Everything posted by Tractorman

-

Driving with 5th gear removed

@Mopar1973Man, this fellow needs your wisdom. I can't answer the question of driving the truck without 5th gear, but personally, it would drive me nuts to drive that far in fourth gear. I will check with the Turbo Diesel Register for a transmission shop recommendation in your area. Edit: I just made the request through TDR. - John

-

Help! No Power Steering or Brakes after vacuum pump swap

I just pulled the fitting from my old vacuum pump. The fitting is and straight adapter - 1/4" 37° male JIC x 1/8" male pipe. Before you replace the fitting, confirm which connection is leaking. If it is the JIC flare part that is leaking, try loosening the fitting just enough rotate the piping back and forth - be gentle. Keep the fitting tight enough to maintain some friction. Sometimes there is a burr or some surface irregularity that can be smoothed out by using this approach. If you have to replace the fitting: * Apply pipe tape or sealant (oil compatible) to male pipe end. This type of fitting is tapered and seals by thread interference as the fitting is tightened. Tape or sealant seals the potential spiral leakage that could occur around the threads. - John

-

Another APPS Problem

Let us know if the original problem is fixed after you drive your truck for a few days. - John

-

Another APPS Problem

Two questions that I was hoping you were going to answer: Question 1 - Does the one APPS reading that starts at "0%" go up to 100% at full throttle (key on, engine off)? Question 2 - What is your idle rpm?

-

Help! No Power Steering or Brakes after vacuum pump swap

Thanks for the followup report and I am glad that you are back on the road. At least you had the stamina to stick with it and figure it out. The actual hose connection is a 1/4" 37° flare (female on the hose side and male on the fitting side). I don't know the size or type of the end of the fitting going into the pump body. Usually this type of fitting is called an adapter fitting. If you can't get it figured out, let me know - I have a used vacuum pump in the shop with the fitting. Make sure you have the correct style and know the thread pitch, thread diameter, and whether it is metric or domestic. It can get very confusing quickly and you could ruin the threads in the pump if you install a fitting that is very close, but not correct. - John

