Everything posted by Tractorman

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Common rail fuel injection started in 2003 for Dodge Cummins engines. Each injector has an electrical coil and is fired electronically. Every injector has fuel pressure available 100% of the time via a common fuel rail. This is why these injectors are very expensive. One new OEM Bosch common rail injector costs almost as much as 6 new OEM VP44 era injectors. - John

-

1999 24v cummins changes engine tone while keeping steady speed on highway

@Doubletroubleand @Mopar1973Man, I appreciate your prompt replies. I agree on many of your points regarding the life of an injector over time - specifically the weakening spring (lower pop pressure) and the internal needle and seat wear. I also understand that the injector tip holes can erode over time. I am in touch frequently with two other Dodge truck owners - one with a 1999 Cummins and the other with a 2002 Cummins. The '99 has 295,000 miles on the original injectors. I have recommended that he replace his injectors. The '02 has has 185,000 miles on the original injectors. Both of them still perform well and both of them have not experienced any change of engine idle rpm. So, what gives here? @Mopar1973Man, is it possible that this engine load / rpm change that you refer to is more evident with aftermarket high horsepower injectors and not with stock OEM injectors? Just my opinion, but I think the average life span for new OEM injectors for this era of engine would be closer to 200,000 miles. Thank you both for your input. - John

-

Questions..

I have heard the same, but it has never worried me. I believe there is a marginal sized oil passage for a particular bearing (not sure which one) that can starve that bearing for oil. I have a NV5600 that has logged 386,000 miles with no issues and I tow up to 21,000 lbs up 6% / 7% grades in hot weather. The only work done to the transmission was to replace the rear seal at 297,000 miles while I had the transmission out when I replaced the first clutch. I do make sure the oil level never gets low and sometimes even overfill it, just because of the above-mentioned oiling issue. I would place a lot more trust in a NV5600 or a G56 than I would in a NV4500 even after modifications were done. Beside, the extra gear is worth a lot, as well. - John

-

1999 24v cummins changes engine tone while keeping steady speed on highway

First, I am not singling you out @Doubletrouble, but I am curious as to why there is so much emphasis placed on replacing injectors at 100,000 - 150,000 miles. Also, I don't understand the engine load / increasing idle concept that is displayed on the Quadzilla tuner relating to poor performance of injectors. The only tuner that I have used is the Smarty S03 during the last 50,000 miles of my OEM injector life. On my personal truck, I ran the OEM injectors for 303,000 miles. I only changed them out because I thought it was time and they had served me well. The engine rpm had never changed at idle throughout the life of the injectors. Fuel economy was always very good, the power was very good, the exhaust was clean (for this era of engine), and the engine always started fine in cold weather right up to the time that I replaced the injectors. In fact, when I replaced the injectors with RV275's, I really couldn't tell any performance difference other than the RV275's delivered a little more torque on the low end, but engine idle was the same - smooth, and at the same rpm, The OEM injectors (303,000 miles logged) are shown in photo below. In my opinion all of the injector tips looked very clean for the miles logged - no evidence of poor performance on any of the injectors. The appearance of the other four injectors looked the same as the two injectors in the photo. - John

-

Different 01 Cummins Laramie SLT 4x4

Looks like you made a good trade. Good idea having the skateboard for emergency transportation while you are getting a feel for the truck's reliability. - John

-

TC lock up switch with PacBrake?

The diagram below shows how I wired my 1999 truck with a 47RE transmission in stock form (3rd and 4th lockup only) when the truck was new. I used a momentary foot switch in series with a throttle switch. This allowed for manual operation of any combination of convertor lockup with or without the use of the exhaust brake or the service brake at any engine rpm in 3rd or 4th gear. I had no aftermarket computer trying to control converter lockup and exhaust brake operation. The system was very effective and would be even more effective in a transmission with converter lockup in all forward gears. - John

-

The Cummins is back.

@Sycostang67, your truck looks really nice! - John

-

The Cummins is back.

