Everything posted by Great work!

-

Starter blues.

So I got the NAPA lifetime warranty starter. I used one of my old basket cases of starters for the core. Can't wait to get it on tomorrow if it doesn't rain. There are a lot of new parts on it.

-

Starter blues.

@Mopar1973Man thanks, I'm going to call NAPA and check on one.

-

AC leak locating

I need to find my AC leak. it only works for about a week. I replaced the evap several years ago and hope that I don't have to do that again. I have a sniffer but can't find a leak and it has dye in the system and I used the special UV light and glasses and not seeing it. starting to think compressor shaft or evap again. I saw an isolating kit https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.amazon.com%2FConditioning-Automotive-Detector-Detection-Compressor%2Fdp%2FB07TYCT8M7&psig=AOvVaw3rwrF9QbMclVBmsU7ayrgG&ust=1685844090532000&source=images&cd=vfe&ved=0CA8QjhxqFwoTCJik39aApv8CFQAAAAAdAAAAABAF Maybe some old fashioned corks would work just as well. I have a home brew vacuum pump and a small hand pump too for testing.

-

Starter blues.

Well now that I have started driving the truck again with the VP44 project going and testing. The starter is doing the ole click-click thing sometimes Ugh. It's probably on a third set of contacts by now. The last set of contacts I ordered were the wrong ones. I was in a hurry so I took it to a shop to be fixed last time and put it back on the truck and the gear would sometimes touch the flywheel going up hill. So I had to take it apart and mess with the return spring. Anybody had this problem before? I'm thing about just buying a rebuilt one because the brushes are likely worn away after all the previous fixes.