-

Another APPS Problem

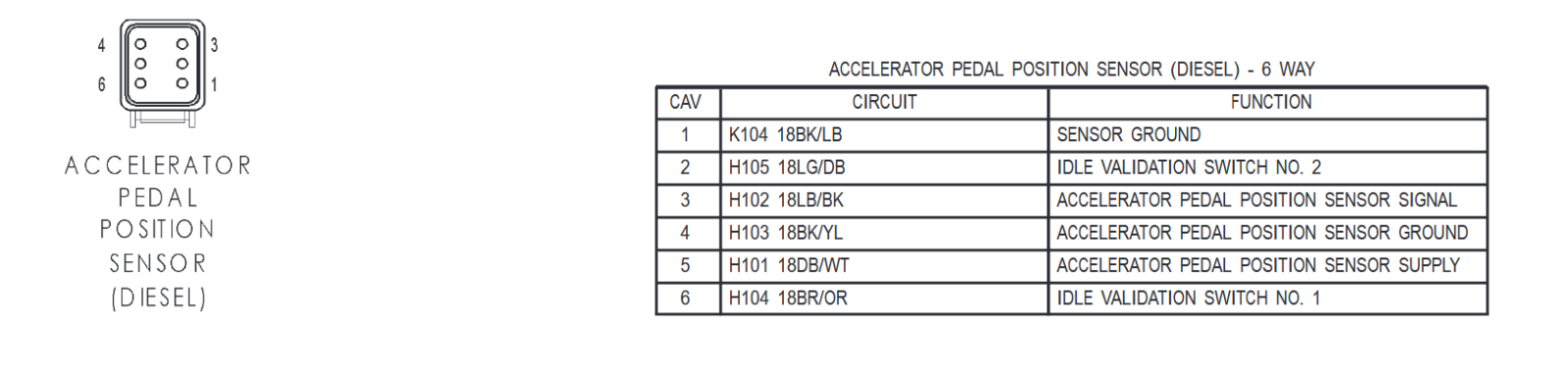

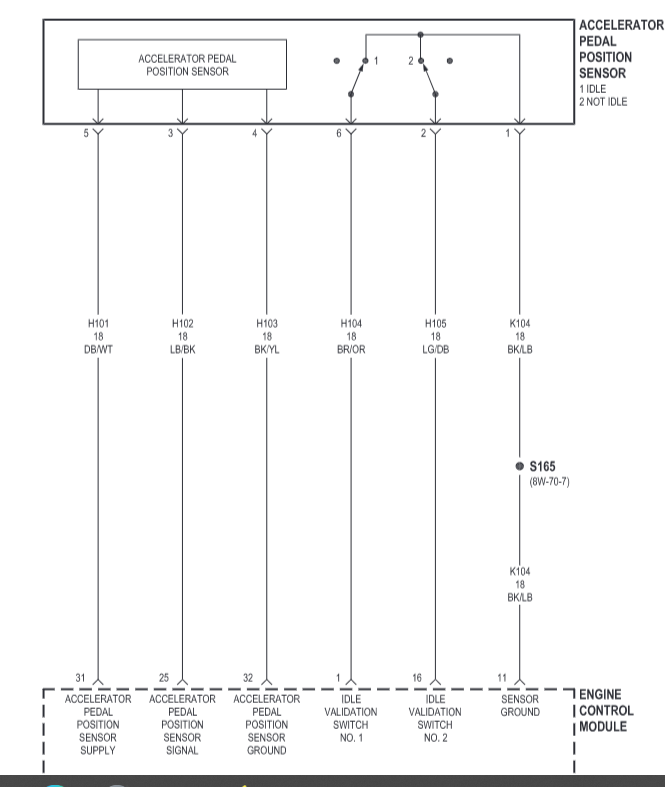

I think you are fine the way you set it. In fact, when I installed my Timbo APPS, I didn't even use a meter. I just screwed the mechanical idle screw inward until I heard engine rpm pickup and then I backed off the screw 1/2 turn. When I checked it with the OBDLinkLX scanner, the APPS signal read 0% at idle and 100% at full throttle and the appropriate per cent readings in between (key on, engine not running). On your Bosch scanner what does the manual say about these two different readings? Does the reading showing "0.0%" at idle go to 100% at full throttle (key on, engine not running)? I haven't experienced using a meter that gives two APPS readings like your Bosch meter. You need to know what your meter is telling you. I think you have something else going on here. This is a very limited circuit - it only involves the APPS and the ECM and ECM power and ground (refer to the wiring diagram). If stray voltage is getting into the circuit from interference, or a poor ground, it could make it appear that there is a problem with the APPS. All the setting and resetting of the APPS won't help. - John

-

Another APPS Problem

Did you perform the above test? What code number was set? You say "codes", not "code" - what other code numbers were set? - John

-

Another APPS Problem

Incorrect. The purpose of the test is to see how much AC ripple is present FROM THE ALTERNATOR while the alternator is charging. Just make sure the grid heaters have finished post cycling and that there are no other heavy electrical loads operating. - John

-

Another APPS Problem

200 or 500 volts, or 200 or 500 millivolts? Your test results: 35 volts or 35 millivolts (.035 volts)? Need to be clear on this. - John

-

Another APPS Problem

I don't know the voltages of each wire, but there are two ground connections that can be checked with an ohmmeter. Both are grounded through the ECM (pins #11 and #32 on the ECM). I would do the W-T wiring mod first, then start with diagnosing the APPS, if the symptoms aren't corrected. - John

-

Another APPS Problem

Since the ECM is the only component that communicates with the APPS, it would be a good idea to re-check connections for resistance and make sure the ECM has a good positive and negative connections. You will be addressing the ECM ground with the W-T ground reference modification. - John

