Everything posted by The_Hammer

-

Fabbing up a new lower and upper dash?

Top dash wise the one that Geno's garage offers is a very nice piece. Is your bottom dash broken or cracked?

-

Sick, trans is acting up, and I need my truck in the morning

After double checking the anchor it turns out that it's not billet, so it's being replaced as well. I don't believe this trans was running much (if any) over stock pressure.

-

Sick, trans is acting up, and I need my truck in the morning

I think it was on purpose to be honest. Before all this I was having issues with my converter slipping so I took it back to the shop (before I knew better). I was told my converter was shot (reman Suncoast triple disk from DPC) so after talking to DPC I sent my converter in for inspection. After cutting it open I was told that it appeared there was a lack of pressure coming from the VB, which caused the converter to slip. I told the shop who's reply was "bullshit, it's the converter". I told them to check the VB and after some arguing they did. Guess what? The guy hands me the converter clutch apply valve and says that it was sticking. He said my VB was wore out and that he could "fix me up" for $500, to which I declined. That's also when the front driveshaft fiasco started, which ended up with me threatening to lawyer up on them to get my front driveshaft back which they had tried to steal while giving me someone else's broken one that didn't even fit my truck. I've already ordered a VB from HTS, I don't want to take a chance of this one causing me any more issues. There wasn't any debris in the oil pan, filter, or magnet beyond normal wear, and the fluid looked like new. It has a billet input shaft, servo, accumulator, strut, and anchor. I'm going to replace the apply lever with a factory ratio billet piece as well. Because of screw jobbers like that shop I prefer to do everything myself. Put a new roof on my house, do all the electrical work (to code as well), install hardiplank, level the house, ect. Operate excavators, backhoes, dozers, trenchers, articulated loaders, graders, cranes, ext. Welding, fiberglass, paint and body work, ect.

-

Sick, trans is acting up, and I need my truck in the morning

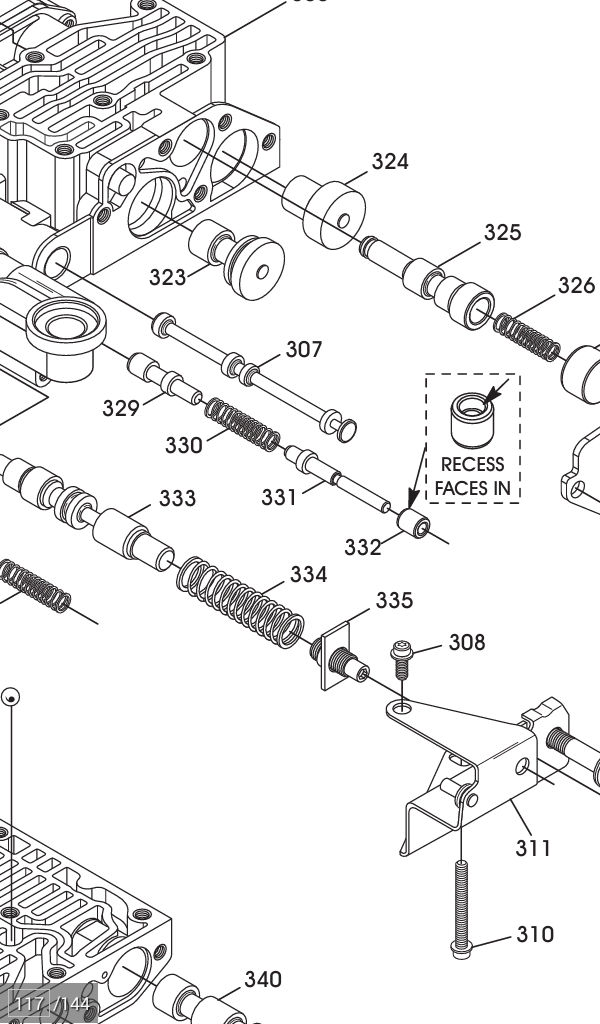

So, what happens if part 331 and 332 are installed backwards? Meaning, you slide 332 on to 331, then flip it around and install it in the VB. That's how it was installed from the transmission shop.