Well, that's going to be problem..., most drivers aren't blind , so are they going to hit it? - John

-

Mystery Plug - Head Light Assembly

Can you give more detail about the year and model of your truck? As for the loose headlight - the piece that you are seeing is not a nut, but a metal clip that holds tension on the guide pin that you circled in the photo. The clip may be missing on the right headlight. As far as the mystery wire connection - the year and any other pertinent information about your truck is needed. For example, on my 2002 truck there is no connector there, just a continuous wire loom at that location. - John

-

98 12 valve cummins no bus, need help please

You can use dielectric grease, but I don't think it will help your situation. The dielectric grease primarily helps keep out moisture and reduces the likelihood of oxidation on the pins. I would carefully inspect the multi-pin connectors for any spreading of the the female terminal and inspect for any wires that may be partially pushed back inside the connector. - John

-

Poor fuel MPG

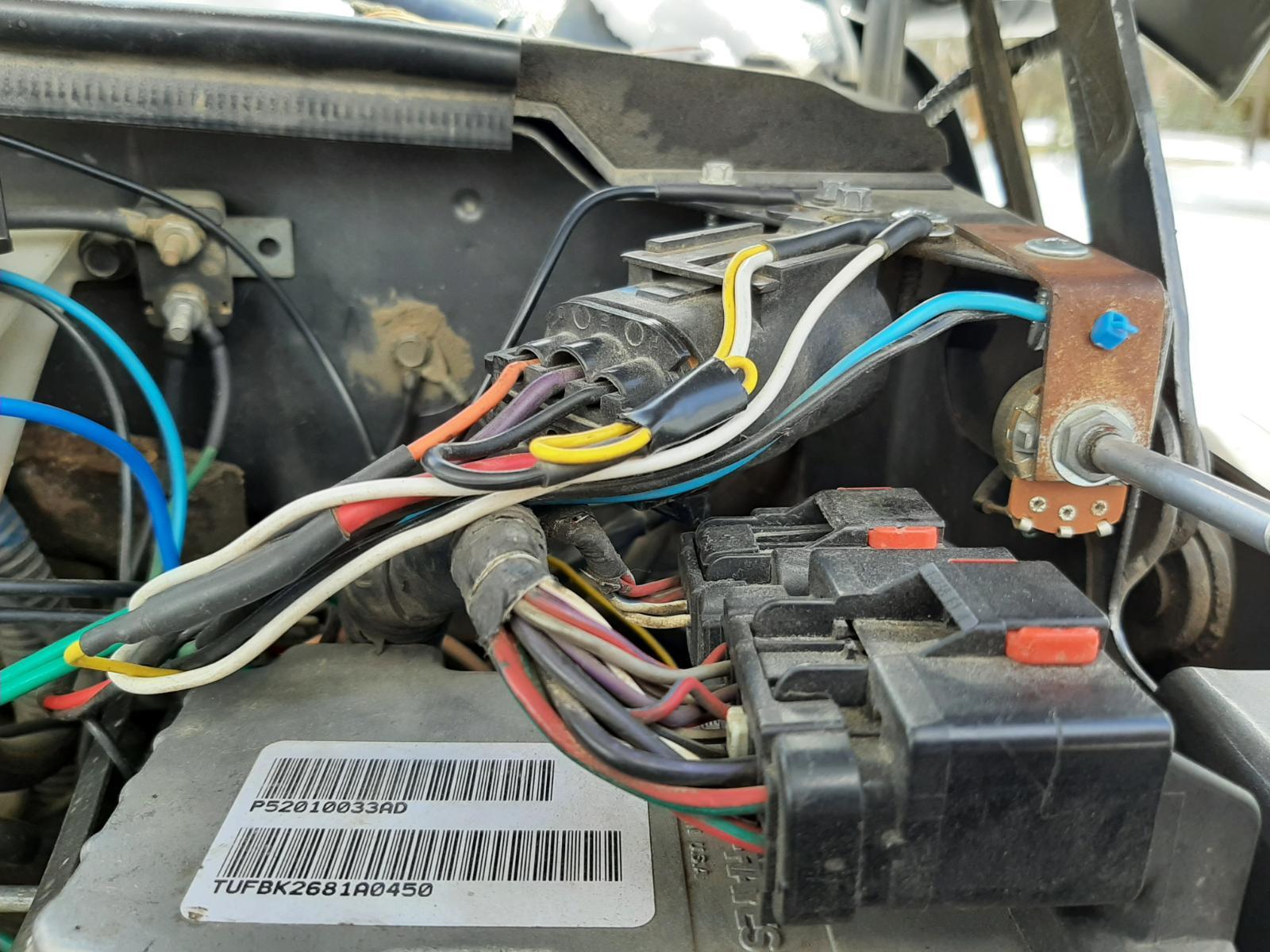

The two photos below show my setup using a 0-5,000 ohm variable resistor (potentiometer). I have it set to display a constant 143° when checking with my OBLink scanner. The temperature never varies. There are lots of resistors (fixed and variable) to choose on Amazon or other sites. Here are some excerpts from Michael Nelson (Mopar1973Man) from a few years ago. They should be helpful for understanding how cold intake air / warm intake air affect engine performance and fuel economy. - John

