-

not sure what i just did but ac coming out defrost vent

Just an update, I think the vacuum line from under the hood might actually go directly to the back of the switch, not the thing by the throttle. There are a number of vacuum lines directly in the back of the selector switch on the dash, and it makes sense that vacuum would go there first. But fortunately/unfortunately I didn't have to (yet) find out for sure, as I was able to patch the line under the hood. I grabbed onto that tiny little piece just barely sticking out of the firewall and pulled as hard as I could, and got it to slide out about 1/2". Just enough to slip some rubber hose over top. There wasn't enough room for a clamp of any kind or to wrap tape around it, so I squeezed a bunch of superglue on it, lol. Seems to be holding for now! If/when it breaks again, I'll probably have no choice but to run a new line all the way from under the hood through to wherever it needs to go. I'm definitely going to run it through on the drivers side though if I need to go that route, I have no idea why they went to the passenger side and behind the HVAC box, what a silly engineering idea.

-

not sure what i just did but ac coming out defrost vent

Thanks for the info @dripley! I was finally able to pull out my air cleaner and look closer, and I found the other end, but I can't get to it. I can see about 1/8" of it sticking out right next to the top evap line, where it goes through the firewall. Inside behind the glove box you cannot see this one, as it comes in directly behind the black plastic box and cannot see or feel it. So...rather than pull out the whole dash, do you know where this line ends up? Does it route over to the driver's side, down by the go pedal? I see some vacuum lines down there. If it really is one of those, I would much rather just route a new line all the way from there, through the firewall on the drivers side since there's already a hole, and then over to the broken piece by the air filter. But, before I pull apart the lines by the drivers feet I'd like to see if anyone can confirm whether or not that is really where that line ends up...? You'd think I could find that part of a diagram on the internet but I'm not having any luck.

-

not sure what i just did but ac coming out defrost vent

Hey guys, rather than start a new topic for something that has been discussed a bunch already, thought I would jump in on this one. I just finished installing new exhaust, and afterwards noticed that my air is only blowing out the defrost. As I've seen all over the internet, it seems like the most likely culprit is that I broke a vacuum line. I started tracing from the vacuum pump, and I'm having trouble figuring out exactly where the line runs from the main run across the cowl into the HVAC box. I see the line from the pump to the cowl line, and I see that it goes back toward the front, I assume for cruise control, and then there is another T that happens around the valve cover - for 4x4 probably? Then the line continues toward the passenger side, and it ends in the thing I'm holding in my hand in the picture. I assume this is supposed to be going through the firewall over there near the AC lines? As you can sort of see in the pic, it looks like the end of this may have melted. Or am I wrong, does everyone have one of these things hanging off their truck over on the passenger side? My 4x4 and cruise are still working just fine, and I'm guessing that is only because this one appears to have melted shut completely at the end. Do you agree? If I actually cut off the end of this hose, then I would probably lose 4x4 and cruise as well? My question really is - where do I need to hook this thing to? I'm afraid since I don't see anything obvious that it might have fallen back into the cab through the firewall, and I don't look forward to trying to find it from inside. Does the vacuum line from the engine bay run into the HVAC box through a port somewhere near the heater core lines?

-

Fuel sumps are illgeal

Sure thing! Here are sections 393.65 and 393.67. https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/pdf/CFR-2011-title49-vol5-sec393-67.pdf

