Everything posted by Great work!

-

Can someone explain delivery valve differences?

Don't know much about delivery valves. But the idle screw needs adjusted to prevent stalling when cold and 2800rpm is because you need to upgrade the governor springs and washers.

-

VP 44 home made brains part 2 getting real now

This is an entirely new method of not just relocating the controller but making one from scratch. It's independent of an ECU. I made a github project with all the details https://github.com/Greatwrk/VP44-EXPLORER

-

Engine heater

Nice setup. I just replaced a 240v heater on a K19 cummins.

-

Fuel injection quantity

I might have to try that. I would need to keep a steady load on it for a few minutes to get any accuracy.

-

Fuel injection quantity

Thank you @Tractorman that's just what I needed. That other spec of 1.9 m/sec at 1000r/min is interesting. That may help define the slope of ramp area on the cam donut.

-

Fuel injection quantity

I'm working on my VP44 and ECM projects and need to know how much fuel is actually injected by the injection pump. This is so I can calculate a fuel rate in milli Liters for determining engine load and also for the overhead trip, mileage display computer. So i dug out my old VP44 core and did some measurements. I thought I would share what I found and get some confirmation or feedback. This is a SO pump with three injection plungers they are 7.3 mm diameter. The cam donut has a thickness of 10.5 mm at the maximum inward point and a thickness of 7.1 mm at the maximum outward point. So 10.5 - 7.1 = 3.4 mm of stroke. I don't have an ultra precise way to measure the stroke. I probably need to have the pump all put together for that with a special instrument and rotor head fixture, but it's probably pretty close. So 7.3 divide by 2 = 3.65 mm radius times 3.14 (pi) times 3.4 stroke = volume 39 milli liter per plunger, times 3 = 117 ml. That's the theoretical maximum injection volume without injector or line losses. So 3 injections per crankshaft revolution is 351 ml. times 1000 RPM is 351000 ml. There are 1,000,000 ml in a liter so 0.351 liters per minute at 1000 RPM. At 2849 RPM that's 1 liter / minute. The vane pump has to fill the plungers and it continues pumping to the tank while the plungers are injecting so that means it needs to pump at least twice the amount as injected. That needs 0.702 liters / minute @ 1000 RPM and 2.8 liters @ 4000 RPM. 1 liter is 0.264 gallon so 0.74 gallons per minute @ 4000 RPM. that's 44.5 gallons per hour. The lift pump would need to be 2 to 3 times that to maintain a good working pressure at the VP. Does the math seem right?

-

APPS info

There had been a new design out for a few years now. It's a non contact moving magnet sensor. No wiper to wear out. Got it at O'Reilly. I wish I could find the receipt for it.

-

VP44 operation, electrical and alternative controller.

I decided to open source my stand alone VP44 electronics project. I started a github repository. It's far from a bolt on replacement. It's just a prototype but it has been running reliably for a couple of years now. Unfortunately, it's not a project for beginners and requires good soldering experience and there is one surface mount part on the board. The circuits have some high energy parts and requires some testing before operating. The software is not simple and has time critical routines. An in depth understanding of the MCU internal peripherals (timers, PWM) is also required. Any mistakes in assembly or coding can cause permanent damage to the fuel solenoid or speed sensor. My project explores the electrical operation of the mysterious VP44. I included some diagrams and tutorial. The mechanical operation is described on various websites so I skipped it. It may help to review some of those sites. https://github.com/Greatwrk/VP44-EXPLORER

-

2001 24v Cummins High Idle Issue

Check the PCM ground to the passenger battery. The PCM is not grounded by it's case. Have you done the blow-by test with the oil cap yet. if it bounces around while setting over the hole you have bigger issues.