-

Auto Enginuity DTC Report - Unknown Freeze Frame codes

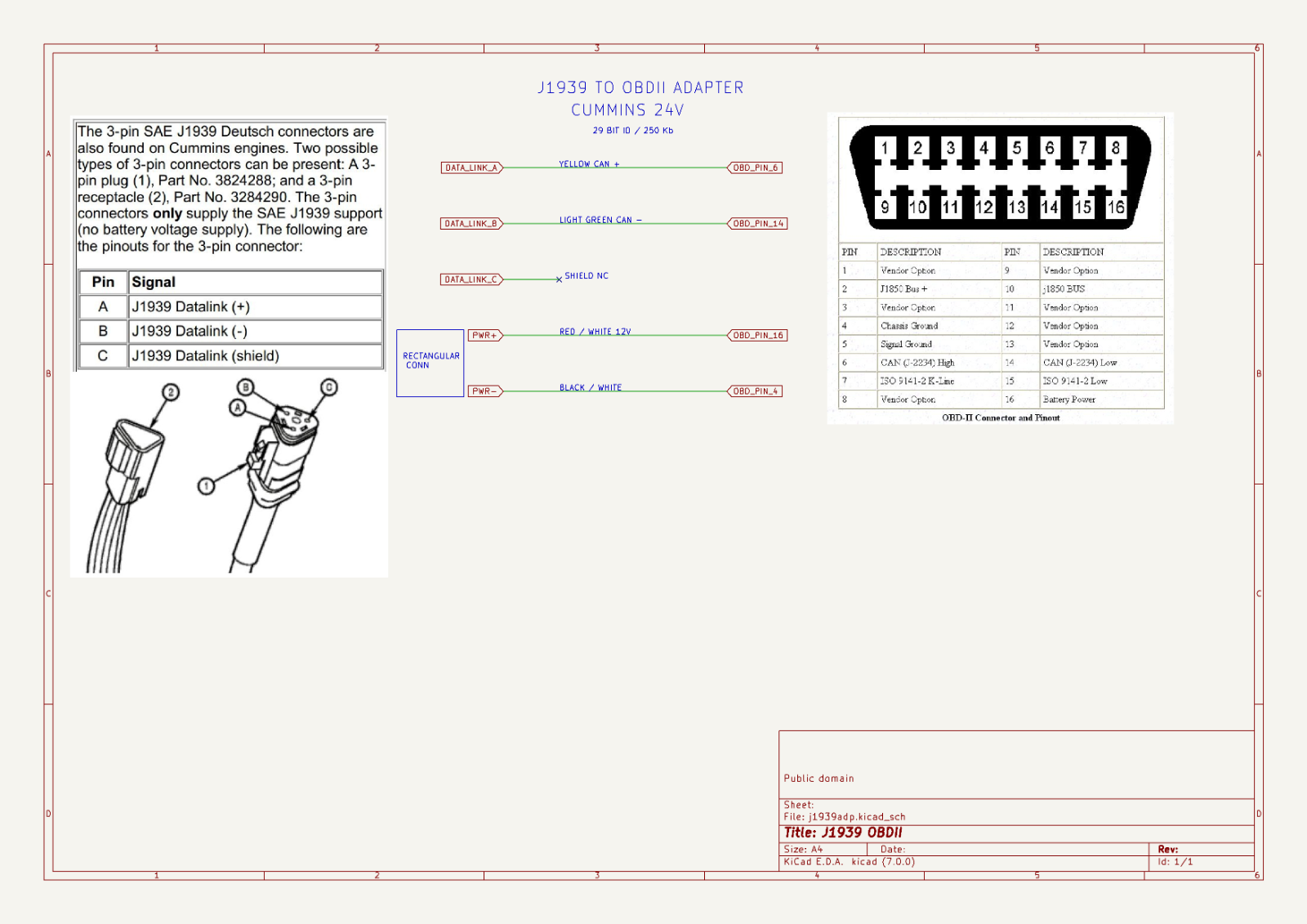

I was thinking about this again. Maybe you could build a little adapter. I saw some adapters that convert the round plug J1939 common on larger trucks to OBDII, but none that fit the old cummins triangle type. Finding the OBDII port is easy just make sure you get one with all 16 pins wired. The triangle shaped one is hard to find. I found one on a poportioning valve on an old junk dodge I have but the pins are smaller diameter and don't make well. Probably need to just tap into the wires. Here is a diagram I made if you wanted to try it. I doubt it will display freeze frame data but It might show live data. I'm curious to know if it would show emissions readiness status and monitors. Here is an example OBDII port. https://www.amazon.com/XMSJSIY-Connector-Extension-Connection-Diagnostic-1/dp/B09WYZGLW3/ref=sr_1_25?crid=1K6R0TYYR2CTM&keywords=obd2+connector&qid=1685755708&s=automotive&sprefix=OBD2+CO%2Cautomotive%2C412&sr=1-25

-

Seat belt light stays on when belt is buckled

Thank you I'll try that. I made a custom sub woofer that goes where the lower center seat goes but kept the armrest and frame. I just shoved that module under there and maybe it moves around too much even with the radio off. So it thinks something is wrong with the motion sensor.