-

Another APPS Problem

Do you have any DTC's set, especially related to the APPS? If you don't, I don't think the APPS is causing the problem. You might try another scan tool just confirm the same readings. Does the engine idle at the correct rpm? I think I would start by checking all battery connections and grounds to make sure there are no issues there. I would also completely disconnect the Edge tuner and put the Smarty back to stock while troubleshooting just to eliminate potential issues. - John

-

2006 Dodge Ram 3500 - Thor Project

The above post indicates that fuel rail pressure rises quickly to well above 4,500 psi, but the engine continues to crank a long time before starting. This post indicates that fuel rail pressure stays well below 4,500 psi during cranking and the engine won't start until the pressure suddenly jumps above 4,500 psi. Which post is correct? - John

-

2006 Dodge Ram 3500 - Thor Project

So, at this point it doesn't sound like you are seeing anything that would be contributing to the symptoms you are having - is that correct? Bummer about the broken injector. - John

-

2006 Dodge Ram 3500 - Thor Project

Whadda ya doin'? - John

-

Replace or Rebuild?

The rust issue would encourage me to replace. I have similar miles (394,000), but no rust, so I continue to invest in mine. - John

-

2006 Dodge Ram 3500 - Thor Project

Interesting - not what I was expecting. I was expecting to see rail pressure below 4500 psi while cranking during the hard start. That would have made sense as the ECM would not have turned on the injectors at that low of pressure. Also, it would have coincided with high fuel return rate. So, if I am understanding correctly, you are getting fuel rail pressure above 4500 psi immediately, even with the FCA connected and the engine still won't start. So, the question for me is, why isn't the ECM telling the injectors to fire right away? This is where my lack of fully understanding the details of how a common rail fuel system works comes into play. If this were my truck, I think I would want to know what all has to be in place before the ECM will tell the injectors to fire. Example: could an engine rpm sensor cause the ECM to not fire injectors, or could the fuel pressure sensor cause the ECM not to fire injectors?, etc. - John

-

2006 Dodge Ram 3500 - Thor Project

I would still be interested in the behavior of the fuel rail pressure while the engine is cranking during a hard start. I don't think you have done that, yet. If the fuel rail pressure is low during the hard start, remove the fuel control actuator electrical connector and see if the rail pressure rises when cranking the engine and the engine starts right away. If it does, you have a high return flow rate problem somewhere - not an "air in the fuel" problem. - John

-

Help! No Power Steering or Brakes after vacuum pump swap

You can remove the flow control / pressure relief valve cartridge without removing the power steering pump. - John

-

Help! No Power Steering or Brakes after vacuum pump swap

@RayNAz, did you skip this step while you had the unit on the bench? - John

-

2006 Dodge Ram 3500 - Thor Project

It sounds like you are on the right path. - John

-

2006 Dodge Ram 3500 - Thor Project

What is the rail pressure while cranking during a hard start? - John

-

2006 Dodge Ram 3500 - Thor Project

I would be more interested in observing rail pressure during the long cranking periods, not when the engine is idling. If the rail pressure is well below 4,500 psi during long cranking, then you know that you have fuel bleeding off somewhere. If it stays around 4,500 psi or higher during the long cranking period, then you know something else is going on. Either way, it offers information. As far as the chimes, are the "grid heater light" and the "wait to start light" the same item on a 2006 common rail truck? Here is what I am finding: WTS and 5 chimes - "The WTS light and chimes are a leak detection DTC, which means that the fuel calculation between the used versus demanded is out of range.." - John

