Everything posted by Great work!

-

98 12 valve cummins no bus, need help please

I would say you already did all that with your troubleshooting. Do check your battery voltage while running since you did an external regulator. High voltage can ruin it.

-

shift boot location on tunnel

I've seen a lot that have a big hunk of foam with a hole cut in the middle that fits over the shift tower and a slot for the 4x4. That is sandwiched between cab and tranny. It blocks some of the noise.

-

98 12 valve cummins no bus, need help please

Returns are really dedicated grounds. The fuel tank is plastic so it needs grounded but it's good practice to keep high current grounds such as an in tank fuel pump and a sensitive sensor ground separate.

-

98 12 valve cummins no bus, need help please

Since the PCM is putting out five volts to the sensors that's a good sign it's getting good power to it.

-

98 12 valve cummins no bus, need help please

There's no easy way to get in the harness there. The PCM provides 2.5 volt bias too so check for it at the cluster plug with it unplugged. The basic guages work the same through the years but some lights and features change. Many Chrysler cars and jeeps use the same CCD bus. The bus works both ways the cluster send messages to the PCM like when the trip button is pressed and the status of the MIl and airbag lights.

-

98 12 valve cummins no bus, need help please

Sounds crazy but clean and reconnect your battery terminals. Strange things happen on these trucks related to battery terminals. I'm running out of ideas. Try the home run wiring or unwrap the harness from the cluster plugs , headlight switch and the point were your glowshift unit was tapped in. Unwrap down to the fuse block. Look for melted wire. Alternator noise? Try disabling it.

-

98 12 valve cummins no bus, need help please

Is it possible to have the PCM plugs swapped I never tried it. Definitely disconnect the batteries first. They are different colors but maybe not keyed. Use a flashlight and inspect the PCM pins and sockets in the plugs look for any thing bent or burned or sockets pushed back into the plugs. I prefer old school test light instead of meter for doing power work. If you have one recheck both power inputs to the PCM and ground. Interesting, I'm playing with a cluster in my lab and notice different lights come on and off based on if I have both grounds connected or just one at a time. Cluster C1 pins 4 and 5. Double check them for grounds. BTW, @Mopar1973Man our wiring diagrams have an error. The OD off light wire is missing. It should be going from cluster C1 pin 7 to PCM C3 pin 6. To go much further than this you will need an oscilloscope, just a cheap USB dual channel one will work. But you will just go crazy. LoL.

-

98 12 valve cummins no bus, need help please

Those diagrams are often simplified. They don't show all the inner workings of black boxes. The circuit board has additional parts like voltage regulators and dimmer circuit. It only is giving you a clue that a ground is needed to trigger the light. Disconnect all 3 connections at the PCM and see if the lights turn off. Is the panel stuck in a self test, lamp check mode? Have you tried a different one? The PCM and cluster both have 2.5 volt bias circuits built in. the other modules don't.

-

98 12 valve cummins no bus, need help please

See if you can find a 5 volt line coming out of the PCM the auto tranny trucks have it but yours may not have a wire in that hole. I think the tach sensor on the front of the 12 valve uses 5 volts too. That sensor wiring on the 12valve gets all oily and the insulation falls apart. You might try unplugging it. The PCM also interacts with the AC clutch if your AC worked before but not now that's another sign. It's looking like your PCM is dead.

-

98 12 valve cummins no bus, need help please

Some don't have ground strap. How are you checking ground? Use the ohms setting and check between C1 pin31 and 32 and the negative term of the passenger side battery. Should be 0 ohms.

-

98 12 valve cummins no bus, need help please

Those square fuses in the PDC can go bad and not look blown. You should check them with a meter or substitute. PCM has to have ground though the black/ tan wires. The bolts and ground strap is not enough.

-

98 12 valve cummins no bus, need help please

Are you sure your PCM is powered up. C1 pin 2 lt grn/ blk 12 key on C1 pin 22 red/WHT 12 v always. C1 31 and 32 grounded. Another sign of life is battery charging 14 v or more at the bat when running.