-

P1688 But Truck Still Runs

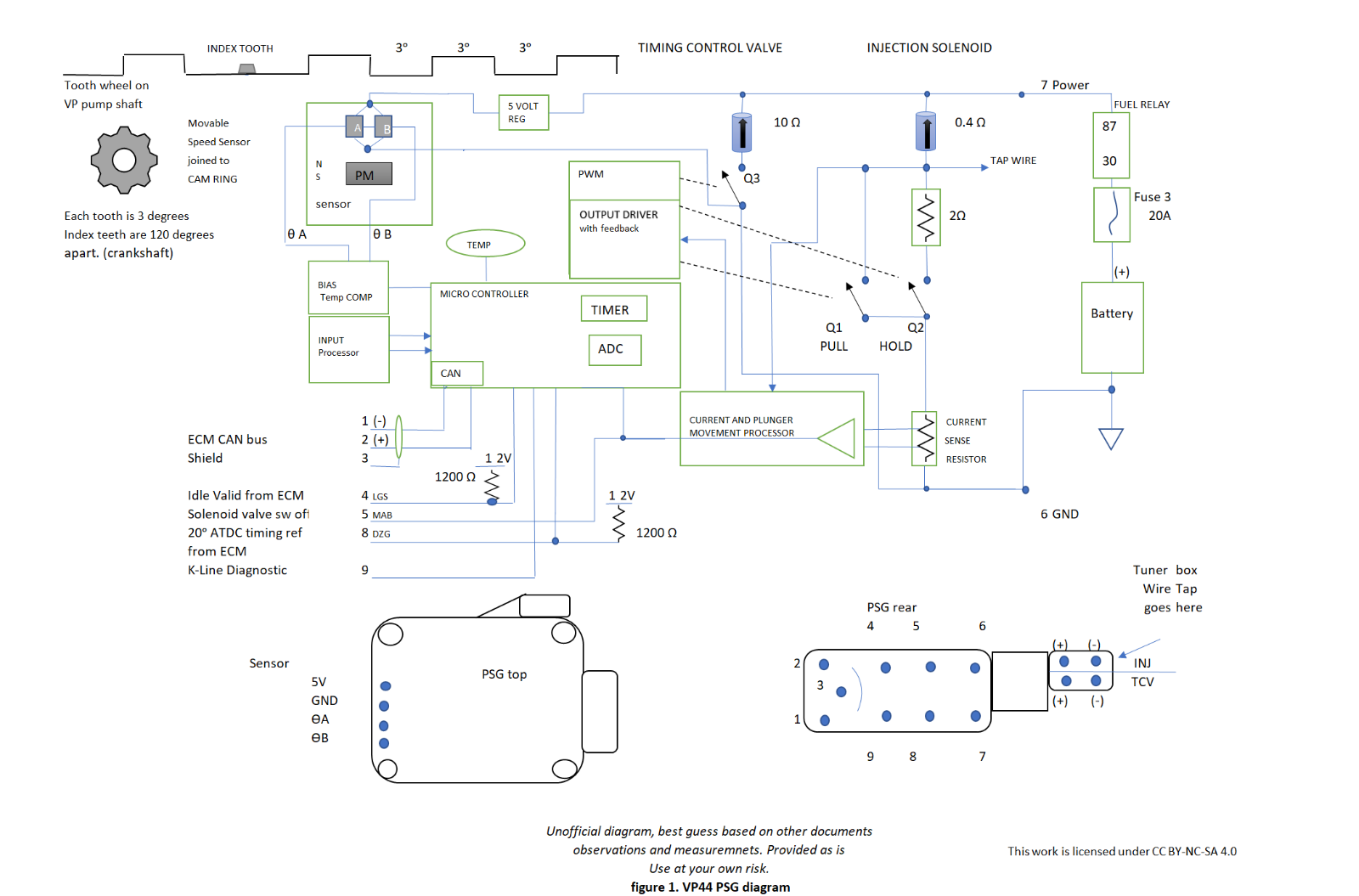

You shouldn't do it but I have done it. The calibration is a lot of solenoid dead time versus battery voltage. Then there's default timing solenoid setting in case of loss of crank position sensor. You'll need steady hands and you can leave it on the motor. Stagger cut the wires on the back so all your splices won't be in a big wad. It's tight to use but splices .maybe solder and heat shrink if you can. Be VERY careful when removing the top there is a thin ribbon cable in there that goes to the speed/position sensor. Rip it and you're screwed. Tie the top up with string or tape so it doesn't get yanked. Pack some wads of aluminum foil around the sensor so the screws won't drop into the pump. Don't use cloth keep things clean. You need a good quality torx # 9 (i think) bit and a magnet to un screw the sensor from its mount . You don't need to un solder the ribbon cable . It may take a few runs for it to smooth out the pump seems to have an ability to learn things as it goes along. Tag the wires on the back if the insulation is crumbling slide some heat shrink over them. Do not attempt to remove solenoids while on the motor they will get broke. The pump needs pressurized with air to assist removing the injection solenoid. Fortunately Cummins didn't marry the VP and ECU together with the k- line like most of the European companies did so you can swap with junk yard parts. Good luck this might help with the wiring. Don't forget and leave the aluminum foil in there.😫