-

Fuel sumps are illgeal

Sorry, this is a duplicate post from where I put it originally, but it applies to this conversation as well so wanted to get all of your opinions on it too... I read over the DOT information, and came away with the conclusion that sumps are perfectly legal. Here are the details on what I found. Please correct me if I read any of this wrong, as I do really want to understand this, but I couldn’t find anything in here that tells me a sump on the bottom of a diesel tank is illegal on these trucks: https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/pdf/CFR-2011-title49-vol5-sec393-67.pdf Regarding 393.65: The “gravity or syphon feed prohibited” absolutely does NOT apply to our trucks. This is clearly taken out of context by that one website and only relates to feeding directly into the carb or injector. (d) Gravity or syphon feed prohibited. A fuel system must not supply fuel by gravity or syphon feed directly to the carburetor or injector. Furthermore, down a little ways in the fuel lines section it even references a sump and the fact that any fuel lines which are more than 2” below the tank or the sump need to be protected: (f) Fuel lines. A fuel line which is not completely enclosed in a protective housing must not extend more than 2 inches below the fuel tank or its sump. Diesel fuel crossover, return, and withdrawal lines which extend below the bottom of the tank or sump must be protected against damage from impact. Regarding 393.67: And then regarding anything found in 393.67 – this does not apply to most personal trucks, unless you are using it commercially. It states at the beginning of 393.67 that these rules are for commercial motor vehicles, as opposed to 393.65 which states just “motor vehicles”: (a) Application of the rules in this section. The rules in this section apply to tanks containing or supplying fuel for the operation of commercial motor vehicles or for the operation of auxiliary equipment installed on, or used in connection with commercial motor vehicles. Even if we did have to conform to 393.67, rule #4 under construction of tanks shows that a drain or bottom fitting must not extend more than ¾” lower than the tank or sump. There again it references a sump as a valid option. (4) Drains and bottom fittings. (i) Drains or other bottom fittings must not extend more than three-fourths of an inch below the lowest part of the fuel tank or sump. And then #5 shows us that diesel tanks are exempt from the requirement that fittings be located above the normal fuel level, so that one doesn’t apply to us either. (5) Fuel withdrawal fittings. Except for diesel fuel tanks, the fittings through which fuel is withdrawn from a fuel tank must be located above the normal level of fuel in the tank when the tank is full.

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

I read over the DOT information, and came away with the conclusion that sumps are perfectly legal. Here are the details on what I found. Please correct me if I read any of this wrong, as I do really want to understand this, but I couldn’t find anything in here that tells me a sump on the bottom of a diesel tank is illegal on these trucks: https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/pdf/CFR-2011-title49-vol5-sec393-67.pdf Regarding 393.65: The “gravity or syphon feed prohibited” absolutely does NOT apply to our trucks. This is clearly taken out of context by that one website and only relates to feeding directly into the carb or injector. (d) Gravity or syphon feed prohibited. A fuel system must not supply fuel by gravity or syphon feed directly to the carburetor or injector. Furthermore, down a little ways in the fuel lines section it even references a sump and the fact that any fuel lines which are more than 2” below the tank or the sump need to be protected: (f) Fuel lines. A fuel line which is not completely enclosed in a protective housing must not extend more than 2 inches below the fuel tank or its sump. Diesel fuel crossover, return, and withdrawal lines which extend below the bottom of the tank or sump must be protected against damage from impact. Regarding 393.67: And then regarding anything found in 393.67 – this does not apply to most personal trucks, unless you are using it commercially. It states at the beginning of 393.67 that these rules are for commercial motor vehicles, as opposed to 393.65 which states just “motor vehicles”: (a) Application of the rules in this section. The rules in this section apply to tanks containing or supplying fuel for the operation of commercial motor vehicles or for the operation of auxiliary equipment installed on, or used in connection with commercial motor vehicles. Even if we did have to conform to 393.67, rule #4 under construction of tanks shows that a drain or bottom fitting must not extend more than ¾” lower than the tank or sump. There again it references a sump as a valid option. (4) Drains and bottom fittings. (i) Drains or other bottom fittings must not extend more than three-fourths of an inch below the lowest part of the fuel tank or sump. And then #5 shows us that diesel tanks are exempt from the requirement that fittings be located above the normal fuel level, so that one doesn’t apply to us either. (5) Fuel withdrawal fittings. Except for diesel fuel tanks, the fittings through which fuel is withdrawn from a fuel tank must be located above the normal level of fuel in the tank when the tank is full.