-

2006 Dodge Ram 3500 - Thor Project

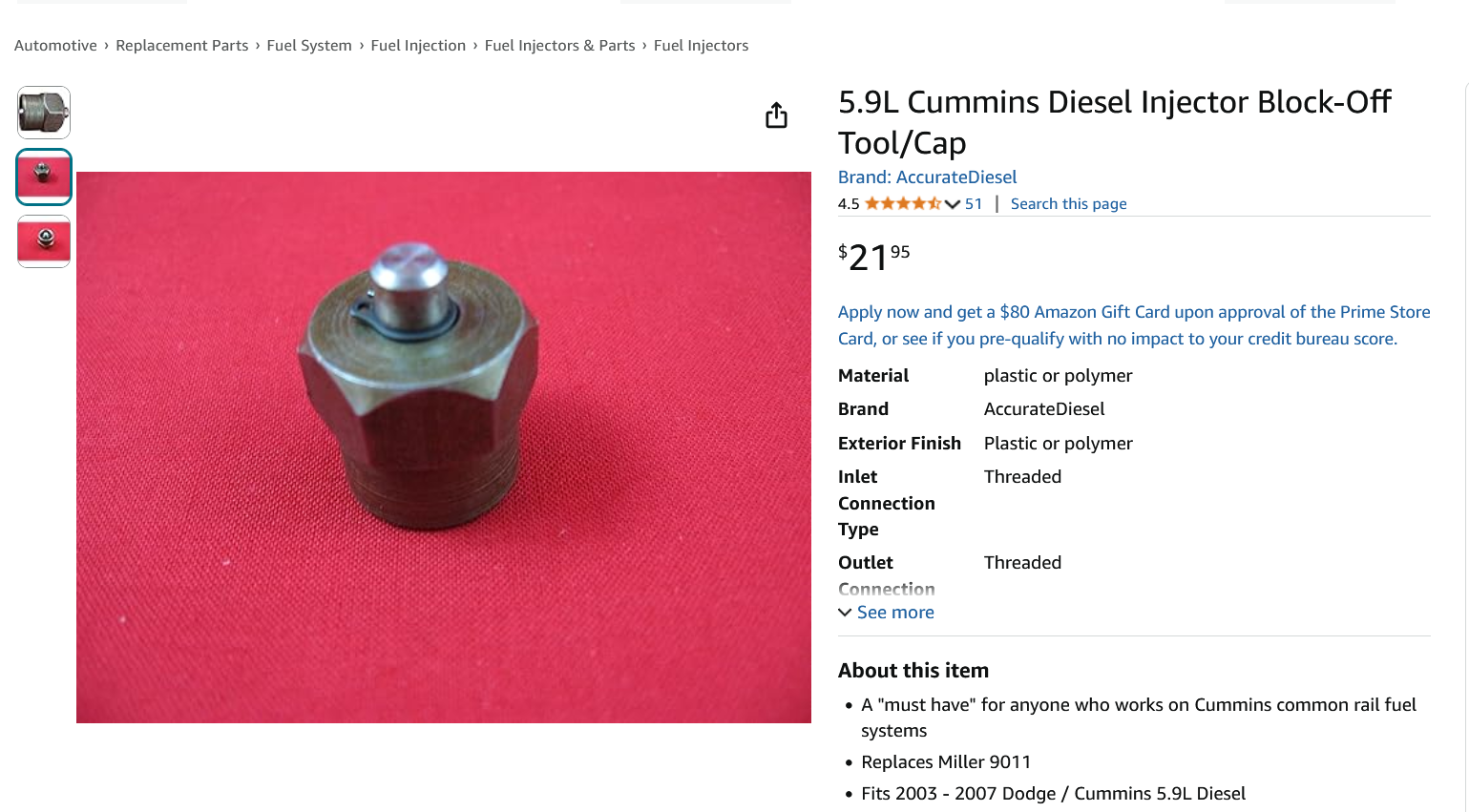

My knowledge is fairly limited regarding the 3rd generation trucks. If you don't already have these tools, a couple of tools I recommend would be a scanner that can read commanded rail pressure and actual rail pressure, and an injector block off tool. I have used them in the past and they have helped me diagnose a faulty injector. I know that when the engine is cranking, if the fuel rail pressure is below 4,500 psi, the ECM will not command injectors to fire. - John

-

ECM bad?

My next step would be to inspect the pin connectors on the Smarty cable and the pin connectors in diagnostic connector under the dash, if you haven't done so already. If everything seems good there, then you might try contacting Smarty for help before you condemn the ECM. - John