-

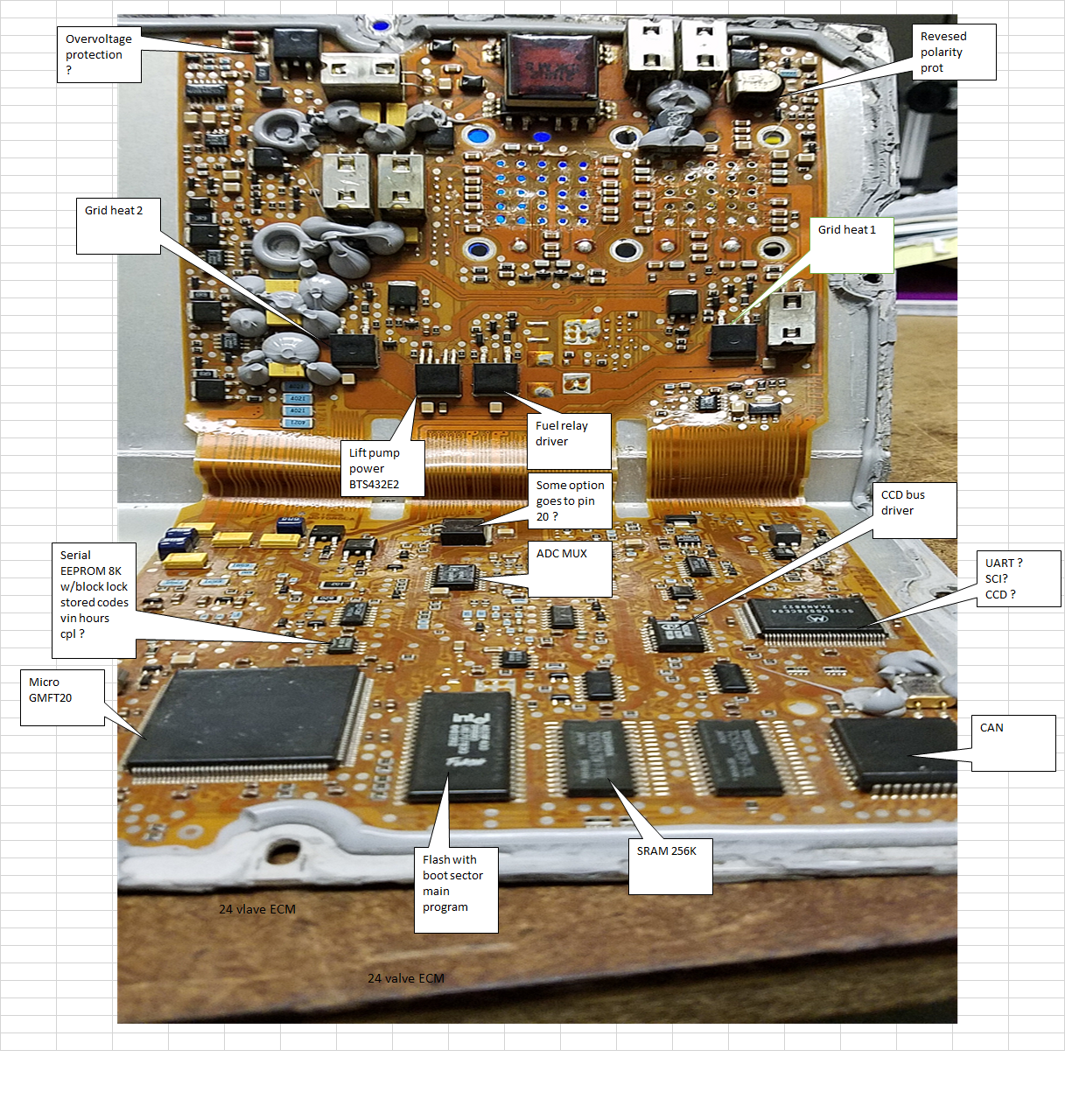

VP 44 home made brains part 2 getting real now

Soon. My VP44 project is being reviewed on github. It's still pretty rough. My ECU project had a couple of screw ups. So I had to cut traces and make modifications to the board. I want to update the schematic and pcb artwork before releasing. The code is going well and technically less challenging then the vp44. I already have the grids, lift pump wait to start, EEPROM save and restore, watchdog working. The idle governor will be the same as the Vp. I already have the code for the temp sensors. Called Stienhart-Heart approximation. Ckp and cmp is the same as vp project too. CAN, OBD2, SAE 1850 and error detection DTCs still to do. I've done some CAN on other stuff so it's not new to me. I have a spare instrument cluster that I can control with CCD too. I can't figure out the CCD part for the overhead mileage computer because I have no working ECU to monitor.

-

Turbo actuator

It's definitely a poor location and unnecessary. I think it was done for less noise.

-

Turbo actuator

The man I was helping had to turn in the old actuator and the core was voided if I opened it to see what was wrong and what was rebuilt on the new one. I suspect there is a potieometer inside for position sensing that wears out. I see John Deere uses a lot of oil pressure powered actuators on VGTs maybe better choice.

-

Home made ECM ? wiring diagram errors.