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

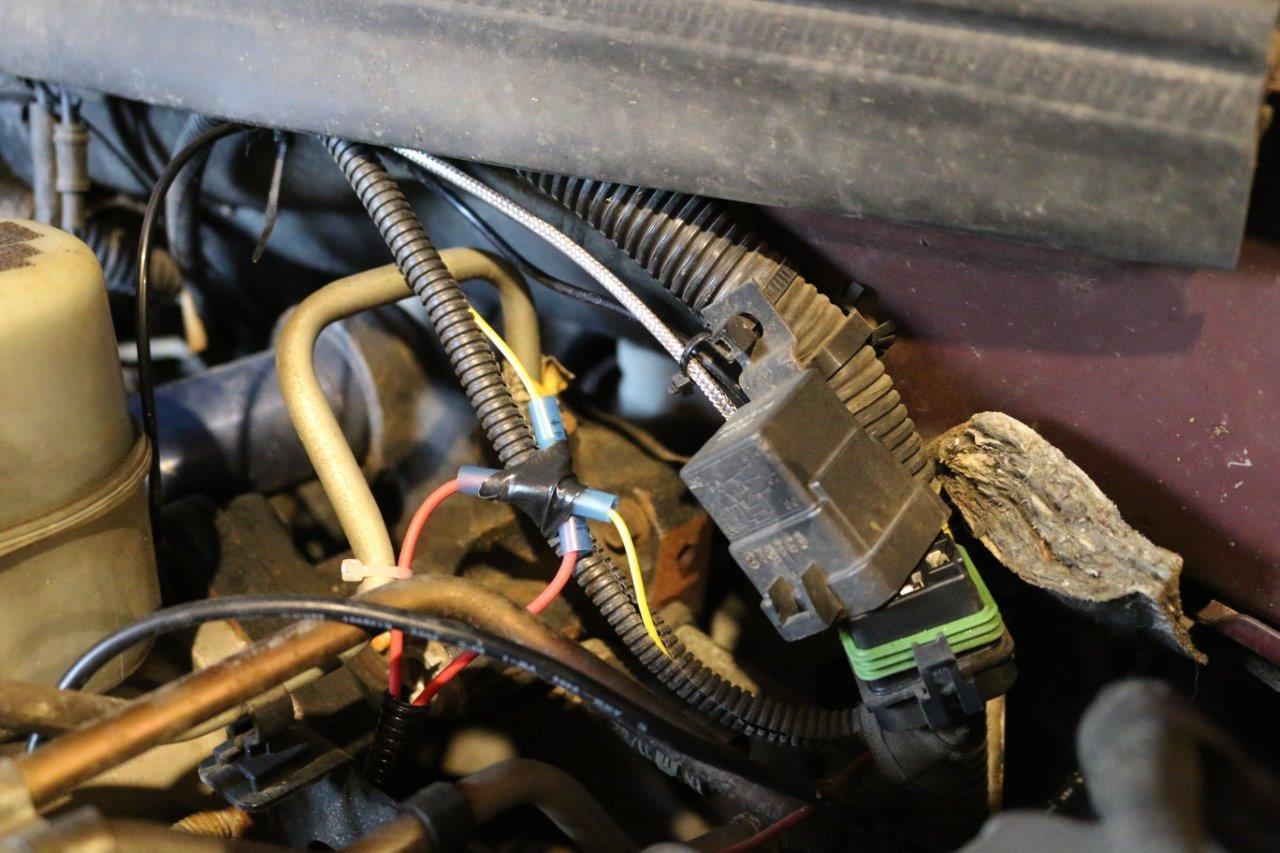

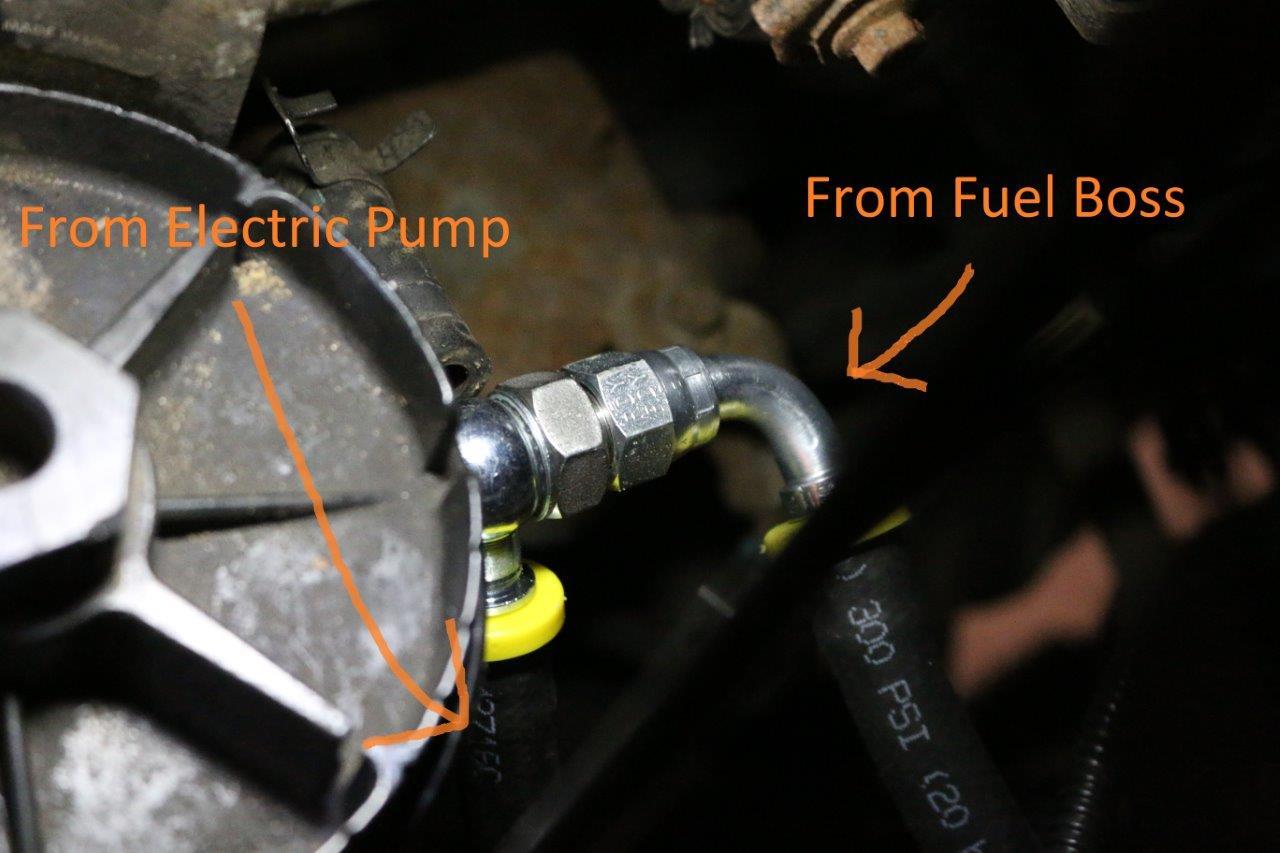

Guys, thanks again for all the advice on this topic. I finally decided on a solution and finished installing it this week. I ended up going with a GDP Fuel Boss mechanical pump that is fed from a Beans Diesel Sump. Going the route of the sump solved the following issues I was concerned about: It allowed me to continue using my in-tank pump as a backup. Since I didn’t have to modify the basket at all, my in-tank pump is still sitting there happily running whenever I need it to. I never had to drop the tank or even touch the top of it! It was nice not to have to worry about dropping the tank for a draw-straw install, and I never even had to touch the top to try and unplug the wiring harness or anything. For the Fuel Boss install you do have to cut one of the lead wires that supplies power to the in-tank electric pump, but I tracked it down under the hood and cut into it there instead. No potential quarter tank issues since there is no draw straw. I know some people have gotten their straws installed well enough that this isn’t a problem, but there are many more stories on forums about people that do have ¼ tank issues after installing draw straws, so it is nice not to have to worry about that. I got both positive and negative feedback on doing a sump, but I’m glad I did it for the reasons above. It works great so far. I installed a shut-off valve on the sump so if anything ever did happen to the hose or if I need to shut it off for whatever reason I can just turn the valve. It also has a drain plug so if I ever do need to empty the tank and remove it for whatever reason, that will be easy too. I wanted to update this thread because I never found a lot of information about whether or not a Fuel Boss could co-exist with the in-tank pump, but it definitely can. Here's a little story to prove that the electric still works as a backup: It’s common for “tank gunk” to have to flush its way out of the system following installation, since you kick up debris and stuff when you empty the tank. Shortly after I installed the Fuel Boss I got on the throttle pretty