Everything posted by Tractorman

-

2nd Gen Cummins heater temp differences between trucks

A couple of things going on here that are not frequently talked about. In the rear doors of the quad cab there air passageways in the lower rearward part of the doors. Each door has an airflow entrance and an exit. The entrance is exposed to the inside of the cab when all of the doors are closed. The exit is exposed to the outside area beyond the door seal when all of the doors are closed. You will have to open the rear door to view the exit. I believe (but have not proven) that there is a membrane inside the rear door vent that acts as a check valve allowing air to only flow outward. So, anytime the outside air is selected, the air will flow from the outside cowling behind the engine hood through the blower fan into the cab and then finally through rear door exits. This long flow path somewhat restricts the airflow. Air flow will improve at faster vehicle speeds as a result of the difference of air pressure - higher at the inlet (cowling behind hood) and lower at the outlet (rear doors of the cab). The difference of pressure has a venturi effect. When Recirc is selected, the re-circulation door near the inlet of the blower fan closes off outside air and opens a path directly from the inside of the cab to the blower fan inlet. This short path offers much less restriction to airflow, consequently more air comes out of the vents. Also, the air re-entering the blower fan will be much, much warmer than if outside air was selected, especially if outside temperature is well below freezing. The part you mention about, "my blower motor spins much harder and faster" is probably not true. It may SOUND like it is spinning faster, but what you are hearing is lots of blower fan noise and more air movement because the re-circulation door is open to the inside of the cab (where your ears are). Something in general about non-positive displacement fans that move air - the least restricted air path will load the fan the heaviest (slower rpm's, more air flow) - the most restricted air path will load the fan the lightest (higher rpm's, less air flow). This is contradictory to what most people believe. Listen to a vacuum cleaner motor when the suction hose is blocked - air flow is virtually stopped, but the motor speeds up. On very cold mornings (well below freezing) I use the Recirc mode to warm up the cab faster. I switch to outside air when I start driving. - John

-

68RFE Column to Console Shifter Conversion

Why make the conversion from steering column shifter to console shifter? Good question. The only two trucks that I have driven with a 68RFE 6spd automatic transmission are a Cummins powered 2011 Ram 2500 and a 2018 Cummins powered Ram 2500. Both were driven hauling a gross combined weight of over 20,000 lbs each. Both trucks were quite capable. My experience with the 2018 truck was in the summer of 2021. However, my focus will be with the most recent trips (August and October of 2023) in which I was driving the 2011 truck. The 2011 Cummins powered Ram 2500 is owned by my neighbor Jim. He is the original owner. Until this time, he has never hauled heavy loads with his truck. The first trip with Jim’s truck was an emergency trip. My receiver hitch on my 2001 2500 truck separated from the frame, while cresting the top of a 5,000 ft mountain pass about 50 miles from home. The GCW was 20,500 lbs. I called Jim and we brought his truck to the rescue. After getting the trailer hooked up to Jim’s truck, Jim activated the Tow-Haul mode and the exhaust brake. We began the 6% grade descent (me behind the wheel) needing to slow for many 40 mph, 35 mph and 30 mph curves. Our first impression was that the exhaust brake and transmission downshifting was too aggressive for our taste in the Tow-Haul mode. The downshifting and braking were effective, just too aggressive. We still had one more 5,000 ft mountain to climb and descend. I suggested that we start climbing the next pass with Tow-Haul mode engaged and then about halfway up the pass, turn off the Tow-Haul mode and manually select the specific gear limit on the transmission. So, as we began climbing the next pass in Tow-Haul mode, unwanted downshifts and some unwanted upshifts began to occur. The downshifts were an abrupt event, and some of the upshifts were accompanied with over-revving. We turned off the Tow-Haul feature for the rest of the trip and manually selected the gear limit when needed by using the -/+ switch on the column shifter. It turned out to be a much better experience. The unwanted shifting ceased and when the shifts were manually made (using throttle control for the shift) the shift was smooth - whether shifting up or down. The descent was made without using the service brakes. Throttle control was used for engaging and disengaging the exhaust brake. We were both impressed with how the transmission and exhaust brake performed using -/+ switch on the column shifter. We finished the rest of the trip through a twisty road with lots of curves using the -/+ switch when necessary. During this part of the trip, we started talking about the awkwardness of reaching for the switch on the column shifter (forcing the eyes to leave the road) and having to avert the eyes to the dash to see if the action actually happened. One of the comments made by one of us was, “Wouldn’t it be nice to have a console shifter with a -/+ toggle right where you rest your hand.” After some research we found that the conversion had already been done by others - and, it was done with OEM parts. Who would have guessed? Before making the conversion, I wrote down what Jim and I thought the pros and cons would be regarding the conversion. Later, after the conversion was complete, we found what is listed below to be true: Pros – * Shifter is located much closer to hand for ease of operation. * Once “Drive” is selected, the right hand could rest on the shifter handle and momentarily toggle the shifter left or right (-/+) for downshifts or upshifts respectively to select maximum gear limit. This would be the most important and impressive improvement. Because the shifter handle’s right and left distance movement is short and has a positive mechanical stop, we felt there would be no doubt that the shift was made. * Eyes would stay on road during shifts * Shift timing and throttle control would be precise for smooth upshifts/downshifts * On icy / snowpacked road driving, the transmission could be easily bumped into “Neutral” from “Drive” if needed when coming to a stop. Cons – * Slightly less console storage area (a very minor sacrifice) * The middle front seat would be sacrificed with certain truck models Here are some photos of the conversion after completion. Note the -/+ symbol below the letter "D" in the photo below. When drive is selected, the shifter can simply be toggled left or right to select a different gear. The shifter is spring loaded to return to center. In the photo below, note how comfortably Jim's hand rests on the shifter when "Drive" is selected. To my knowledge, there are no 2500 and 3500 Cummins powered trucks that come with the 68RFE transmission console shifter (could be wrong here). However, gas powered trucks during those years that came with the 66RFE had console shifters. The basic difference between the 66RFE and a 68RFE is the strength of the transmission (note the second digit). Because the two transmissions are basically the same, all of the shift controls, wiring harness, shifter, and console for a column to console conversion can be purchased and installed with no cutting or drilling. While we certainly weren’t the first to do this conversion, I could not find any detailed information regarding the real benefits for doing this conversion. We had to figure that part out for ourselves. The console shifter does not do anything that the column shifter can’t do; it’s just that the console shifter does it more efficiently, and much more intuitively. Precise shift timing matched with throttle control makes for smooth shifting. Jim now drives his truck as a daily driver much differently than he did before the conversion. When he drives to town and back (about a 25 mile round trip), he now uses the shifter many times in the manual mode slowing for curves at highway speeds, thus maximizing the use of the exhaust brake and minimizing the use of the service brakes. He is a happy camper. - John