The ecu scales the fuel from tps resting to wot those values are stored. If the get corrupt then the idle changes. You could try to read the EEPROM repeatedly with arduino and get a good read then copy to a new one and solder it in. Very tricky. I'm working on a githup repository but I'm old dog and don't know what I'm doing. Lol If you have delayed WTS light then the the ecu processor is going out too.

-

Home made ECM ? wiring diagram errors.

The ECU is loosing it scratch pad EEPROM So that's where the tps calibration is. You can't fix without a special tool and software. I put a 1k pot on my tps signal signal to fool it and idle it down but your ecu will die soon. My VP44 project doesn't need ecu just CKP ,tps and map.

-

Alternator failures

I think some had plug in connector on back vs. Studs and nuts.

-

98 12v coolant temp sensor pigtail location

Some older 12 valves have a small bypass hose near the thermostat. I think that hole is where the newer engines have the temp sensor screwed in. At some time a change was made so the hose wasn't required. The other 12 V style is at the back of the head, it is delicate they break easy.

-

Hunting at idle when in gear

Try moving the ground wire(s) from the transmission control box to the engine block temporarily, see if that changes anything. Are those fault codes current? Some of them need addressed.

-

VP44 amp draw

Definitely check the solenoid wiring on the back of the pump. The insulation gets old and crumbles away which can cause momentary shorts. Usually the timing solenoid wires go first which throws the timing to extreme advance or retard.

-

VP44 amp draw

To get an good measurement you need a current sense resistor in line with the power, about 0.05 ohms. Connect an oscilloscope across it. A battery operated or isolated power scope is best. The logic part draws maybe 150 - 200 ma. The timing solenoid has a 10 ohm coil and operates at 50 or 60 Hz at about 20 to 75% duty cycle so that's about 1.4 amps when switched on. The injection solenoid is done in 3 stages. It is about 0.2 ohms and 250 micro Henry's and changes to about 320 uH when the plunger is seated. Step 1 an electronic switch completes the solenoids path to ground the current ramps up according to the inductance formula V=L di/dt. So rearranging we have dt=di/(battery V/ L). The solenoid is saturated at about 18 amps. Using 300 uH for L. Gives us 385.7 micro seconds for the current to ramp to 18 amps with a 14 volt battery. Step 2 the current is reduced to about half that for another 150 to 300 uS so the plunger doesn't slam it's seat so hard to reduce bouncing. Like hitting an anvil with a hammer. Step 3 for the rest of the injection duration a 2 ohm high wattage resistor is switched in series with the solenoid that gives about 7 amps at 14 volts. The resistor and switch transistors are cooled by fuel flowing under the psig controller. The two solenoids also cause voltage spikes when switched off. The timing solenoid can reach 100 v spikes. All the rapid current surges and voltage spikes can cause all kinds of electrical noise. That's why proper grounding and wiring layout is so important. If the current in the solenoid is too high for too long the solenoid will cook within seconds. That pump definitely has a problem.

-

Hunting at idle when in gear

How does it idle in the vp44 hot wire mode after warmed up and in gear and out of gear? By those pictures I would say someone really wanted to cram that engine in a F250. Definitely custom. You may have electrical noise. Find the WT ground mod on this site and see if you can apply it. Especially the elimination of the large ground wire going across the front of the engine and the joining together of the ECM,Vp44 and sensor grounds and then terminating them to the timing cover box.

-

98/99 Cruise control

Interesting read, but just adds to confusion https://www.turbodieselregister.com/threads/clutch-pedal-safety-switch.258150/ Some say it causes problems others say not so. There may be more going on with the clutch switch it is an expensive part so maybe it's more than a simple switch. Maybe your PCM doesn't have CC it could've been a stripped fleet truck or had it programmed out.

-

98/99 Cruise control

I think the earlier trucks like 1997 had the CC light in the steering wheel switches instead of the cluster. But a very different PCM. Do you have the clutch safety switch hooked up or bypassed?

-

98/99 Cruise control

Do you have a 98 instrument cluster to try. The CC light is turned on by the CCD bus. Unlikely but maybe the command structure is different. I always wondered about the CC on manual trucks. Seems like the motor would Rev away when the clutch is pressed. Maybe the diagram has something missing about the clutch switch. Maybe someone will chime in that has a manual. Do you have good vacuum at the servo?

-

98/99 Cruise control

No I'm working on a custom ECM

-

Another bad VP?

Do you have a delayed wait to start light. The high idle and delayed WTS is how my ECM started it's death.