hard and my pressure went up close to 20, and when I let off the pedal something must have gotten stuck in the bypass valve and held the piston open because my pressure suddenly dropped down to 5. It stayed between 5-8psi the rest of the way home. I figured something must be stuck in the bypass, holding it open, but before I took apart the bypass valve and cleaned it out, I experimented a little. If I unplugged my electric pump my pressure would read zero when running. The bypass was allowing so much "overflow" fuel past it with the piston stuck open that my gauge was registering zero, yet when I was driving home I never saw zero, it held itself at 5 or above. I say this to prove that the Hobbs switch which tells the electric pump to engage when pressure drops is an immediate reaction. As soon as my pressure dropped the electric pump kicked in and I never even noticed in the truck, except that I was watching my fuel pressure gauge like a hawk because I was only a few miles into it after having installed everything. By the way, I took the bypass valve apart (super easy), put it back together, and I’ve never seen that symptom again. It takes about 30 seconds to pop the bypass off, so even if this happened on the road it would be very easy to fix it with two crescent wrenches. Hopefully this post isn't too long. I created a video with some detail on how I ran everything and how I did the wiring, if anyone is ever interested in doing one of these installs. Otherwise there are pictures and descriptions down below. Sump on bottom of tank goes with 3/8” lines straight up to the Fuel Boss that is mounted via the front three oil pan bolts. The only thing in-line on the way to the pump is a fuel strainer that comes with the Fuel Boss install kit. I mounted this on the driver’s side of the transmission for easy access to change it out in the future. Then from the Fuel Boss you head back to a “T” that is directly underneath the fuel filter canister. From the T you go both to the back of the truck, as well as upward toward the filter. On the line that goes to the back, you install the bypass valve. This is what opens at roughly 18psi and allows excess fuel to return to the tank. I hung the