-

Poor fuel MPG

Mine has been on my truck for about 8 years. I will take a photo of it tomorrow and post it here. From what I remember, it is a 5,000 ohm 1/4 watt variable resistor. I mounted it in the engine compartment near the driver side hood hinge. Essentially, the IAT sensor is disconnected and sealed off. A two-pin Deutsch male electrical connector with a six inch lead can be purchased from Amazon and used to lengthen the wiring to the the mounted potentiometer. It is a relatively simple process. I can post more detail tomorrow. Also, I forgot to mention that I use a homemade winter front during the winter months for faster engine warmup and improved driveability. This also helps improve fuel economy. - John

-

Poor fuel MPG

The speed was quite variable. On the way to Cresecent City, the roads were snowpacked for about 350 miles, so speed was about 45-50 mph with a lot of time in 4WD. On the return trip, speeds were about 60-65 mph where the roads were clear which was most of the way. The speeds were slower through the mountain passes (7 passes each way). - John

-

Poor fuel MPG

Have you done the IAT sensor fooler with a resistor yet? I use a varaiable resistor that sets the IAT sensor reading at 143° all the time. This really helps for winter performance and fuel economy. Plus, the engine runs quieter when cold. I use a Smarty S03 on a mild tune with stock timing - RV275 hp injectors. About a month ago, I made a trip from Baker City, Or to Crescent City, Ca (a 1,000 mile round trip) carrying about 800 lbs in the bed for traction. I averaged just over 20 mpg with ambient temperatures ranging from 5° below zero to 40° above. Most of the time the temperature was in the 20's. - John

-

Surging

How about when the engine is at idle. Does the APPS stay at zero percent when the engine rpm's vary? - John

-

Surging

I use an OBDLink LX OBD2 Bluetooth Scanner through my Android phone to read live APPS signal data with the engine running. Do you have this capability? It would be good to verify that there is a 0 percent APPS signal commanded when the engine is at idle. What exactly do you mean when you say, "I can watch my throttle on my adrenaline and its fluctuating up and down when using accelerator."? Are you talking about the per cent of throttle commanded? A steady throttle should result in a steady per cent value for the commanded APPS signal. - John

-

Surging

Since the W-T wiring mod essentially shortens and improves electrical grounds for the ECM and PCM and alternator, I would think it would be less likely for electrical interference to be a source of your problem. Not sure if you have done the mod and also not sure if your question was referenced to after the W-T wiring mod, or before the mod. - John

-

Surging

Interesting that the surging goes away while using cruise control. With manual transmission trucks, the ECM controls throttle while using cruise control - the APPS is completely out of the loop. It seems like you are getting an unwanted signal through the APPS when driving without using cruise control. I think you need to physically disconnect the Adrenaline completely and then test drive. If possible, use a scanner to observe the APPS signal with the engine running and while driving the truck. With the engine at idle, the APPS signal should be 0 percent. This is controlled by the idle validation switch in the APPS. I recall someone having a similar problem and it turned out to be that the throttle low limit set screw was loose and the APPS couldn't set the idle validation switch. - John

-

Finally decided to add cupholders! We shall see.

I was wondering if there was a latch adjustment of some kind. Thanks for the tip. - John

-

Finally decided to add cupholders! We shall see.

@Doubletrouble, I received and installed my cup holder. It works well with my 6 spd. I think the truck has just a little more power now, too. At this point, I didn't use any hardware to fasten the cup holder. I did notice that the console lid doesn't latch anymore with the added material of the cup holder. Did you have the same issue? - John

-

Lift Pump Suction

Something else you may be interested in..., After dropping my fuel tank twice over the last 20 years, I decided to make an access door through the truck bed. One of the best mods I ever did. The actual time it takes to do the mod is about the same as dropping the fuel tank, replacing the basket, and re-installing the fuel tank. With the modification completed, I can now remove the fuel basket in about 10 minutes. Easy access to electrical and fuel connections, easy to remove the large threaded nut, easy to remove and install the fuel basket. Also, the job can be done regardless of the level of fuel in the tank. - John