-

Seat belt light stays on when belt is buckled

@wish4hemi I just spent 2 hours trying to figure out this stupid light. Every time I thought I had it would do something different. My driver seat has 4 wires, none on the buckle. Two wires has the retractor solenoid that's 60 ohms. The other 2 are shorted when belt is retracted and open when pulled out. One of those wires is blue with white I found it on an old diagram before the seat belt was in the chair it was in the roof area the diagram showed it grounded by the rear speaker. But mine isn't grounded in fact doesn't seem to do anything my seatbelts light goes out after a few seconds regardless. Maybe the truck has to be moving. Disconnecting the module or seat wiring will turn on the light .

-

Intake plate removal

If the lines are rusty or been on a long time soak them with your favorite penetrating juice a couple days in advance especially the pump end. It's a lot faster if the nuts don't have be wrenched off the whole way.

-

Seat belt light stays on when belt is buckled

Has anybody tried putting a newer all mechanical retractor in a 99. Mine stops working after a half hour or so and locks. Then the light comes on. It's very uncomfortable and I have to unbuckle. Let us know what you find.

-

Homemade Arduino VP44 & ECM project update #3

@Linux I look forward to it. BTW that 8 pin ic outline is for a CAN transceiver future use. My ecm died before I was able to decode all vp44 communications but I know how to command fuel and timing. its the reply from vp to ecu with the actual amount injected that I did not figure out. I may need some recorded logs and dump into spreadsheets or even some graphs. Your PCM project with some CCD added for us Dodge guys would be nice.

-

Homemade Arduino VP44 & ECM project update #3

I know some of use want to keep these trucks as forever vehicles. I have all the parts for a p-PUMP conversion minus the injection lines and I would save me alot of time and headaches but I like the variable timing of the vp. So I'm working on alternatives. Sadly though trying to sell aftermarket ecus and pursuing a CARB# would require a team of lawyers. The days of keeping forever vehicles and restoration maybe coming to an end in just another generation .

-

P1688 But Truck Still Runs

Yep like @Mopar1973Mansaid. Internal software checksum, failed check points or watchdog triggering. Sounds like just speculating, problems loading calibration data so it uses default values just so it runs but not optional.

