Everything posted by Red Rambler

-

Isspro fuel sender

Thanks, gotta keep it clean, I heard they don’t make em anymore.

-

Isspro fuel sender

Haha, I hear ya. I have some clear coat failure on my horizontal panels. Vertical panels still clean up pretty good.

-

Isspro fuel sender

Been pissed about fuel related items on my truck lately. Didn’t touch it much, but she was due for a bath and I am now sitting at a happy 17 psi fuel pressure. So she got a bath.

-

New Inj's and VP

I would say gauges, as that VP will need steady fuel. Check your turbo for play(fore/aft) in the drive wheel. Coolant likely needs a swap while you are at it, and summer is here. In my experience, drive it, she will tell you what she needs in one way or another. But gauges help you beat her to the punch.

-

Isspro fuel sender

I am thinking mine may have been a touch loose as I’m at roughly 35k on my old belt. Good luck on your leak. If any of you get time, you care to snap a picture of your belt, turn your bottom pulley so one side is tight so I can see the bow in the opposite side that the instructions speak of? I uploaded the picture of my belt from my PC, instead of my phone, so maybe now it is visible. I am having issues seeing a few pictures in other threads as well. It just has the picture icon of mountains I think it is, but not an actual picture.

-

Isspro fuel sender

As an update. I ordered a few 1/4 JIC fittings, barbed, that took a few days to arrive. The truck fired after putting my new fuel hose on the fuel pressure fittings, and to the gauge. PSI reads low again, 10 PSI now. So in testing I unplugged my lift pump wiring so it would be running 100% mechanical. Fuel pressure kept falling and it finally sputtered so I shut it off. Plugged my stock lift pump back in, bump the starter to cycle the lift pump. And she fired. PSI is at 10. So this tells me that possibly my mechanical pump possibly isn’t working. I take it off, check it, appears to be no blockage. I tried calling glacier to see if there is anything else to check on their pump, but no answer. At a loss at this point. Edit*** So, after taking my pump off and cleaning it, making sure it was spinning fine. I did notice my belt looked a little worn, so I decided to swap it out for the new one in my glove box. Fire it back up, and BOOM 17 psi. My worn belt was causing the issue the whole time. Long circle to find the solution, but glad I figured it out. User error on my part for sure. Now I need to figure out the best way to adjust belt tension and ensure the problem is fixed.

-

Isspro fuel sender

The Hobbs switch controls the stock lift pump and turns the stock lift pump off once a certain preset pressure is reached, the preset pressure is set within the Hobbs switch. So, once your fuel PSI reaches say 6 PSI, it commands the stock lift pump not be used. No, the only pump I have is the mechanical pump that is driven by a pulley on the harmonic balancer, and the pump itself attaches at the lip of the oil pan. Not my picture, but how it works.

-

Isspro fuel sender

I think I will give that a go, try to eliminate the hobbs switch and see what results I get. I am going to get new fuel hose today as I am making a shorter run of hose for my pressure gauge. I had it running in the cab before(mechanical gauge) and used the same hose(electric gauge), so it is too long currently and I have to make a loop. I am going to get some extra hose as well in case its needed to bypass the stock lift pump entirely. Unsure if I can simply unplug the hobbs switch or if it will throw a code? Slowly but surely, going to get this lined out.

-

Isspro fuel sender

Here is a video of my fuel pressure doing what it does. Sorry for the unsteady hand. Under acceleration it tanks pretty quick, but as soon as I start to go downhill the pressure rebounds.

-

Isspro fuel sender

So you arent running the hobbs switch? My pressure has been great the last few years, up until recently. The Hobbs switch was just something I thought to maybe isolate to verify if it could possibly be causing the issues. I am doubtful, but who knows. As a last resort I can clean/replace fuel hose to make sure there isnt some blockage in my system. I do have a new fuel sending unit, but I ran a tank of fuel through it and had good fuel pressure 16+ at all times.

-

Isspro fuel sender

New check valve. Same results. Fuel pressure dropping upon acceleration which isn’t normal. Not sure about my next steps in trouble shooting. Need to get in touch with rich at glacier diesel, see if my pump is able to be cleaned or taken apart to ensure it isn’t pump related. Other thing I thought of is to unplug the Hobbs switch and see if that changes anything. Not sure a bad Hobbs switch can cause the stock lift pump to activate in some fashion.

-

Isspro fuel sender

Still waiting on my parts, usps is killing me lately...