-

Lift Pump Suction

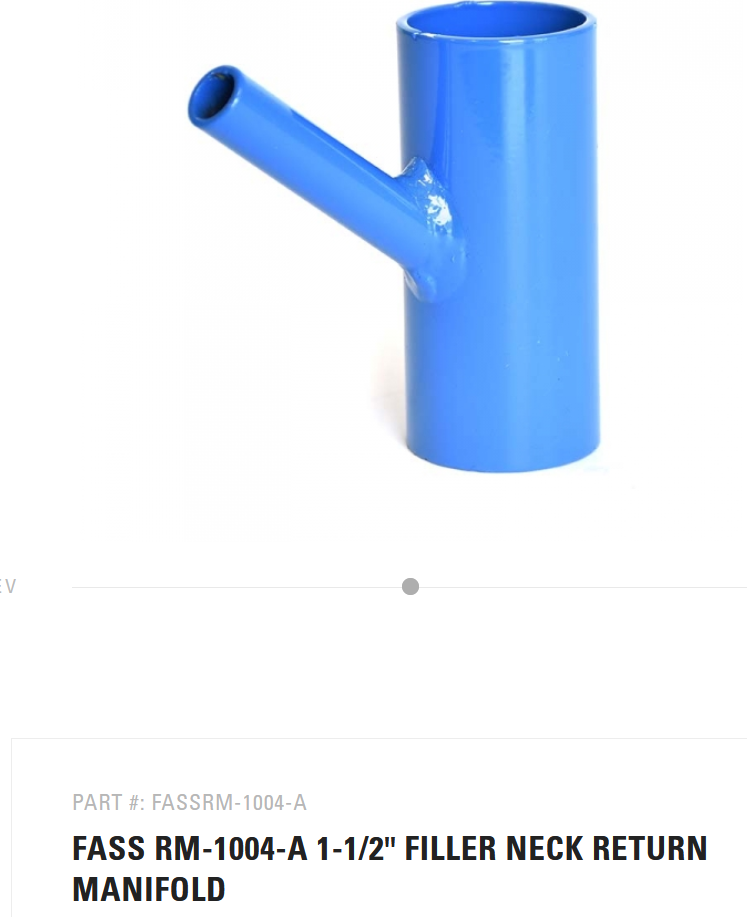

There is another option without modifying your new fuel basket plumbing. On my truck with an OEM fuel sender basket (no pump), I installed the basket and hooked up the fuel lines in an OEM fashion. Along the frame I cut the return fuel line and installed a three-way valve and added a fuel line and a tee to the fuel tank filler neck. With the newly added three-way valve in one position, fuel returns to the basket - a good option during winter months when warm fuel is desirable. With the valve in the other position, fuel returns to the fuel tank via the tank filler neck. This is a good option during the hot summer when cooler fuel is desirable. Just be aware that whichever method you use, more fuel will flow through the one-way check valve in the bottom of the fuel basket when the fuel is returned outside of the basket. This will result in running out of fuel sooner as the fuel tank nears empty. When fuel is returned directly to the basket (about 70% of the volume drawn from the basket), then the fuel level can be drawn down a little farther before running out of fuel. Here is the filler neck T. - John

-

Finally decided to add cupholders! We shall see.

Thanks for the photos and the followup. I think I'm going to do it Is this the correct cup holder? - John

-

Finally decided to add cupholders! We shall see.

I am curious to hear back after you drive the truck using the cup holder. I may have to do the same mod. - John

-

Anyone close have a smarty I can borrow?

I have a Smarty S03 and the high idle is enabled on my truck. I was not impressed with it at all. First, there are many times I wished the high idle would come on in the 6 cyl mode, but it never did. Then, when it did operate, it ramped up to the 6 cyl high idle and then switched to the 3 cyl high idle. OBNOXIOUS!! HORRIBLE!! The first time it activated, I was in the house. I thought the oil drain plug must have fallen out and all the rods were knocking. Not for me. These trucks are already noisy enough - especially when they are cold. So, last summer I decided to install my own mechanical high idle. It works very well and I get to be the boss and turn it on whenever I want. It is also nice to have on a 100° day in a parking lot. I posted what I did on this site. Here's a link. - John

.jpg.2acadf2b12045e6968f9be5dcfa49cfa.jpg)