-

2013 Ram trouble codes

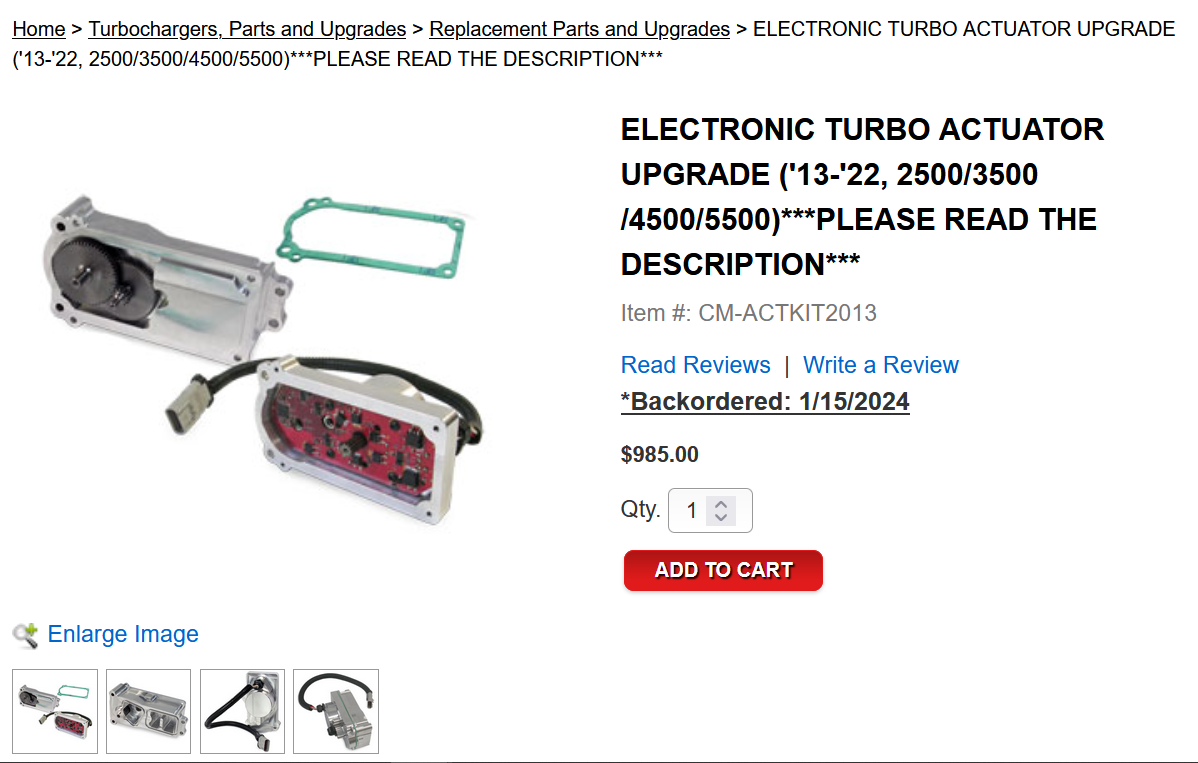

He can purchase a City Diesel actuator. It does not need to be calibrated. He can purchase the actuator from Geno's Garage. It explains in detail what to check for on the turbocharger to help evaluate whether or not an actuator replacement will fix the issue. - John