-

Homemade Arduino VP44 & ECM project update #3

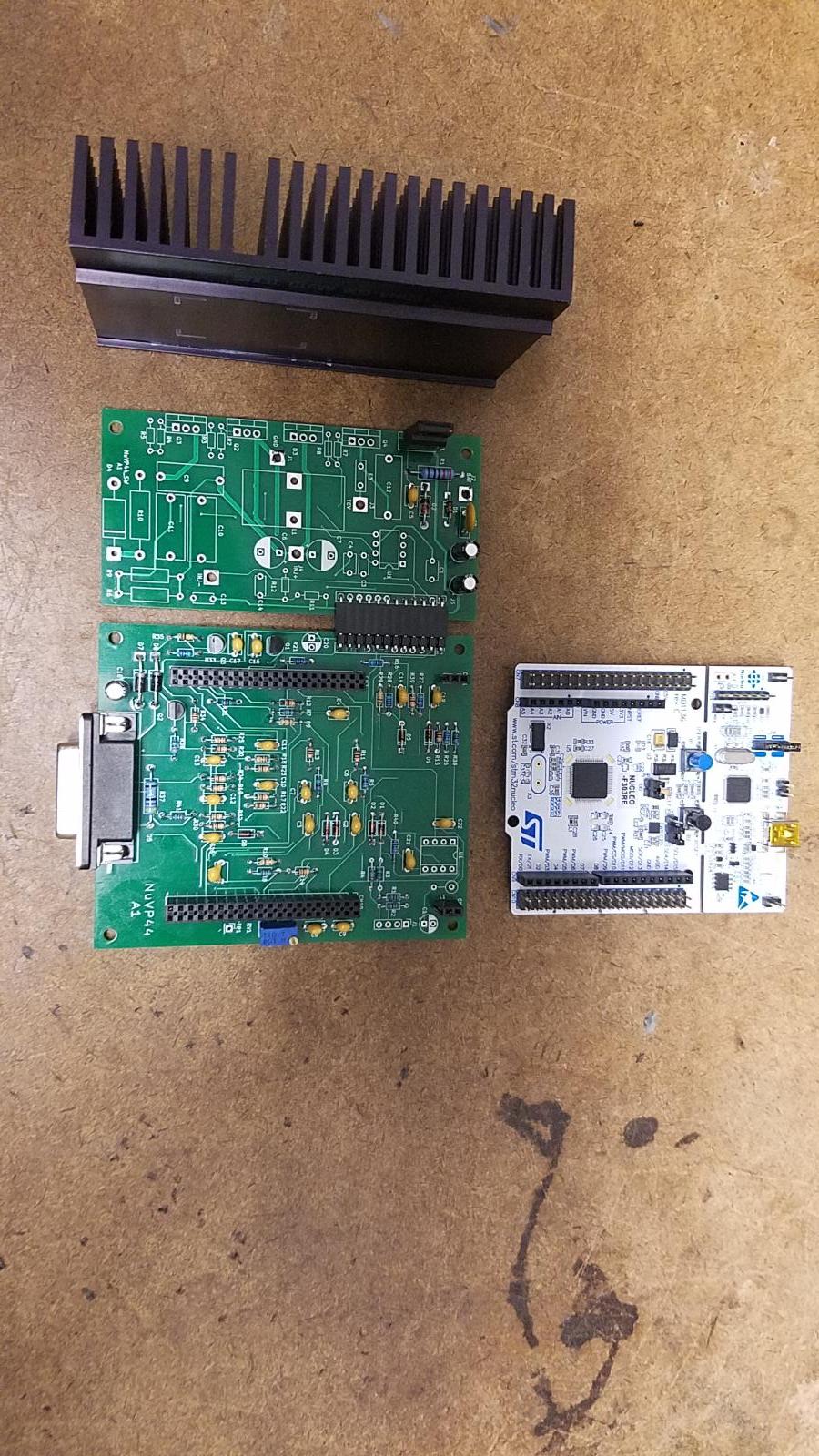

Update. The boards are here and look great. They were not that bad to design and the open source KiCad was pretty easy too learn. I did have to upgrade my PC though. The Gerber and drill files were sent to PCway.com. they were fast and efficient I got 3 different boards times 5 copies of each 15 total for $15 plus $25 for shipping from China. About 5 days from upload to delivery. I have the control board that goes under the ST Nucleo board and 2 different solenoid driver boards one is a high speed switching design the other is a linear design similar to the bosch design. I'm going to see which one I like better. The switching design is going to run much cooler. The Nucleo board was way cheaper than i could buy some of the main components for. I got some of them loaded up already. Parts came from Mouser, Digikey, and Amazon.

-

Auto Enginuity DTC Report - Unknown Freeze Frame codes

My truck has no ecm plugged in and the check engine light is off and no DTCs are present which is strange not even th p1639. So the obd2 is only getting data from the pcm. The downside is the gauges don't work. These trucks use a whole bag of communication standards and protocols some have multiple protocols on the same wires. The can bus uses both 11 bit and 29 bit I'd the vp44 is 11 bit 4 messages proprietary. Some tuners and scan tools can request 29 bit sae1939 pid this is your best bet for real time data. The can bus was not extended to the obd2 port. That was required in 2008. Other buses are k line iso 9141 that's the obd2 Chrysler implantation its shares with SCI which is the drb2 tool for flashing. Then there is CCD which is for the instruments and other items like radio and overhead display. There was a lot of changes going on in those early years with all the manufacturers winging it on there own. There are some online obd2 to sae1939 and others converters that may help. There are some pcm simulators that can wire in too.