-

Isspro fuel sender

Same, I don’t like getting nickel and dimed to death, but it’s a necessary evil at times. I have taken my check valve apart a few times and it appears to be working as it should, but does have the tiny wear groove, IMO not enough to cause my return valve to open, but if it allows fuel to pass by in some fashion it could be the issue. I don’t run any strainer or pre filter before my pump. I run a strainer on my return line(post pump) that was replaced when I replaced my VP. Which was roughly two fuel tanks ago. I will get my son to watch fuel pressure and pinch the return line. I haven’t done that yet. I guess I don’t see why it couldn’t be junk/blockage anywhere in the system. For sure possible. If my new check valve doesn’t solve the mystery than it would be a free option to check all my line connections/fittings. Blow them out with compressed air. I did put a new sending unit in as well, twice, so possibly some gunk moved around at that time, even though the inside of my tank looked really clean.

-

Isspro fuel sender

My struggle is the dropping pressure under load which is new to me. Normally, upon acceleration the fuel pressure would rise, but lately, it goes down if I do a WOT run. In my mind, the only viable reason is the check valve is allowing fuel to bypass, thus lowering pressure. If my new check valve corrects the issue than the check valve is a wear item and I might proceed as silverwolf has and get a true fuel regulator lined out. @IBMobile are you still running the stock brass check valve?

-

Isspro fuel sender

I received my test gauge from Vulcan on Saturday, and immediately did some testing. My sender does not appear to be the issue as the test gauge was showing low pressure as well, 14 PSI. My thought was to buy a new check valve as one part in my check valve has a small wear groove in it, the poppet. Unsure if it is causing the issues at this point, but worth replacing. The check valve on Glacier Diesel's website is right at $70. I did some digging and was able to find what I hope is the exact replacement check valve for a cheaper price. Through my research, it appears the check valve is an Enderle check valve, unsure if Enderle is the brand name or not. The check valve I purchased is 6AN, and comes with the springs for 17psi. In the check valve, it appears there is only two wear items, the spring and the poppet. The website I found these parts on looks like a drag racing website on the west coast, good vibes racing. I have already received tracking for my order. I purchased both a new check valve, and a new poppet. Once these show up, should be a 5 minute deal to swap these out. I also see an aluminum bodied check valve, and it has a stainless steel poppet. In this instance Im not sure if the brass body or the aluminum body would be better. Both brass and aluminum are softer than the SS poppet. Currently I dont see any wear on the Brass body insides, just the poppet itself. http://www.goodvibesracing.com/check_valves_&_components.htm

-

Isspro fuel sender

Thanks @Silverwolf2691, after looking at my check valve a bit more, it has the tiniest of grooves in it from where it has come off the seat and then back on, multiple cycles obviously. However, it isnt enough of a groove to catch my finger nail. If I get a low reading on my new test gauge also, meaning its not likely my sender I will look into the fuel pressure regulator you mention, that might be the better setup versus the check valve. If my check valve is allowing the slightest of fuel pass when its not supposed to, could be the main issue obviously. I have added more shims to my check valve to try and make the spring stiffer with no change to my issues.

-

Isspro fuel sender

Yeah, that’s the check valve. It has a piston valve that is spring actuated. It can get debris lodged in the piston or spring and not allow the valve to open and close properly lowering fuel pressure. But I have cleaned mine twice and no debris.