-

98 12 valve cummins no bus, need help please

Choose one speaker wire , say the one with a stripe and connect to the wire with wht/blk at both ends. Then the other speaker wire to the vio/brn.

-

98 12 valve cummins no bus, need help please

Frustrated? Ready to home run that B? For that you need about 10 ft of light duty speaker wire. Cut the Ccd wires wht/blk and vio/brw an inch or so from the PCM plug and wire the speaker wire to the plug and note the polarity. Likewise at the cluster cut the CCD wires and wire the speaker wire to the cluster plug. Double check the polarity. Leave the ccd wires in the harness hanging for now. No need to do any fancy splicing just temporary for now. If that doesn't do it then you got bigger problems. If it works then try tapping in the CCD wires from the harness to the speaker wire one end at a time and see what happens.

-

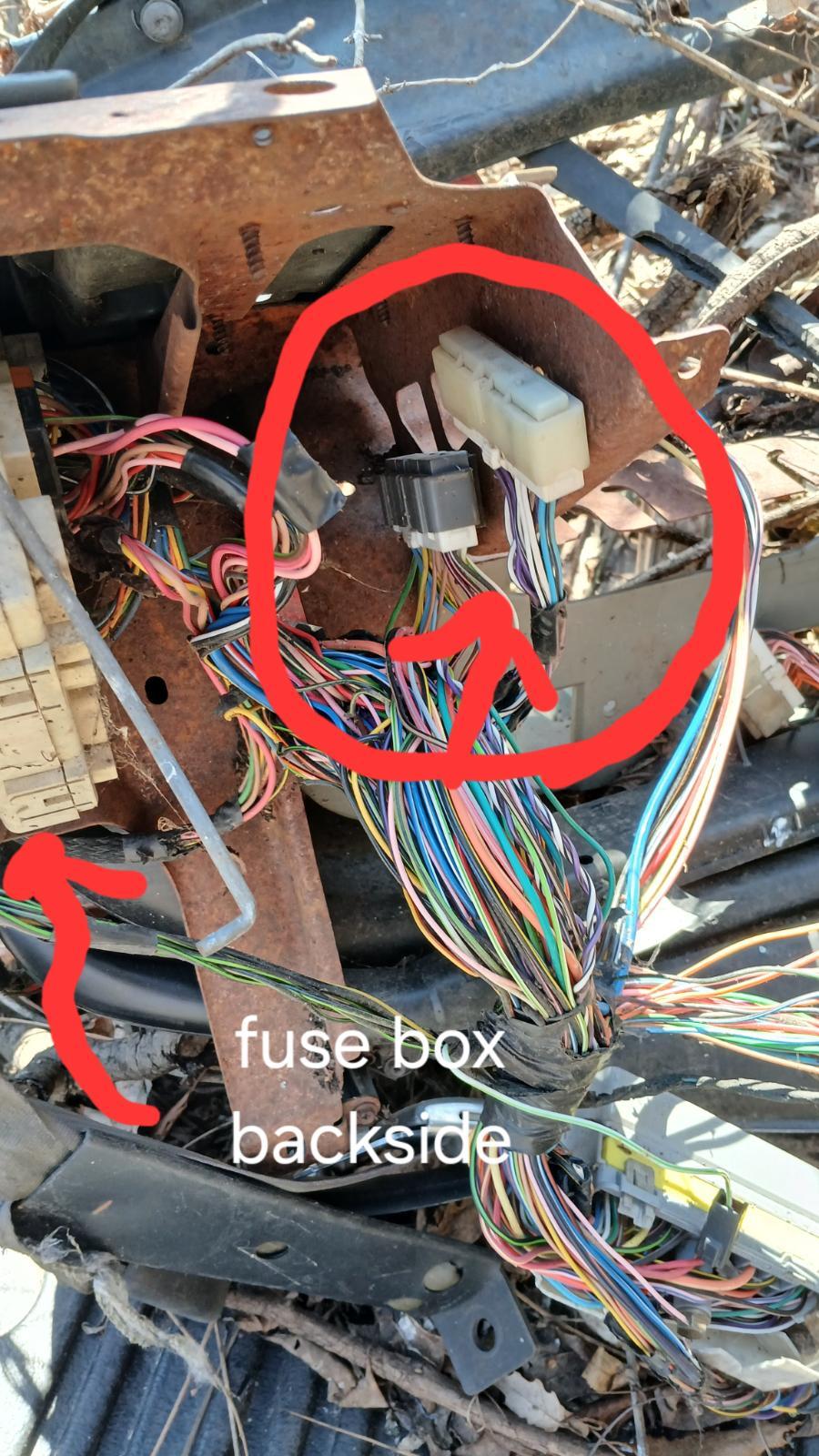

98 12 valve cummins no bus, need help please

Luckily I found a dash out in the wild. My diagram has some errors on it and apparently there are more. The locations are swapped on the diagram. The joint connector you want is directly above the hood release you might have to remove the knee panel and hood release lever. The joint connector above the column and below the cluster is air bag related. Fortunately Dodge made the dash out of fragile plastic so it can be broken away under the cluster for access. Looks like fuse 1 is for the marker lights and part of the dimmer circuit.

-

98 12 valve cummins no bus, need help please

On your wiring diagram look for the things labeled joint connector. The CCD bus ties together there. try reseating the plugs and use some contact cleaner. There's a group up past the E brake , clutch area. Also more strip looking things in the PDC spray them and wiggle a bit with a toothpick or something. I don't recommend you try prying them out. Edit note there are joint connections for the airbag system. Leave those alone.

-

98 12 valve cummins no bus, need help please

Those readings seem reasonable. I think you mean pin 30 not 31. All you need is the PCM and cluster plugged in and some of the guages should work. Check the voltages by back probing or piercing the wires too with it all plugged in too. Just one place is enough. Check for 12 volts at the cluster C1 pin 2 and 6 and verify good grounds on pins 4 and 5.

-