-

Auto Enginuity DTC Report - Unknown Freeze Frame codes

Are you plugged into just the port under the dash or the cummins bus by the power steering or both?

-

Code reading question for a smog test

Interesting read, scroll way down for vehicle anomalies. Looks like dodge had a lot of unsupported OBDII responses. If it's a federal emissions over 8500 GVW it pretty much gets a pass on emissions monitors readiness. https://www.bar.ca.gov/industry/obd-test-reference

-

VP 44 voltage issue

The ECU stays on for about 30 seconds after you turn the key off. So wait awhile then turn on key and check the WTS light.

-

VP 44 voltage issue

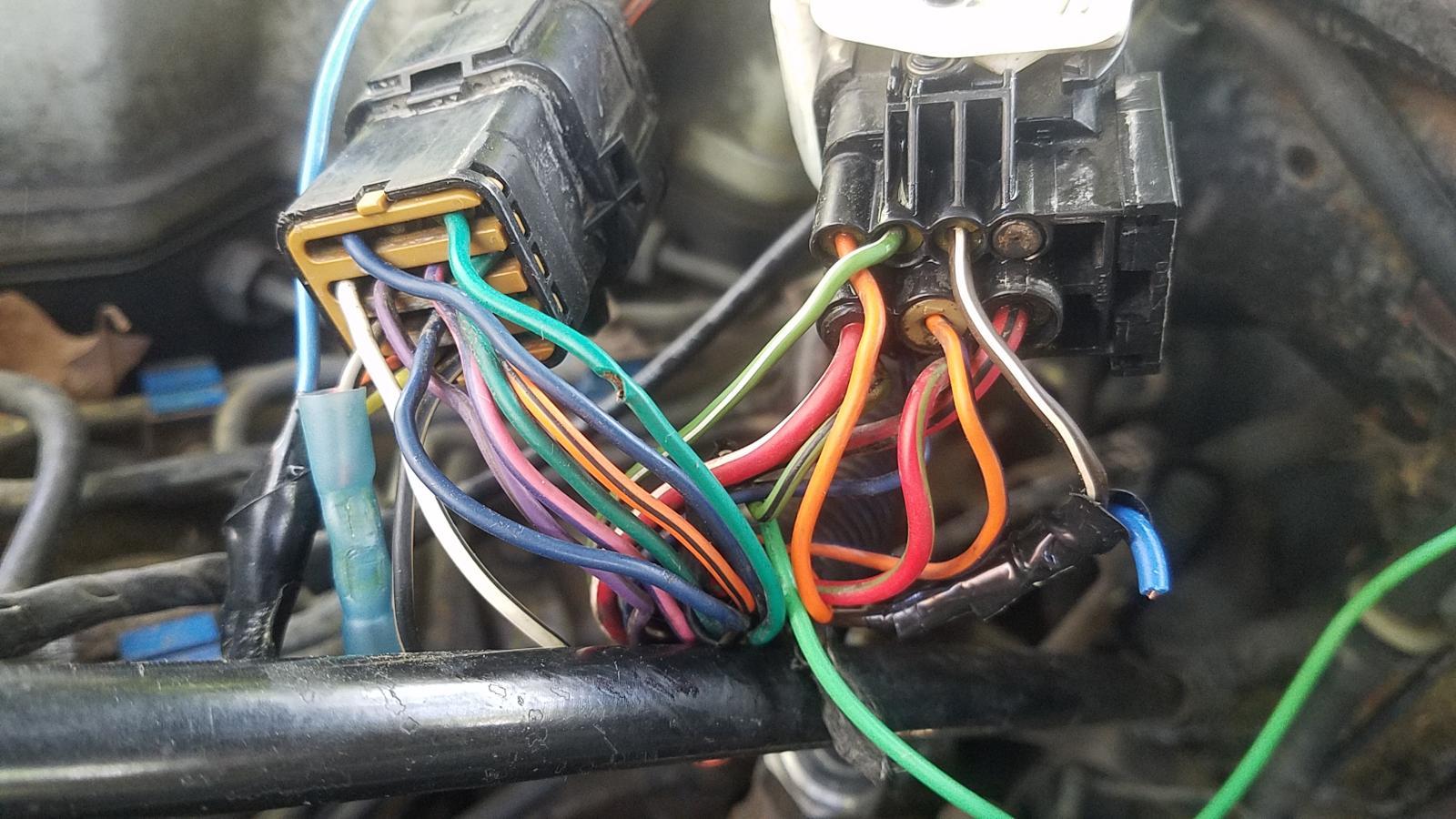

Here is a photo of my 1999. As you can see my wiring is transitioning for my new project. I hope this helps.

-

VP 44 voltage issue

Dirty fix is tap brown/white wire going to the relay into the lt green/black wire that comes on with the key. Down side is you loose reverse polarity protection for the vp.

-

VP 44 voltage issue

Is the ECU that's installed now present when the shorting with the test leads happened? Have you tried the old one again? Probably damaged the relay driver circuit in the ECU. There is a dirty fix for it should you need it. Totally agree with John a test light is the way to go. I'm taking the 5 th on wire piercing controversy.

-

Options to Trigger Relay

Bolt this into a tranny test port. Cheap alternative. https://www.amazon.com/AUTOHAUX-Universal-Automotive-Radiator-Temperature/dp/B0BKSV137N/ref=mp_s_a_1_17?crid=3IC0IY4GZQUOL&keywords=1%2F4+npt+coolant+fan+switch&qid=1682264714&sprefix=fan+switch+1%2F4%2Caps%2C413&sr=8-17 The iso programmable gauge would be a good like @Mopar1973Man said.

-

New IAT, temp goes above 293, watch it drop on the code reader

I should mention the engine that I was working on had massive blow by out the breather and oil cap and white puffs out the exhaust until warmed up. The valves were fine. We really won't know what happened on yours until the head is off.