-

truck failed it's MOT test today

I also think the front brakes on trucks that haul heavy loads with automatic transmissions have a big impact on heat generation conducted from the rotor to the hub. Excessive heat will harden the seal that is protecting the front bearing and cause premature failure of the seal. The bearings will suffer after that. I replaced my front hub bearings for the first time at 374,000 miles. Of course, I have a 6 speed manual transmission and an exhaust brake which is used all of the time. I am sure this contributed to the longevity of the front hub bearings. - John

-

NV450 5speed blew at 184k miles.

Your explanation along with the photo is clear. I am glad that you figured it out. You will be in a much better frame of mind when it comes time for the repair. - John

-

NV450 5speed blew at 184k miles.

I can only imagine how you feel. I am sure you have thought a lot about what could be causing this - any ideas at this point? Any possibility that it could be something external (just being hopeful)? Does the shifter feel like it is making its full travel going into first gear? - John

-

truck failed it's MOT test today

I guess perseverance pays off. Good job! Let us know how the truck handles with the new ball joints - should be much better. - John

-

MoparMan, Where's the pictures of the snow...

Since he wouldn't send you any pictures of the snow - I will. The first photo is from Sunday, December 3rd. The second photo is this morning.

-

Power Steering Pump bad after flush?

Back in September, you installed this pump and noted the noise and vibration. Prior to that, you don't mention a noise or vibration. I would suspect a faulty pump. You could try using the right type of synthetic oil in the system after you determine what you are going to with the steering gear box. - John

-

2nd Gen Cummins heater temp differences between trucks

My mom lived in a cabin north of the Arctic Circle for years. She used a single raisin for mouse bait. She had it down - one raisin used over and over will take out many mice for several weeks. The mouse has to tug fairly hard on the raisin and then..., well, you know. Sometimes, because of all the commotion, you would have to search for the raisin so that you could reuse it. - John

-

2nd Gen Cummins heater temp differences between trucks

I think you won. - John

-

Truck runs great but P0252 P0253

From my 2002 FSM - no P0252 code shown. Can you confirm that you are seeing a P0252 code? - John When you say "truck seems to run great", does that mean you have driven the truck and the engine performs normal? - John

-

Not starting straight away every time

Thanks for the photos. The break looks like it is located in an almost impossible place to inspect. Who was the manufacturer? Do you know how long and how many miles it had been installed on your truck? It is amazing how fortunate you were when that event happened. - John

-

2nd Gen Cummins heater temp differences between trucks

"The DIode" must be like "The Surgeon General". It's just there, somewhere. - John

-

Not starting straight away every time

Holy cow! You were very fortunate with the end results. Glad to hear that you and no one else got hurt. So, was it the ball joint that joined the Pitman arm to the drag link? I would like to see a photo of that failure. Always like to learn from experiences like you had. - John

-

Curse of the 5th gear nut!

I have never owned a vehicle with an NV4500. But, with what I have learned about the NV4500, if I would have owned one that failed, I would have immediately replaced it with a NV5600. In my opinion the NV4500 transmission is too light duty for a high torque, low rpm Cummins diesel engine. There is no fix. The nut loosens or the shaft breaks because the nut loses its clamping force, It loses its clamping force because it is under-designed for the clamp load. Locktite / set screws / Loctited set screws do NOT maintain clamping force. Welding the nut will cause a properly torqued nut to immediately reduce its clamping force. For all of these mentioned conditions, when the clamping force is lost the nut will always come loose or the shaft will break. Every time. I am sorry you are having to go through this. - John

-

Not starting straight away every time

Well, I'll be gobsmacked! Isn't it rather obvious what is the matter with your truck? The ECM on your truck not only communicates with various sensors and the VP44, but also communicates with diesel truck forums, so it knows what you are thinking and saying about your truck at all times. And you have been saying plenty. Things like, "I've bought a AM General M50A2 so pretty sure the ram is going...". Wow!! How is the ECM going to take that profound statement? Maybe give you a little trouble next time you try to start the engine? Duh! I always wanted to use that word "gobsmacked". - John

-

Now vs Later?