-

Isspro fuel sender

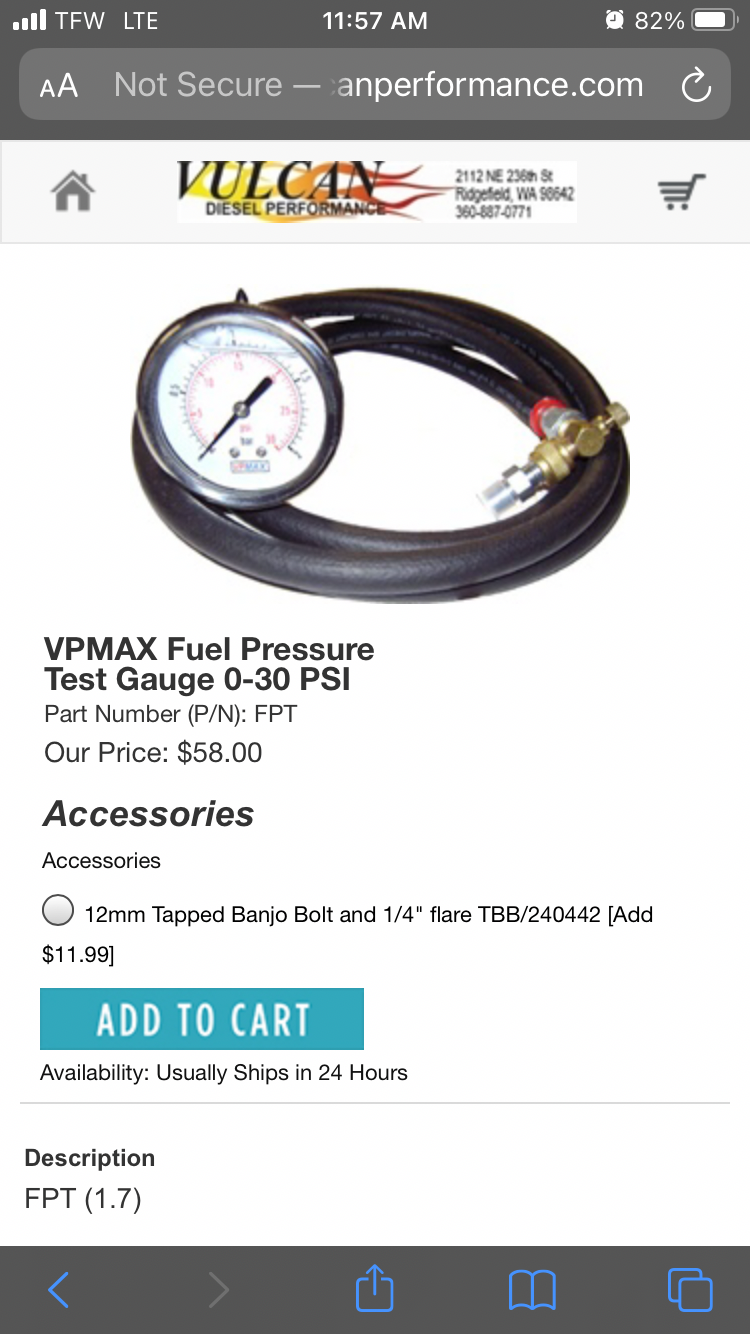

I ordered the vpmax test gauge kit from vulcan. So will do some testing once it shows up. Thanks all for input so far. Has anybody rigged up a permanent test spot that could be used. Basically hook the test gauge up as needed. I was thinking of getting a tapped banjo bolt to use at the VP inlet and put a needle valve on the end of the banjo that could be opened and closed as needed. Use that needle valve to hook my test gauge up to.

-

Isspro fuel sender

Where would I hook up the test gauge. I don’t have a Schrader valve on the back on my filter. Is there an alternate test port location? I assume I could unscrew my sender and use that location to hook up a fuel pressure test gauge.

-

Isspro fuel sender

I feel pretty confident it isn’t a ground issue. I have checked all my wiring and it all looks just fine. I have unplugged all gauges and they come back on just fine. Just low fuel pressure. Pretty sure I am going to need to spend some coin to isolate the issue. Dang it!

-

Isspro fuel sender

I will give it a shot, see if anything changes. Could be the sender, the check valve, or mechanical pump. It has all new filters currently. My only other thought is possibly air in the system but it is running just fine.

-

Isspro fuel sender

I checked my single ground for my 3 gauges, it’s clean and the metal has been scuffed to bare metal. Not 100% sure if this is the right direction, but I am going to get a new sender first, and barely crack my needle valve. See what happens, then go from there. Unless anybody has any other ideas.

-

Isspro fuel sender

I read online that the isspro boost gauge could have issues sharing the same ground as the other two gauges. I will separate each ground and see if that helps, my boost gauge is flaky as well. All the wiring is new (year old), my gauges are daisy chained together currently so may need to do some new wiring. I think the daisy chain was just for power/illumination. I am going to have to look it over again. I looked over my wiring and as my gauges are daisy chained, they all share the same ground wire. I will change this so all of my gauges has its own single ground wire versus sharing. See if that helps.

-

Isspro fuel sender

I can’t recall if my new vp has a test Schrader valve or not, will check. I might be fighting the inevitable in getting a new sender. I don’t have an older gauge to test with otherwise. I wonder if a feed line could be found that has a Schrader valve and an outlet to my sender?

-

Isspro fuel sender

On my previous mechanical gauges, they would come up to 16 psi within 4 seconds. On my electric gauge it takes roughly 10 seconds to come up to 16 psi. I guess my sender could be hammered to death. I feel my sender is protected very well with the needle valve and snubber, guess I could be wrong.