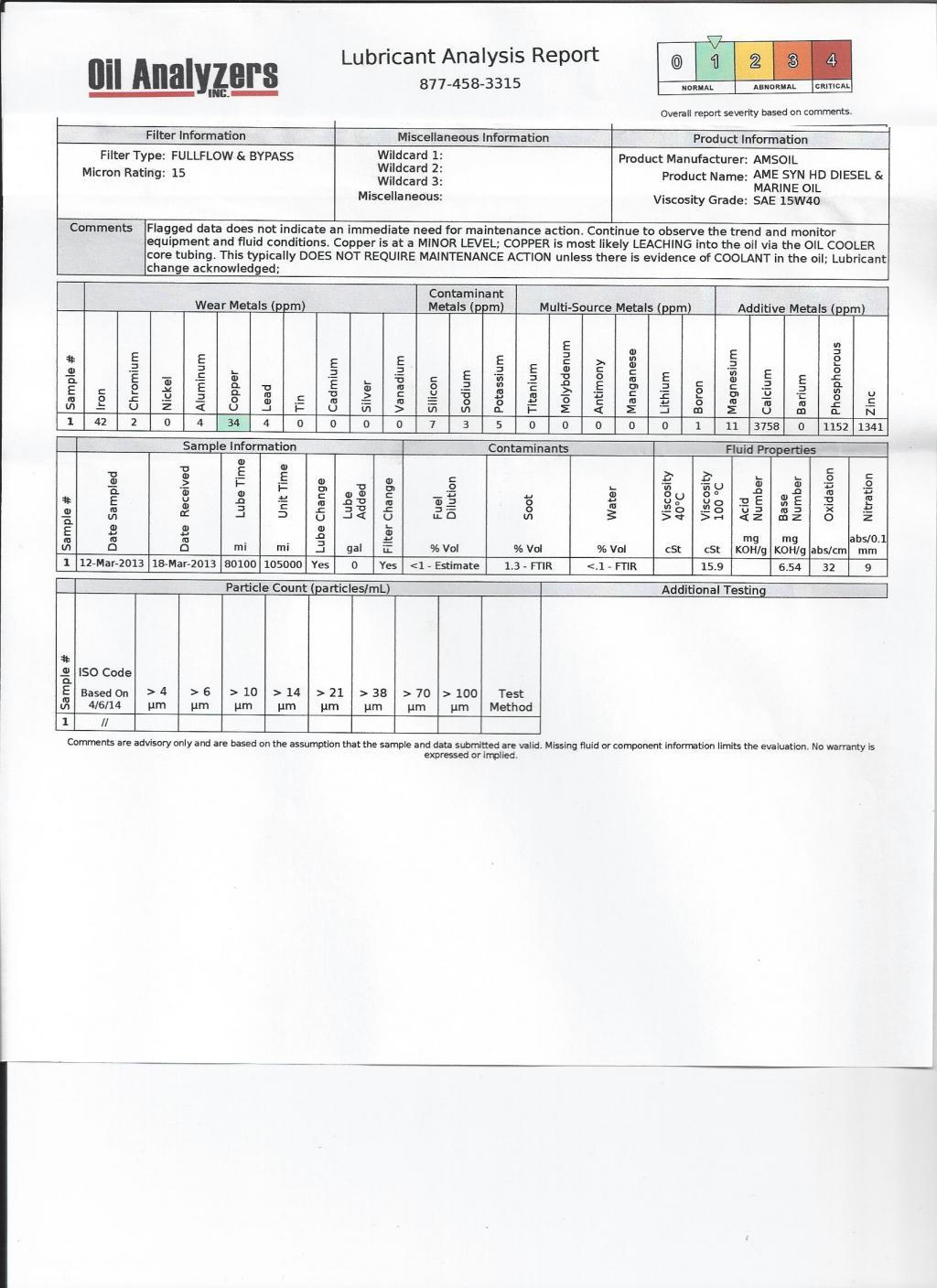

Help me understand my analysis

I think that CAT SOS and OAI are almost identical in most ways they way they present and lay out the info as well as the amount of info, I would say it is a wash either way. I use OAI for all of my personal stuff just because I am tied into Amsoil as a dealer. If not for that I would use CAT SOS as it is local right in Bismarck, we also have a MVTL lab right in Bismarck, I have not used them personally but the last coal mine I worked at used them for a lot of non Cat equipment, I have never seen one of their reports so can't comment on the info they present.

-

Help me understand my analysis

If you are comparing yours to mine, I have no unit average as this was the first sample for that rig, as I continue the previous results are listed in order of the sample so you can look down the list from newest to oldest and see everything not just the average. As far as universal average that is a pretty broad and basically useless comparison in my book not knowing exactly what they are averaging. Every fleet is going to be different and every piece of equipment is going to be different, one is looking for issues with the one individual unit that is being sampled, as I said I deal with a few dozen samples every week as part of my job, we use CAT SOS only and they too do the same as AOI and show the results of about the last 10 samples directly under the current sample so you can see exactly what has changed, not just an average. I learned about the K&N first hand with my own sampling on my 02 cummins and upon seeing the cumulative results did some checking and found others had similar issues, that was about 8 years ago. I try to tell as many people as I can to stay away from K&N ever since.