-

Sick, trans is acting up, and I need my truck in the morning

I Talked to Dusty at HTS earlier and he said it sounds like the TV bore is wore out and needs to be sleeved. He said he would accept my VB as a core so I'm getting one of his. I told him I was planning on going through the trans to verify what parts were actually upgraded and he said that if I ran in to any issues to give him a call. I'll keep yall' updated on how everything goes. This is an issue I haven't found on any forums so if a wore out bore is the confirmed cause it would be nice to add it to the database.

-

Sick, trans is acting up, and I need my truck in the morning

@isaac hall: With the TV cable removed, trans in N, you can't push the TV lever more than an 1/8" without pressure forcing it back. @Me78569: I'll do that. I'm wanting to turn this from a "being so angry I want to beat a refund out of the jerk!" thing in to an enjoyable learning experience. So far I'm still leaning towards beating a refund out of the jerk lol.

-

Sick, trans is acting up, and I need my truck in the morning

Well, I've decided to pull the trans and go through it so I can verify what parts were actually upgraded. I'm not taking the word of the of shop as they've proven themselves to be nothing more than crooks. I downloaded the ATSG manual (from the ATSG site) and have been going over it for a while now, doesn't seem too bad actually. I'm going to inspect the VB and if it's good for a core I'm going to buy one built by a known reputable company who has the ability to function test their units. Needless to say this is no longer an emergency so feel free to move or lock this thread.

-

Sick, trans is acting up, and I need my truck in the morning

I ended up getting sicker overnight then the job got cancelled due to rain. This is my only vehicle so I have to figure this out asap. The only trans shop anywhere around here is the one who screwed me over so that's a big ol' negatory ghost rider. I can rebuild engines, differentials, hydraulic pumps, hydraulic cylinders, ect, but a damn automatic transmission eludes me I'm thinking I may just have to drop the VB and see what's going on. I need to pick up either a FSM or ATSG manual, not sure which would be better. I appreciate any and all information

-

Sick, trans is acting up, and I need my truck in the morning

Thought I had my trans sorted out but unfortunately that's not the case. Currently the TV lever on the side of the trans pushes back so hard I'm unable to push the throttle pedal down much beyond idle. I'm unfamiliar with how the TV interacts with the VB so I have no idea what could be causing this. I need to know if this is something that I would be able to fix tonight or if I'm just screwed.

-

47RE 1-2 shifts happening to quickly

I spoke too soon. It ran fine for a whIle but now the throttle gets hard to push down because the TV lever is fighting back. I'm going to put the resistor back in and see what happens. I'm really starting to not like this trans.

-

Slight popping/sputtering sound

The fuel heater has been deleted for a few years now because it was a never ending sorce of air leaks. I'll check formed hose and metal line as well just to be sure. Thanks for the help yall' I appreciate it!

-

47RE 1-2 shifts happening to quickly

Well I found the cause of the 1-2 shift issue, it was the 100 ohm resistor that is sometimes used to keep the trans from going in to limp mode after line pressure is increased. Seems the truck was never tested to see if it actually needed the resistor, which it didn't. With it removed I was able to adjust the shift points via the TV cable. Now 1-2 shifts happen around 17 mph and 2-3 shifts around 30 mph or so. 3-4 is around 40 mph and lockup around 48 mph since wiring in a pot to replace the TPS.

-

Slight popping/sputtering sound

With the pedal to the floor it only takes half a crank before it pops off. Just got back from the local stealership. Went to have my PCM flashed so I could use a lockup switch but was told they can't flash it, after charging me $60

-

Slight popping/sputtering sound

Hell, maybe it's just me then. I'll see if I can get higher quality audio uploaded. Here is a higher quality sound clip https://youtu.be/qUtefcnqbDM

-

Slight popping/sputtering sound

Mine never clears up and stays the same regardless of temperature. Did you check out the video I posted?