I am in a similar situation. I am at 382,000 miles on my truck. New RV275 injectors at 303,000 miles. Rebuilt VP44 at 87,000 miles, currently 295,000 miles on the replacement VP44 with no issues. Turbo is still original. Personally, I would never replace injectors at 100,000 miles, but at 300,000 miles your injectors have served you well, so it is time to replace them. On my truck before replacing injectors at 303,000 miles, the engine still idled smooth, power was good and fuel economy was good - probably like yours. I plan on running my VP44 until I start seeing something that warrants replacing it. Same goes for the turbo. Usually, symptoms will show if a problem is starts occurring with either the VP44 or turbo - not likely to leave you stranded. And, the turbo is easy to inspect for any rubbing that may begin to occur. I have plenty of oil leaks to find and I am just going to tackle them one by one. I have already replaced the tappet cover gasket - good to follow MoparMan's advice regarding no sealants. As far as the head gasket, I will wait until I can schedule some down time, so I am not rushed. A couple of years ago when I was performing fuel return flow tests from the VP44, I installed a fuel line bypass (with a one-way check valve) around the frame-mounted lift pump. After testing was completed, I kept that bypass in place in case of a future lift pump failure. With the bypass in operation I would still be able to drive the truck home without a functional e lift pump. - John

-

Just out of curiosity

Now, for sure, he will never come back. - John

-

Just out of curiosity

W-T is doing okay. He is going through long processes of collecting insurance money and other resources so he can rebuild to some degree. At this point, I believe he wants to stay in Paradise if everything works out. As far as "chicken man" (DRipley) goes, I think you guys picked on him so much that it caused his disappearance. I only picked on him a little. - John

-

Website is going to get busy again.

If it was a color photo, you would see the blue hair. - John

-

AM General M50 6x6

-

AM General M50 6x6

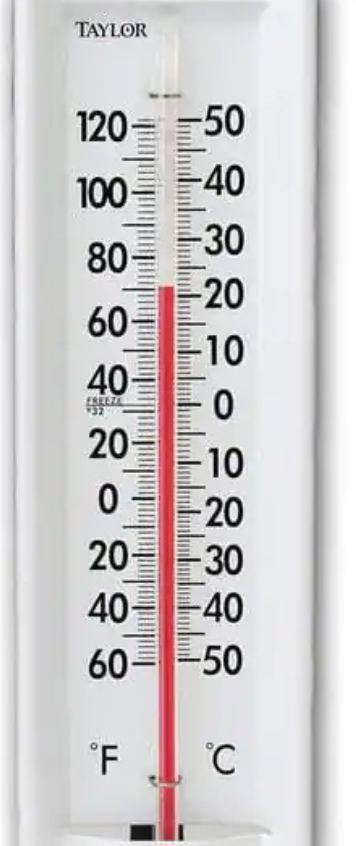

Well, it looks like you have your work cut out for you. If you are going to go to the trouble of taking the truck to London, you should install a large green environmental decal that says, "FLex Fuel Vehicle" Then, in smaller hard to read print, "Meets 1959 Emissions" That way you won't feel bad making all those people mad. One important thing to check is whether you have a hydraulic braking system with a single or a dual master cylinder. Here, in the U.S., dual master cylinders didn't come out until around 1965. Driving with an aged single master cylinder braking system could be inviting disaster. By the way, -40°C is the same as -40°F - but, you probably already knew that. - John

-

Weird rough idle

All alternator wires need to be connected for the AC voltage test. The test is not valid if the alternator is not working. I suggested disconnecting the alternator output wire to check if your rough idle disappears - not to check for AC voltage. The factory installed in-tank lift pump is fine - I had one installed under warranty for over 150,000 miles. It was still working fine when I replaced it with a frame-mounted lift pump for easier access. If you end up replacing the VP44, be sure to purchase one that gets a new (not rebuilt) PSG and that the PSG is calibrated to the pump on Bosch 815 test stand. Don't know the quality of your current VP44, but it may be sub-standard, especially considering the 1688 code set. I do not recommend two lift pumps in series. It will work fine, but it complicates the system and there is no benefit. Plus, it is another component that can fail. I would either continue to use the in-tank lift pump or remove it and install a frame-mounted lift pump. I think the frame-mounted lift pump is the best option because it becomes a pusher pump and its location is easy to service. - John

-

AM General M50 6x6

Great pictures. When I was living in Alaska in the early 60's, my dad had a 4x4 version of that truck. He just ran it on gasoline. But, I do remember late one November it was about -40° (Celsius or Fahrenheit, doesn't matter) and the truck hadn't been run for a couple of weeks. Standard procedure - take battery into house for an overnight warmup, build a small bonfire underneath the engine for about three hours to liquify the oil (no mulit-viscosity oil back then). Wait for the outside temperature to warm to - 30°F and then start the engine. Works great. Do you know what year your truck is? - John