98 12 valve cummins no bus, need help please

I re- read your first post and saw you had a tap on a fuse. Double check that fuse position sometimes those taps spread out the prongs or melt back into the plastic. Use a small pick and make sure the prongs have a good grip on the fuse.

-

98 12 valve cummins no bus, need help please

Yes, if the voltages are correct then notice which module kills it when plugged in. If the voltage is wrong to start with or is wrong when plunging in a known good module then open up the harness.

-

98 12 valve cummins no bus, need help please

CCD shows up at OBDII port and on some early quad cabs a seat belt module under the middle seat. Don't forget to unplug them. Sometime before a fuse blows small wires will get hot and burn through other wires in the harness creating a short. Particularly where the harness is wrapped tight. Check the voltages on the CCD wires with all the modules unplugged except the cluster. Should be approximately 2.5volts (With key on engine off) refer to detailed troubleshooting guide in manual and on this site. If the voltages are near 0 or 12 volts you probably have a short so start unwrapping wiring. If your truck has the overhead temp/mileage display that is CCD too so disconnect that. In fact the wiring for that runs up the A Pilar where your guages are. Investigate that wiring since that's where it all started.

-

NV450 5speed blew at 184k miles.

The last couple times I used two ratchet straps over the top of the frame. No jack, works pretty good.

-

Turbo actuator

Has anyone opened up the turbo actuator to see what failed? Some have core charges so maybe there is an easy fix.

-

Air leak Hard start in the morning.

I have a cpl 2174 on a 97? Auto California with catalyst 180 hp 14 degrees I don't know what the pump number is someone rebuilt it and scribbled 31837 at the end of the number.

-

Air leak Hard start in the morning.

Just curious what is your timing set at and which method did you use to set it. Lift measurement or fuel spill port closing? Or a shop pre set it.

-

1st or 2nd gen Cummins in a 3rd gen?

Anyone here try it yet? I saw some videos, looks like you need to fab up some simple motor mount adapters and change the exhaust manifold to drop the turbo down. Is the turbo move because of the air conditioning? What about the gauges and an auto transmission. Obviously easier with a manual.