-

im new here

Why did you choose an electronically controlled 47RE over a mechanical 47RH on a conversion like that? Would have been a lot simpler and less glitchy in the long run.

-

Help me understand my analysis

Silicon is the finest form of dirt dust whatever you want to call it, it is super fine, if you have a bad air filter or loose connections on the intake system it lets the super fine dust or silicon through which fills the small pores in the cylinder liner and picked up by the oil film and carried directly into the system. Its every where! lol http://en.wikipedia.org/wiki/Silicon

-

Help me understand my analysis

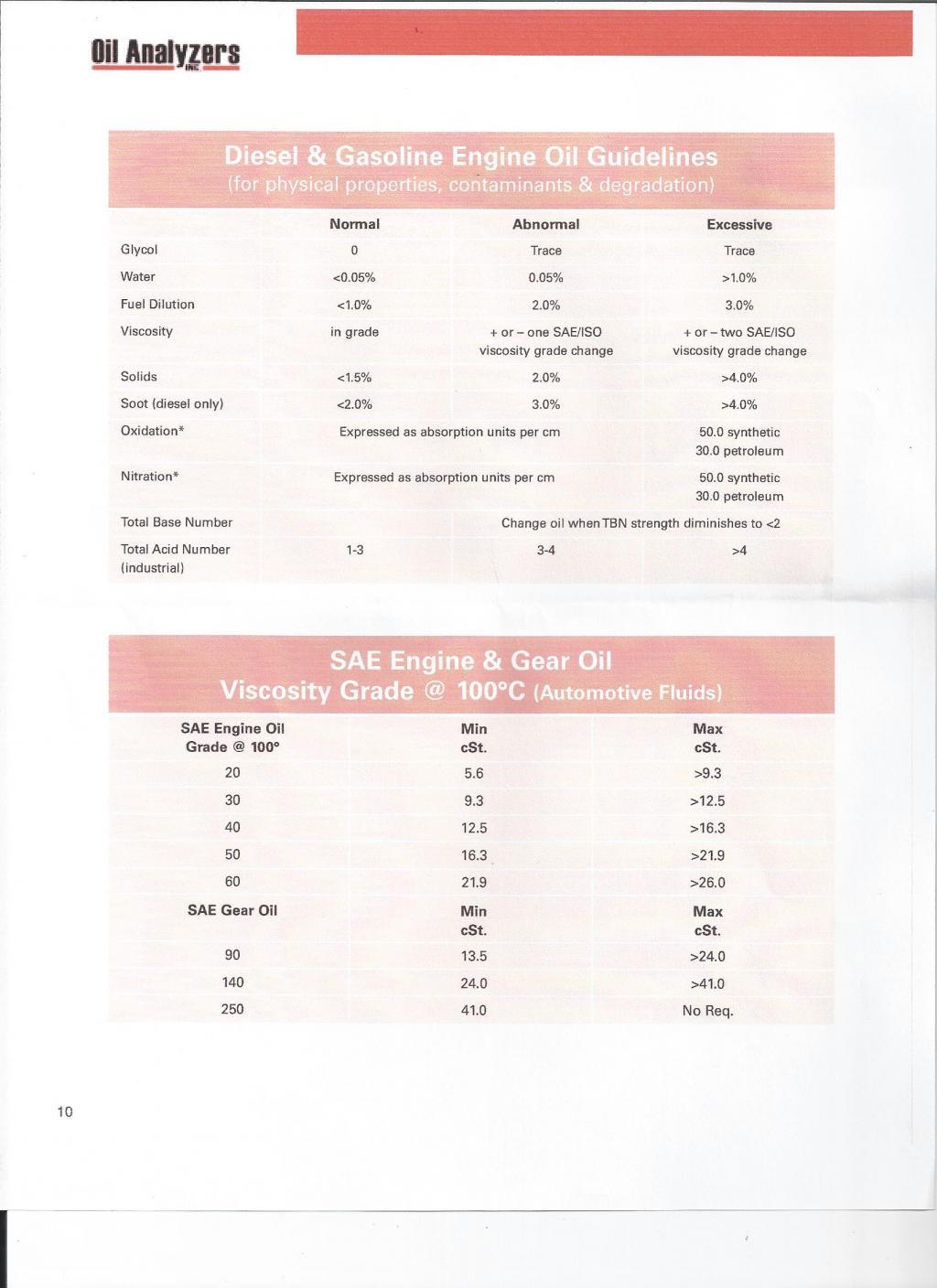

AH64 summed it up pretty well, Silicon is very fine dirt "Micro dust" my term to clarify your question. As AH said time for a new air filter, I saw very high silicon when I had a K&N filter on my 02 and it was climbing for a few samples until I ditched it for an AFE system and the silicon disappeared. Another way to get it in the sample if indeed you have a good air system is how did you take the sample? Many many samples are contaminated during the sampling process if done carelessly or the wrong way to take care not to get any dirt in the oil. I attached a pic of what oil guidelines are from OAI, it gives a good description of normal good and bad numbers for a few of the items you are looking at. Click on it a couple times to magnify it up to a readable size, I will include a pic of what the OAI report looks like. I deal with CAT SOS samples every day.