-

New IAT, temp goes above 293, watch it drop on the code reader

I've rebuilt a 12valve. Same problem burned up number 5. The heat builds quickly in 5 and 6. I had to get the block boared 40 over to get a clean cylinder. Have your machinist make the back cylinders at the loose end of the spec. The crank and cam is pretty tough and can usually be reused without re sizing. I used mahle pistons and a stock head gasket thickness. They shaved the deck 5 thou and the head 11 but the mahle pistons were almost designed for that and the clearance was spot on. The cause was high egt. The pump and injectors were turned up the turbo bearing was shot and the turbine was touching the housing so boost was low and towing with large tires and 3.55 gears cooked it. It was about $4500 but I did everything except the machine work my self even rebuilt the turbo my self. The head was decked but not rebuilt. If the crank needs turned expect a few hundred more. I put a full spline shaft in the NV4500 and a couple bearings and 5th gear nut that was $2000. I wish I sleeved the rear main seal because it started leaking about 10k miles later. The bearings were Michigan clevlite IRRC the head gasket was felpro or cummins. Get a good gasket. For peace of mind maybe a water pump and belt tensioner.

-

1998 DODGE RAM 3500 5.9 DIESEL TURBOCHARGED PCM

So sorry you had a bad experience. These computers are 20 years old now and just like a 20 year old auto tranny it will let you down shortly unless rebuilt which is probably the word they should use instead of repaired. The newer trucks get a bad rap because of the mystery black boxes. That's why the die hard swear by the 12 valves. I have many old vehicles with carbs and points and love them but it sure is nice too jump in a new fuel injected car and turn the key for instant starts and smooth idle and shifting with all the other comforts and performance.