bypass valve right by that fuel strainer, so they are both super easy to access. Then from the bypass valve you just run to the back and return to the tank. I cut the filler neck hose and inserted the return manifold there. Again, for this I did not have to drop the tank or even have to remove the filler hose – I just cut 1” out of it right where it was. Moving back toward the front, the top of the “T” as you can see in one of the above pictures heads directly north toward the fuel filter. In this section of line you install the Hobbs switch which tells the electric pump when to turn on or off. Two wires go from the Hobbs switch to one of the lead wires for the electric pump. I cut into those wires right behind my master cylinder. If your stock lift pump is still on the block you’ll have to tap into them in another place, but mine was so easy to get to: Before you hook your new line to the back of the fuel filter canister, figure out how you are going to plumb in your factory supply line from the electric pump. I ran a new piece of hose from the metal hard line under the driver’s seat up directly to the filter. You have to install a check valve in this line (comes with the Fuel Boss kit) so that the Fuel Boss doesn’t back-feed down this stock supply line. In some cases you can probably re-use the factory dorman connector and tap back into the dummy “fuel block” that Dodge put in place of where the on-block pump used to be, but mine looked gross and rusty so I bypassed that whole mess and went directly to the fuel filter with both my Fuel Boss supply line as well as my factory supply line. I used a banjo to 3/8” quick connect fitting for the factory line, and then a JIC 90 for the Fuel Boss supply line. And that’s it! While I had the whole fuel system apart I also installed a big line kit between the filter and the VP with a needle valve and snubber for my gauge in that run. I hope this helps someone else be able to make the decision on which direction to go. Installing a FASS or AirDog would have been much simpler, but I'm glad I took the extra time up front so that I now have dual pumps in the event that something goes wrong while I'm on the road. Jordan

-

Mean While on Hoth....