-

Tires: Treadwright

:thumbup2:I know several folks who have run the treadwrights and nobody had anything bad to say about them, I have thought about getting a set some times but always forget about them when time comes to buy.

-

Just added CRE Rocker flares to my 05

They are not steps, buy I have had people step on them they are just 2 sided tape and screws holding them up, I had one crack from someone steping on it once. My wife and I do not have any issues with hitting our shins on them but we are both taller people. Problem with flaps is the bigger they get the more chance they have of getting torn off, deep snow and ice and mud build up hanging on them weighing them down and rough roads and country section lines, over the years I have kept to average sized molded flaps and found in my driving conditions last the longest with less damage.

-

Roadtrip Adventure spare parts list!

The only time any rig of mine was behind a wrecker was when I first got a smarty for my 02 and did the first download at home, drove 40 miles to meet a guy along the Interstate to pick up a trailer for another guy, while sitting there I decided to try another program and that is when the Engine ECM gave up the ghost during the second ever program change. Thanks to AAA to get my rig home a couple hours later and Bob Wagner getting me into direct contact with Marco we found that the ECM fried, rare but does happen. Bob overnighted me an ECM on him and I was back in business 2 days later.

-

Roadtrip Adventure spare parts list!

That's what I go with myself, if you need to carry half a vehicle worth of parts with in fear of failure means you are not doing a good enough job looking things over during normal "PM" preventative maintenance service time. I carry a spare belt in all vehicles "although in 20+ years I have never failed a serpentine belt" and basic tools specific to the vehicle and on road trips far from home a fuel filter and a bit of engine oil since I use Amsoil and during summer a box of rags and window cleaner. In the winter I have little room in the cab as I carry enough cold weather gear to keep 2-3 people dressed for sub zero and have had to use it to help other out a few times over the years.

-

Just added CRE Rocker flares to my 05

I have thought about the spray on liner but our gravel has a clay base to it and it sticks better than super glue and dries hard as concrete and when it has a rough surface like spray on liner to adhere to it is near impossible to clean off plus these help keep the heavy stuff underneath and not sprayed up the whole side. A local store carries them but are going to drop them as they doubled in price in the last year and demand fell off for them and at nearly 300 bucks it will be the last set I buy also.

-

Pics of me towing things

Never too early to plan ahead lol!!!!!

-

Just added CRE Rocker flares to my 05

Thought I would throw in a couple pics of my recent rocker flare install. I have had these on my last few pickups and I like them a lot with the amount of gravel I drive the running boards I had on this rig were totally trashed by gravel so back to flares I went.

-

Pics of me towing things

Headed to my mother in laws farm to clean out a couple of her barns and corrals that are too small to get a full sized tractor in. Got my B2150 24hp Kubota tractor loaded on my 1995 30' DCT trailer, it has a 26' deck with a full width 4' pop up beavertail and 7k axles. Also have to do some driveway repair for her, it got really washed out and rutted out during our last 18 inch snow storm, the frost was already out and it turned to mud and the run off washed through some ruts so the box scraper will get a workout as well, drive is about 200 yards long.

-

Trans. temp gauge

You got it, the front line on the tranny is the hot line going to the "Heat exchanger" I still see people referring to it as a cooler. It is dual purpose hence the name Heat exchanger. The cooler is up front by the radiator.

-

Trans. temp gauge

As the last 2 posts say....... If it is an electric gauge it should max out if the sender wire is grounded and second if the sender is mounted in the pan and the temp gauge starts at 100 or more you will think it is broke until you get some good around town driving or long trips. I had 2 gauges at one time checking temp differences at different spots on the tranny and in the front converter output line it the fastest reacting and most accurate, I saw no difference in temp between the servo port and the pan but both were always consistently 30-50 degrees colder reading than the cooler line port.My tranny ran around 150 on average driving reading at the cooler line and thus the gauge hardly ever moved when I was reading at the pan or servo port because the gauge started at 100-110 degrees at the low end.

-

wally is sold out... what next?

Nope memory isn't long enough to remember a thread from a year ago lol. I do not know anybody from the Fargo Cummins North Central store "I did have a week long service school class there in the mid 90's and 2 weeks of class in the St Paul Minn store", At work we use the Minot CNC store for service. I live about 230 miles west of Fargo and only go through that god forsaken flat land when I absolutely have to, Minot is just a tad over 100 miles north of me and I went to diesel school with the service manager there. Over the years I have been involved in two 903 conversions, one to an 855 and one to an N14 Cummins on 4wd ag tractors. One was a Versatile and one was an old Steiger. I will have to look up the filter head and filter # cat uses to filter the engine oil on the ORS "Oil renewal systems" equipt engines we have. They filter metered engine oil from the crankcase directly into the fuel tank. What kind of info did Brad school you on?