-

Slight popping/sputtering sound

If it was sucking air wouldn't it be hard to start? Here's what it sounds like

-

Slight popping/sputtering sound

Also, there is no smoke of any kind when this is happening. The best way I can describe the sound is that it sounds like a 7.3 powerstroke with a straight pipe under a load.

-

Expanding my tool collection...

Well, I tried to quote Mopar Man but instead I got some kind of jacked up quote tree that I can't delete. I'm always looking to improve my tool set and add things to make life easier. I'm not one to buy tools just for the hell of it though, whatever I buy has a specific purpose.

-

Slight popping/sputtering sound

From around 1700rpm on up there is a slight popping/sputtering sound while accelerating from 1/2 throttle on up and it gets worse with a load. The first thing I did was install a fuel pressure gauge to help diagnose/ eliminate possible causes. The results are as follows: Idle: 22psi2500 RPM (no load): 38psiPressure never drops below 20psi while doing a WOT run.This is the truck's current setup:*100 plate and AFC full forward. *Stock injectors that were cleaned, pop tested, and shimmed a couple years ago. *1st Gen air filter (was on the truck when I bought it, been meaning to do a BHAF). *Stock HX35 in good working order, minor amount of play and zero contact with housing. Will boost to 38+ psi but keep it at 32psi and under. *Timing set to 16.5 degrees.*Valves adjusted to spec. *4 1/2" DP, 5" the rest of the way including stacks.*Built 47RE. *4.10 gears. *35/12.50R16 tires. There are no leaks anywhere on the pump or from the injector lines. The truck starts fine, hot or cold, and idles smoothly. I'm starting to suspect the governor springs because the truck falls on it's face right around 2k RPM. When I say "it falls on it's face" I mean this: Imagine your taking off from a dead stop and you floor it, then at about 50mph (for example) you let off the throttle to maintain speed. That's what happens around 2k rpm, except I'm not letting off the throttle.

-

Front bumper

Depends on the wall thickness but generally 1/8" - 1/4" can be bent fairly easy with a manual tubing bender.

-

Fabbing up a new lower and upper dash?

I'll get them uploaded this evening. I had to reconstruct mounting points for the hvac controls and top dash which is what prompted me to reinforce everything. The top dash is in far to many pieces to do anything with, which sucks. Due to the extra thickness of the glass none of the factory push in threaded clips will work, so I'm simply going to epoxy on some different clips from the back of the dash. It's been a LOT of work but I'm never selling this truck so I'm setting it up for the long haul.

-

Fabbing up a new lower and upper dash?

I just pulled the entire lower dash out, drilled out all the rivets holding the plastic to the metal sub-frame, removed the plastic and put down a layer of fiberglass on the back side for reinforcement, then riveted it back to the metal subframe. While doing this I started thinking about fabbing up a completely new upper and lower dash to replace the plastic garbage Dodge so graciously blessed us with. Has anyone done something like this? I'm not talking about a bare bones dash you see in a race truck but rather something that looks factory. If I decide to do this I'm heading to the local junk yard to find a cab to use for R&D work.

-

Front bumper

This is the bumper I have on my truck http://bumpersuperstore.com/i-11597331-tough-country-afr0025d-apache-front-bumper-dodge-ram-2500hd-3500-1996-2002.html?utm_source=google&utm_medium=cse&utm_term=11597331&gclid=CLTbk9P3g8kCFQiraQodNx0KJw It's built by a shop that's about 20 minutes away from me. It's built very well and I've been happy with it. Here's the place that builds them http://www.toughcountry.com/fronts.php

-

DIY: Lockup Switch install into Gear Selector Arm

A momentary switch is definitely the way to go. I too would love to automate it, if I had the money I would try one of the aftermarket PCMs. I wish my VB was set up for 2nd gear lockup, I need to see what needs to be done so it will.

-

47RE 1-2 shifts happening to quickly

Just found out my neighbor has a scan tool with live data stream so I'm going to see what the sensors are doing before dropping the pan. I'll post up what I find.