I can almost hear Jeff Foxworthy in the background: "If, for any reason, you find yourself with three open beers at the same time.......you might be a redneck" ;) lol

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

Just an update for those interested in what Richard@GDP had to say about using a Fuel Boss alongside the in-tank pump on my 2001. First of all, you all were right - what a great guy. Easy to talk to, picked up the phone right away, and is a straight shooter. In fact, he told me I really don't need to change anything on the truck at the moment...more on that later. I can definitely run a Fuel Boss alongside my in-tank pump in order to have it for priming and as an on-the-fly backup in case the Fuel Boss belt breaks or something like that. What I need to do if I go this route is make the order over the phone, as he will get me the 2005-2007 install kit, but with the 2001 pump mounting bracket. The 05-07 kit includes its own draw-straw style pickup tube that the Fuel Boss will pull from. Then after leaving the pump, you T to the factory filter and to the return. The existing in-tank pump continues to be plumbed directly to the factory filter as well, with a check valve in place so that it only runs and pumps fuel if/when the Fuel Boss is not keeping up to pressure. This way the in-tank will run during starting and for priming, and if the Fuel Boss stops working. Otherwise, the Hobbs switch turns off the in-tank as soon as pressure is up. He said at least half of their customers use no electric lift pump whatsoever. As long as you don't lose prime, you never need to use the electric during starting. When it comes time to prime, you can either remove the inlet line from the VP and crank the engine to pull fuel through, or some people just pop the belt off the Fuel Boss and spin it with a drill or something similar, and manually prime it that way. Rich then asked me what my current numbers were on my in-tank. When I told him 8 idle and that I can drop it below 5 when I step on the gas he said "That's normal, probably been those same numbers since it was installed. If you're not modifying the truck at all, I'd just drive and enjoy it." The majority of the failed VPs that he has seen have boiled down to a build issue with the board, not having anything to do with fuel pressure. On mine particularly, since the VP44 was replaced in 2008 with a new one from Chrysler, I should have one of the newer "good" ones that do not have this design flaw, and it'll probably run forever just like it is. While that makes me feel better about puttsing around with it here and there unloaded, I still plan to upgrade the lift pump before I tow anything serious with it. ;)

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

Haha, nice. At this point I will just be thrilled to see more than 10psi on my fuel pressure gauge, whichever solution I end up with. Good to see someone else here from the mitten. I'm straight west of you a few hours, close to Holland. Are those Silver Lake flags in your profile pic...?

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

@jlbayes Where in Michigan are you located? Maybe you can stop by and p-pump mine too. Should only take a couple hours, right? lol

-

Battery minder, tender

Keep in mind too that voltage at the battery only drops about 1.5v from a fully charged to fully dead battery. You should only see this amount of fluctuation on a good battery. I don't remember the exact cut off number, but if you ever see voltages lower than 11 - there's a good chance your battery is toast. Sorry, "fully dead" is probably the wrong way to describe it, but if a battery measures lower than that threshold it will be dead enough to appear to be dead to a vehicle anyway.

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

That is a great point. I do not typically see dirt roads, but do have a quarter mile of gravel driveway and it is amazing the amount of large stones my new tires pick up. Every time I leave the driveway I hear them pinging off the side steps constantly until I hit about 30mph. So many choices. I do plan to at least call GDP and ask what kind of experience he has with people running a Fuel Boss alongside the in-tank pump. I imagine the plumbing would be more complicated than with a block-mounted pump, but it's what I've got to work with.

-

New Cummins owner - Intro and beating the dead horse on fuel delivery

@Mopar1973Man Thanks! That is the info that I had surmised after reading through all the posts, but it's nice to see the numbers laid out to know exactly where I stand. My PSI numbers have likely been the same numbers for the past 75k, which is when it got the in-tank pump and a new VP44. So I'm partly scared that replacing the lift pump at this point will cause the VP to choke again, but I know that if I leave it and drive it, I'll end up toasting both for sure, so I'd like to make it right asap. As for the color - I'll admit that in certain light it looks purplish. But as I told dripley earlier I checked the window sticker and it says "Beast Mode Red", and ain't nobody gonna tell me otherwise ;)

-

Battery minder, tender

I just got the "Battery Tender Junior", and I love it so far. Didn't get it for the Cummins, as I can let that one sit for weeks without starting and it still never takes more than 2 cranks to fire up. So to that point - yes you should definitely figure out where your juice is going, because these trucks don't suck the batteries dry as normal behavior. I rotate the tender between batteries in the cars that sit in the barn over winter, and it works great. I should really get more of these so I don't have to rotate it, but I switch it from one to the next about once a week or every other week, and it seems to work great so far. Spring will tell for sure, as I usually have to replace the battery in the Chevelle almost every year after I neglect to take care of it over winter.